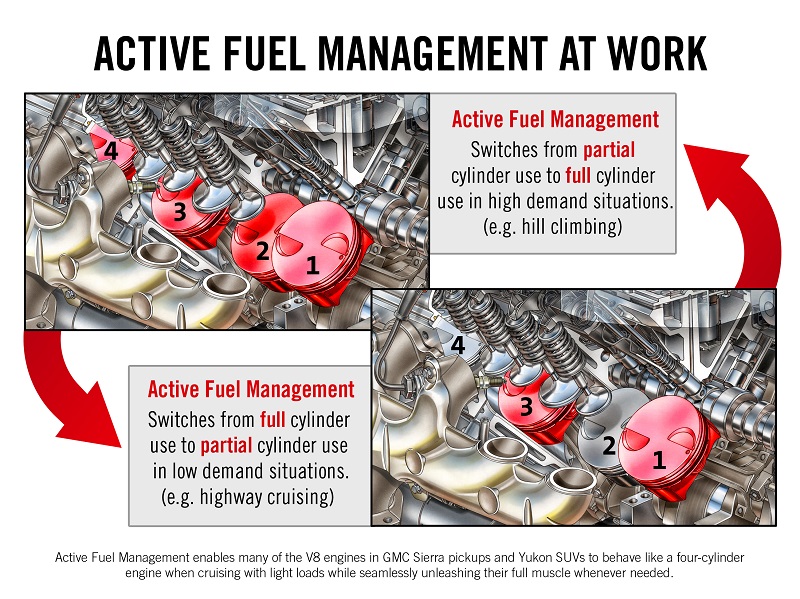

Active Fuel Management (AFM) is a trademarked General Motors technology that improves gas mileage by shutting down half of the cylinders under light-load conditions to reduce fuel consumption. It is also known as Displacement on Demand (DoD) or cylinder deactivation.

How Does AFM Affect Performance?

AFM is good for gas mileage and can be 5-7 percent more fuel-efficient under certain conditions.

So Why Turn it Off?

There are a few reasons:

- Many people find the four-cylinder sound annoying if their vehicle is equipped with a louder aftermarket exhaust.

- Some drivers want V8 power under their foot at all times.

- AFM lifters have a history of failing and oil consumption can be a problem.

How to Delete or Disable AFM on GM/Chevy Engines

There are two ways to disable or delete Active Fuel Management on your GM or Chevy Gen IV LS or LS-based Vortec engine—one is to install an AFM Disabler, and the second is to install an AFM Delete Kit. Here’s what you need to know:

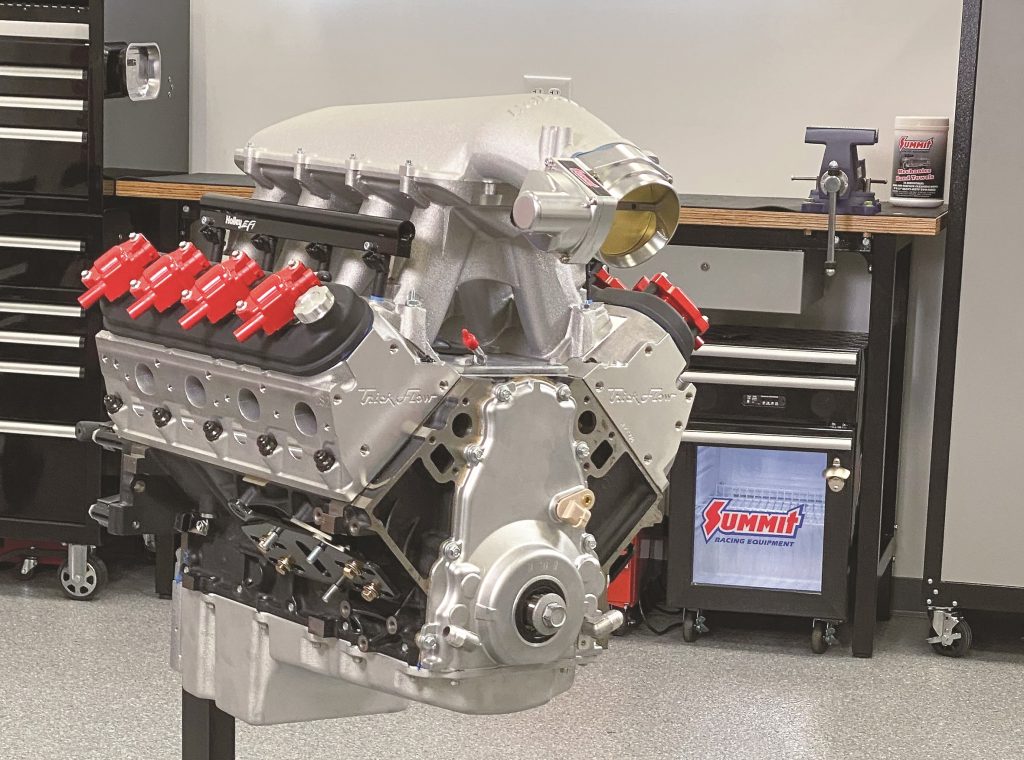

1. Install an AFM Delete Kit

An AFM Delete Kit is recommended when an AFM lifter fails or when doing performance upgrades. It replaces the AFM components with standard parts.

When installing an AFM delete kit:

- You MUST upgrade to a non-AFM camshaft because the cam lobes in the four AFM cylinders are ground differently. The engine will have 25 less pounds of compression in those four cylinders which can result in a misfire code.

- You will need to turn off the AFM system using a computer programmer or custom tuning.

- It’s a little more work, but it’s recommended that you plug the pressure relief valve in the oil pan.

- It is also recommended that you switch to a standard-volume oil pump.

2. Install an AFM Disabler

An AFM Disabler is an electronic device that plugs into the OBD-II port, under the dashboard. It prevents the computer from switching over to four-cylinder mode. It’s a simple and effective way to turn off the AFM system and provides the added bonus of improving exhaust sound.

NOTE: A disabler device should ONLY be used if the valvetrain is in good working order.

Engines with AFM use a high-volume oil pump. When you eliminate the AFM system, the extra oil is no longer needed. Excess oil will be pushed out of the pressure relief valve into the oil pan. This will spray oil on the bottom of the cylinder walls which can cause oil burning, especially in high-rpm engines.

Which Option is Best—a Disabler or Delete Kit?

As long as a lifter hasn’t started to fail, you can get by with a less-expensive disabler as preventative maintenance. If a lifter has already started to fail, an AFM delete kit and non-AFM components are the way to go.

…

NOTE: If you were in a situation where you’ve installed the AFM delete kit, but don’t have access to a programmer—a disabler can still be a viable option. To do this, you need to leave the AFM solenoid pack connected to ensure no codes are thrown. You can reuse the original valley cover OR use a non-AFM valley cover, leave the harness connected, and tuck the solenoid pack away.

GM/Chevy Engines Factory-Equipped with AFM

| Engine Displacement | RPO Code | |||||

|---|---|---|---|---|---|---|

| 5.3L | LY5 | LC9 | LH6 | LMG | LS4 | |

| 6.0L | L76 | L77 | LFA | LZ1 | ||

| 6.2L | L94 | L99 | ||||

How to Identify AFM Engine Components

The AFM system can be identified by its components. Look for the following:

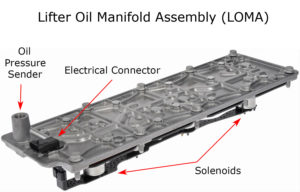

1. Valley Cover

The AFM cover is called the Lifter Oil Manifold Assembly (LOMA). It’s ribbed with solenoids on the underside. It also has an electrical connector on the back. (Non-AFM engines have a smooth cover.)

2. Engine Block

All Gen IV engine blocks have AFM towers and oil passages cast in. However, they are only functional on engines that used AFM.

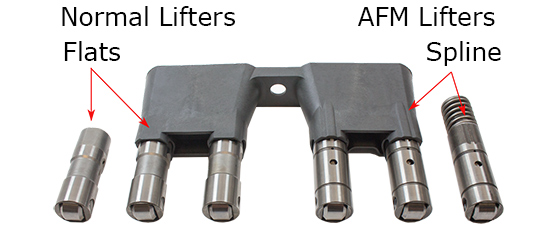

3. Lifters

AFM engines use special lifters for cylinders 1, 4, 6, and 7. They are taller and have special oil holes.

Engines with AFM also use a special camshaft, a high-volume oil pump, and a pressure relief valve in the oil pan.

3. Oil Pressure Relief Valve

This valve is located on the oil pan rail and prevents excessive oil pressure from negatively impacting the AFM components. The original version sprayed oil on the cylinder walls and increased oil consumption. In 2010, GM added a deflector (p/n) NAL-12639759 to redirect in into the pan. This should be added to your earlier model if you experience oil consumption.

The valve itself is part number W0133-2574213. If you want to delete it entirely, it’s a M14 x 1.5 pipe plug or you could use the Improved Racing plug p/n IRP-814-M14-Kit.

How Active Fuel Management (AFM) Works

When engine load is low:

- The computer sends a signal to the LOMA.

- The LOMA solenoids open.

- Oil flows to the special lifters through the AFM towers.

- The oil collapses the plunger inside the lifter.

- The collapsed lifters will not engage the pushrods and both valves remain closed.

Since no air can get in or out, four cylinders provide no power. The engine is running on only four cylinders.

The AFM cylinders are opposite of one another in the firing order. In four-cylinder mode, they act like air springs and allow for smooth operation.

As engine load increases:

- The computer sends a signal to the LOMA.

- The LOMA solenoids close.

- Oil bleeds off the lifters.

- The lifters return to normal operation.

All eight cylinders are now powering the engine.

NOTE: Some parts are not legal for use in California or other states with similar laws/regulations.

…

NOTE: You can find engine specs and detailed engine upgrade advice for every LS and LS-based Vortec truck engine in one place: The Definitive Guide to LS Engine Specs and LS Engine Upgrades.

[…] For more on that, read: How to Delete or Disable Active Fuel Management (AFM) on GM Engines. […]

[…] LS Tech: How to Delete VVT or Disable AFM […]

What if the pressure relief valve is stuck “OPEN” and the oil pressure never gets up to where it needs to be? I’ve got about 6 to 8 psi of oil pressure after the engine gets warm and I have to stop at a traffic light. NOT GOOD!!

It could be the filter screen under the oil sending unit. they are known to become plugged.

WATCH THIS VIDEO https://youtu.be/1MJMf3nnQhQ

another common cause for low OP is the oil pick up tube O ring. GM uses 3 different styles all are engine specific. also in the pan is another AFM oil filter near the external engine oil filter.

I had the same issue on a 2012 5.3 and in my case it was the camshaft trust plate on the front of the engine (behind the timing set)

sounds like you have an oil pump problem or clearanced cam bearings, working for g.m i see this type of thing every week. we perform a mechanical oil pressure test at the oil filter, if it drops to 8 psi when hot then you either have an oil pump or bearing problem. due to the fact cold you have good oil pressure indicates the relief valve is closed. other wise your oil pressure would be low all the time. unfortunatly the only way to find low oil pressure is to either inspect the oil pump for wear and or a broken pressure relief spring. but do the mechanical oil pressure test first. there is a special tool that screws onto the engine where the oil filter is. hook your guage to that, if the pressure stays good at the bottom of the engine, it is not the pump. then you can start looking at an oil problem in the vlom assembly. or top end.

I have 2007 with 256 000 miles on it been great up til now cyl 7 misfire all new wires plugs and coils probably needs new lifters when it be visible to do that to this motor with this many miles on it or not

2009 Avalanche 5.3 with 410,000 km had #7 failed low compression mechanic took off the head lifter collapsed # 7 going to replace lifters on that side. And going to disable the 8 to 4 AFM with a Range or turner haven’t decided yet.

Is the Pressure relief valve replaceable? Does the Pressure relief vavle ever go bad??

It is replaceable.. just remove oil pan and it will be on top at the filter

Where can I buy a bolt to replace this relief valve ??

Having a hard time finding one ..

Easier said than done. With 4×4, it’s a enormous Jon to remove the oil pan.

GM tried this on cadillacs about 20 years ago and if memory serves me correctly it was a disaster

368 CADI

1981 Cadillac V 864. I sold them when they were new. They lasted one year with big problems. GM switched over to the 4100 v-8 in 1982.

I had an 82 caddy 4100 with alumn block and cast iron heads ,, Exploded in Philidelpha, Garbage..

I had privilege to work on some of that garbage they never did work . Anyway that horrible experiment was in the late 70’s early 80’s along with those converted Diesel engines…..those like the 8-6-4 nonsense were just terrible failures. All I can say is they now try this again and they are still having trouble…..when will they ever leave well enough alone

It’s not GM’s choice to use AFM. They are being forced by the feds to use stuff like AFM to meet the CAFE requirements. Just like Ram and their trash MDS system or Ford and their throwaway Ecobust engines.

This is what I keep telling people…. it is the regulator guy!

Yeah they gotta get rid of those FED regulations , there not doing nothing for clean air when they let the military burn that fire retardant stuff in the incinerators faa or something like that , I forget it’s name ..hypocrites ..

As soon as you get the EPA and the Government out of everyone’s business this is why everything cost triple what it should Government blow hards.

Remembered that after I bought my Tahoe. Now I’m here tring to figure out what to do.

Ditto , never buy a throw away vehicle again is my recommendation and my fix . The wife however found this ‘deal ‘ on an Envoy Denali . .That was a year ago and now I have a collapsed lifter and the most inexpensive repair $2200.00 for a partial lifter replacement. Looking for another Toyota at this point to match my 1985 4 runner with 380.000 miles and no issues since new. Oh,the ‘throw away’ vehicle has 77,000 miles and has always had meticulous maintenance . Junk . I remember those Other GM vehicles that the consumer tested for GM and paid GM for the honor. On the caddis it helped to relocate the computer inboard the passenger compartment to keep them cool helped . Now it appears GM and their handlers want to push the ‘electric market ‘ with throw away junk that is mechanically weak . Now I know why there wa such a push to get ‘ older ,less efficient’ vehicles off the roads. Welcome to socialism folks . . . .IMHO .

I couldn’t agree with you less, yet I respect your opinions. I read something the other day which I found to be funny. “Don’t follow just anybody” I know where it originates but in today’s world I found found it to be amusingly accurate.

Interesting that gm still hasn’t gotten the bugs out of their Volt and now their 2nd attempt. I switched from gm to dodge in 1984, have had 3 1st gen Durango and 4 2nd gen Dakota’s, all used, with impeccable reliability. My Wife’s ’17 Buick with afm was my attempt to get back to gm. Never again, except for my gen4 Z28 that has a perfect engine/trans on an otherwise rolling pc of gm crap chassis.

GM should have a recall to replace these sticking lifters. Been a GM guy since 14 yr old. I’ve owned 9 GM vehicles, won’t buy another.

Dummy Me thought gm learned it’s lesson in 1981 but they never did and I Too am stuck with a Buick that’s just waiting to self destruct. I’m praying that my RangeTech buys me a few years. I’ll Never Ever buy another gm.

Jimi, I hate to tell you I had my AFM programmed off in the computer and it didn’t do any good. My 5.3 failed at 74,400 miles with a collapsed lifter and bent push rod. I purchased the extra warranty to 72,000 miles. I asked GM to help with the repair and was refused any help because I was out of warranty and had turned off the AFM. I was told had it been under warranty it would have been no problem. So having a disabler does not guarantee you are not going to have the problem. The engine the way it is designed is destined to fail and most of the time the customer has to absorb the bill for the repair.

Yep my2017 6.2 Chevy Silverado just failed with lifter problems from AFM now waiting on a new motor bummer indeed

Gm is a bunch of JUNK.

Yes that’s true. But the problem at that time was the computer technology. The computers had not evolved enough to control the sytem. Todays computers are faster so it does work. But if you don’t like it. RANGE TECNOLOGY.COM.

It was in the late 70’s or early 80’s and it was a “POS”

Your absolutely correct.

Your memory serves you pretty well I too have the same nightmares lol

We had one for a company car in ’82 and it never did run right from new but at least it didn’t destroy itself. Troubles begin with Bean-counters decide on what can be used for production and engineers who aren’t Gear-Heads. Take a look at what bmw did in it’s R1250 bike. They shift cam lobes by sliding the cam, never actually shutting down the value but riding a different lube!

My 5.3 is. Pod. I hate it. Had nothing but trouble out of it.

One of the biggest issues with the Cadillac 8-6-4 system is that the V8 engine is only inherently balanced in 8 and 4 cylinder mode. It’s not balanced in 6 cylinder mode and will cause a lot of vibration. The 6 cylinder mode should have never been implemented. That’s why the systems now only have 8 and 4 cylinder mode.

I got as high as 23mpg on the highway in my ’89 K1500 with 350ci and a five speed manual. How about if they just let us have a manual transmission agains for fuel mileage?

Double digit MPGs in my 98 K1500 would be a dream lmao. i currently get 8 mpg with the vortec 350 and a 4l60…

I have a 99 Sub k1500 that i get 16 to 18 hwy loaded lightly

Me too

I get about 14 on my 95 Tahoe 2 door with 5.7 and 4l60

They should let us the better mileage. If someone didn’t want to spend gas buy a Toyota.

I know a few guys with Tundras. They don’t so any better than domestics on mpgs…

I had a 2005 Sequoia V8 only got 12 mpg

I may just do that Vic. I have 4 GMC’s in my driveway right now only one with AFM it’s always popping DTC’s, ’06 Yukon (not AFM)never had a light in 12 years! GM get a clue! Did Obama make them do this?

Toyota’s 5.7 is one of the biggest gas guzzlers among half-ton trucks. Plus the 5.7 has its own problems with VVT reliability and the rest of the truck is flimsy junk.

I have a 2012 Chevy Avalanche. Thanks to a properly maintained 5.3 with AFM, I can routinely get over 20 MPG on the highway. No other V-8 truck of similar weight can do that (except another GM with AFM). This is my second Avalanche and I never had any issues with either of them.

My Chevy truck with fuel management can not touch my 2000 Chevy with out fuel management. The older truck gets 19 mpg the newer truck with fuel management gets 14.

I wouldn’t trade my 2000 Silverado, 5.3 liter that has constantly gotten 20 mpg since I bought it 15 years ago, for a dozen of these new $50,000 POS. I have 217,000+ on it and it never fails me…ever!

No other truck my ass .lol my 99 silverado 1500 with the junk LR4 4.8l and 320k miles 9n itgets 21mpg all day long with 93 octane gas in it

My 97 k2500 suburban with a lightly modified 6.5L diesel gets 20ish. I can literally drive from Seattle to Redding CA on one tank. I’ve only put a straight pipe exhaust, intake, and a boost controller on it.

I have 1999 Silverado with out AFM that gets 21 mpg and a 2008 with it that gets 14.6. Now you tell me AFM works and I will tell you; that you are full of shit!

I have 1999 5.3 Silverado that gets 19-20 miles to the gallon all the time this shit pile with dod only gets 14 miles to the gallon. How is that an improvement. Dod is the biggest failure sence the 8-6-4 caddie in 1981

I call it active obama fuel management .A scam .

Your 1981 caddy was your fmu I got glue inside of it and it stuck the potentiometer for stochiometric if you get a new fmu or you pick the glue out of the potentiometer you can set it to stoichiometric and get a lot better fuel mileage as far as your truck why don’t you look at the intake manifold I got a crack or a vacuum leak somewhere for gas mileage thank you truck service

Near 1981 it’s your fmu it has glue inside the potentiometer you have to either RNR it for a new one or pick the glue out of the potentiometer for stochial magic is the only variable resistor inside that you can turn with a screwdriver once you get the glue out of it it’ll read still kill metric just be careful and then you can set it properly with your own meter on your monitoring your O2 sensor and then on your Silverado thingy your 5.3 just check the intake manifold for lakes I’ll get you a better gas mileage if you don’t have any intake cuz they’re plastic and they crack and stuff like that other than that yeah that’s it

Larry Jenkins, I have a 17 GMC Sierra 6.2 SLT, I got 25 to 27mpg regularly with 93 gas and cylinder deactivation. Now I get 24 to 26 with deactivation locked out and full power. Why would GM ever produce such problems with such little to gain. I drive the same 320 mile trip every two weeks and drive the same route and full tank. Verified over hundreds of trips, makes no sense

I use the range technologies deactivator

Why can’t you stop the send signals from the computer so that the solenoids don’t open and the AFM system is never engaged?

You Can. RANGE TECNOLOGY.COM.

I have a ’08 6.0L out of a Silverado with an aftermarket oil pan that has no provision for a pressure relief valve. What can I expect with the AFM in place, or, with AFM disabled (not deleted)?

Disable the afm. Install ls3 valley cover. It has the orings in place, that seals the towers. The pressure relief in the pan opens at around 45psi to prevent over pressurization of the vlom solenoids. They have plastic casing, so you can imagine what will happen with aged plastic.

When I first bought my newer truck with fuel management, the GM tech at the dealership told me; if I wanted the engine to live a long life keep the RPM’s below 4500. He stated if I continued to exceed 4500 RPM it would blow the lifters out. So now at 168 thousand miles it still runs good but gets bad gas’s mileage.

6.0 doesn’t have afm

Afaik the 6.0 escalade hybrid does have it so wondering if safe to delete. have yet to find a read that shows an escalade with high oil consumption and i have read a lot on the hybrid

If the 4th cylinder lifter has failed, would driving it damage the engine? Would you get enough power to drive at freeway speeds? Our 2013 yukon with 47k miles just failed. Having it fixed now, just curious Seems like a problematic design. Very expensive repair too!

Just had my afm lifter fail had to drive 500 more miles home on 7 cylinders in my 6.0 lt chev.

Just pulled it down in the garage there was no other damage , luckily.

I had one fail and it chattered the cam to the point that I had to Install a new cam. Basically rebuilt most of the engine while in the vehicle. Don’t drive it if you have a dead cylinder due to afm failure.

Driving around with a bad AFM lifter is the fastest and easiest way to destroy an engine. A bad lifter can be a minor repair if you get it fixed immediately after you hear an issue. If you ignore it and keep driving, odds are you will destroy the cam as well.

if GM wont make a dependable truck for 60,000 Toyota is sure to take over even with very poor gas mileage .

GM should recall every vehicle with this terrible design flaw! Every one of these engine will have a lifter fail, this is a travesty!

I didn’t have lifters fail, I had the 4 cylinders 1,4,6,7 have such blow by that my choice was a valve and piston job or a new motor. I went with the new motor for the warranty. I only had 81k on the motor. My 2002 I had over 298K on it with no engine related issues. I will be installing the AFM deactivator tonight when I get hoe.

What type of disabler did you go with? I just got new warranty engine and don’t want this issue again?

You can email racelabperformance. Com and we can set you up. You can then enable..disable…add power..etc.

I have a 2013 1500 with the LC9. has 92,000 miles and was just told I have cam and lifter failure. $8500.00 fix. Looking to tear down myself.

My 2013 LC9 just had #6 lifter fail, got a misfire code but the ticking gave it away. Seafoam with syn oil change only fixed for a week. Getting ready to diy for $450. How did your turn out? Any problems to watch out for?Did you replace the VLOM?

Do not pay that amount. Call chevy.They should being paying most of that.

8000 grand for the repair mine was 1,700.00 to repair

I had a 2004 small block v8(4.8) 331,000 miles on the truck,it was the usual on the maintenance front axles,etc. Never did strand me on the side of the road way. September 2017, I got talked into trading for 2017 AFM this was a bad choice 5.3 engine. Only wish I’d did my homework, nothing but issues, from 14,000 miles it starts this motor noise,as if lifters at cold starts, let set up for 8 hrs same noise, this noise is on the right side of engine, it lasts 5 seconds but never heard this until we had this cold spell in the state low temperatures or it was just time for this to start? I have always loved Ford and Chevys , I don’t like this Vehicle not one bit, starring shaft has to be lubed or it whines, front A arms has done been replaced, tapping in motor, leaf springs has been lubed, retorqued, put completely new leaf springs back in on the rear , grease all down from rims to body of truck, you have to clean often,console shakes as if milk shakes in console which later they also put rubber bushings in front of coils of shocks ( front end) .You lock it down in 4×4 it s metal to metal , As of now I’m at 32,000 done gone threw all the arbitrator laws depending on how it goes? Pushing forward

Absolutely agree, but we all know GM can’t afford to recall them all & definitely won’t, gettin’ a Toyota, but first will go to GM dealer and ask to see a truck without AFM & when they say they don’t have it I’ll say “See ya, I have an appointment with the Toyota dealer!” Always had GM’s never anything else till now. AFM Sucks!!!

Toyota has their own problems. The 2016+ Tacomas are junk. So bad they’ve been rated least reliable midsized truck by consumer reports for 3 years in a row. Constant engine and transmission problems. The Tundra fares better but the frame has the rigidity of wet spaghetti and the 5.7 has had problems with VVT solenoids and the plastic timing chain tensioners. They’re also notorious for bad cam tower oil leaks.

I have a shop 39 yrs . Jasper makes aGM engine that deletes AFM & will warranty the engine to a 100,000 miles parts & labor . It works .

I have a 2012 chevy avalanhe with AFM system . Can I replace the engine with a regular engine?

What makes you think it was a design flaw ? It was well researched and tested back in the late seventies and eighties . . . Was a disaster then but a profitable disaster. Yes a poor design but a flaw ? Perhaps a flaw by design would be a more appropriate description . IMHO .

AFM sucks I’m paying for a truck that has broke down twice replace the cam and lifters and now it’s broke down again 105000 miles never heard of that in a 350 Chevrolet.

Right with ya Chris!

I have a Yukon 116k it now needs its 3rd set of lifters and cam.

It is a bad deal for sure.ive fixed a few best thing u can do is delete it in buy kit.no sense in fixing a flawed problem with the same flawed parts.

Happened to me twice 2009 Silverado, finally deleted DOD and installed a performance cam and lifters. bought at Brian Tooley Racing !

Runs better than new now and no more oil consumpsion!!

If I had wanted a 4 banger I would have bought one. 2018 new truck has me really disgusted If I had checked this out better, there would have been one less POS Chevy sold last year !

put tran fluid in oil for a day till lifter became active, had to change the fouled plug. changed oil , its all working now, but want to disable this sorry system.

I’m curious as to how much tran fluid you put in?

how much tran fluid did you use

It actavated the lifter? The detergent. How long did it take?

I used 1 quart of tranny fluid in the crankcase ran it for 20 minutes, no luck. Next day, fired it up to take the the junk yard and it ran great. Run it and let it soak overnight. I still get a P0336 code every once in a while but still good to drive around town. Would never take it on a long trip. Last GM I’ll ever buy unless it’s got a diesel.

You were lucky that it worked. If the lifter actually fails so that the mechanism won’t release, it won’t work. It depends on the failure mode of the lifter – however, certainly worth a try. Some guys have been able to use a tool through the top with the cover off to get it to release. You could also have tried that if the trans oil didn’t work.

Since the tranny oil worked, you should now change the oil, right? And consider using a higher grade of engine oil like Mobil 1 or Amsoil, etc.

so the trans fluid worked for you then? is it still working good since you have done that with the trans fluid?

Just shut AFM off. How stupid do you have to be to whine like a welfare check cashing idiot when there are literally 3 or 4 different ways to totally disable AFM.

I have successfully used a gadget that plugs into the ODBII. Cost about $250, but it is not fool proof. Once the lifter has been damaged, the cam is probably also damaged. Then it takes out the lifter again and again until you bite the bullet and replace the cam.

If doing that, the full blown AFM delete is about $1000 depending on how far you go (full overhaul or cam with lifters only). Once the failure has occurred, the AFM shut off methods other than that probably won’t work.

I speak from some experience. My daughters car had about 230,000 miles when she complained of the problem. She had driven it for a couple of months that way. I pulled the head off, replaced the lifter and put the gadget in the ODBII for about $400 total.

I told her to never pull the gadget out. She started to have the lifter problem again after 60,000 miles more. So I did the job one more time. Told her that it would not last and that she needed to find a different way to get around. She drove it for another 35,000 and it went out again. But then she passed away from cancer. I am going to do the full repair of the engine now, but not an overhaul (too hard to get at the pan). But I can replace all of the other engine parts without doing the pistons and bearings – so that is what I plan to do. If I had been able to push the issue and get the time, I would have done the full fix at first without the hassle. This is my project car and will be my drive (about 5000 miles a year).

Because I want to.

What type of ODBII gadget did you use? I am trying to prevent same issue.

https://www.amazon.com/gp/product/B00BR1R8N8/ref=ox_sc_act_title_1?smid=A359W9MWR50ZG1&psc=1

I did a delete on an 07 avalanche and no have no power, any thoughts on what might be going on? I have had some say that it is the valves and others say that it is the cat’s plugged. I don’t know where to being to look for the problem.

Chris, when you did your delete, did you also change the cam at the same time? If you left the original cam in, the AFM cylinders will be down about 25 lbs. of cranking pressure because the duration is longer on those cylinders to being with to offset the AFM lifter design. You may eventually see a check engine light from a misfire code and the ECM dialing everything back to protect your engine.

One alternative is to swap in one of the larger 6.0 non-AFM truck cams. If you are using VVT, you could use the NAL-12612273 (L92) cam. If you don’t have VVT, you could use part number NAL-12561721 (LQ9) along with a 4-pole 3-bolt 2005 Corvette cam sprocket p/n NAL-12586481 to make it compatible with your ECM.

If you swapped in a LS9 cam, you will find it makes good power at the very top, but it’s actually down from 5,000 rpm and lower where the truck spends the majority of its time. If that’s the case, Summit Racing has dedicated truck cams that will increase power through the range…bottom to top…but the meat of it is in the mid-range where your engine spends the most time. Give the folks in Summit Racing’s tech department a call (330-630-0240) and they can work on a solution for you.

I just did the delete and replaced the cam as well. Still have no power. I have no clue what to do now. I have already dropped a lot of money on this truck (08 suburban). Any help would be appreciated.

Hello Mike, if you don’t have any obvious signs like check engine lights etc., there are couple different possibilities. If you installed a factory truck cam, there shouldn’t be any particular reason for it to be down on power. We recommend taking the truck to a local chassis dyno tuner and talking with them about a reflash.

They may be able to find some of those missing ponies. If you installed a performance cam intended for a car, it may be bleeding off some low end compression. A tuner can often fix that as well by giving it some more ignition advance in these regions.

We’ve written some articles on the various Vortec engine upgrade paths, such as this one on LQ4 and LQ9–it discusses some of the better options for choosing a cam intended for use in a truck. You can search our site by engine code to find some of the upgrade articles we’ve published and more are on the way.

You also need the disabler installed in your obd connector. You will be placed in derate if the ECM does not see the correct resistance from the ATF intake.

sorry AFM intake my bad

Why can’t u just unplug the solenoid on back of engine by oil pressure sensor?

You can unplug the sensor on the vacuum booster and it will fool the computer into thinking there is a high demand on the engine and shut down the AFM system but you will have a ‘ Check engine ‘ light in your face for doing so . Also I don’t recommend doing this as you may be in violation of some emission’s standard or manufacturers ethics code . . .or something similar .

Chris,

I had the same issue and had to have the AFM information deleted from the computer and the car tuned.

Question – i just bought a 2005 Saab 9-7 with 5.3 v8, (same as GMC envoy) which came with AFM, the car runs fine, so if i just install the OBDII electronic device, is it just as likely that my lifters will still go bad? Im a little confused on the problems too, I’m reading that the 2007 pick-ups with 5.3 really had bad oil consumption and plug fouling problems, but is the 2005 5.3 that came in the trailblazers, envoys, and sabb 9-7s the exact same design as these pick-ups and prone to the same failures? I guess they also went to aluminum blocks in 2007, not sure if that has anything to do with this issues… thanks for the advice!

I guess what I’m really trying to ask is,, are there any cons/disadvantages to installing the AFM delete Electronic module? You mentioned that it will shoot oil into the pan and on the cylinder walls possibly causing some oil consumption… So i have a running vehicle and my only concern is making it as reliable as possible, should I disable the AFM or not?? thank You so much!

Hello Keith, if your lifters are still in good shape, an AFM Disabler is a good idea. When they are locked into position, they won’t wear further and cause issues down the road.

The vehicles affected were 2007 to Feb. 2011 AFM equipped engines (Aluminum or Iron block-L94, LZ1, L99, LC9, LH6, L76, LFA, LMG, and LY5). The secondary pressure relief in the back of the pan began to open at 55 psi and was completely open by 75 psi.

In October of 2010, GM added a deflector (p/n NAL-12639759) to keep oil from being sprayed directly on the rear cylinders.

Another option is to plug it entirely if the AFM is already removed. It uses a M14 x 1.5 thread plug like Dorman 65217. More information can be found in the GM TSB bulletin number 10-06-01-008g. It also mentions a valve cover replacement with revised PCV valve design.

Wow, thanks for the wisdom,, i checked my VIN Code (position #8, M=LH6) and my 2005 Saab 9-7x does have the LH6 motor with iron block,

Are you sure it’s only 2007 & newer motors? I’ve read at many websites that the GMCs envoys, Chevys and saabs did start to come with AFM in 2005 with the LH6 motor,It says here it started in 2006 on the saabs, then the pick-ups got AFM in 2007.

http://www.autoserviceprofessional.com/article/91652/ticking-gm-v8-lifters-and-dtc

There is no light on my dash or anything that indicates the system is active or exists, so it’s very confusing, I’m still not sure if my vehicle has it or not. I can’t really tell from driving. I guess I might have to call a dealership or GM to get a definite answer on this one.

I won’t bother with blocking the relief valve. a little burning oil is a minor thing, my main concern is avoiding a multi-thousand dollar repair needed to the motor.

Keith, we’re happy to help. The LH6 in 2005-06 was a little different than the one used in 2007-09, but both had AFM. As a side note, the early ones had a 24x reluctor and plastic chain guide (good) vs. the later ones with 58x and the spring loaded tensioner (not so good).

There is a note in the TSB that states the bulletin doesn’t apply to the LH6 used in the Rainier, Trailblazer, and Envoy due to a different design oil pan and AFM relief valve. Because your Saab is mechanically similar to the Trailblazer, we’d suggest that you are correct and no changes need to be made to the relief valve.

At this state, a disabler would probably do what you need it to do. You can monitor the oil level on your dipstick for 3,000 miles to determine if the deflector or plug would be needed, but chances are you won’t based on the TSB.

yep, you are 100% Right, I called a local saab shop and they filled me in, in 2005 the trailblazer and clones have DOD (displacement on demand), My next issue is getting extra ignition keys on the cheap. Apparently all passkey III keys are not the same,, I bought one that said for 2006 impala assuming all pk3 would be the same, and I could not get it programmed in my saab 9-7,, so how I’m waiting on ones that specially said for saab 9-7. hoping they will work. will feel like a jerk asking the clerk at lowes to cut them again.

Brian,

My 2011 Tahoe has a LMG motor in it with a build date of May 2011. You may want to update your post. Yesterday my motor (116,000 miles) felt like it went into “limp mode” when decelerating from 8 cyl to 4 cyl but it recovered.This is the second time that this has happened in 6 months so I think that I am on “the slope”. The “Service Traction Control” and “Check Engine” lights also came on again but went out after a few minutes. I ordered a electronic disabler for it today. In the mean-time I found that you can keep the engine from going into 4 cyl mode by using the manual shift (if so equipped) and keeping it out of 6th gear. In 5th gear on deceleration and “99” for fuel mileage estimate on the dash it still didn’t go into 4 cyl mode.

Regards,

Dave

I also have a 2008 LTZ avalanche with 106,000 I have the exact same symptoms at this point I just want to sell it will the disabler help remove the check engine light won’t pass inspection with light on thanks for your help Chris

My 2012 Silverado 5.3L just did the same thing as your Tahoe Brian. Accept i only have 60K on my truck and it hasnt recovered. I tried the trans fluid in the oil. Then changed the oil. Then had to drive the truck back to Tampa from Cheifland Fl. This happened on a camping trip with my kids last friday night. Now i have my mechanic trying to follow a YouTube video I saw with a guy and a rod and a hammer. Hopefully he can free up the stuck/collapsed lifter. Then I guess I have to spend a bunch of money and get the delete kit. This really sucks. I loved this rtuck until this happened!!

[…] For more information on AFM, including a comprehensive guide on how to completely remove it from your engine, check out this article. […]

My 2013 GMC Yukon XL 6.2L is currently having a failed lifer replaced. It is being covered under warranty since I only have 72,000 miles on it. Since it is not costing me anything out of pocket, I did not go with the Delete Kit (did not want to spend the money). Once I get it back, could I install the Disabler safely. I would rather stay a V8 full time than deal with AFM issues in the future.

Keith, sometimes they will only replace one lifter rather than the whole set–If that’s the case, another lifter can fail again pretty quickly.

You are correct. Install the disabler when you get your Yukon back and it will remain in good working order.

hi brian when you replace the lifters do you have to change the guides also?

Brian, I just purchased and installed a remanufactured L76 AFM engine for my 2007 Suburban. We were getting a code that the cam position sensor was not functioning properly. Changing the sensor didn’t help. As it turned out one of the cam bearings was failing and causing the cam to wobble (my guess) which messed up the AFM and probably some other stuff too. The engine had 200K miles. As we were installing the sensors prior to installation in the vehicle, we noticed that there was no fitting on the oil pan for the oil level sensor. I asked my local Chevy dealer, from whom I purchased the engine, to find out why the oil pan lacked the fitting. They learned that the oil level sensor was necessary and that we were supposed to have been advised that we needed to reuse the original oil pan. Fortunately, the old engine hadn’t been shipped back to the remanufacturer. When we removed the oil pan from the new block, we noticed a metal shield covering the bottom of the block. In other words, the crankshaft and bearings were not visible. Is this the shield you referred to in a past post? Side note, after 200 hundred miles of trouble free driving the transmission failed so we had to replace that too. I am leaning heavily on installing the AFM disabler. Thanks.

Hi Mike, the metal shield you noticed is probably the windage tray. The Oil pressure relief valve deflector added in Oct. of 2010 is small and it’s part number is NAL-12639759. If AFM has been deleted, it’s common just to use a Dorman drain plug (m14 x 1.5) to remove the pressure relief valve entirely.

We recently purchased an 08 Suburban and noticed some shuddering around crusing speeds, usually 45-55mph and highway speeds around 75mph. Took it to a shop and they advised that it could be due to the AFM system not functioning properly. We are looking into the AFM Disabler option, but my question is- how do we know if a lifter is already bad or not? The car runs great apart from the shuddering at those speeds. Would it be fine to go ahead with the AFM Disabler? Or is the shuddering indicative of failed/failing lifters that need to be replaced before moving forward?

Brian, I have the same question as Scott. I also have 08 Burb, but have different symptoms (high oil consumption, blue exhaust smoke at start, and now a really rough start after sitting overnight). How do you know if the lifter has failed? I have no other engine problems and I’d like to fix the issue. Do you think I can still disable AFM?

Brian, I have a 2010 burb with the exact same symptoms and questions as Shawn… please help! Thanks.

If a shop pulled a DTC code P0300 and found AFM to be the issue, it may not be too late to try the disabler. It will show up as a misfire code in a cylinders 1,4,6, or 7. There is a filter screen under the oil pressure sender that may be clogged and not getting enough oil to supply the solenoids. This may show as low oil pressure or code P0521 or P0523 and is a relatively inexpensive fix as well.

As the problem gets worse, you’ll hear a lifter tick and eventually you may see clearance between the pushrod and the rocker which will quickly destroy the cam. I’d try the disabler and the screen cleaning first and do the AFM delete if that doesn’t solve the problem.

what deleter (if that’s a real word) have you heard good things about. Ive heard the Brand name “Range” thrown around in other forums

This is how mine started out…then 6 months later on the highway the service stabilitrak light and flashing engine light came on. Stopped at nearest gas station and found I was a quart low on oil…added oil and lights eventually went off and luckily we made it the 5 hour drive home. Next day I drove my car to work and was fine but when I left work all lights came back on and terrible noise in the hood. Took it to my dads and he tore things apart and found that I had a lifter that was stuck. He unstuck it and I took it for a drive and same thing happened. My dad ended up running seafoam through it and some transmission fluid, changed the oil pressure sensor which I definitely think was bad and also cleaned out the little screen and he said it was so full of junk and metal scraps. I have driven it now for 2 days without issue but I am having the AFM disabled/tuned out today. I am hoping this does the trick. I always have done my oil changes on time, not sure about the people who owned it before me though. Although the last oil change I had they offered a more expensive oil that would let me go every 5,000 miles and when this happened I was almost at 4,000 so needless to say I will never do that again…

Hi Brian,

I bought a 2010 GMC Sierra 5.3L Truck in 2013 with 24K miles. Right now I have just over 77K miles with no lifter problems… Knock on wood… I am thinking of the AFM disabler. However I do have 7 year bumper to bumper warranty that covers this problem if I start to get lifter problems over the next 2 years.. On the other hand if get the AFM disabler installed I am pretty sure that I void the warranty from what I read on the policy. The problem I am facing is that I want to drive this vehicle for at lease another 77K and do not want to drive my vehicle with this AFM issue. What would you do if you were in my situation? Install the AFM disabler now or wait until my warranty just about to expire to get this AFM issue resolved?

That’s a tough call, if the warranty will cover it…I’d let it run out. As a side note, Range Technologies recommends removing the disabler between visits to the dealer as they will need to access the OBD-2 port.

thanks brian love the info I’m thinking of buying a ford now

I am going to buy a new truck in about a month it would be a Chevy but Dodge has lifter problems so they are out and Chevy has DoD problem.If they come out with Silverado without the DoD then i would buy one.But they aren’t so i will become a Ford man from now on

Have fun with that Ecobust motor & stretched timing chain 🙂

Hello. I have a 2011 Chevy Tahoe with the 5.3 Gen 4 LS (VIN Code 0) and I bought a CAM motion DOD/AFM delete kit, 3 bolt drop in CAM Motion stage 2 camshaft, VVT delete kit and finally a Diablo Predator 2 Premium for GM programmer. I was told that before I start the vehicle up I will need to have the AFM and VVT disabled in the ECU but that would require a custom tune from a tuner as the ECU cannot just be told that the AFM and the VVT is gone. I am trying to find out of this is true. Diablo says yes but they do not provide tunes. CAM motion says no just have to disable the AFM and VVT with a stock tune as the camshaft is not an aggressive camshaft but a drop in. There are no changes in the valves or the springs. I have also heard that the oil pump is to be changed and I have also heard that it does not matter. Very confusing stuff out there. Any advice that you could offer would be great. Thank you for your time.

A custom tune by a knowledgeable tuner with access to a chassis dyno will pay a lot of other dividends other on top of turning off afm and VVT. You will get codes thrown if the afm is physically removed without telling the ECM you did so. The tune is the best bang for the buck outside a cam swap anyway and what I’d recommend.

The oil pump is high volume, but there are a lot of people that don’t change it and rely on the pressure valve to keep the volume manageable. The only problem is the extra spray on the cylinder models if a deflector isn’t used and this can show up as increased oil consumption.

I ave noticed the point about excess oil spray. My point is that the engine likely on uses dod a small percentage of the time so can not really imagine that the delete causes any more issue than normal which may be the high oil consumption but do all of these engines with dod consume a lot of oil? I was looking at the 08 escalade hybrid with dod on its 6.0 so wondering if the delete would contribute to the high oil consumption and therefore would adding the deflector be a good idea. It seems to me that the high volume oil pump should not hopefully cause premature wear but if it is pushing more oil through the heads than I guess the valve stem seals have more work to do. Would really appreciate your comments on this point as really interested in an 07/08 escalade without or an 09 hybrid with dod. thx Brian

Knock on wood I drive a 2011 silverado 4×4 Ltd with the 5.3 AFM/DOD not tuned out or delete being used and have experienced no problems or any sign of problems for that matter juat rolled over 210,000 all original factory parts would you suggest I tune it out or juat let it ride I change my oil religiously and also use lucas products for all aspects of my motor

Have an ’06 Yukon with 5.3, original engine had bad knock, was told it was lifters so had them replaced. It was good for about 10 miles and started with same loud knock noise. Replaced the engine with remanufactured one and had the AFM turned off with a computer hooked to the ECU. Have misfire code and engine has what I would call a surge while driving. Is this due to the AFM being shut off? Didn’t really notice a loss in power other than the surging, (wondering if that’s the engine trying to switch between 4 and 8 cylinders).

With the AFM tuned off, it shouldn’t be trying to switch over to four cylinder mode. I don’ know what else would cause the surge, but I’d research the misfire code and see which cylinder is problematic. There may be an ignition related issue on that cylinder.

I got a 09 Chevy I’ve had the 1 go out then the 7 about 2 weeks apart if I known what I know now I would’ve changed them all at once but now I have a misfire on cyl 4 but it came back in why are these lifters going out one at a time like this the 1st two that went out I was coming off the interstate an stabiltrack came on now the 4 misfired twice both times pullling out my driveway

Yes, always change all the lifters at once. What was happening to the first is slowly (or quickly in your case) happening to the others. Keeping the oil changes regular is important and it’s possible that a previous owner may not have been as diligent as you are.

I can tell you for the past 2 years I changed out my LC9 5.3L fully synthetic oil every 3,000, even though Mobile Oil claims 10,000 miles or more. I have read synthetic isnt good for AFM lifters. Any truth to that?

I have a ‘12 wit 4.8 Silverado 75000 miles

A 14 gmc 5.3 Sierra 85000 miles

2 15 with 5.3 Sierras both with 100k and

A 17 with 5.3. With 40000

I ran 0W-20 on more the 5000 miles between changes. No problems with any to this point.

I have a ‘12 with 4.8 Silverado 75000 miles

A 14 gmc 5.3 Sierra 85000 miles

2 15 with 5.3 Sierras both with 100k and

A 17 with 5.3. With 40000

I ran 0W-20 no more the 5000 miles between changes. No problems with any to this point.

Good point which begs the questuion, why does the Service Stabilitrak error seem to coincide with lifter failure? Mine did at the exact same time.

[…] for performance, LS9 engines didn’t use Active Fuel Management (AFM), Variable Valve Timing (VVT), or Flex Fuel (E-85) technology. The materials used in the engine were […]

I have a 2018 GMC with the Eassist and AFM

Should I buy one to disable the V4 mode?

Yeh truck has 5237 miles on it

Oil 0w or 5w -20

Thanks

The Jury is still out on the Gen. 5s but the warranty could be an issue. I’d wait until the warranty expires then disable. Hopefully more is known by then.

whith a disabler. the extra oil isnt needed. do you fill to capacity anyways????

Brian, we have a 2007 Yukon Denali in our shop with a 6.2L v-8 that has suffered a lifter failure with camshaft damage. We have purchased a used low mileage 6.2L as that is all the extended warranty company would pay for. My tech just installed the engine, only to notice that he doesn’t have anything to plug the AFM solenoid pack into. The owner of the vehicle has apparently owned a few of these vehicles and stated that this vehicle doesn’t have AFM…never did? He claims that GM used the same engine whether it was or was not equipped with AFM in this year and model? I phoned the dealer and gave the VIN number, told it isn’t equipped with AFM. It had the AFM wiring & lifter cover installed with solenoid pack in the original engine, we even removed it to inspect. This replacement engine has the same camshaft sensor plug plug, 5 wire like the AFM would use, instead of the 3 wire. My concern is if I leave the non-AFM lifter cover in place & have nothing to plug the 5 pin AFM solenoid connector into, will I get a MIL? Logic says that it should not as the ECM isn’t programmed to use AFM, but will it see a lack of resistance from no solenoid pack plugged in? I could just transfer over the AFM lifter cover, but it is really nasty on the bottom side & I do not want to risk damaging this replacement engine if it is loaded with debris from the lifter & camshaft failure. Then again, it should have never been controlling those solenoids. Any thoughts or suggestions would be appreciated.

Billy, there is some interesting trivia here on the L92. Per bulletin 10-06-01-0007b, 2007 L92 had first and 2nd design. The 1st design (built prior to April 1, 2006) was had afm components but wasn’t connected. The 2nd went with a conventional valvetrain. As you said, the ECM was never seeing the AFM so I think you’re good to go. Please report back if you have any issues, but I think you are in good shape.

Brian, thank you for the quick response. We chickened out though and just bolted the AFM solenoid plate onto the used engine. We figured we already had the intake manifold off to install the engine, why run the risk of MIL only to have to removed the intake manifold again without being paid. We did take it apart to check for metal possibly being trapped inside, it looked like brand new. We believe this confirmed that the AFM has never been operating in this vehicle. Thank you again for the response. 🙂

Production date on the vehicle is 04/2006 oddly enough. Who knew? lol

Hi. Sylinder one lost compression on my 09 5,3. No movement on the rocker arms. Replaced all lifters. No it runs fine on sylinder one but not on 6 or 7!!! Pulled the inntake and replaced valleypan With all the solenoids. Did not help. Pulled right valve cover an rockers on syl 6 dont move. Well, they move a couple of times after startup thats all.Asume its the same on syl 7 on the other side.Disconected the Connector to the solenoids, no difference. Seems my oil pressure sensor is bad, are showing the same oil pressure at all times, even when it dosnt run.Dont know it that fault was there before i replaced the lifters. (Bought car 1 day before lifter died!) I asume low oil pressure cant make some of the DOD lifters to malfunction? All New lifters were from AC delco. Can they be faulty? Its not possible to install them wrong? They layed over night in engine oil before instalation. Thankfull for any ideeas!

Took the heads off again. On the AFM lifters that dosnt work i have installed them With the oil hole Down! Installed them again, all facing upwards, will know tomorrow if that was the solution.If this is the cause i cant beleve why they arnt build so that it is impossible to install them the wrong way in the plastic holder.And altso that there was no warning or installation advice With the New lifters.If these are the only lifters in the Whole world that must be in

stalled in a certain way a warning wouldn be a bad idea…

Ketil, let us know what you find out. We’d recommend a call to our partners at Summit Racing. Their tech guys have seen it all and may have some thoughts on this as well. 330-630-0240.

Hello,

On June 4th you stated “The vehicles affected were 2007 to Feb. 2011 AFM equipped engines (Aluminum or Iron block-L94, LZ1, L99, LC9, LH6, L76, LFA, LMG, and LY5)” I am looking at purchasing a 2012 Tahoe with the LMG per the build sheet. 50,000 miles. Are you saying that I am in the “clear” by a year and issues fixed? My local mechanic suggested whatever I buy with an AFM he will send off the ECU to have the AFM flashed out. Thanks for your help.

I’m servicing a 2011 Chevrolet 5.3 with AFM. Truck has an active P0300 code and runs very rough. Found that all passenger side cylinders are not firing. Only running on drivers side cylinders. Driver reported this occurred suddenly while driving down the highway. Truck ran fine before that. Not sure which direction to go from here.

Plugged converter?

[…] they have a downside? Just one or two. Most will want to get rid of the AFM immediately and VVT isn’t for […]

Brian, I repaired a 2012 GMC Yukon Denali as the AFM lifter on #4 I take failed. Everything else looked good. Replaced all lifters on passenger side as well as pushrods for even wear. Everything was fine for two weeks, ow customer complains s it same noise it made as before. What’s the next step? Replace the cam or do the delete kit?

There is a good chance that some of the driver’s side lifters decided to go. It does seem that when they start going…they go quickly.

There is a chance the cam lobe was stressed and started to deteriorate. That might show up if you cut the filter and looked for debris in the pleats. But yes ultimately, it might be time for a cam and any AFM lifters that weren’t replaced. I’m always sorry to hear when people run into issues like these.

2015 SILVERADO 1500 4×4 crew cab with 5.3L engine:

So two weeks ago with approx 70K miles, I had an odd noise when accelerating and then engine light flashing and riding rough. Took it to the dealer and was told I had a “collapsed lifter.” I had purchased an extended warranty when I bought the truck new. Glad I did. Covers me to 100K. They replaced all the lifters, said no other damage, problem lifters were on cylinders 6 and 7.

Shame this happened. Love the truck. Have an intake and Borla exhaust. Don’t want to make a move on a new truck or jump to a 2500 yet.

Open to suggestions about best course of action. Delete the AFM, buy a tuner/chip, take it to a performance place and get an actual “tune” done that fixes it, replace the AFM lifters with non AFM type, change other engine components with this……etc…..etc…..etc…???

If buying a “tuner/chip” which works best for that truck/engine?

Thanks for any input/suggestions.

Respectfully,

Jim

Have a lifter problem on my 2010 5.3 Silverado. Happened once 1yr ago, truck was not used for a week and worked fine when i started it back up. Now the problems back, I have 180k miles on it now. Jusy 3 weeks ago I quit driving it because of the lifter, but it worked fine when i started it back up. No clue what to do. The lifter seems to recharge whenever the truck sits for some time.

Hello! I’m considering just replacing the 5.3 ( should be LMG, 2007 YUKON ) with the L96 crate engine. Can you tell me what needs to be done with the VVT?

If possible, will simply not using VVT provide a powerful,good running engine?

Thanks in advance!

I have a 2007 Gmc Envoy Denali with LH6 cant find a good LH6 engine but I found a 2011 LC9 engine w 52000 miles will everything plug up or what am I getting into?

Hello Brian, I just purchased a 2018 Silverado with a 5.3 AFM engine, I have 200 km on it. I traded in a 2004 4.8 L with 256000KM on it that ran like a clock and never gave me a problem. After reading these forums I’m a little concerned about my decision to stay with GM. Do you think it would be wise to put a AFM disabler on a brand new truck to avoid engine damage? Should I wait until the warranty runs out, or will that be too late to stop possible damage? Does the disabler prevent the engine damage in the first place?

Thanks in advance!

I bought a new 2017 Cadillac CTS back in January – 3.6L V6 with 8-speed trans. I love the car so far. I’ve been a Ford guy my whole life, so I was unaware of AFM until a recent trip where I did a lot of highway driving and happened to bring up the real-time mpg display, where I saw it switch between V6 and V4. I was getting ~ 30 mpg, so I love that. But after reading this thread, I’m a little concerned about the long-term reliability.

Is this an issue only with GM SUVs and trucks, or does it include cars too?

I only have ~ 5k miles on it, and it hasn’t been driven hard, so I’m assuming the lifters are fine. Given that, would you recommend buying one of the OBD-II devices to disable AFM? Is there any potential down-side to doing this – in other words, might this do more harm than good?

Thanks!

I am wondering the same thing. I just bought a 2018 Silverado. It has 8,000 miles on it. I just took a long trip and it used 1.5 quarts of oil. I’m confused from the write up about the plug in. Will the plug in cause my truck to burn more oil or will it fix the oil consumption issue? Why have you not gotten a reply from Mr Nutter

Buying a Silverado 6.2L. It’s a CA EMMISIONS TRUCK. Will this AFM DISABLER damage anything???. Friend will send to me from Arizona. Thank you. Gary

[…] 3 engines didn’t have AFM (Active Fuel Management) or VVT (Variable Valve Timing), so you don’t have the expense of an AFM or VVT delete […]

Brian, I have been reading your article about the AFM. I had a 2007 Yukon XL 5.3 with the AFM. Traded it with 180K miles and did not experience any problems. In 2015, I purchased a new Tahoe with the AFM and two weeks ago with 71K miles on it, the engine light came on. I wear hearing aids, but I thought I heard more engine noises, but after checking the gas cap, the light went out for a week. It came back on last Wednesday starting with a flash. I called my service station and they told me to get it in ASAP. I did and they diagnosed it as being on Cylinder 3, not one of the cylinders that deactivates. Anyway, after some pushing and pulling I took it to the Dealer who sold it to me. They took the engine down today found so much damage inside they ordered a new engine from Detroit. My question is: do I install the electronic disabler on the new engine to avoid future issues?

I would. From what I’ve read new and low mileage engines with no issues is ideal to do a afm delete, tune, or use of a disabler.

I have a 2008 Buick Lacrosse super that I am having a hard time finding a tuner or a tune shop that can turn off the afm. HP tuners is not for someone like me that doesn’t know how to use it and from what I read neither the range nor diablo plug and play device will work since the buick’s pcm files are different than all other GM vehicles that came with afm because it was tuned in house at gm’s performance division. any help?

[…] For more on that, read: How to Delete or Disable Active Fuel Management (AFM) on GM Engines. […]

[…] way. On one hand it has an aluminum block, which is nice. One the other hand, it came without AFM, VVT, or flex fuel capability. That’s not all bad because it saves the cost of an AFM delete kit. […]

Hi Brian please help, yesterday after ice fishing was climbing a hill back home and check engine light flashed. Took it in this morning and mechanic said cylinder 6 misfire, he said the lifter hasnt failed. He used seafoam and changed to synthetic oil. Now im thinking of buying a disabler asap, am i in the clear to do so without the oil splashing problem? I have an 07 Silverado 1500 ltz.

A lot more info with the ongoing GM 5.3l AFM engine issues on Cargurus.

https://www.cargurus.com/Cars/Discussion-t30884_ds822284

Seems like the AFM disabler device is working for a number of people including myself as the 5.3l AFM engine has inherent design faults. If you already own this engine you will need to deactivate the AFM system or even better DO NOT buy any GM vehicle with this engine.

Hi Grant is that disabler still working for you ? how many miles do you have on your engine?

My question on a 2007 Chevy Tahoe 5.3 AFM

Replaced all 16 lifters due to collapsed lifter on CYl #4.

Also replaced push rods rocker arms and rocker plate guide because if wore push rod and crack in rocker arm.

Put everything back together proper torque, gakets, valve seals, etc.

Engine starts but is throwing a misfire on cyl’s 4,7. Fouls those plugs. New plugs and wires. Plugs spark fine engine has power at higher RPM’s although it is still in Limp mode / stabilitrack message, even after driving it a few times above 60 MPH then clearing errors with handheld programmer. 4,7 plugs foul runs rough at idle.

Would installing the Disabler solve this?

Are there errors or something only the dealer can clear?

Battery was unplugged for a week..

Really could use some pointers. 190k on the motor always ran AMSOIL full synth since new. Had similar problems under warranty, no telling what they rigged me up with at the dealer. HELP

I have 2005 envoy that runs makes lifter noise then dies in about 30 seconds then I started it one day and it ran with little noise for 5 min started next day and it starts and dies again got heads off was told I could put ls 3 lifters in is that true or is there something else I could do thanks Duane

2012 5.3 Tahoe AFM, #4 lifter collapse,replaced all lifters,started engine ran ok, then rough, got #6 misfire code. Both #6 lifters only move when turning engine by hand, if you use the starter they stop moving. Unplugged AFM engine only runs on 4 cylinders #2,3,5 and 8. Engine oil pressure is fine.

Dale, I have a 08 Tahoe that’s doing the same thing.Any info you have on this would be appreciated

[…] Do they have a downside? Just one. Most will want to get rid of the AFM immediately. […]

I have 2007 5.3 it’s a new motor this truck scares me 9000.00 these trucks are jokes

Lost number four

The lifter came apart and chewed up the lobe on the cam I’m selling it I also told my friend at work when he asked me about my truck .I said I’ll never by another GM ever

I just got a 2013 Silverado extended cab 4X4 with 124,000 miles on it. the body is in great shape.

I didn’t even think about AFM until I got to drivee it on the highway and encountered the 4 cyl syndrome.

I have only put about 600 miles on it and noticed that the oil was a bit low and am hoping that it was that way when I picked it up.

I have ordered an ATM disabler and will be putting a can of Textron in the gas at the next fill up. It looks as if I’ll need to start saving for a complete AFM delete kit with a new cam.

I am a long time GM fan but after reading how they messed up the 5.3 ( I had a fantastic 2003 Z72 off road) I’ll look else ware for my next vehicle

i just bought a 2018 Silverado with the 5.3

I want to put a AFM disabler in it what all do I need to have done.

Hi Mike,

I am considering the same. If you scroll back, you will find that it is recommended to change lifters and camshaft and looks some more. I will keep reading and take notes. I would appreciate it if you let me know how you make out.

Ralph

I just bought a 2015 5 3 17000 miles I was thinking about eliminating the 4-cylinder if I delete it with just the programmer will it hurt my motor?

Replacing engine due to issues caused by AFM. Also putting in a new transmission vs. rebuilding.

I plan on getting a tuner to disable the AFM. Can I (should I) also change to a standard volume oil pump? I don’t plan on installing the delete kit at this time.

2011 Chevy Avalanche LTZ

Bought an ’07 GMC Yukon 5.3 with the AFM, 87k. Loved the looks and interior and thought a I got a great deal at $6k even. One month to the day driving on the highway got the ‘Service Stabiltrak’ message quickly followed by the misfire code. After taking a $3.6h bath on the lifter/valve work and doing a little research, how can GM allow a problem like this AFM continue from ’07 to present? Can’t believe they haven’t fixed this in a decade. At least Dodge admitted they had junk transmissions in the early 2000s and picked up sales each.

I have a 2011 GMC Sierra 1500 with the 5.3. There has been a lifter noise since I bought the truck 1 year ago. I have been assuming this is just a slow to pump-up lifter or lifters. I quites down to nothing after running for about a minute. I wii be using this truck to haul a camper for full time RV living and am thinking of a tuner to shut off AFM and maximize performance and economy. Most of all, my concern is reliability. I would appreciate any feedback.

I have an ‘08 Suburban that is currently getting the lifters replaced a second time within a three month span. Would doing the disabler option once I get it back be the right one?

Does anyone know how to disable the new Dynamic Fuel Management on the 2019 Silverados?

[…] block engine used in GM hybrid trucks and SUVs between 2008 and 2009. The LFA was upgraded with AFM and […]

[…] For more on that, read: How to Delete or Disable Active Fuel Management (AFM) on GM Engines. […]

[…] For more on that, read: How to Delete or Disable Active Fuel Management (AFM) on GM Engines. […]

[…] improvement over AFM, DFM has 17 different cylinder firing patterns and switches seamlessly between them to provide just […]

This is in response to pretty much everyone. I own a reputable repair shop. I have seen more internal engine failures in the last 5 years or so than I have in the first 15 years in the business. The biggest problem is nobody changes their oil on time. I would say maybe 5% of my customers keep up on their oil changes. There are so many moving components in an engine these days as opposed to the past. Clean oil is crucial. I can’t stand seeing customers continuously going thousands of miles over on the oil and wonder why there’s problems. I service plenty of these vehicles with AFM, and the ones I have to open up the engine for repair because of a failure doesn’t surprise me anymore. The oil is baked on to every component. When an engine is contstantly running on oil that is broken down, it not only where’s out components because of no protection. But it also restricts passages that the oil runs through. There are so many more oil passages on engines these days. You cannot compare them to old 350’s. Unfortunately because of emission standards nowadays, manufacturers cant go back to those style of engines. So for all of you that continue to complain about how bad these things are. Change your oil. Because it’s not just GM that have engine problems. It’s Chrysler and Ford. I have a 2014 Silverado with a 5-3. It’s got a hundred forty-five thousand miles on it. When you drain the oil at three to four thousand miles it’s still clean. Have not had a problem yet. CHANGE YOUR OIL!!!!!

Why doesn’t anyone make an aftermarket set of replacement AFM lifters that are the right length but DO NOT COLLPASE! Correct me if I’m wrong- If such an item was available couldn’t you then just replace the lifters in the 4 AFM cylinders and then just run a disabler or have your ECM/PCM reprogrammed to have AFM disabled permanently. From what I am reading this would eliminate the possibility of failure, prevent false check engine lights and continue to make the appropriate power??? Only issue might be the oil consumption due to pressure run off and spraying of oil in crankcase?

[…] 5.3L engines start in the $600-$1,000 range and go up to a little more than $2,000 for the 6.0L and 6.2L engines. These engines made 270-400 hp from the factory will run smooth as silk for over 300,000 miles (unless you have AFM). […]

[…] It’s a Gen. 4 5.3L iron-block engine, so you’re getting the better intake manifold, connecting rods, and ECM. The engine also had 799 or 243 casting heads which are closely related to the LS6. The engine has flex-fuel capability. The engine is close siblings with the LMG which shared many of the same features…except the LMF isn’t saddled with AFM. […]

All these comments on the 5.3 are blowing my mind!!!. I have a 2011 GMC with over 162,000 miles on it and it runs great! My fear now is not will it happen but when! I am not in a position to have a new cam and lifters installed but I’m also not in a position to not having a running truck!

I would just have the AFM disabled (tuned out) then. I am having that done today on my 08′ Suburban and it’s only costing me $225. I’m crossing my fingers it does the trick!

I know I felt the same way. I have a ’07 Yukon with 180K and no issues what so ever. I did noticed the oil consumption but it was rare that I would have to add oil. I got the AMF disabler anyway and so far so good.

I am confused about the plug in disabler. I recently bought a 2018 Silverado 5.3L with AFM. It only has about 9k miles on it. I recently took a long trip and it burned 1.5 quarts of oil. The write up confuses me. Will the plug in deactivater fix the oil consumption or will it cause more consumption?

I have an 07 Yukon with 230k on the engine. I had #4 lifter stick and now i am looking at replacing the engine with a non-dod version. My 5.3 has a vin code of O. Did gm make a non-dod version of the 5.3 with iron block that would work in my application? If so what would the vin code be? If i am successful locating a non-dod vin would i just need to have the ecm reprogrammed?

Thank!

i have a 2007 suburban 6.0 and the number 4 intake lifter took a dive.i have already started to disassemble the engine as i plan on replacing all the lifters and reassemble the engine as i never had any other problems with it. the vehicle has 120,000 on it and 30 to 60 psi of oil pressure never lower or higher. i’m going to plug in a dissabler when i’m done to keep it V8 mode all the time. in your opinion will this work, i really don’t see any reason it wouldn’t. please respond with your opinion

I have an 2004 1500 Suburban 4WD that I am about to replace the motor in. The motor I pulled was a 2007 LY5 with about 77k on it. It has AMF. Question is, since my 2004 ECM and wiring harness were made before the AMF came about will this motor work properly as a V8 or will I need to replace the lifters, cam, oil sensor, etc as the delete method mentions?

[…] swaps come with an extra step or two thanks to the General’s fuel efficiency efforts (VVT and AFM). This video covers the steps you’ll need to take before upgrading to a larger […]

I am installing a complete delete system, just wondering what it will do if don’t plug the oil pressure relief valve? I am worrking on a 2007 chev Silverado 6.0 engine

[…] the L76 that was equipped with AFM and had a ribbed valley cover, the L98 cover was […]

[…] 3 engines didn’t have AFM (Active Fuel Management) or VVT (Variable Valve Timing), so you don’t have the expense of an AFM or VVT delete […]

I have an ’07 Yukon with over 180K. I haven’t has any lifter or cam issues. Only thing I noticed with the oil consumption issue. So I researched and got an AFM disabler. Been driving with no issues but I did notice that the AFM disabler removed a P0449 code (Evaporative Emission Control System Vent Valve/Solenoid Circuit Malfunction) don’t know if this is a coincidence or they are related??? I already ordered the parts to replace myself and remove the code.

Hi my name is noel I am a mobile mechanic and I have a client that was having trouble with the lifters on a 2011 gmc yukon Denali 6.2 I placed the lifters after finishing I still had a problem with cylinder 8,6,3 rocker arms were not moving so I replaced the cam OEM part but still having miss fire on cylinder 6 what should I do to get rid of this problem

[…] computer cannot switch over to four-cylinder mode. This system is the most effective way to disable AFM. Also, it is the easiest way […]

[…] for the 2010 Chevy Camaro SS—is also a Gen IV 6.2L aluminum-block V8, but with the addition of Active Fuel Management and Variable Valve Timing. Below you’ll see references to the L99 as a result. For a primer […]

[…] 3 engines didn’t have AFM (Active Fuel Management) or VVT (Variable Valve Timing), so you don’t have the expense of an AFM or VVT delete […]

[…] cathedral port cylinder heads and used Active Fuel Management (AFM). The engine was not Flex Fuel (E85) capable and did not use Variable Valve Timing (VVT) […]

[…] The L76—like its LS2 sibling—is a 6.0L, Gen. 4, aluminum small block engine that was used both in GM cars and trucks. The L76 is an adapted version of the LS2, featuring new rectangle port cylinder heads and Active Fuel Management (AFM). […]

[…] rugged iron block 6.0L came with VVT, but without Active Fuel Management, which saves you the cost of an AFM delete […]

[…] they have a downside? Just one or two. Most will want to get rid of the AFM immediately and VVT isn’t for […]

[…] The LH6 engine is a 5.3L Gen. IV aluminum engine that replaced the LM4 in 2005. It was the first Gen. IV LS truck engine and offered Active Fuel Management (AFM). […]

[…] as the LS engine family’s hybrid engine in trucks and SUVs. The LZ1 was upgraded with AFM and […]

Hi there,

I have a 2007 Yukon XL with the 5.3L and am planning to do this as my lifters have failed and it rattles loudly if it starts, and runs limp.

I saw two Summit Racing kits, with different valley covers…which one do I need for my Yukon? With the nipple, or without? Thank you.

I recently bought a low mileage 2013 Silverado and the lifters collapsed. It is currently at the dealer having a new long block installed under warranty. Should I buy a Diablo AFM disabler to prevent the new block from dropping to 4 cylinder?

[…] Here is a guide on how to turn off AFM: https://www.onallcylinders.com/2017/11/30/how-to-delete-or-disable-active-fuel-management-afm-on-gm-… […]

[…] Guide to disabling AFM: https://www.onallcylinders.com/2017/11/30/how-to-delete-or-disable-active-fuel-management-afm-on-gm-… […]

[…] Here is an article on how to deactivate AFM. […]

I have a 2012 Silverado Z71 bought new. Vehicle has been serviced more regular than the manual calls for and the AFM has caused problem after problem with fouled plugs. General motors sent out a service bulletins to their dealers however, all dealers will not tell you about the bulletin. The dealer in Rockhill, SC when asked only said they had not had a problem. I contacted service manager in Gastonia, NC and he was kind enough to tell me the whole history of the problem.. EPA required better fuel mileage and less emissions and GM, Ford and Honda(V-6) came up with this failed AFM system. We need availability of a replacement engine without the AFM. These trucks cost too much to have a terrible product. Toyota will be my next truck unless GM owns up and makes wright with consumers. After all we bailed them out of bankruptcy. The service manager that I spoke with said, GM states if 2 qts of oil is used between oil changes the engine needs rebuild. Get this, rebuild is only rings and maybe lifters. Service manager said nothing else needs to be replaced because the engine has a Teflon coating. Teflon coatings does not last. The cost of just rings $4,000.00

[…] Disable your Chevy AFM: https://www.onallcylinders.com/2017/11/30/how-to-delete-or-disable-active-fuel-management-afm-on-gm-… […]

[…] like front timing cover, knock sensor location, cylinder head style (cathedral ports), AFM (Active Fuel Management), and other components are key clues to which engine family you’re looking […]

Thanks for the advice Brian! Unfortunately, I found out about the lifters too late. I had to replace them all and the camshaft as well. Fortunately I received a reducing in house shop hourly rate. I went ahead and purchased a Disabler on Amazon, for preventing it happening in the future. Is there any reaction to the disabler when pulling a boat or trailer? I have the towing package on my ‘13 Tahoe LTZ. Thanks for the detailed post!

Question I have a 2015 Silverado and had a transmission go bad when I had it rebuilt I had the AFM/DOD turned off. Ever since that which was Feb/March 2020 i get a intermittent rattle does not do it all the time and I am not getting any codes i.e. misfire or anything. Sometimes it will do it all the time and other times can drive it for 10 miles and then it starts but doesn’t do it constantly when driving. If under the truck while parked and it is doing it it sounds like it is towards the back of motor. But not sure very annoying. Any guidance would surely be appreciated.

Brian Nutter & others;

I have a 2014 Chevy Z51 [w/dry sump oiling etc.] Corvette that does employ AFM. Vehicle has 40k miles been maintained well and shows no signs of lifter concerns at present.

I’ve been reading, with disgust and concern of the lifter/cam situation.

Have there been “improvements” in more recent model years employing AFM [2014 or newer]? I noticed this discussion mainly addresses Chevy Silverados and other trucks?

I’m looking at the Range Disabler but want to make sure it is required/suggested/recommended/safe?

Looking forward to input from the forum, Thank you.

Ray

[…] engines is that when VVT (variable valve timing) appeared and was later followed by AFM (which is Active Fuel Management, when the engine deletes four cylinders under light load) both of these packages drastically affect […]

If I were to put a 2006 5.3L in a 2007 Avalanche and buy the unit to plug into my OBD2 port would it work? Or not because it is the cast iron block and not he aluminum block?