Ford’s powerful 335 Series family of middle block V8s displacing 351 and 400ci was a brief chapter in Ford North American history. We still don’t really know where the 335 Series “Cleveland” family of engines originated, nor why its production life in North America was so brief when Ford Australia continued to offer this engine well into the 1980s long after production ended in the United States.

Want some more reading on Ford’s 351s? Read this: What’s the Difference Between a Ford 351 Windsor, Cleveland, or Modified Engine?

The 351C remains one of the most popular V8 engines in automotive history. Enthusiasts love it for its demeanor and ability to make abundant power. It is a nice compromise between small block and big block. When you study the 335 Series engine block’s architecture, it really doesn’t seem like a Ford engine at all, with the exception being a distributor in front and the oil filter mounted on the left-hand side.

The Cleveland’s unusual block looks like a mirror image of the Oldsmobile V8 block with a 12 and 6 o’clock fuel pump mount (the only Ford engine ever done this way) and timing components wrapped in iron like the Oldsmobile. Bore spacing is nearly the same as the Olds, yet spot-on small block Ford to be sure. What makes the 351C different in appearance is its wide poly-angle valve cylinder heads and “dry” intake manifold.

The 351C was manufactured in a totally new process at Ford’s Cleveland, Ohio engine plant, with engines fired and tested in something of a “Merry-Go-Round” process before they were prepped and shipped to Ford assembly plants. Both casting and manufacture were performed in Cleveland, Ohio. Parts for these engines came from both suppliers and Ford plants.

Ford’s original game plan was to design and build a V8 engine with fewer potential leak points, more perfect mating surfaces, wider main bearing journals, and better gasket/sealing technology. Ford’s belief was the 351C had fewer potential leakage points thanks to a steel plate timing cover, a better relationship between oil pan and block, and a cooling system that bypassed the intake manifold entirely. Coolant flowed across the block instead of within the induction system, which reduced or eliminated leaks and reduced induction temperatures.

It is well known Ford’s then President, Semon E. “Bunkie” Knudsen, looked to racing legend Smokey Yunick to help develop a Cleveland racing engine for Indy competition. That idea never made it to fruition. Yunick had a long and successful history with General Motors, developing Chevrolet’s Mark IV 396ci big block introduced in 1965. Like the Indy engine at Ford, the Chevy had huge poly-angle valve cylinder heads with small wedge chambers and large ports along with a rugged skirtless block.

Ford’s prototype Indy engine was very similar to the production 351C. It had bizarre poly-angle valve geometry and the same bore spacing as the 289/302/351W small blocks. Its angled pushrods crisscrossed over one another to racing-specific monster port cylinder heads. Regretfully, the Knudsen/Yunick-inspired Indy Cleveland went the way of Bunkie Knudsen, who only ran Ford for a very short time in 1968-69 before being fired by Henry Ford II in 1969. Knudsen was never a good fit for Ford’s rank and file, which was very different than GM.

The ”Cleveland” name resulted from an identity crisis in Ford dealer service departments and automotive repair shops where there was confusion among service technicians regarding which 351 engine they were working on. Ford already had the 351W, which was a raised-deck 289/302 engine with 4.000 inch bores introduced in 1969. It was a planned stop-gap engine at the time to compete with GM’s 350ci engines. Ford needed a fast mid-displacement solution, which came from the 351W. In fact, Ford never intended for the 351W to be a long-term engine. The 351C was going to take its place. Ironically, the 351W lived and the 351C was dropped.

When the 351C arrived in 1970, there were all kinds of confusion with service mechanics though the two engine families are vastly different in appearance. Ford issued a bulletin addressing identification of the two 351ci engines. Because the 289/302ci based 351 was produced primarily at Ford’s Windsor, Ontario foundry and engine plant across the river from Detroit, it would be known as the 351 “Windsor” or 351W. The 351 Cleveland, due to its manufacturing location at the Cleveland foundry and engine plant in Brook Park, Ohio, was named 351 “Cleveland” or 351C.

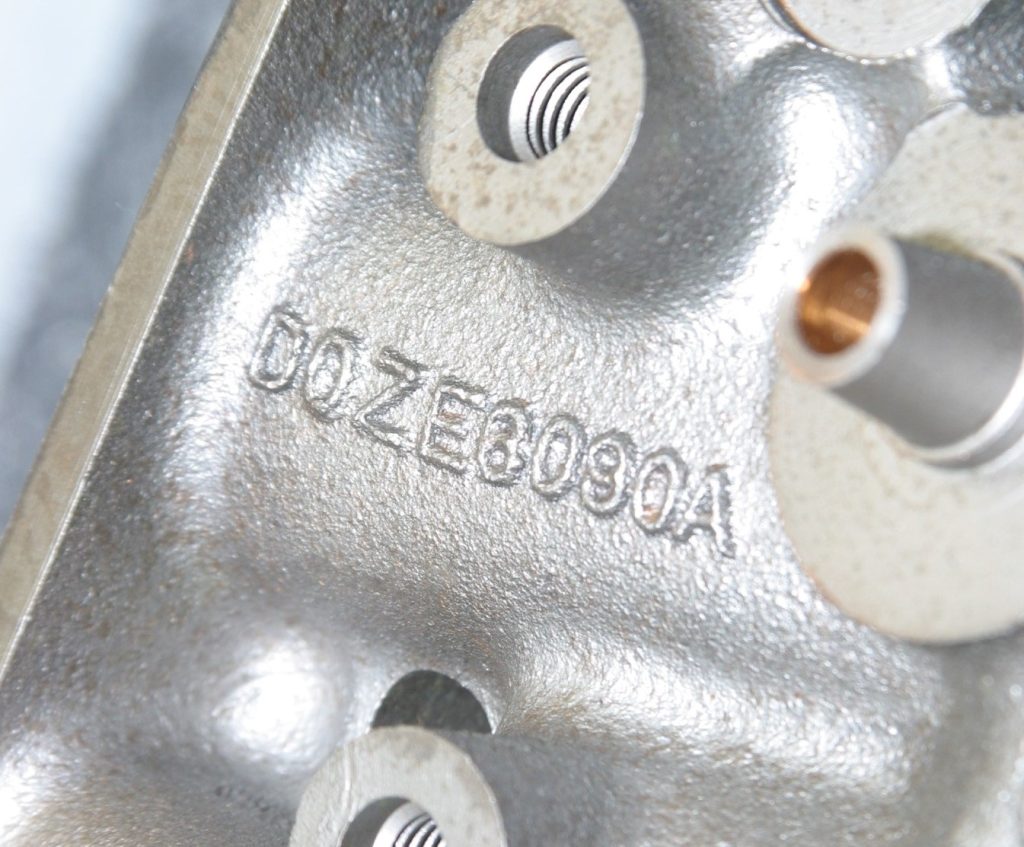

Where the 351 Cleveland gets confusing is where the castings were produced. Don’t be surprised to find a Cleveland or a BOSS 302 engine with cylinder heads cast at Windsor, Ontario with a “WF” logo. The quickest way to identify the foundry is the way it is marked in the casting. A circled “C” logo indicates the Cleveland foundry. A “WF” indicates the Windsor foundry. These heads were produced in both foundries.

The 400

When Ford introduced the raised-deck 400 Cleveland in 1971 to replace the 390 and 428 FE Series engines in 1972, this made the Cleveland journey more involved. Ford never called the 400 the “400M.” It was always called the 400. In 1974, Ford ended 351C production and destroked the 400 to 3.500 inches to get 351ci. This was a terrible idea, of course, because you still had the added weight of the 400 with less displacement. Ford called the destroked 400 the “351M” for either “Modified” or “Midland.”

What makes the 351M and 400 different than the 351C is the block, which has a one inch taller deck and a 429/460 big block bellhousing bolt pattern. Early 400 engines have both big block and small block bell patterns. The 400 was fitted with 351C-2V heads with open chambers. The 351C-2V head was the only head used on the 400 and 351M. The 400 Cleveland and 351M were never offered in Australia.

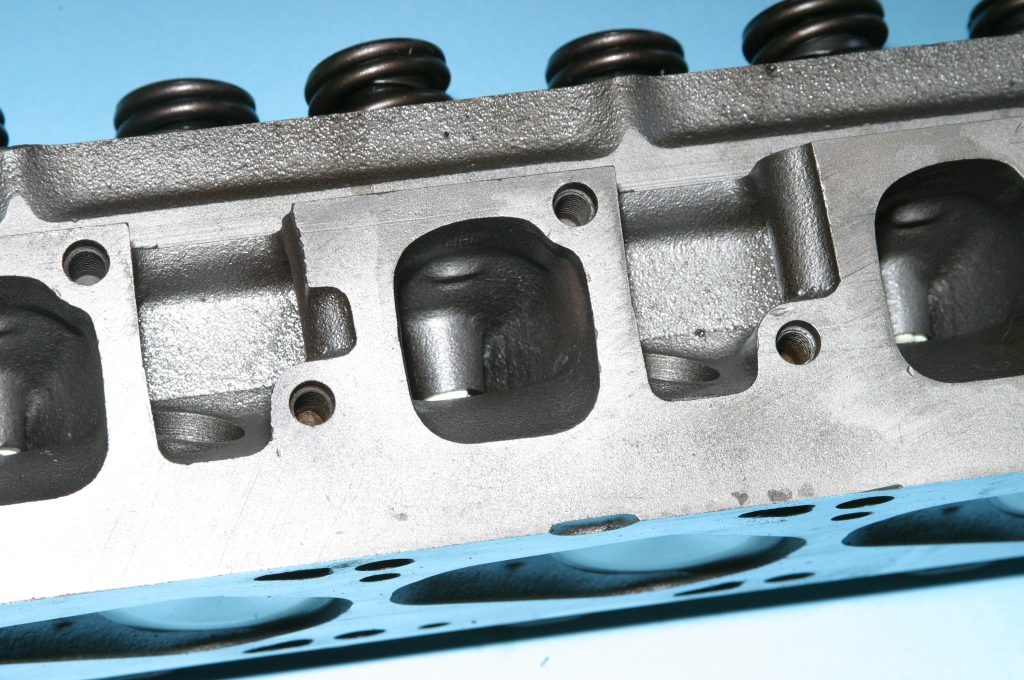

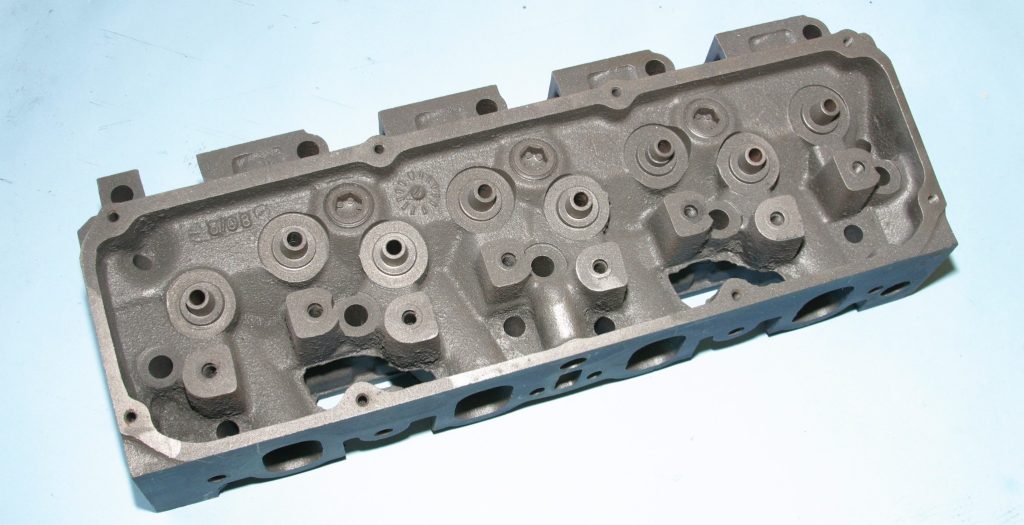

Ford 351 Cleveland Cylinder Heads

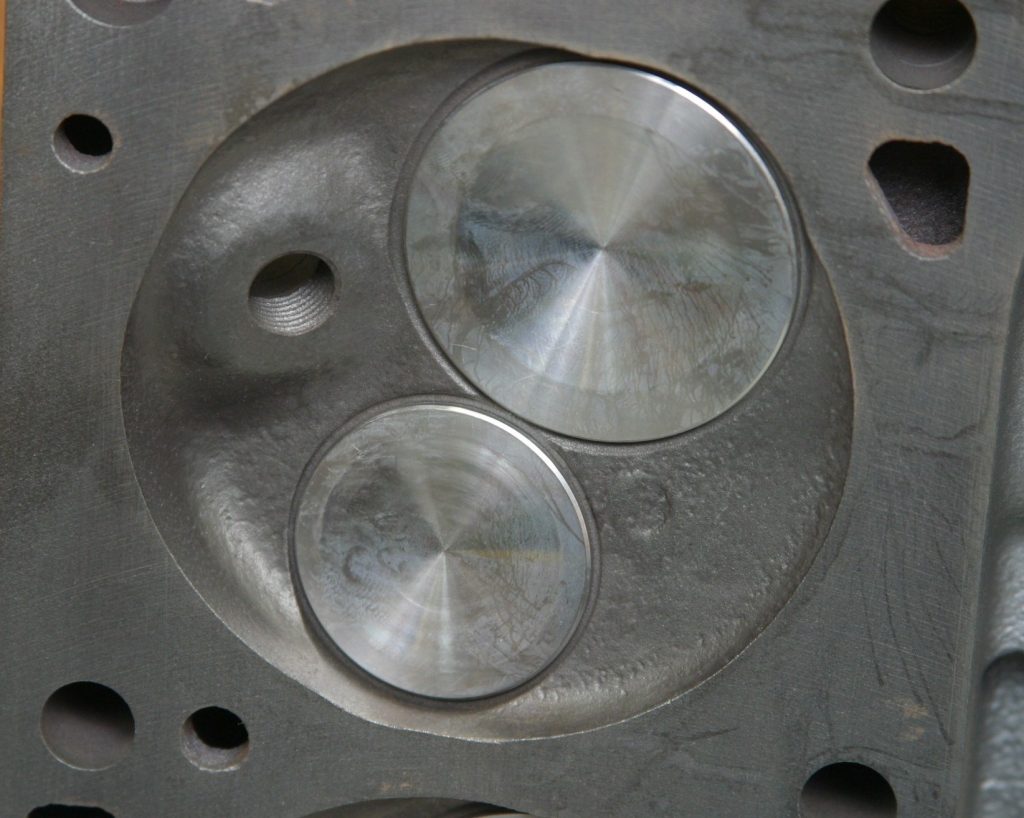

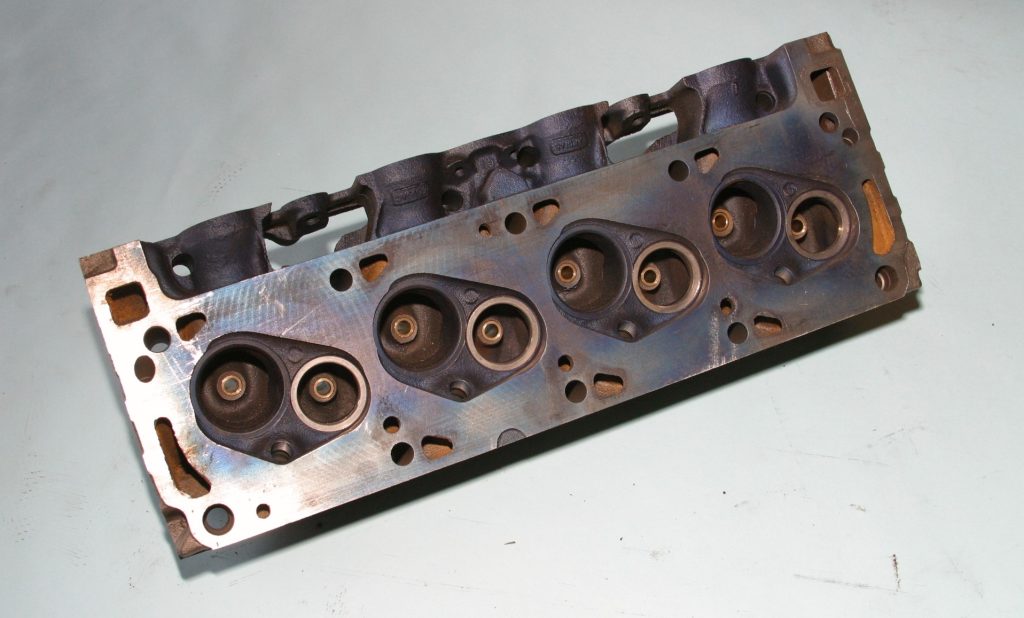

All 351C-2V heads have smaller 2.040/1.670 inch intake/exhaust valves with 2.020 x 1.650 inch intake ports and 1.840 x 1.380 inch exhaust ports, along with 74-77cc chambers for reduced compression. The 351C-2V head is the most common Cleveland head out there, yet not a popular casting. The more robust North American 351C-4V heads were produced in four forms—Early 4V (1970-71), BOSS 351 (1971), 351C High Output (1972), and Late 4V (1972-74). This does not include the Australian 351C heads.

Early 351C-4V heads sport 61-64cc wedge chambers with 2.190/1.710 inch intake/exhaust valves and 2.500 x 1.750 inch intake and 2.000 x 1.740 inch exhaust ports. The 1971 BOSS 351 and 1972 351 High Output head differs from the Early 4V head due to an adjustable valvetrain with screw-in rocker arm studs with guide plates.

Later 4V heads have the 2V head’s open 74-77cc chambers and the same 2.190/1.710 inch intake/exhaust valves and port sizing. The open chamber 4V head is the most undesirable of the four Cleveland head castings with modest compression and those huge intake ports though we’re bound to get arguments on that one.

The open chamber Cleveland head lacks quench. Quench is also defined as the distance between the flat portion of the piston crown and the cylinder head surface at top-dead-center (TDC), including the head gasket’s compressed thickness and any positive or negative piston deck height.

We stress “quench” because good quench creates turbulence in the combustion chamber pushing the air/fuel mixture toward the spark plug and reducing the chance of unburned gases being left behind, which can play a significant role in reducing detonation and hydrocarbon emissions.

If you’ve heard someone start a warm 351C-2V (1970-73) or a 351C-4V (1973-74) on a hot day and heard spark knock (detonation) on start-up, this is what we’re talking about. The experts say quench should be as tight as possible without the piston hitting the cylinder head. This minimizes spark knock.

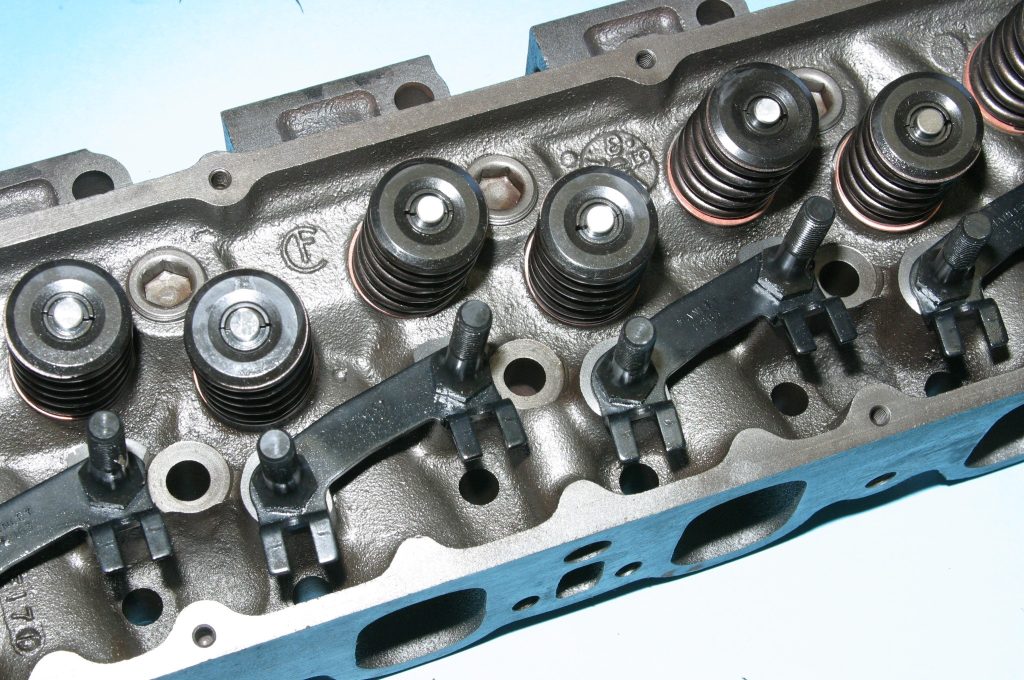

Ford 351 Cleveland Valvetrain

The Cleveland (335 Series) and the 385 Series big block pioneered a fresh approach to valvetrain with stamped steel rocker arms and either a no-adjust “bolt-fulcrum” pivot or an adjustable stud-mounted rocker arm. The BOSS 351 and High Output had adjustable stud-mounted stamped steel rocker arms due to their mechanical tappet high-performance camshafts. Spring pressures were higher with these camshafts due to a more aggressive profile. The stamped steel bolt-fulcrum rocker would find its way to the 5.0L and 5.8L Fords in the late 1970s.

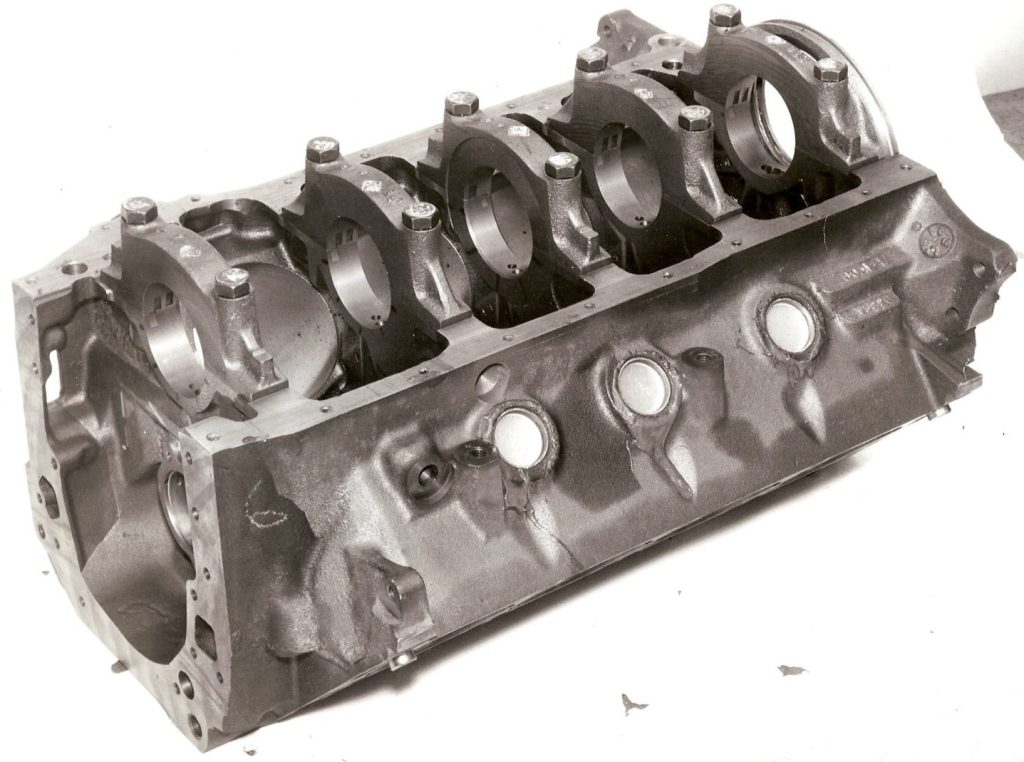

Ford 351 Cleveland Block

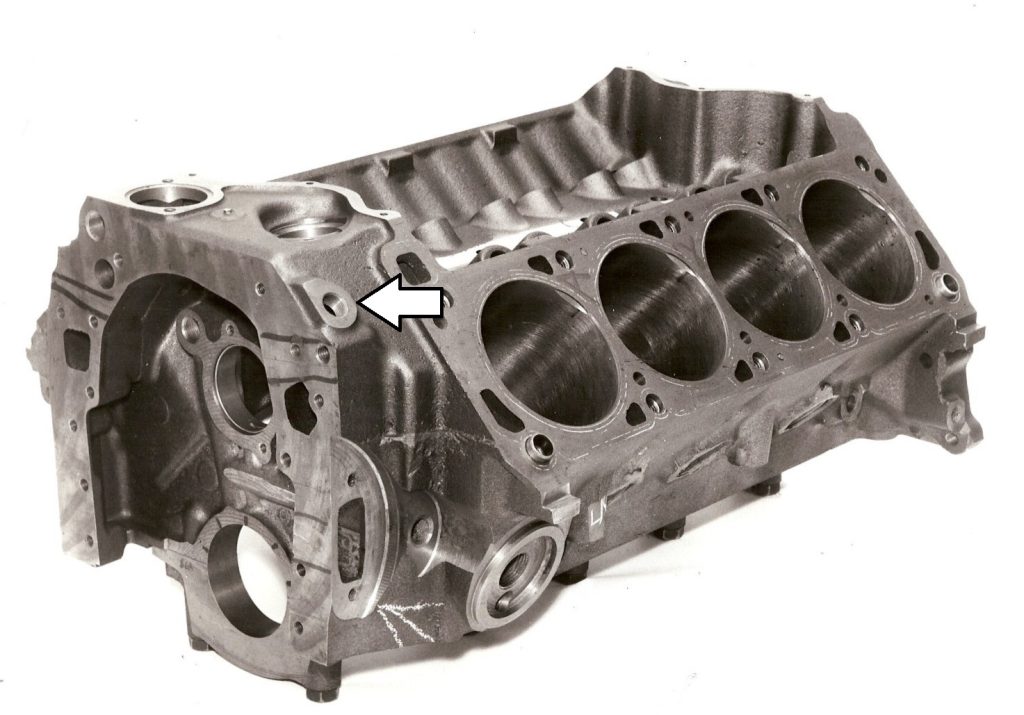

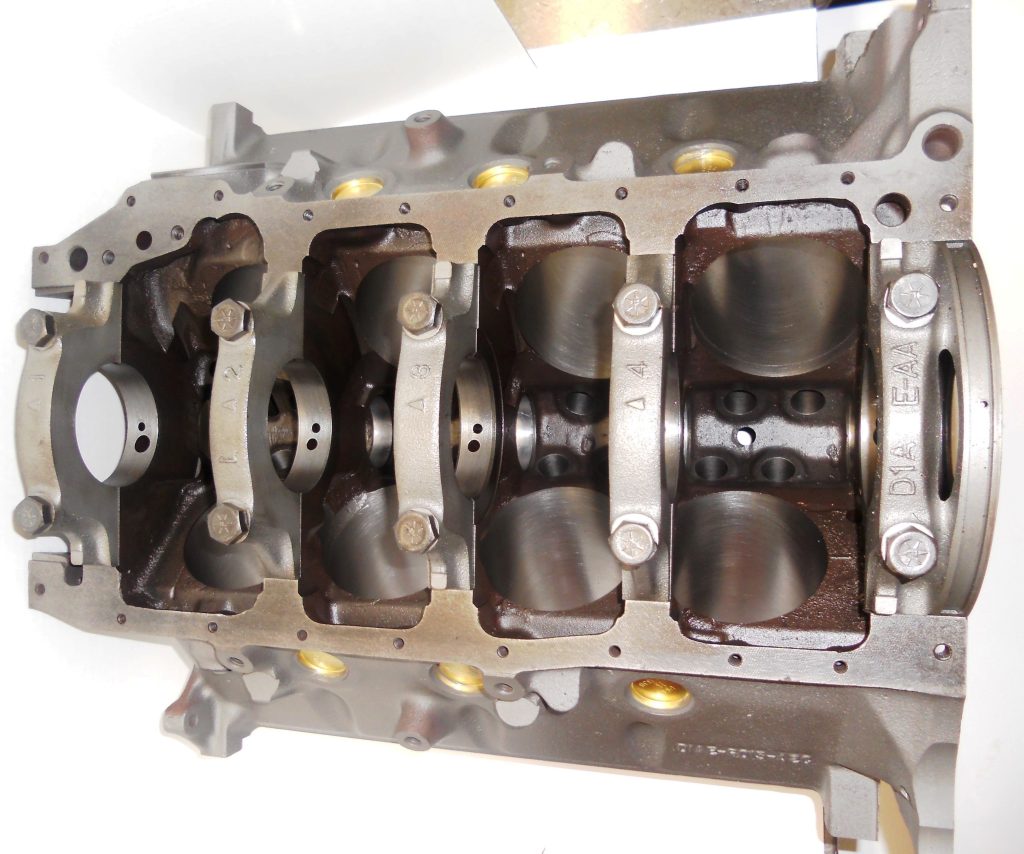

Cleveland blocks were engineered for four-bolt main bearing caps. Ford engineers wanted more beef down under for added strength without having a skirted block and cross-bolted main caps. Though Ford produced 302ci and 351ci Cleveland engines in Australia, very few of them were fitted with four-bolt main caps like their North American counterparts. Those fitted with four-bolt main caps were either converted or were experimental blocks. If you find a Cleveland block void of a Ford North American casting number and a “GF” foundry designation, you’ve found a Ford Australia block.

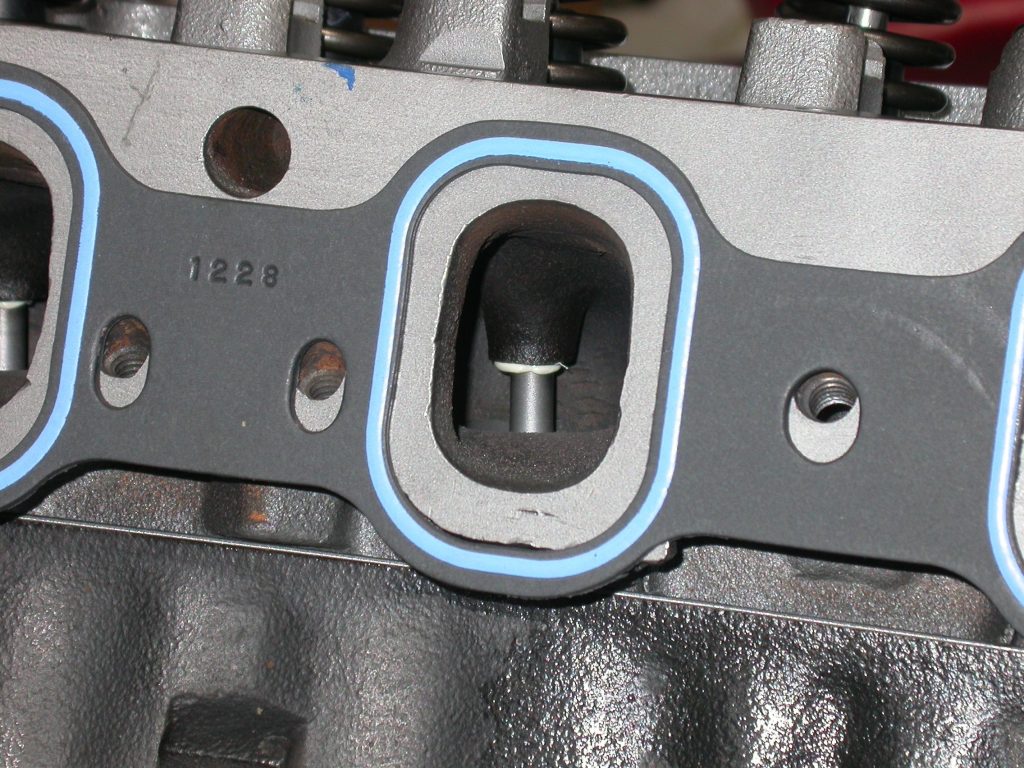

The round brass orifice plate below the thermostat on the engine block is there to control coolant flow to the thermostat and should never be removed. Ford called this insert the “Controlled Bypass System”. This new coolant control system provided improved cooling without frequent thermostat cycling. It also provided for improved warm-up by keeping hot coolant inside the engine. When Ford introduced the 400 a year later and the 351M in 1975, it eliminated the orifice plate, instead casting the controlled bypass system right into the block.

Although the 400 and 351M engines get a lot of criticism, there’s more to these engines than what you see on the surface. The 400 could have been factory grown to 430 to 450ci—a mid-sized block with a big-block personality without the weight penalty. The 351C block castings, despite different casting numbers, are all basically the same casting and can all be converted to four-bolt main caps with help from a qualified machine shop. All have the same main webs and pan rails. If you take away the casting numbers and date codes, these blocks defy detection except for minor casting changes. Where Cleveland blocks get confusing is 351C versus 400 and 351M. The 400 and the 351M both use the same 1971-82 raised-deck block casting. The “M” designation was conceived to differentiate the 351C from the raised deck 351M, which replaced the 351C in 1975.

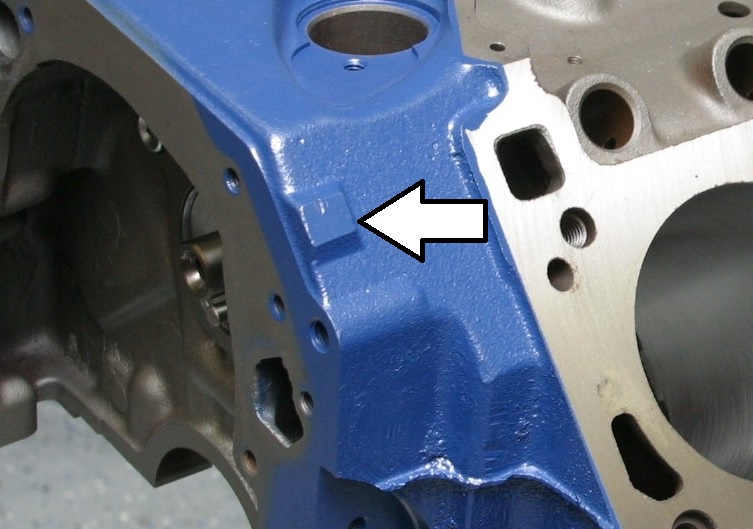

You will hear the terms “D” block and “Square” block in the Cleveland forums, which refers to the boss that rises from the left-hand block deck near the distributor above the fuel pump. “D” blocks have a “D” shaped boss and “Square” blocks a square boss in the same location. It appears early 351C block have the “D” boss, which was actually a provision for a water temperature sending unit on some early production blocks. Not all had the sender provision.

Experimental block castings tend to be hidden away in race shops, garages, and barns everywhere. These rare blocks can be very limited production pieces to factory experimental “XE” and “SK” castings. We’ve seen factory aluminum Cleveland blocks, unusual iron blocks with heavier webbing and pan rails, you name it, most with the “XE” factory experimental casting identification. Sometimes, you will find raw castings that have never been machined. Expect to also see rough cut Cleveland blocks with 3.990 inch unfinished bores.

According to reliable sources, some “XE” blocks found their way into regular production because they weren’t acceptable for racing, however they worked well in passenger vehicles. That makes your Cleveland block search a crapshoot because it is unknown what you will find out there. Another find known as the “pillow” blocks are race blocks, which have bulges or “pillows” in the external block sides.

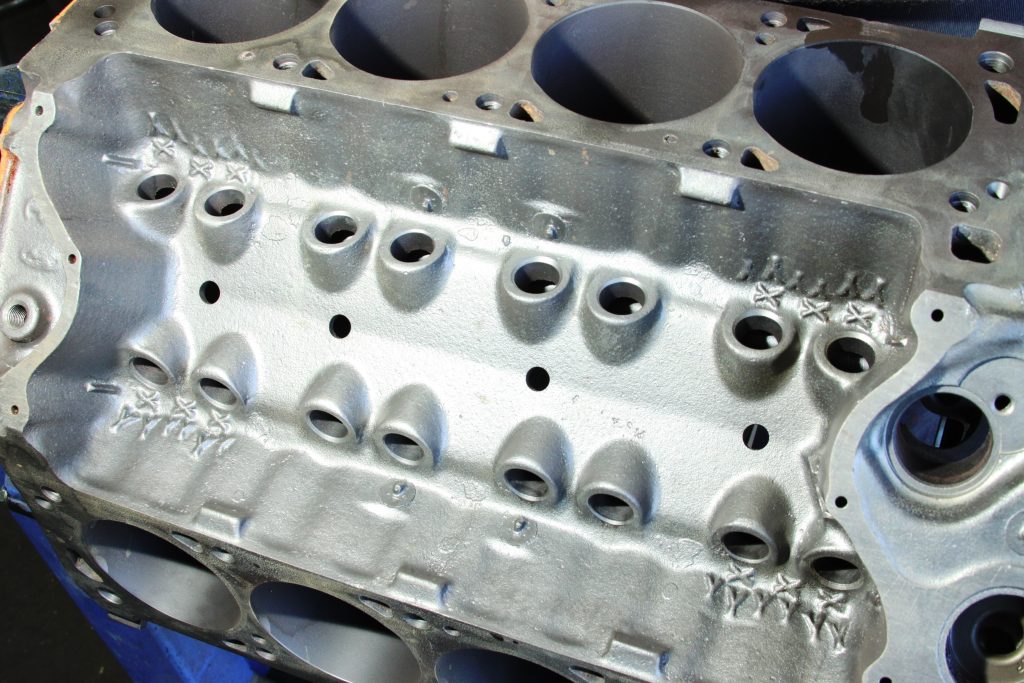

It has been often theorized in the forums the Xs and Ys cast into the lifter valley of most Cleveland blocks means a higher nickel content, but we’ve never seen anything from Ford to confirm this. It’s like the belief Mexican blocks are of higher nickel content, which has never been proven. When Mexican blocks and U.S. blocks have been weighed, they weigh the same within a pound of one another, which means there’s no difference in nickel content. It is said the X’s and Y’s were cast in the valley to prevent cracking — a running production change in Cleveland blocks.

Early Cleveland blocks seem to have been plagued with cracking issues in the lifter valley. And, when they cracked, coolant found its way into the oil. It appears the best Cleveland block to use is the D2AE-CA casting—the final evolution of the 351C block before production ended in 1974. Though the Ford Master Parts Catalog indicates the D2AE-CA block is a four-bolt main casting, not all of them were drilled and tapped for four-bolt mains. Always pull the pan to confirm before committing to a D2AE-CA block casting.

Ford Australia

The 351C was introduced in Australia at the same time it was offered in North America. In the beginning, Australian Falcons were fitted with 351C engines produced at Ford’s Cleveland engine plant. Blocks were also cast at Cleveland and shipped to Australia. Early in production, many of these blocks arrived in Australia painted dark Ford Corporate Blue. In due course, Ford Australia began producing complete 351C engines along with destroked 302ci Clevelands.

The Aussies opted for the Cleveland “wedge” chamber head with the smaller 351-2V ports for better low-end torque in all 351C engines. The 302 sported a different head entirely with smaller 57-61cc wedge chambers. Port sizing was more street friendly with Ford Australia 351C engines. This is the head you want for a street 351C. Here in the States, Ford packaged the 351-4V heads with the small wedge chambers and huge intake ports, which worked well at high rpm, however, were less than adequate for the street where low-end torque was more critical. The Aussies were smarter about Cleveland cylinder heads employing the smaller wedge chamber with the 351C-2V ports for good street torque.

Did you also know Australian Cleveland blocks are clearly different than those we had in North America? The 302 and 351C were produced in Australia from 1972-82. At least two things make the Ford Australia Cleveland block different than its North American counterparts. As a rule, Aussie Cleveland castings don’t have Ford North America casting numbers, as said earlier, though it is believed some of the North American molds were shipped to Ford’s Geelong, Australia (GF) foundry for those first Aussie castings, which means there are some with North American Ford casting numbers cast in Australia. Another belief is Ford North America shipped discontinued Cleveland casting molds to Australia in 1974 when production ended.

There are as many stories as there are Cleveland blocks.

Ford Australia sold early 70’s Galaxie’s here in Australia. I have one.

These cars were fitted with 2V 400 Cleveland engines.

They were big block patten on both the engine mounts and on the back of the block.

Interesting point I once bought a Japanese import 400 Cleveland that had a factory cast iron 4 barrel inlet manifold. I was told it came out of a Lincoln.

I bought that engine for the crank as my mate had an XW GT with a 351 Windsor in it.

Both with the 3” journals he built a stroker back in the day.

I did not know this. However – Ford didn’t build 400 Clevelands in Australia. Were the Galaxies right hand drive?

Nice file Story on ”C” ford.

Years ago when i found my 4 v clevland saw rows of ysxs under intake found that to designate a cobrajet 4bolt main engine still have it today. Could not beat it to death just put in my 64 country sedan in progress.

I have one question can I good street 351C 4 bolt mains block be good to use for a power adder, specifically twin turbo’s?

Ford Australia did fit a Holley to a factory engine. The Ford Falcon GTHO phase 3 had a 780 Holley as standard equipment. I’m not dead sure but I believe this model had the highest output 351 Cleveland ever offered. So it had a R code 351c 4v with additional solid cam and lifters, 780 Holley and headers supposedly 380hp. Car was good for 145mph.

I have a set of Australian 302 2V heads on my Cleveland and I run 93 Octane pump gas in it. I keep timing at 35 degrees max. No detonation or

pinging here. I do have a question though. I have what seams to be a date stamped on the oil pan rail near the oil pump mount (12 469) just as you see in parentheses’. What is this for?

My 70 1/2 Falcon (US) with a 351C 4 V had a 780 Holley and a solid flat-tappet cam with studs and 4 bolt mains. It was an Automatic transmission with a loose (for a factory) converter. And it had low gears, 3.89 I believe I am over 60 now, lol. I wanted to put a 4 speed in it but I am glad I didn’t. A 69 428CJ Torino could take in the 1/4. But I guess it was a rare car, black and black interior 2 dr sedan with chrome pillars and cop caps. I was stupid to let it go. I really wish that they had made the 4V C heads to fit the FE. When the 4.25 stroke kits came out, I have a 4.135 bore block that would have been great for them. I have 2 Pro Gram cross bolt diesel iron caps and the 427 thrust main, and a CapSadlle to brace the 3 center. Stand pipes in the valley to let the crank case breathe. And Enough grout to fill it to the core plugs. 457 ci with those heads would be sweet!

I meant to ask. Has any company ever cast the 351 4V closed chamber quench heads at 4.63 FE bore spacing . I would still love to built my 470-472 ci stroker. I have built 455 ci FE strokers with a short fill and studs with 2 cross bolt caps at 2 and 4. 588 ft lbs and 700+ hp that are driven and raced for 20 years.

I am from the US. I see your parts houses sell a DSO decal for the 351C. It was used in the US rarely but was on my 428Cobra Jet Mustang because the first 50 engines were rushed into production to win a drag race. When was the decal used on your engines?

I was a development engineer over here on the Ford Mustang and enjoyed reading the history of the 351C -so many engines to keep up on. The 69Mustang had 7 different ones as I remember it.

Thanks Roger

A bit of forgotten history that may interest some guys, some of the public does not know there was a 9.2″/9.250″ deck 351 “W”indsor # XE 93532 race block made back in 1966 way before GM’s B Kundsen’s “C”leveland block was even on the drawing board & this 351w XE 93532 9.2″/9.250” deck Windsor race block got as big as 398/400 ci back in 1968/69 for Can-Am racing. 302 & 351 windsor XE race blocks were tested with canted valve head prototypes in 1968 just before Kundsens new block was & there were plans WAY BACK in 1964-65 for a stretched deck 6.9-7.0L aluminum Windsor race eng for Can Am racing. IMO, with Kundsen taking resources away from the Ford engineers we might have even gotten a GT4VBoss 402 ci “W”indsor engine as the 69 W block could have become a 400ci eng if it wasn’t for GM’s Bunkie Kundsen screwing things up at FORD with Fords XE 93532 351W race block development by selfishly ramming through his own “Oldsland” inspired block for the short time he was there. H Ford should of fired him sooner… goo gle “351w xe 93532 block” for more info…

To Jim Smart:

In the article above, you made this statement: Ford called the destroked 400 the “351M” for either “Modified” or “Midland.”

I believe you are merely continuing to spread urban myth here! To the best of my knowledge, Ford NEVER designated the M portion of 351M to mean either “Modified” or “Midland”. Your statement even contradicts itself! is it “Modified” or “Midland”?!? It cannot be both!! Please provide PROOF that Ford made an official designation as to the meaning of the “M” or strike the statement from the article. You also need to stop spreading the myth… if you cannot back up what you wrote with said proof.

No, in the grand scheme of life, what the “M” stands for is hardly a matter of national security but at the same time, it is important to get the facts right. One of the biggest problems we have in society is an ever-growing number of people who live in denial and/or delusion. How do they do it? They’ll state something along the lines of “I’m living my truth”. That’s another way of saying that they simply are in denial of the real and only truth… which is backed up by facts. Reality dictates that truth and fact are one in the same – they cannot be separated from each other and you cannot have one without the other! A successful and functioning society depends on the acceptance of facts. To allow falsehood to creep in allows for conflict and the degradation of society. I point these things out in this case because in the Ford world, the meaning of the “M” has been debated, argued over and even fought over since the 1970s. So, I’d love to see some proof offered to back up your statement. Again, to the best of my knowledge, there isn’t any. If there is, I’d sure love to see it as I’ve been following this topic for decades without resolution! Nobody, and I mean NOBODY, has ever come up with anything from Ford which resolves the issue as far as I know. Magazine articles, parts counter books, aftermarket repair guides and books about Ford don’t count! Why? They aren’t produced by Ford. The terms “modified” or “midland” have been used for so long that they’ve come to be accepted terms to differentiate the engines… and everybody knows what you’re talking about when you use them… but that certainly doesn’t mean either of those terms were put forth by nor used by Ford. The meaning of the “M” isn’t unlike how people call the 400 cubic inch engine a “Ford 400 Cleveland” or a “Ford 400 Modified” but those too are incorrect to the best of my knowledge.

So, to make my long comment a little longer, please provide proof from Ford if you’ve got it. It isn’t just me. There are a whole bunch of people out there that would like to see it. Thanks in advance for any help!

– Texas Brian

Early in his descript it was stated that many people used these tedms (351M,400M, Modified, midland) in my opinion he was not endorsing these terms.

I personally belive that, 351M was the only correct phrase, and it stood for the 351C being ‘modified’ by change bell housing to 385 series.