Fusible links—also spelled fuseable and fusable—serve a similar purpose to a fuse. (You can read more about fuses here.)

Just like a fuse, the link is designed to handle a lower current (amp) load than the rest of the system so, in the event of a short or overload, the link will be the first failure point. When it fails, it will break the continuity in the rest of the circuit, preventing damage to other components down the line.

A fusible link typically costs a couple of bucks and can be replaced in 30 minutes. A starter motor or ECU? Not so much.

But fusible links look much different than fuses and are used for different applications.

***

Story Summary Overview

- Similar to a fuse, a fusible link serves to protect the rest of the electrical system from excessively high current loads

- Too much current (amps) will cause the fusible link to fail, cutting power to more expensive components downstream in the electrical circuit

- Fusible links can be cheaper and easier to install than a replaceable fuse

- Generally, a fusible link’s wire is four gauges higher (smaller) than the rest of the circuit, making it the weakest link in your electrical chain

- A fusible link can be tested with a multimeter

***

What’s the Difference Between a Fuse and a Fusible Link?

In an automotive context, fuses are typically used on circuits with a relatively low current draw, measured in amperes, ranging from one amp to 40 amps.

But certain automotive components require momentary higher peak current levels depending, so a fixed-rating fuse may not be ideal. Fusible links are also cheaper and easier to install than a dedicated fuse block, which is why you see them in OE applications.

We have an in-depth article on fuses here: All About Vehicle Electrical Fuses

How Does a Fusible Link Work?

Wire is measured in “gauge,” often abbreviated AWG for “American Wire Gauge.” The lower the number, the bigger the wire. Bigger wires handle more current (amp) draw. Check out this cable calculator chart to learn more.

Again, a fusible link’s function is very similar to a fuse. It’s designed to fail before your wiring harness melts to goo.

As a general rule, a fusible link is made of wire that is four gauges higher (smaller) than the rest of the circuit, making it the weakest link in your electrical chain. For example, a fusible link in a 10-gauge wire would be 14-gauge.

The smaller-gauge wire handles less current than the rest of the circuit, so it will overheat first and, by doing so, will break the physical connection between the wire to which it’s inserted.

Where Will You Find a Fusible Link in a Vehicle?

Generally speaking, you’ll find fusible links in the parts of a car or truck’s electrical system that see the most current draw (measured in amps). For a vehicle, that usually means the starting system, where battery power is sent via a larger (lower) gauge wire to the engine’s starter motor. A stuck, cold, or damaged engine may put excessive strain on the starter motor, which can result in a higher than normal amp draw—hence why a fusible link is often found here.

If you’ve ever had to crank-over an engine by hand, you know that the cylinder compression means it often requires a lot of strength to move the rotating assembly—in other words, a starter motor demands a lot of current to make enough oomph so the the engine can turn over.

Another location where you may find a fusible link is in the vehicle’s charging system, near the alternator (or generator, if so equipped). Again, this is an area of your electrical system that often sees large amounts of amperage (current), so a fusible link is often used to prevent excessive current draw from damaging your battery or alternator.

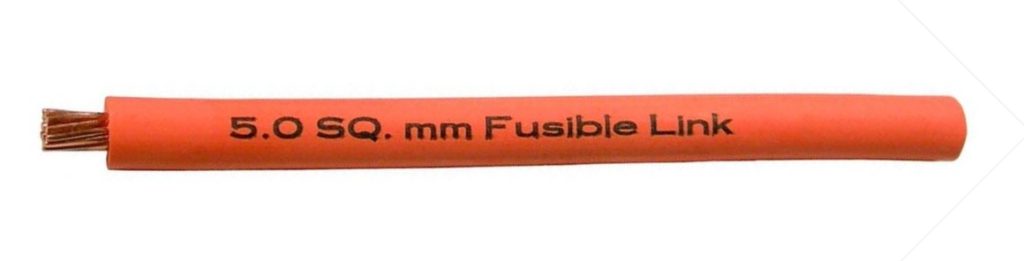

What Does a Fusible Link Look Like?

Well, that’s the fun part. They look like wires, which can make troubleshooting a headache—we’ll get to that in a second.

When you’re combing over your wiring harness, you’ll want to look for a short section of wire (usually a few inches long) that has a smaller diameter than the wire into which it’s connected. There’s also a good chance that the link will be a different color than the wire.

Remember, a fusible link is going to be four gauges higher (smaller) than the rest of the circuit.

If it was a factory-installed link, it will probably have a nice jacket or boot covering the splices.

The link may be at the very end of the harness as well, ending at a ring terminal secured to a solenoid, battery, or motor.

Understanding Wire Gauge Size & Power Demand

We’ve alluded it before, but it’s worth repeating simply because it’s a bit counter intuitive: The higher the gauge, the smaller the wire, and the less current it can handle.

Here’s a handy chart that can help.

Wire Gauge to Wire Diameter Comparison Chart

| Wire Gauge (AWG) | Wire Diameter (Inches) |

|---|---|

| 4-0 | 0.460 |

| 3-0 | 0.409 |

| 2-0 | 0.364 |

| 0 | 0.329 |

| 1 | 0.289 |

| 6 | 0.162 |

| 8 | 0.128 |

| 10 | 0.101 |

| 12 | 0.081 |

| 14 | 0.064 |

| 16 | 0.050 |

Troubleshooting a Fusible Link

When a fusible link does its job, it will break the circuit continuity, which is akin to cutting the wire. That results in cutting off power to the component.

We see this a lot in starting systems. A fusible link will blow, and folks will incorrectly diagnose a failed starter motor—turn the ignition key…and nothing will happen.

If this (or something similar happens), you should check for blown fuses in your fuse box first. If everything looks okay, pop the hood and inspect the wiring harness for melted, scorched, or broken wires.

Don’t panic if you see one, as it may simply be the fusible link doing its job.

You can also check for electrical continuity using a multimeter‘s continuity setting. Clip a lead on one end of the circuit and the other to its opposite end. If continuity exists, then your problem is likely elsewhere.

Learn how to do these tests in this short tutorial: 3 Basic Electrical Multimeter Functions That Every Home Mechanic Should Know

Avoid using a simple 12-volt continuity test wand for something like this, as your circuit may not automatically have 12V present. (An upstream switch or relay may also prevent an accurate diagnosis.)

Replacing a Fusible Link

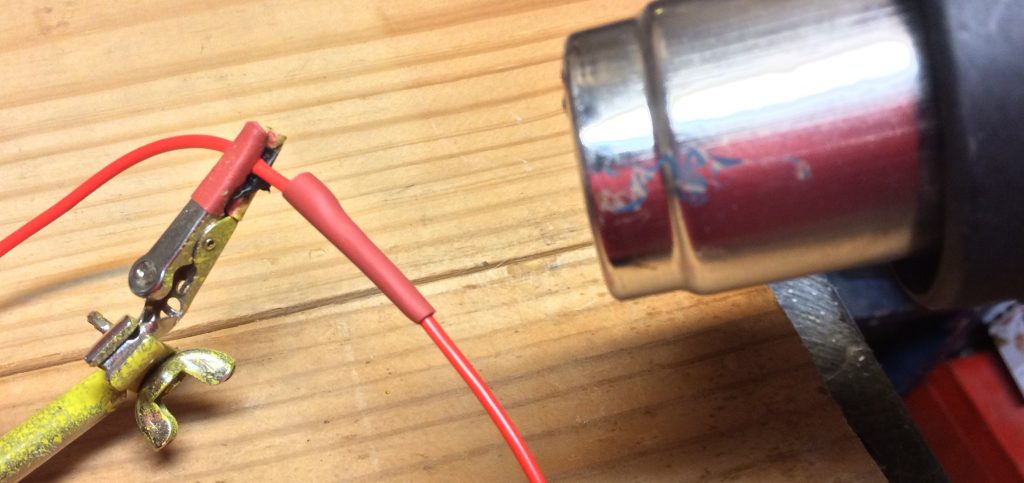

Replacing a link is as straightforward as cutting out the broken link and installing a new one.

Many fusible links now come with a crimp connector pre-installed, which simplifies the installation process.

Remember to weather-proof your connections—cover your joints with heat shrink tubing or tightly wrap your connections with electrical tape.

Need a good 101 tutorial on electrical wiring? Check this out.

And we also have a nice walkthrough on how to make clean soldered electrical connections here: The Lineman’s Splice—How to Make Reliable Electrical Connections

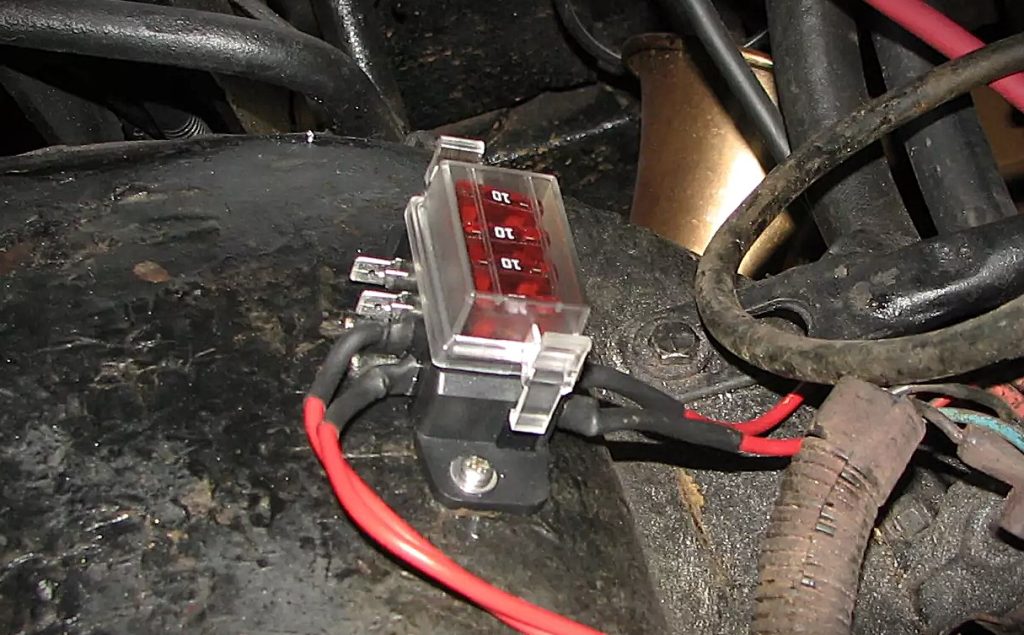

Alternatives to a Fusible Link

Nowadays, many companies offer standalone fuse blocks that allow you to run several separate and fused circuits to vital electrical accessories. Keeping your fuses in a single spot like this can unclutter your engine bay, and make service and fuse replacement a lot easier in the future.

You could also opt for individual in-line fuse holders for single circuit applications too.

A Final Caution on Replacing a Fusible Link

A fusible link is a vital safeguard against catastrophic electrical damage resulting from excessive amp loads in your vehicle. So don’t fret if yours goes bad—often times, it means that the fusible link did its job and sacrificed itself to save more expensive and sensitive electrical components downstream.

But that also means that you should FIGURE OUT WHY IT FAILED IN THE FIRST PLACE!

Simply replacing a fusible link isn’t good enough. You should determine why it blew, elsewise it could fail again soon—potentially leaving you stranded or, worse yet, damaging more costly parts of your electrical system.

It could be due to age, corrosion, or a failing component downstream—like a bad starter that’s pulling too much current, or internal engine damage that’s making the starter work harder than normal.

Once you figure out why it went bad, replacing a fusible link is fairly easy to replace and, if done correctly, should give you years of trouble-free service.

Starters don’t use fuseable links as they will draw over 300 amps.

Fuseable link wire is nichrome so it will not solder.

Fuseable link wire has stopped being sold in most countries now as it is a fire hazard.

Hey Scott–thanks for the heads up. We’ve made some adjustments to the story based on your insight.

Paul Sakalas, thanks for the refresher on Fuselink . I had known that the Fuseabke link was 4x smaller than the circuit it protects . However, you made this clearer to me. I want to post this on your On All Cylinders 10Years Site.I own some Chilton’s Truck and Van Manuals. From the Vice President & General Manager to Special Projects ; over 9 are S.A.E.,A.S.C.Mechanics , so I just am at the T187Ford page T319.FUSELINK.The fuse link is a short length of special, Hypalon ( high temperature) insulated wire integral with the engine compartment wiring harness and should not be confused with standard wire.It is several wire gauges smaller than the circuit it protects . You hit it on the head about higher being ( smaller ) this is what I’m grateful for. Man a reliable source of help . Thanks for the past comments as well . Hope this refreshes memories .Mike M .October 23,2022 . It’s getting cold here in Colorado with an Alert! Winter Storm warning yesterday at 2:23PM yesterday , but now it’s 63• Thanks again . Great information .

One more comment about your customers friends etc. about fuseable links there are two really more out of my brain groups that I kind of looked into one is the official maker of the fuse link itself out of Texas as I remember and one about AWG but HVAC and Automobile wiring Charts that helped me . Never mind , don’t mean to aggravate or bud in to your site . Good News . Finally thanks .

Why in the world would fuseable link wire be nichrome? Nichrome has moderately high resistance, and a very high melting point. Kind of the opposite of what you want in a fuseable link. You want it to burn open in a hurry when overloaded – not to melt all the insulation off and sit there glowing cherry red.

You’re absolutely right Joe and in reference to Scott’s comment about fuseable links not being used in starting circuits my Expedition has a fuseable link between the battery and starter/solenoid +power wire

Exactly! Unfortunately the first users comments is inaccurate. Fusible link is copper wire, like the wiri g in the test of the system. And where did it state that “fuseable links are fire hazards”? They are not. Also, they are still sold like they always have been. Terrible info.. should be deleted.

Please excuse my spelling errors. Buttons are so small.

We still have them in stock

Please, sir. Put the crack stem down, and step away from the keyboard. Such erroneous information could be taken as fact by someone looking to learn, and mistakenly believing that you have a superior knowledge base.

Remember, there’s absolutely NOTHING wrong with ignorance. It’s simply a lack of knowledge of a certain piece of information. We are ALL born ignorant of all things. Every piece of information we learn makes us a little more educated and a little less ignorant. And then, there are some, who learn incorrect information, believe it to be accurate, and pass it on to others. This is where ignorance becomes dangerous. As in, you know just enough to be dangerous. Please, take the time to verify what you learn is actually factual. You obviously have intelligence. So use that to gain factual knowledge and then pass THAT on to others, who wish to learn from you. And I can climb down from my high horse/bully pulpit and use my intelligence for the same. Best Regards, P. Welch, F-1 Ferrari propulsion systems engineer.

Glad I read Scott’s reply. I was ready to purchase a link for my starter.

“Replacing a Fusible Link”

Get a decent, marine grade, waterproof fuse holder and use that in place of the terrible, corner cutting, garbage that the factory used.

Or let’s just keep cutting corners, doing shoddy work, and making vehicles not last so we can sell more vehicles and make more money.

“What’s the Difference Between a Fuse and a Fusible Link?

In an automotive context, fuses are typically used on circuits with a relatively low current draw, measured in amperes, ranging from one amp to 40 amps.

But certain automotive components require momentary higher peak current levels depending, so a fixed-rating fuse may not be ideal.” Completely FALSE!!!

Standard automotive fuses are what’s known as “slow blow fuses” and they behave the same way as fusible links, except they are much safer, and easier and less expensive to replace.

And there is no limit to the available amperage of fuses.

What would be better in a lot of applications is circuit breakers.

Normal automotive fuses are not slow-blow. Check the manufacture BUSS, and they can clearly show a picture of both types of fuses. In standard electronics, a slow-blow fuse may have a small resistor in the glass envelope. A slow-blow fuse is used to withstand a higher current draw during an initial start up; EX a circuit that normally draws 1 amp of current when operating, however that same circuit may initially draw 1.5 amps on start up.

Hopefully that explains the difference between the use of a slow-blow, vrs normal fuses.

I dont have power to my fuse box located in my trunk on a 2007 volvo s80. Its module A the black box. Do you think it could have a fuseable link blown? Not sure what color wire feeds that module or where it gets its power from

I have a 2002 nissan maxima that has a link connected directly to the positive battery terminal that appears to be blown. I tested the battery which holds 12 volts yet not enough power to keep the car running. Before i go spend a bunch of cash on something that still works id like to hear what is thought about my problem. Perhaps even put me on a trail of adventure trying to find out what is wrong

Thanks for the info i learned a little now i will fix my wiring on my 1985 c10 truck.

The 85 c/10 has a fusible link at the starter I know this because mine blew apart on my 85

QUESTION, DOES A 2010 TOYOTA TUNDRA HAVE AN INLINE Fusible links? if where would they be located… going agro!!!! please help! thank you much.

Hi

I was (am?) having trouble starting my riding mower, John Deere LT133. Brake safety switch was broken so I changed it, and I noticed a wire coming from engine block was burned out cut…cover melted and wire in it looked much more like a little metal rod. I’m guessing it is fusible wire. The mower is working: engine starts, gears engage, cutting blades engage and mows…

So my question: Do I need to have that fusible link replaced? It seems to be working just fine with that wire burned off and not connected.

Thank you

The circuit will work without the fusible link, but leaving it out removes the protection from current overload, which may cause something more expensive to get damaged – better to replace it with the proper link, or a fuse of similar resistance (if you can figure out what that is)

IAM HAVING TROUBLE STARTING MY 05 CHEVY TRAILBLAZER

AFTER REPLACING MY FUELPUMP/SENDING UNIT, WHERE IS MY OR ANY FUSABLE LINKS THAT CONTROL THIS UNIT ?

Don’t ask what others have done for you, but ask what you have done for others

[…] Download Image More @ http://www.onallcylinders.com […]

My car battery died when it stormed one day and there was so much water on the streets that I was having to drive through it so after driving through some water off and on my lights went doom and my car cut off the battery was completely dead while going down the road I got a jump then next day battery died again I noticed my alternator belt was broke could the fuseable link blow then car keep driving to the point where the alternator belt breaks bc now im overheating when I turn on my air conditioner so could the fuseable link cause the engine to overheat when more power is used to run the air

Um, no – it sounds like your alternator belt broke first. The car will continue to run on stored power in the battery until it died. Jumping it probably charged the battery enough to go run the car a little longer before it died again.

Cars generally don’t use power from the battery once they are running; they use power from the alternator. If the alternator is not working, then the battery has to sustain everything, which is why your lights would get dim and you gradually lose power. The storm and water probably had nothing to do with it either.

I have a 8ga.blk wire fusable link from my starter solenoid on my 71torino but not sure where it goes to

No comment just question

I have 2 equinox 2009 Traction control is on And my 2005Equinox has a problem with electrical5 fuses out I jumped it out And it runs good

My husband’s 93 Ford ranger has no lights other then his headlights and front and back blinkers… All the fuses in both boxes are new and still can get lights to work!!! Help please…

2013 buick encore next to battery coming out of pack of wires this is only one and cantfind where this fuseable link goes but ir keeps my engine light on it been 2 1/2 years with reject sticker please does anyone have an i deal where this wire went to i think code 1715 or1517

Very nice information. otherwise it was very difficult for me to find bad fusible link.

I want to add fusible links to my wiring harness in my 62 Plymouth, There are none. So where should I put them, what items should have fusible links inline to protect them. Also another question my 62 Plymouth has an ammeter. The orgnial alternator was 36-40amp. I’m installing a mopar 78amp alternator with an mopar electronic voltage regulator…now for the question would the 62 plymouth ammeter have a problem with the 78amp alternator ? would it be safe to use ?

You’ll typically find fusible links in the starting circuit—upstream from the starter—anything with a high current draw. It’s also worth mentioning that a fusible link is only one solution. For example, a high load fuse (60, 80, and more amps) would do the job just as well. Contact the folks at the Summit Racing tech department and they’ll give you some more precise recommendations.

…

As for your ammeter, many folks often advise adding a fuse inline or changing it entirely to a voltmeter, as the way the ammeter circuit works means it could generate a ton of heat behind the dash—even when the key’s out. Read the ammeter section of this article for more details: Basic Vehicle Instrument Gauge Functions & Fixes

from what i have read as i am a shade tree mechanic a hotwire is almost the same with the exception of the fuse link is that a correct assumption