When it comes time to talk about engine swaps, the first motor that comes to mind is probably the GM LS.

Long the darling of the industry, the LS has all but taken over where (it might be argued ) the original small block Chevy left off. The LS-swap-the-world crowd has seen to it that the GM V8 has graced the engine bays of just about every vehicle imaginable. In fact, the swaps are not limited to just cars, but frequent marine and aviation applications as well. It wouldn’t surprise me in the least to hear that someone LS swapped a submarine.

As versatile, cost efficient, and effective as the LS engine family seems to be, there are obviously many other candidates that will (when properly modified) provide not just adequate motivation, but amazing performance.

In fact, it might be argued that it’s high time the trend setting, dare-to-be-different crowd find something else beyond an LS to swap into their favorite performance vehicle.

For the adventurous swappers (Fiero and S10 owners, I’m taking to you) or the great many factory applications, it is time to take a look at the supercharged 3800 V6 L67 and L32. Truth be told, we actually ditched the factory M90 supercharger for a more efficient turbo, but we will get into all that later.

For now, let’s take a look at what went into a 600 horsepower 3800 build up!

The GM 3800 V6 Engine

For those unfamiliar with the GM powerplant, you can think of the 3800 V6 as the replacement for the turbocharged (and legendary) 3.8L Grand National motor. Better in almost every way, the 3800 V6 offered improved head flow and a hydraulic roller cam, but ditched the intercooled turbo for an Eaton M90 supercharger. Rated at 240 hp, the L67 was soon replaced by the 260 hp L32. The additional power came from revised heads and an improved (Gen 5) version of the Eaton M90 supercharger.

What makes this 3800 V6 so desirable is not the use of the M90 supercharger, but rather that it was designed and equipped for factory forced induction. In fact, elimination of the (power limiting) M90 roots blower gives way for the amazing power potential, thanks to a low-compression short block that will take significantly more power than the factory ever dreamed of. It is not unheard of to double or triple the factory rated power output of the 240 to 260 hp using the stock bottom end.

Upgrading and Turbocharging a GM 3800 V6

For our build, we were looking to top the 600 horsepower mark, a goal we easily achieved using a cheap turbo and few essential (and one non-essential) mods.

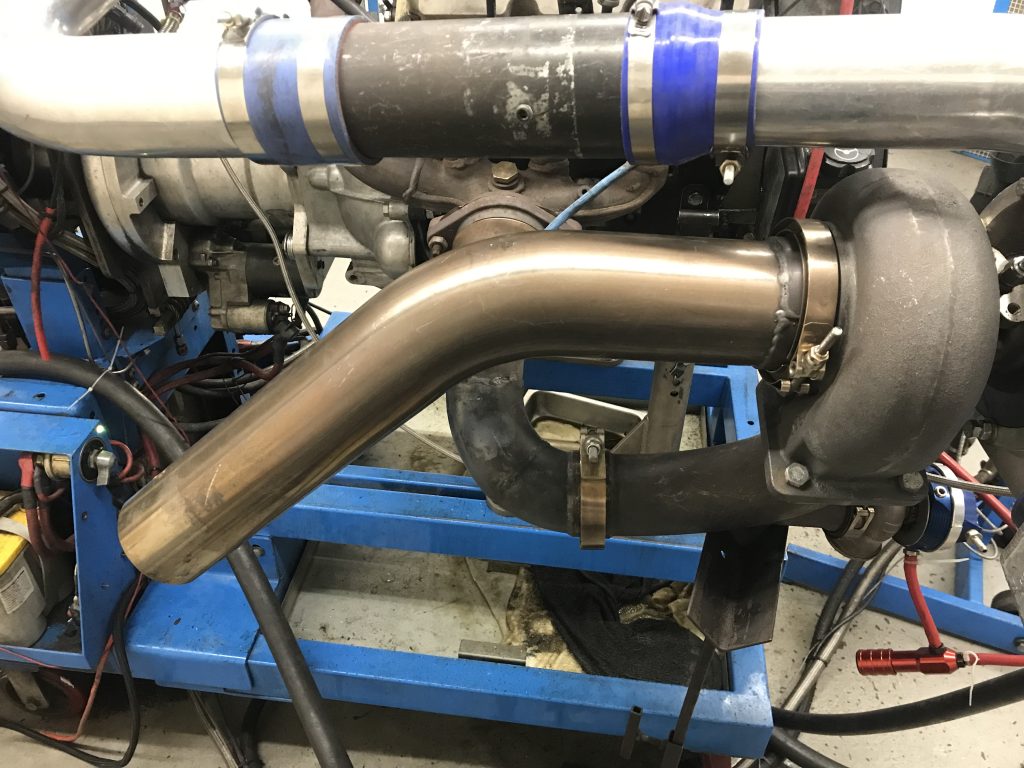

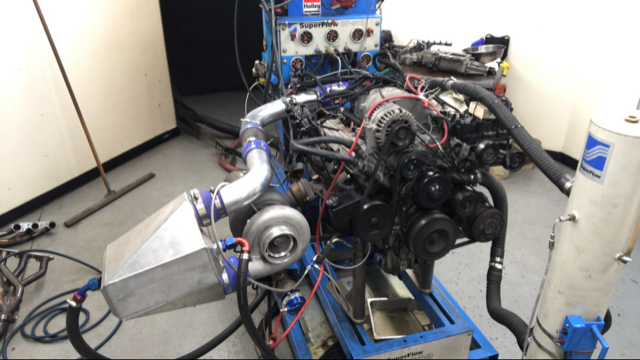

With a power goal of 600 hp, the first step was to replace the M90 supercharger with a more efficient and powerful form of forced induction. Off came the M90 supercharger and on went a cheap GT45 turbo. Capable of supporting over 750 hp on the right application, it offered more than enough flow for our 3800.

The GT45 was teamed with a Procharger air-to-water intercooler. The combination resulted in a much lower charger temperature than even an intercooled version of the M90 supercharger.

Rather than just add boost, we decided to further improve the power output of the naturally aspirated 3800, as gains made NA are often multiplied under boost. To that end, we decided to augment the 3800 with ported heads, a healthy cam, and a revised intake (to replace the blower). We had a local machine shop surface the heads, perform a valve job, and do some mild port work.

In anticipation of the cam upgrade, the heads also received a set of 26918 beehive valve springs and matching retainers from Comp Cams. The spring seats on the iron heads were machined to accept the new springs and produce an installed height of 1.75 inches. Once set up, the heads were installed with new Fel-Pro head gaskets and stock head bolts, but MLS gaskets and ARP head studs are on the way for the future (high-boost) runs. The modified heads were run with the factory roller-fulcrum (like an LS) rockers.

The machined and ported heads were teamed with a new cam profile from ZZ Performance. The ZZP NIC cam offered 0.507 lift (intake and exhaust), a dual-pattern duration split of 220/230 (at 0.050) and 112 degree LSA. The cam was run with the factory hydraulic roller lifters and stock pushrods.

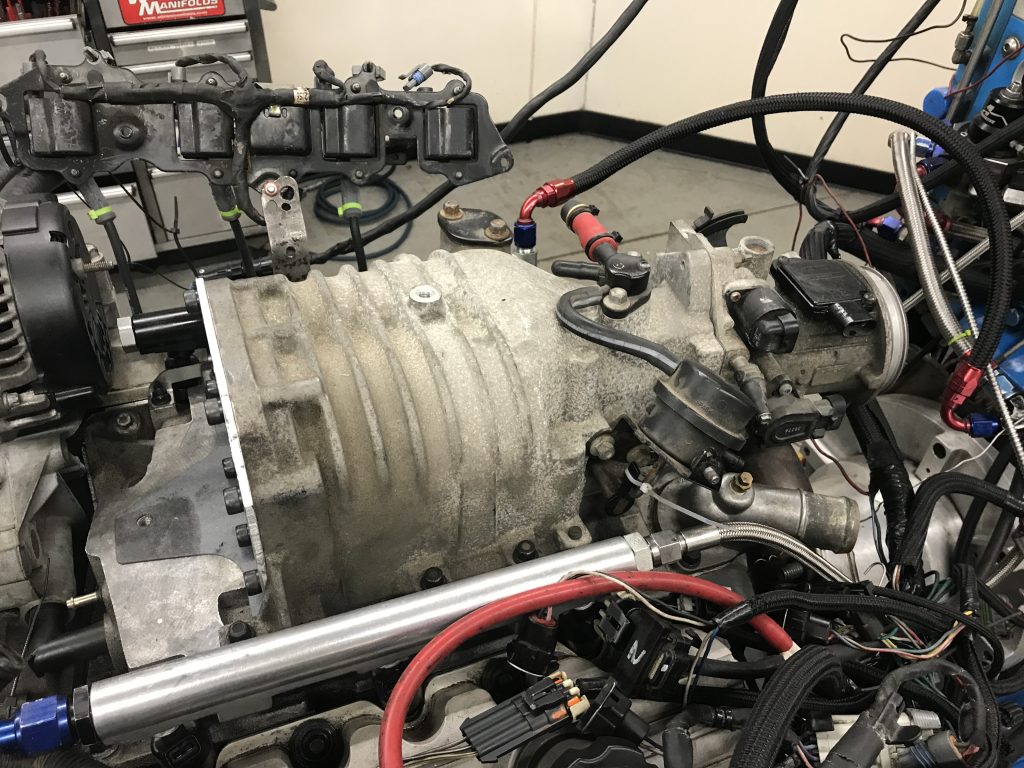

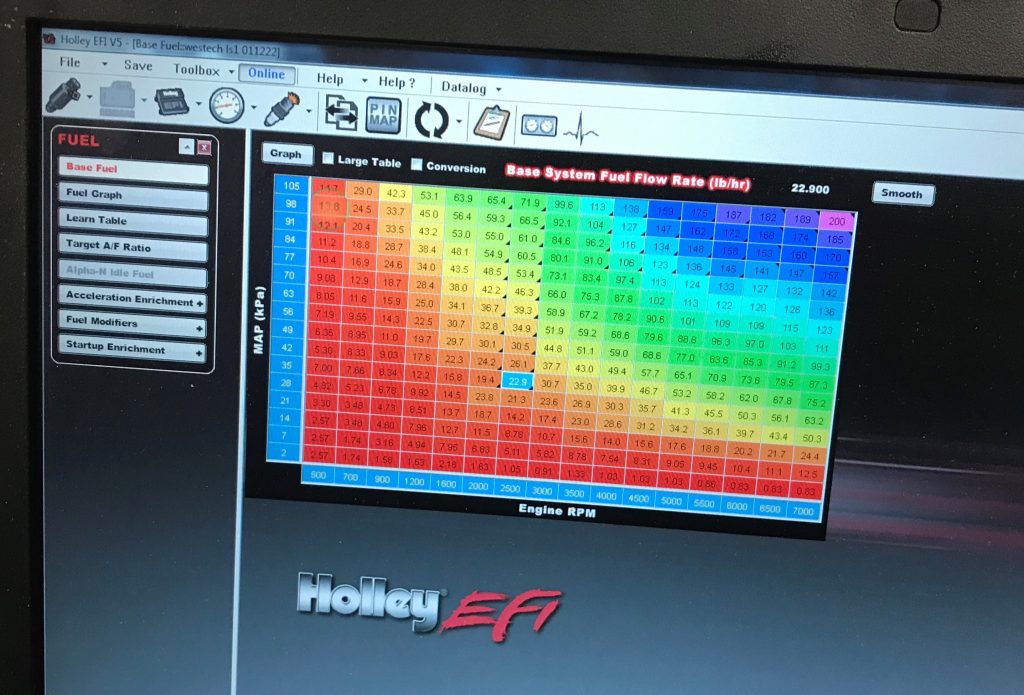

The finishing touches included use of the factory L67 lower (blower) intake topped with a gutted M90 blower housing. To produce a suitable upper and lower intake, we removed the rotor pack and made a cover plate to seal the upper intake. All the boost from the intercooled turbo system blew through the stock L67 throttle body and gutted blower housing into the lower (short-runner) intake—a better choice for street use would be the long-runner 3800 V6 Camaro/Firebird intake.

3800 Dyno Testing & Results

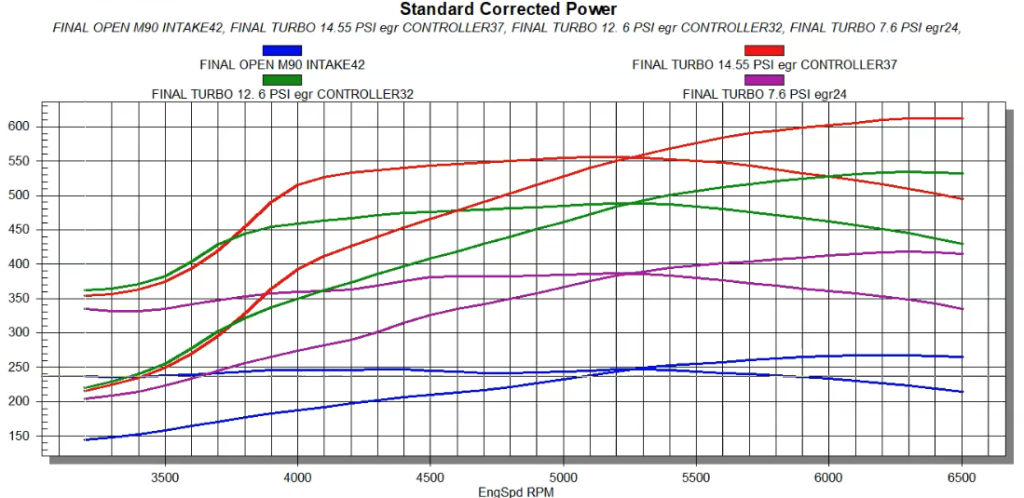

Run in naturally aspirated trim, the low-compression 3800 V6 produced 267 hp and 247 lb.-ft. of torque.

Run with the DIY turbo kit (using the stock FWD exhaust manifolds), we first applied 7.6 psi from the intercooled turbo setup. Run on pump E85 from a local station, the turbo 3800 produced an easy 418 hp and 387 lb.-ft. of torque.

Raising the boost up to 12.6 psi resulted in 534 hp and 488 lb.-ft. of torque.

Eclipsing our goal of 600 hp required 14.55 psi, where the turbo V6 pumped out 612 hp and 556 lb.-ft. of torque. It is at this point we started thinking seriously about adding ring gap, MLS head gaskets, and ARP head studs to the combo before getting serious!

Imagine what this motor would be like swapped into a little S10 or Fiero!

Do a 60 degree V6 next!

Hello do you build the v6 motor turbo charger? For 700hp as I’m very interested I’m in Australia

more boost lol

So you think the 3800 can see 1000hp?

I love this guy and his tests. I don’t miss his YouTube videos and I enjoy articles like this.

I would like to use Holley smart coils on my 3800 series II engine, so I would like to know how you made the 3x and 18x crank sensor work?

I do not know if you will ever visit this page again, but your question about getting the 3x and 18x crank trigger to work was provided from a guy in Houston, Texas. The person’s name is Brian Pryes, I am the one who introduced him to Richard Holdener.

Hey this was a great, very simple build…this guy always goes outside the box with his test sessions.. I wish more people would remember that there is affordable power to be had and not all of us have a billion dollars to dump in a LSX / exotic platform

Could you do the same thing to a 4.3 TBI engine

Yes but I would try to lower compression first and put in stronger internals if you want to make huge power. If you want a 400 hp daily driver with gobs of torque at tap then yeah go for it. There are cheap ebay kits that fit and are great.

Having a hard time locating that management system.. so many other questions .

I’m curious why E85 was used and not 93. Under that pressure would the fuel pre-ignite whereas the E85 doesn’t?

Only a year later on this respond, but E85 has about a 105 to 107 octane rating and it is a great fuel for running high boost. My 2000 Buick Regal GS is calibrated for E85 and I am converting my Buick Regal Grand National to E85 from 93 octane and methanol injection. E85 has become very popular.

Could someone with general mechanic knowledge manage this in a home garage? If not, how much do you think it would cost to have a garage do the work?

How much did all that cost

Hi Richard. I have a 87 GN intercooled set up with worked heads not roller. And larger turbo in a 37 ford Street Rod. I would like to do your swap since my motor is tired. I have intercooler , new turbo. Can I start from there? Any particulars you can supply me. A list of what n where I can get hold of what’s needed would be great. I’m in Long Island NY

I was looking for ideas for a cutlass ciera sleeper and I was already planning to use the 3800 sc series 3 engine, however reading your post I knew I was right that you can get more than 400hp out of a 3800.

I have doubts about the transmission, what would be your recommendation?

Look into Triple Edge Performances guidelines on what they put into their builds, and be prepared to write a big check! More then once! Or learn how to build your transmissions if you haven’t done that yet. They are complicated but you can do it. Books are good here. Info can be tracked down online for guidelines as to what goes into making a strong 4T65e -HD. I’m gearing my self up to upgrading mine ‘ again ‘ even though it’s been working fine now for 5 yrs next to my tuned up SSEi mill. But I’m also planning on more engine upgrades again! If you have plans on smashing the right peddle, having a spare trans built up is a darn good idea, start on your first, get it finished and then start on the backup unit, put it in a box sealed up to keep it from getting humidity in it and stick it on a shelf or under the bench. Good idea to soak the clutches with synthetic trans fluid, use trans assembly lube liberally on bushing. In valve body and on planetary gears, thrust bearings ,etc.. Or just have your backup core on hand with all the pieces you intend to use, there on hand, ready to assemble the trans asap for when you need it. Doing it this way, with the proper manuals you can teach yourself how to do it, as was mentioned earlier. These transmissions can live next to 400 HP for awhile when done well with the proper pieces but this is getting to the limits for them with any reliability.

,

Ultimaately the drive chain becomes one of the weakest pieces in there. I was just at a local trans shop doing some part # searching, mainly for upgrading drive chain assembly. They did an internet search for sprockets and chains, everything pretty much came back as used only out there and the GMR, race chain assembly which was a 1 inch single chain arrangment is no longer available new or used. We had some pieces on the counter that looked very close to interchangeble but the offset of one of the sprockets was not the same. Changing the final drive ratio but selecting the lower ration pieces will help some by removing a lot of the torque strain, going to a higher number all the way to 3.69 I think but that takes away your top speed considerably past the high engine RPM which will always shorten the life of it. This is great being able to make and see these high power numbers on an engine dyno but what good is that if you cannot put it through a transmission and to the drive wheels? Who wants to build a transmission, race it a couple of passes and replace it before you can finish a race day everytime you go racing? It’s pretty hard to get one of these FWD’s done between rounds when your numbe is called. I kknow a lot of people ask questions about building this 3800 and confusing these with the Buick GN engine, that’s a whole different animal, like comparing Donkeys and Ponies, or Zebra or Mules, yada yada. 3.8L is about the end of it. Different block, rods, pistons, heads, intakes, ignitions, bell housing patterns and on and on. Made by the same company and pretty much completely redesigned from the pan up. The fact is, what works for one would work for the other as long as you can get the parts that have the same basic specs although shaped and arranged different for the particular block design you are working with. It’s just getting that power to a drive shaft, or half shaft. People are working on swapping out the 4T65e for 4T80’s in FWD’s and as with the old G.N. the choice of trans was the TH200 overdrive which had a much better ratio spread for racing over the 700 and later 4L60 which was pretty much a transmission intended for under powered pickups and not racing vehicles. This run of articles was not intended to discuss drive line systems only to make a point of how good this engine is at making POWER, what it can take to get there. This is also a sad issue as I have said, what good is that power with a way to put it to the road>? GM pretty much dropped the ball here which was not a necessity. They could have a done a much better job at producing something a certain group of people were absolutely going to want.

These articles and videos about the Buick 3800 SII are priceless. Been an LS, Windsor, Modular guy for years. Huge Holden fanatic also, had a PPV, SS, have a GTO. Recently moved to Brazil… because women…they sold the Holden Commodore here as the Chevrolet Omega with a 3800 SII from 1998-2004 and they sell Ethanol pump fuel everywhere and cheap. They sell for $2,000-$6,000 used in good shape, usually without too many miles, often with level III armor. I suspect that I will soon have a few of them. Definitely cammed, turbocharged, converter, maybe a manual swap… maybe eventually an LS swap. I think a 600-700hp 3800 SII with a GT45 or VS 78/75 will be a nice piece here. If I could pull down 20-25mpg hwy on Ethanol cruising 70mph with the a/c on and get 500-550whp with the taps open, I’m going to be a happy guy.

I have a 1980 Monza Sypder, that originally had a 3.2l V6 4 speed. I swapped in a old school 350 with a 700r4. Lots of fun, but the weight bias and over abundance of HP made it go for smoking tires and drinking gas. Its handling was somewhat less than ideal. I moved as much weight as I could to the rear and lighten the front a bit with aluminum heads, battery relocation, etc, but still, more show than go. I am now working on the 3800 series II with a Tremec 5 speed. And before anyone says it cant be done, it can be if you find the right machine shop to build you and adapter for the crank and bell housing. I still have lots of work to do, but this article has solved many of my engine setup issues, so may thanks for that! I am using the l36 version as my base engine, and although I do have a turbo kit for this, I will get the car up and running again using the NA specs provided here. I suspect that the L36 will give me a bit more power given its higher compression. With the l36, I will install the the turbo, get it up and running. Once I get it all dialed in, I will get an l67 short block and swap out the l32 short block for the l67 and start making HP with the turbo. As for the Monza chassis, I already have a Ford 9″ custom rear end to replace the s-10 rearend. If all continues to go well, I should be done in the next 8-12 months. I wont dial it up to 600hp, but I think 350-375 will be fun enough. With so much weight taken off the front, it should actually handle a bit better.

Whoa, cool project! Glad our the article could help–if you think about it, keep us posted on its progress!

Its going prety well, but to quote from your article “Holley HP management system. This system allowed us to tune the 1500cc Snake Eater Performance injectors running E85. ” was used. Where can one find the configuration and setup for this? Holly was not able to provide any support, and I cant find enough info on the engine harness to figure out how you folks made this work. Any hard info you can provide would be great. And another question, can I make the factory bits work?

Hey, you guys crack me up! I have a 2007 Buick Lucerne. Series III 3800. Used to work at GM and yes, fantastic engine. Going to do a rebuild and my daughter and i think it would awesome to add a turbo on left side (facing front of vehicle). Then smoke my Dad in his Holden Chevy SS. Is there an exhaust manifold i could purchase containing the turbo flange? I don’t have time to fabricate one.