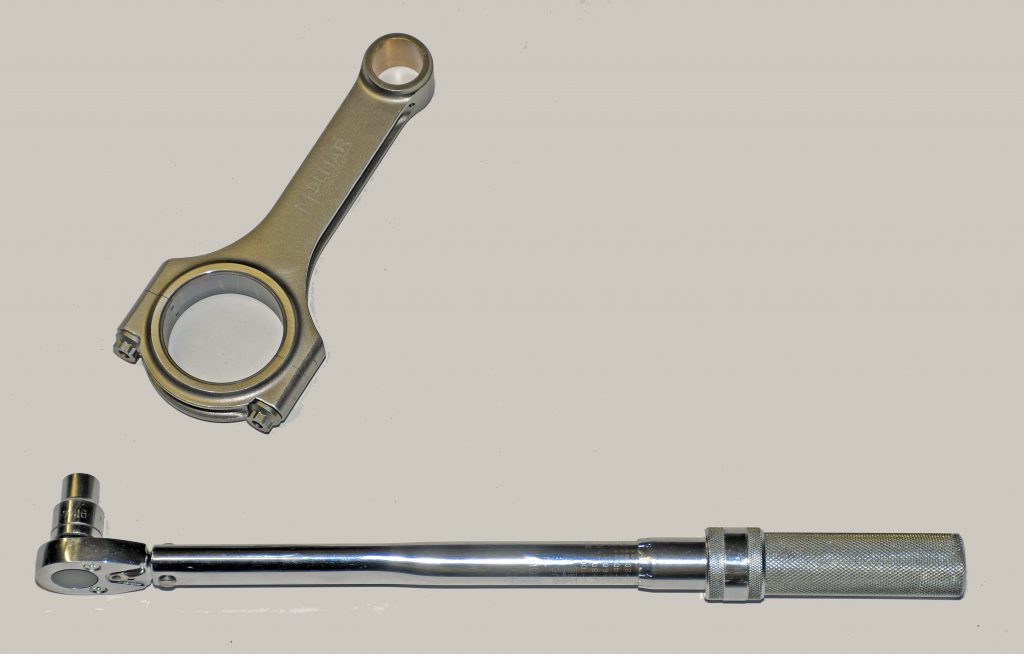

It should come as no surprise that Torque Angle is the measurement of choice for some engine components (the main example being connecting rods). When tightening fasteners by way of the torque angle method, the fastener is first preloaded to a specific torque. Next, a torque angle gauge (meter) is used to tighten the fastener to a specific angle. You can either use a specific torque angle gauge (similar to a torque wrench) or you can use a torque angle gauge attached to a breaker bar.

What makes torque angle superior to good old fashioned torque is that it is not affected by friction. Fellow OnAllCylinders contributor Jeff Smith provides an excellent overview of both torque angle and the use of the basic gauges, you can click here to read it.

Meanwhile, you can check out this video with Summit Racing’s Brian Nutter on how to use a dedicated torque angle gauge here:

When it comes to torque angle gauges, you’ve got several different options. Included in the mix are dedicated digital torque wrenches that also read torque angle, as well as adapters that simply attach between your breaker bar and the applicable socket.

The digital torque wrenches are a bit more expensive than the adapter style gauges—but the basic takeaway, is anyone can afford one of these tools.

Here’s the rundown on what’s available, starting with a couple of the more expensive electronic torque wrenches:

Summit Racing carries a digital half-inch drive torque wrench from ACDelco Tools, part number ARM303-4A340. As mentioned above, this torque wrench can also determine torque angle. The readout is LCD, and because of that, the wrench requires a battery. In addition to the digital display, there’s a built in buzzer that provides audible confirmation of the reading. The torque wrench will read up to 720 degrees when set as an angle measurement device.

Another ACDelco Tool is part number ARM315-3A. This torque wrench is similar to the above wrench, except it is a 3/8-inch drive model.

Fair enough. But what if you don’t have deep pockets or you don’t perform torque angle measurements on a regular basis? You’re covered there too. There are several different torque angle adapters available. In no particular order, here are a few examples :

OTC Tools has a half-inch drive torque angle gauge with a 360 degree scale (all of the adapters here have the same style of gauge face). In this case, the face is marked in 360 degree increments. This particular tool makes use of a L-shaped stop arm. The part number is OTC-4554.

Next up is the Performance Tool torque angle gauge, part number WMR-M205. It is similar to the OTC tool.

Another option is the Lisle Torque Angle Meter, part number LIL-28100. It too comes with a 360 degree face, with increments of two degrees. Where it differs is the method used to stop or “anchor” the tool for use. It incorporates a cable and clamp setup instead of an L-shaped stop arm. This makes it a bit more user friendly for some applications. This tool is a little bit more costly than the others, but it’s still a bargain when compared to the digital torque wrenches.

As you can see, there are plenty of options when it comes to torque angle gauges (meters). Picking the right one for your toolbox depends upon your application and how often you need to use the tool.

For a closer look, check out the pics below:

Comments