Well, our (really) big block Chevy is done and had its maiden voyage on the dyno. We already gave away the ending by telling you how much horsepower the 540 cubic inch engine made (it’s in the title and everything), but can still show show you the installation of the induction and ignition systems, headers, and other parts like the harmonic damper and electric water pump.

If you haven’t seen the other stories in this build series, be sure to check them out:

• Part 1: Short Block Assembly

• Part 2: Oiling System, Cylinder Heads, Valvetrain

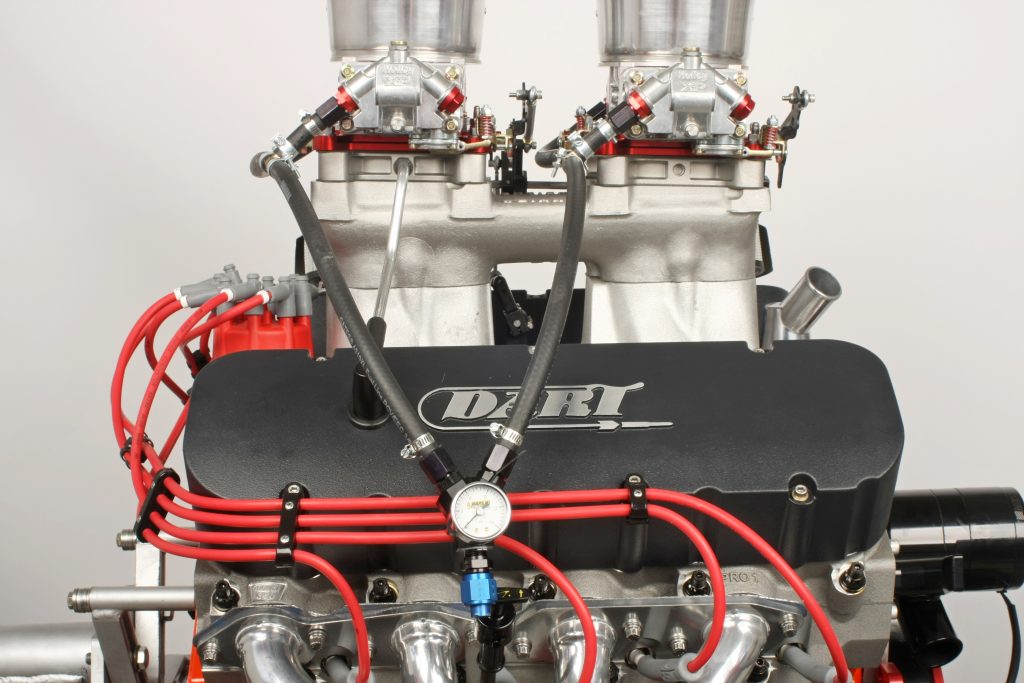

Intake Manifold and Carburetors

The Weiand Hi-Ram dual quad intake manifold is a two-piece design. The upper secures to the lower with the supplied gaskets and four 5/16-18 x 1.25-inch bolts. I swapped the fasteners for 1.50-inch long bolts with split-lock washers for easier access and more thread engagement.

The intake is secured to the heads with an ARP intake bolt kit and Fel-Pro gaskets. The front and rear rails were sealed with a bead of Permatex The Right Stuff RTV. A small bead of Permatex Optimum Max Flex was applied to the Fel-Pro gaskets around the water and intake ports. The Dart Pro 1 cylinder heads are not drilled and tapped for the four bolts at the center of each pair of manifold intake runners, so only 12 bolts were used.

The all-aluminum 950 CFM Holley Ultra HP carburetors were mounted on one-inch tall spacers so the rear carb’s throttle linkage would clear the roof of the intake manifold. The carburetors were mounted with 2.7-inch long ARP stainless carb studs to accommodate the spacers.

Carburetor Plumbing

We set up a fuel system for the dyno session using an Earl’s Performance Y-block. We ran a -8 AN fuel line to the Y-block’s inlet port and 3/8-inch hose to dual fuel inlets on each using -6 AN female to 3/8-inch barb nipple adapters and T-fittings. Not fancy by any means, but simple and functional method for dyno testing.

Throttle Linkage

The Weiand throttle linkage assembly provides simultaneous throttle movement on both Holley carburetors. There are a total of five adjustable pivot points. It may seem intimidating at first, but with patience you can get all of the pivot point connections clocked/oriented and adjusted properly. If this is your first time dealing with this system, plan on about an hour.

Velocity Stacks

I had a choice of using a Hilborn-style scoop with dual air filters or a pair of Mr. Gasket velocity stacks. I opted to go with velocity stacks. The riveted-in crossbars have a center hole for a 1/4-inch diameter mounting studs. The straps are not wide enough to enlarge the mounting stud holes to match the 5/16-18 studs on the Holley carburetors, so we used adapters to attach the stacks.

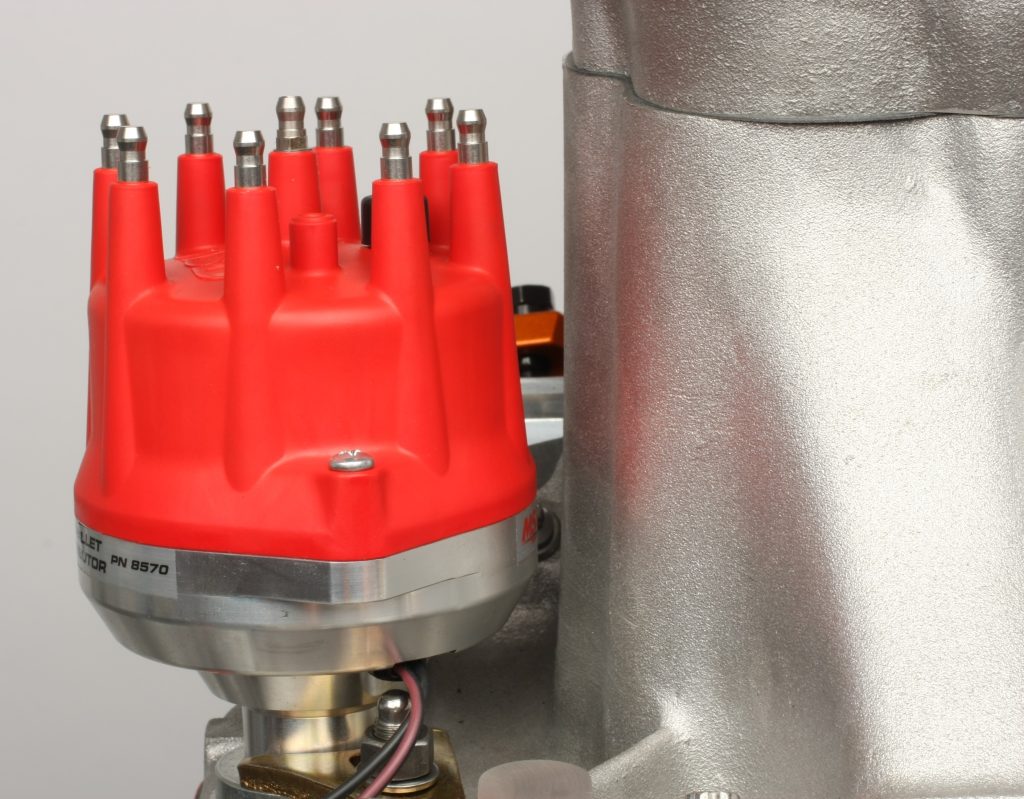

Ignition System

The ignition system is all MSD. The Pro Billet distributor is a small-cap design and is required to clear the Weiand intake manifold. Since we’re running a Flying Magnet crank trigger I locked out the distributor advance. The MSD Digital 6AL CD ignition box sends 520-540 volts to the NAME coil and is rated for applications up to 15,000 RPM.

I routed the MSD Super Conductor ignition wires along the outside of the valve covers using Made-For-You wire separators following the COMP Cams’ camshaft’s 4/7 swap firing order (1-8-7-3-6-5-4-2). The Autolite AR3924 spark plugs were gapped at 0.042-inch.

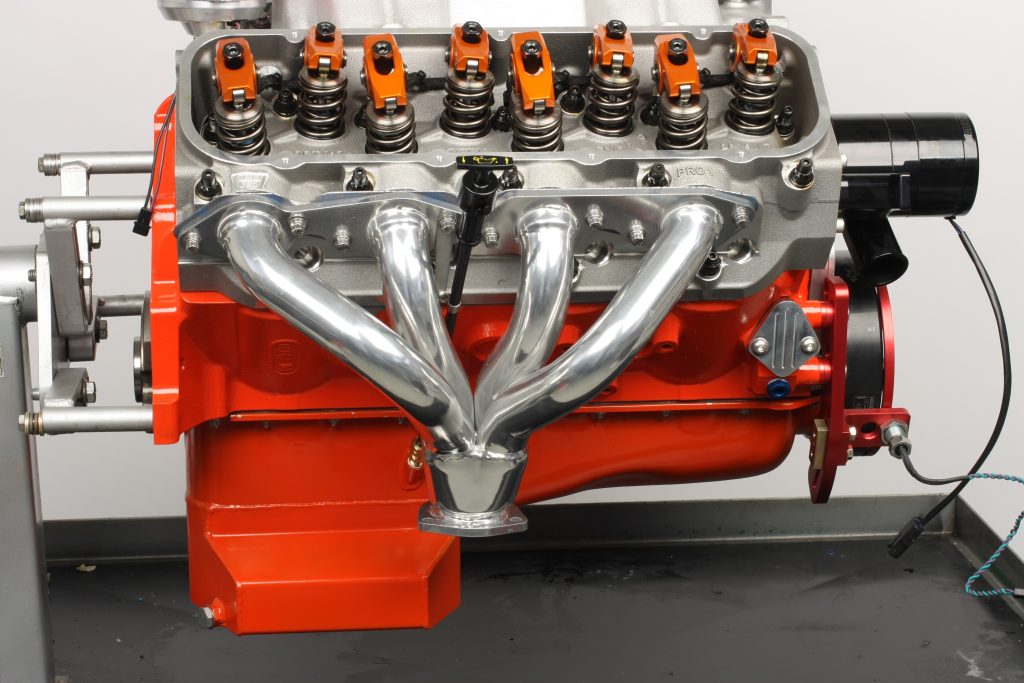

Headers

While we used the dyno shop’s long-tube headers for the break-in and test runs, the engine will leave the shop with a pair of Flowtech blockhugger headers. The headers feature 1.75-inch diameter primary tubes, 2.5-inch collectors, and mandrel-bent tubing for smooth exhaust flow.. The headers are no longer available with the ceramic coating, but are available at Summit Racing with a black painted finish as noted in the parts list.

Valve Covers

The Dart inverted flange valve covers provide ample clearance for the stud girdles. The cast aluminum construction and inverted lip design provides extreme rigidity to prevent warpage and maintain proper gasket seal. Both covers were treated to a light coating of SEM etching primer, followed by several coats of Duplicolor satin black ceramic engine paint.

Since we opted not to use a vacuum pump system for crankcase breathing, I installed a pair of Moroso weld-in breather tubes and filters on the left bank cover. They were positioned close to the top of the covers and centered about 3.750 inch from the front and rear. This avoids areas where oil from the rocker arms might get thrown directly into the breather tubes.

Since this engine will see street use, I added a Summit Racing 90-degree PCV valve to the rear of the passenger side valve cover. It was plumbed to a vacuum port nipple fitting in the rear Holley XP carburetor’s spacer.

Harmonic Damper

The eight-inch Fluidampr viscous harmonic damper is for internally balanced engines. Features include a steel body with black zinc finish and engraved markings are provided at 50 BTDC to 10 ATDC. Additional markings are located at 90, 180, and 270 degrees. The damper has 3/8-24 fine thread holes on the front face for mounting a pulley or in our case, a crank trigger wheel.

Water Pump

The Meziere electric water pump flows 55 gallons per minute of coolant. The pump clears the thick COMP Cams timing cover by 0.600-inch so clearance was not an issue. Each side of the inlet gaskets were lightly coated with Permatex Ultra Flex RTV. The mounting screws were snugged to Meziere’s spec of 25 ft.-lbs.

Fuel Pump Blockoff Plate

The Dart block has provisions for a mechanical fuel pump. We decided to run an electric fuel pump, so I sealed the hole with an aluminum block off plate and a Fel-Pro gasket. The plate’s stainless button head screws got a dab of medium strength thread locker and snugged to 18 ft.-lbs.

Oil

We used Maxima 15W-50 break-In oil for the dyno runs. The oil has high levels of ZDDP and a shear-stable polymer formulation to provide fast and effective ring seal. After the dyno session, the break-in oil was drained and the crankcase filled with Maxima High Performance 10W-40 oil. The mineral-based oil mineral-based formula with lots of ZDDP and a proprietary additive system to ensure protection at any temperature.

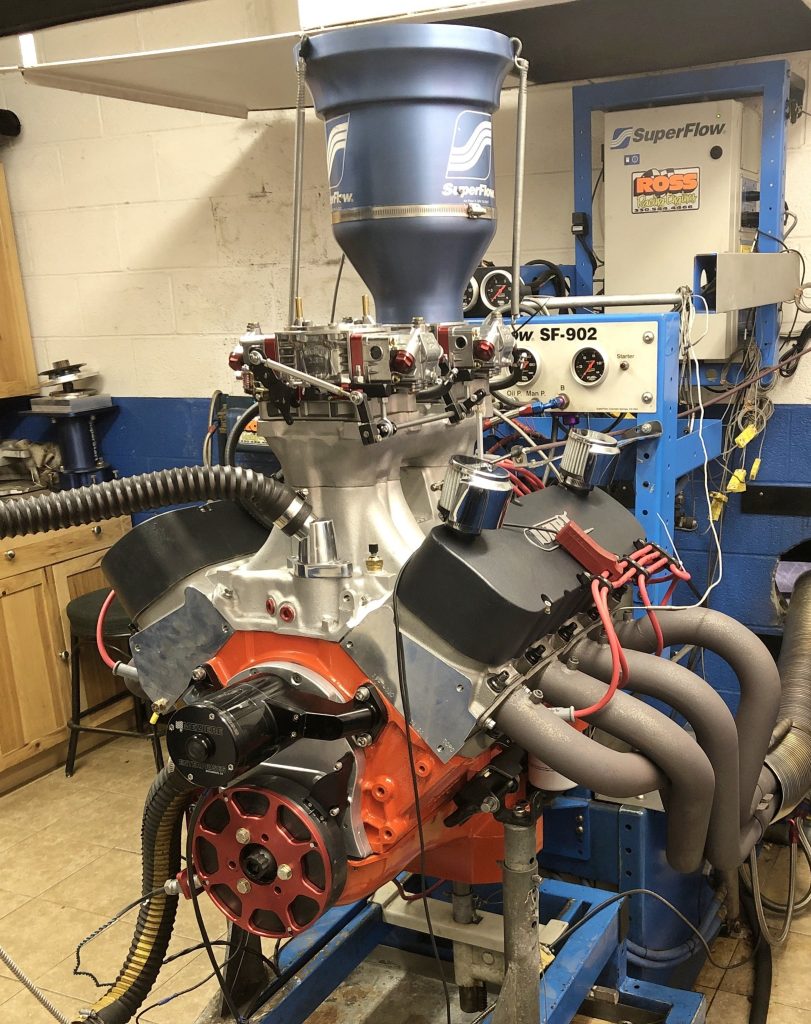

Dyno Session

The dyno session was performed on the Superflow dyno at Ross Racing Engines in Niles, Ohio.

After shop owner Tony Lombardi fiddled with timing and a few carburetor adjustments, the 540 popped to life with 68-70 PSI of oil pressure and warmed up to operating temperature with no leaks or funny noises, which is always a plus. Following the initial fireup and cool-off, Tony performed the usual checks (looking for leaks, adjusting valve lash and adjusting carb accelerator pumps, etc.).

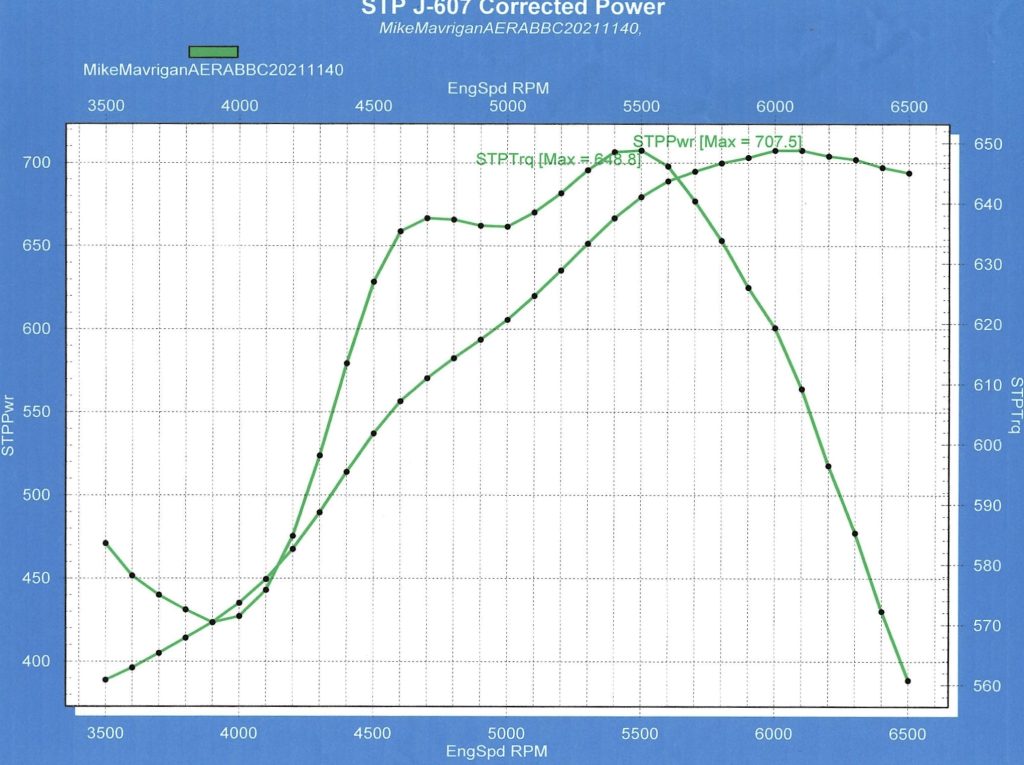

On the very first power pull, our big block made 707 horsepower at 6,000 RPM and 648 lbs.-ft. of torque at 5,500 RPM. With some minor tweaking, output jumped to 712.8 horsepower at 6,1500 RPM and 653.8 lbs.-ft. of torque at 5,500 RPM.

Our time on the dyno was brief, but we were happy with the results. Additional tuning will likely improve the numbers, but we came away happy with an engine that runs hard with no issues. Many thanks to Tony for interrupting his hectic race engine building schedule to handle our project!

Parts List

Weiand Hi-Ram Tunnel Ram Intake Manifold

Weiand Hi-Ram Carburetor Linkage Kit

Holley Ultra HP Carburetors (x2)

Mr. Gasket Velocity Stacks (x2)

Holley HP Billet Fuel Pressure Regulator

Earl’s Performance Fuel Distribution Y-Block

Earl’s Performance Fuel Pressure Gauge

MSD 8.5mm Super Conductor Wire Set

MSD Flying Magnet Crank Trigger

Dart Cast Aluminum Valve Covers

Made-For-You Horizontal Wire Loom Kit

Meziere 300 Series Electric Water Pump

Maxima Performance Break-In Oil, 15W-50

Maxima Performance Engine Oil, 10W-40

Summit Racing™ Aluminum Water Neck

ARP Stainless Steel Intake Bolt Kit

ARP Bolts for Valve Covers (1/4-20 x 3.500”)

Dupli-Color Ceramic Engine Paint, Satin Black

Comments