Depending on engine bay size, you may find yourself limited in accessory drive space when doing an LS engine swap.

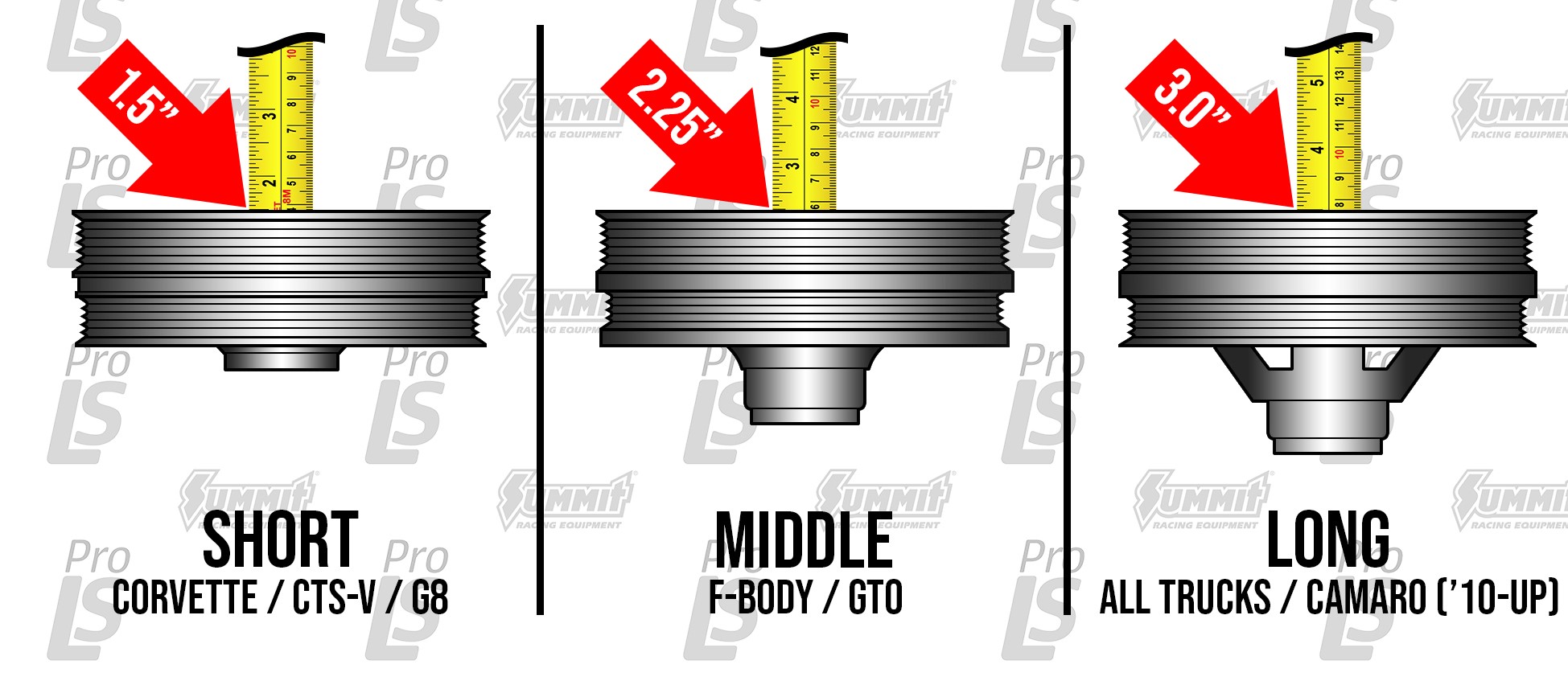

GM used three basic serpentine systems on the LS engines, each with application specific spacing. Most crankshaft pulleys will bolt onto any LS engine, however, you need to know which pulley you have (or may need) to ensure proper belt alignment and clearance.

Planning an LS swap? Here’s a good place to start.

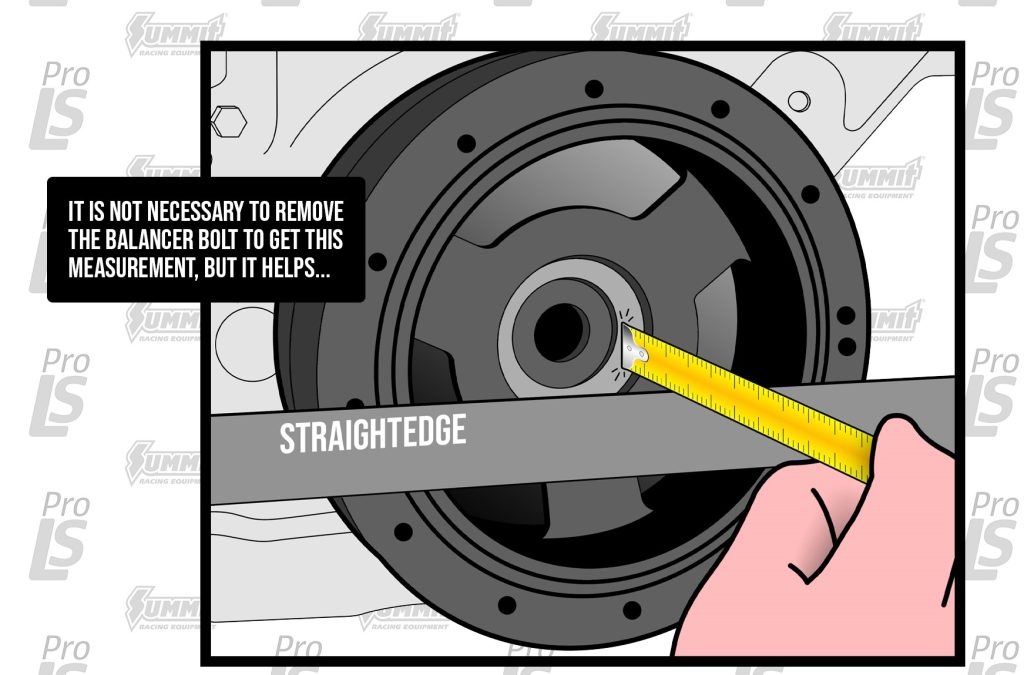

The easiest way to identify which accessory drive you have is to measure the depth of the harmonic balancer by placing a straightedge across its face, see the illustration below.

Pulley alignment is often a concern during an engine swap—if any of your pulleys are out of alignment, you will chew up and throw the belt, leaving you stranded.

One solution to this issue is to source an alternate accessory drive system from another LS engine; for

instance, installing a Corvette drive system on a truck engine is very common for additional clearance.

If you change the accessory drive, ensure you have the right harmonic balancer so it all lines up. Another option is to upgrade the whole accessory drive system with a kit from ICT Billet, March Performance, LS Classic, Summit Racing, and others.

Spacing guidelines apply to water pumps, as well. Matching the correct water pump to your accessory drive is essential for proper belt alignment. In some circumstances, water pump spacers can correct spacing when adapting car pumps to truck accessory drives.

Comments