Chevrolet’s 307ci small block has long been viewed as a mild-mannered grocery getter. You’ve seen hundreds of thousands of them in Chevelles, Novas, Camaros, and untold other mainstream Chevys. We used to call them “Belly Button Motors” because everyone had one—right? I recall new 1968-73 Chevelle wagons, sedans, and hardtops up and down our Maryland block with 307s. They were good solid dependable engines with a long legacy of service.

Jeff Latimer, a savvy engine builder and racer who used to manage JGM Performance Engineering in Valencia, California, came to us with an intriguing engine build project no one had ever tackled before. This one was the humble Chevrolet 307ci small block, which replaced the venerable 283 that had been in production since the 1950s. Like Ford with the 289 turned 302, Chevy stroked the 283 to 307ci. Chevy borrowed the 327’s crank, which made it easy to increase the 283’s displacement to 307.

“I’ve never understood why Chevrolet never hotrodded the 307, which had the same kind of potential as the 283. Chevrolet produced the 307 from 1968-73, which means there are a lot of cores out there waiting to be rescued and built. Chevrolet never did a high-performance 307 like it did with the 283. Right off the assembly line, the 307 delivered 200 horsepower and 300 lbs.-ft. of torque. Marine versions with four-barrel carburetion made 240,” Jeff commented.

Jeff Thought He Could Double the 307’s Factory Ratings.

The 307 never caught on as a performance engine because it was so easily replaced with a 327 or 350, so why bother? Most opted for the larger 350.

In Jeff’s mind, the 307 was a sleeper. It could be built to make a lot of power and, because cores are so plentiful and cheap, you could get into one for not much money. It could make a lot of power yet be fuel efficient for the daily driver. The 307 has the bore advantage over the more popular 305/5.0L engine—3.875 inches over the 305’s smaller 3.736. Jeff was positive more could be done with the 307. What’s more, the 327’s 3.250 inch stroke made the 307 a clear winner. Plenty of low-end torque.

So, What Can You Do with the 307?

Because this is not a budget build, but more an experiment, not many will be interested in trying this. Jeff tells us he has witnessed many 307 builds, but not to the extent of what he was about to build. He wanted to make the most of 307ci, with a 0.030 inch overbore to 311ci, with 3.905 inch bores.

His original intent was a street/strip engine. Civil for the street and coming on strong at wide-open throttle for the freeway and strip.

Jeff could have easily infused a lot of compression and cam into the little 307 and built a monster mill. He wanted a civilized street engine with a good torque curve and high rpm horsepower. He wanted double that 200 factory horsepower number.

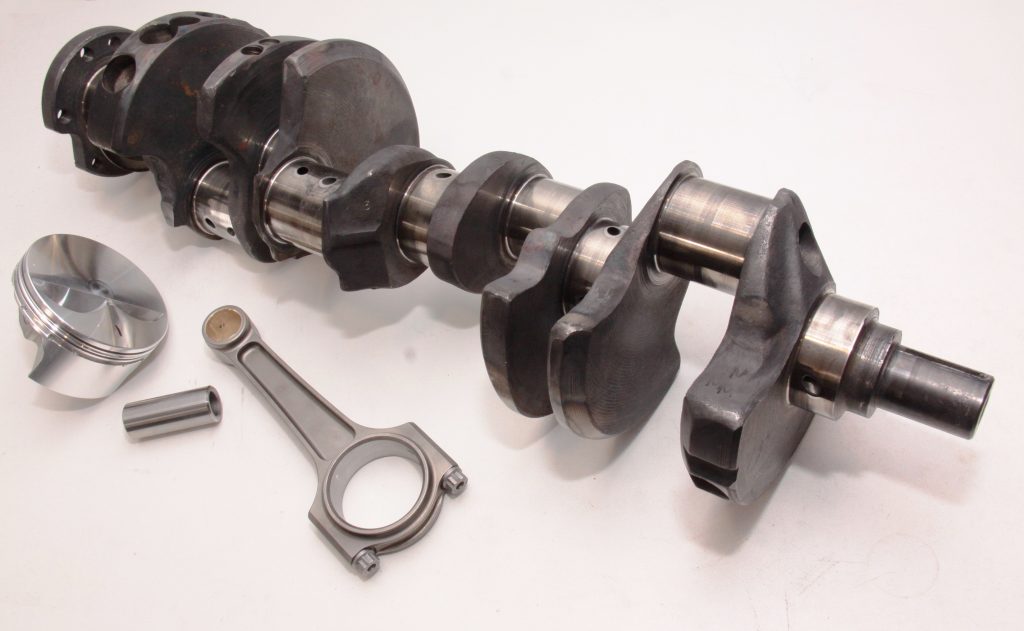

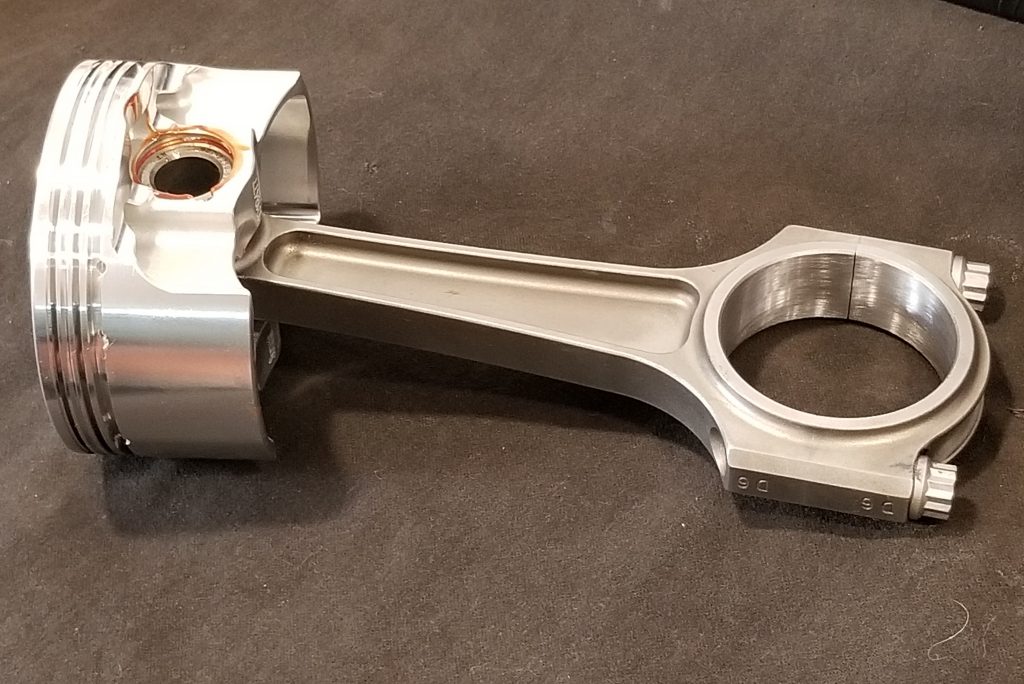

“If we had put this much effort into a 350 or 383 build it would obviously make more power,” Jeff told us, but that’s not the point of this build. The point is how to make real power from 311ci. “To increase the piston dwell time, I have opted for a long 6.250 inch rod combined with custom pistons with a 1.125 inch compression height to get 10.75:1 compression,” Jeff commented.

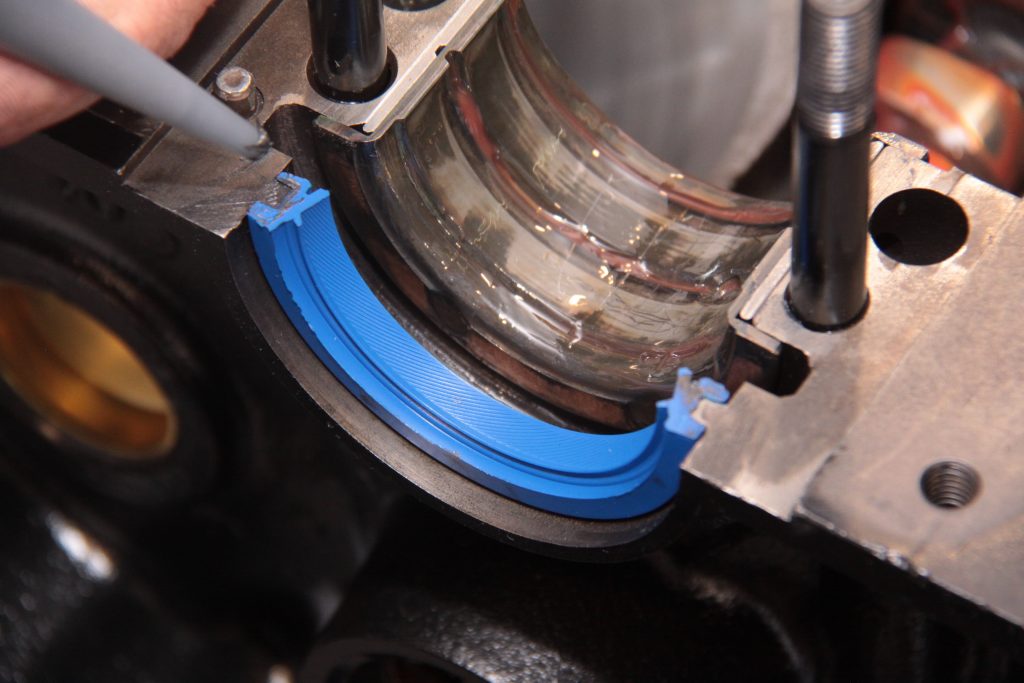

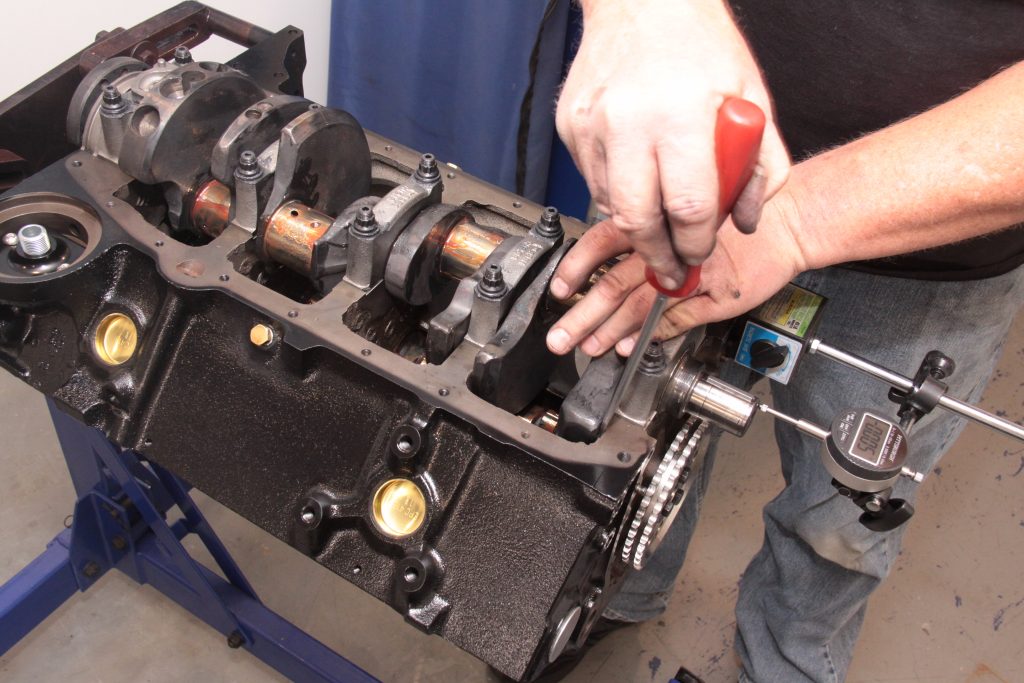

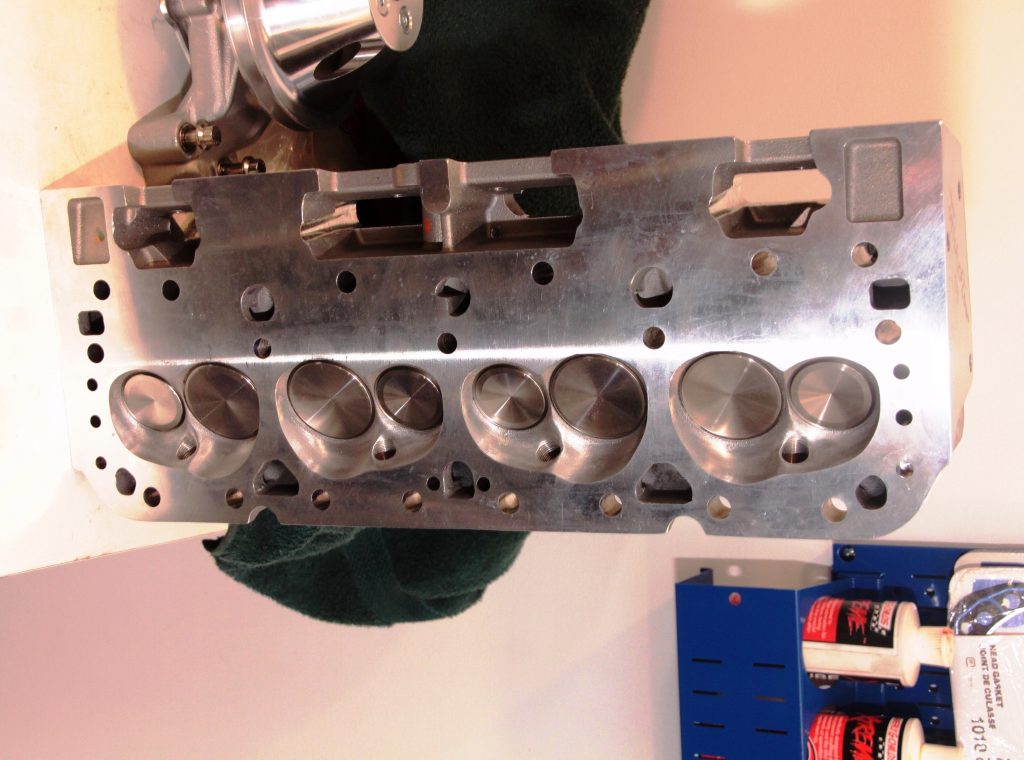

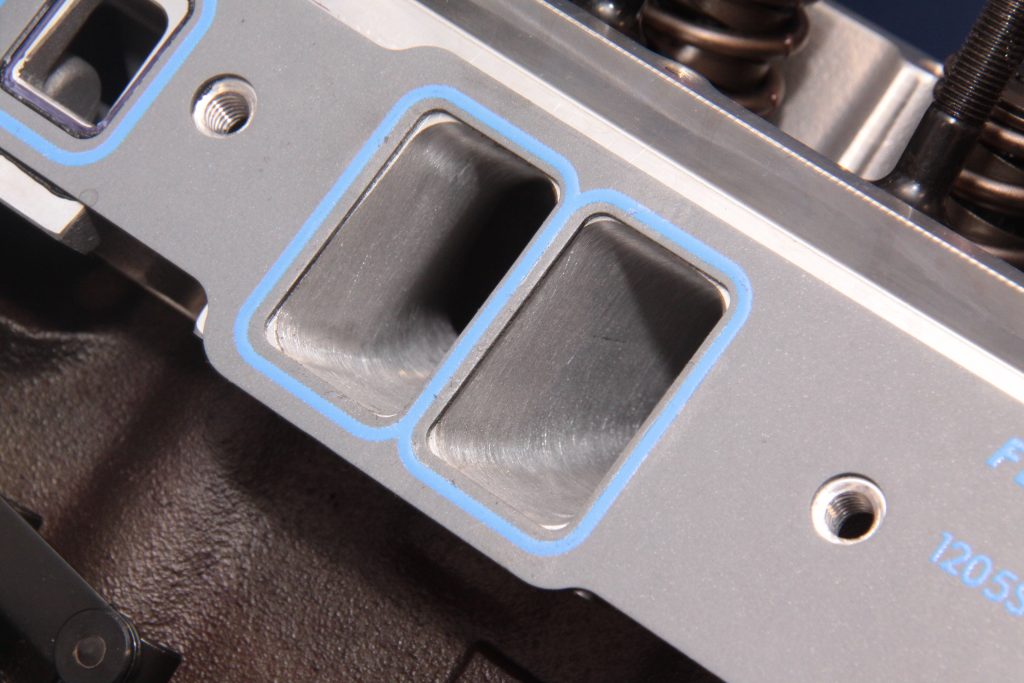

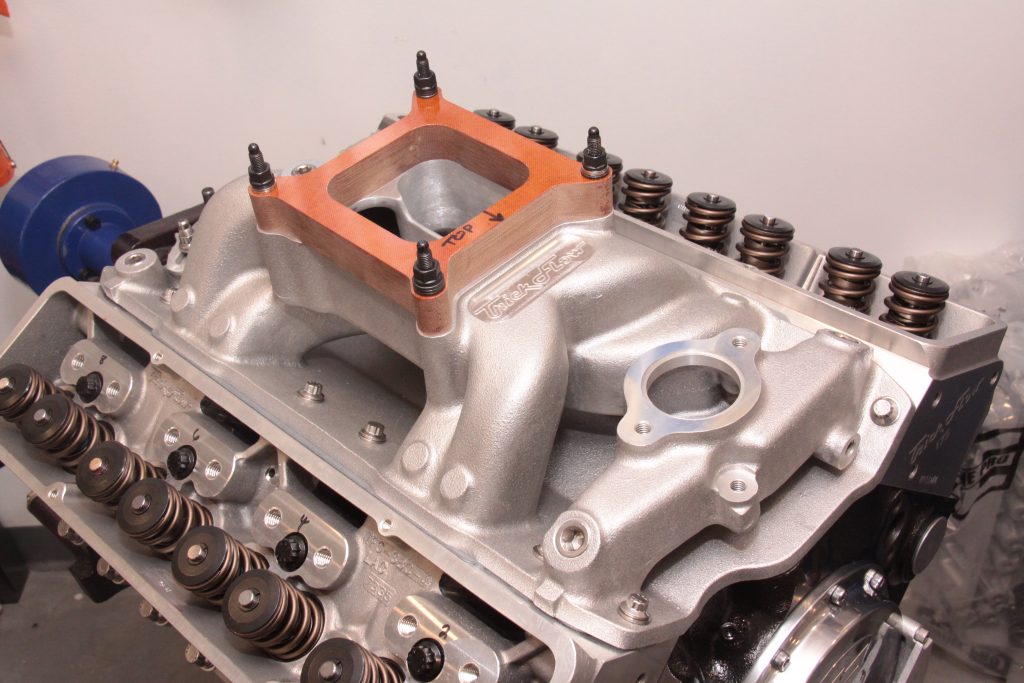

Jeff opted for Trick Flow (#30310003) cylinder heads and intake, which were ported for a perfect match and improved flow. These fabulous heads could have been used out of the box, however, Jeff wanted maximize the 307’s potential with a good port job. He opted for a small journal 327 forged steel crank with bearing spacers for the large main journal block. The block was align-honed and fitted with ARP studs. The bottom end was balanced and fitted with super light bob weights at 1,550 grams. Jeff quips, “I have seen aluminum rod engines with a heavier weight than that!”

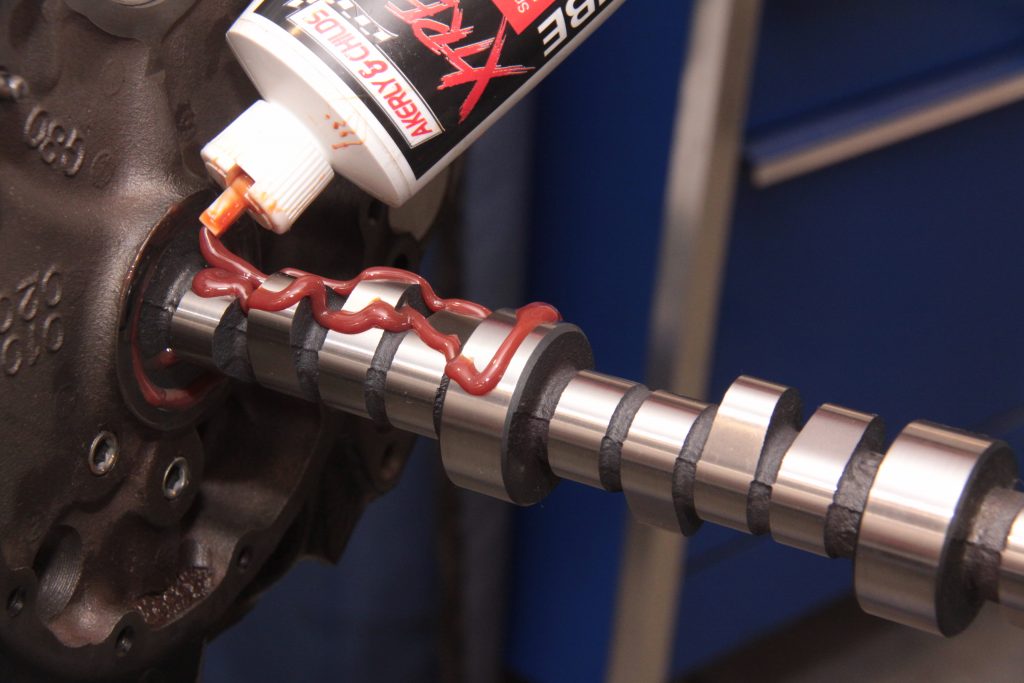

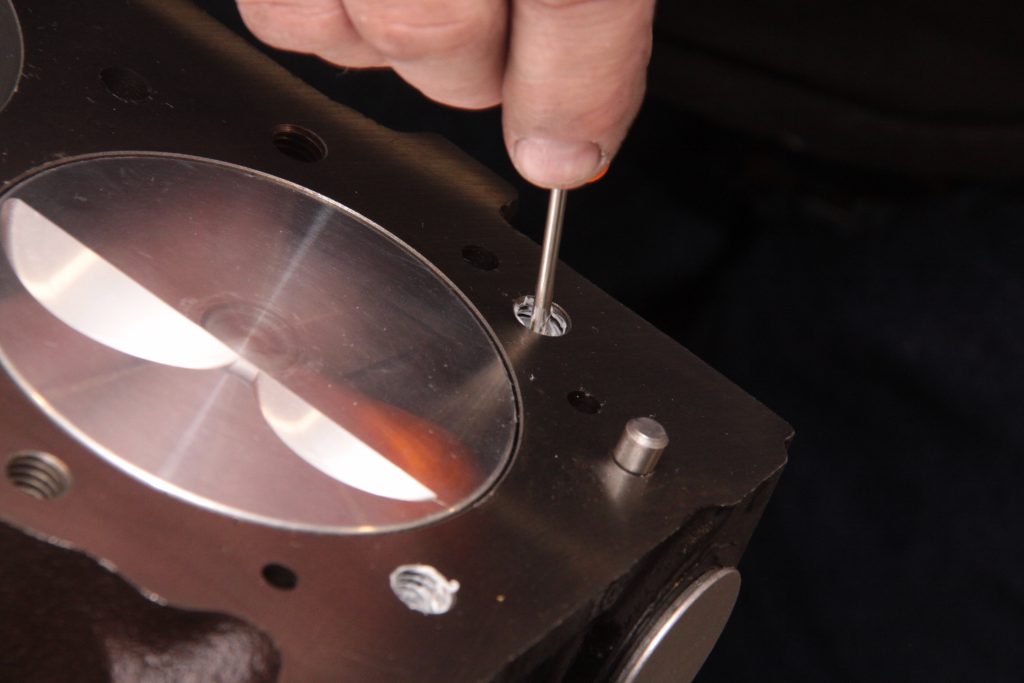

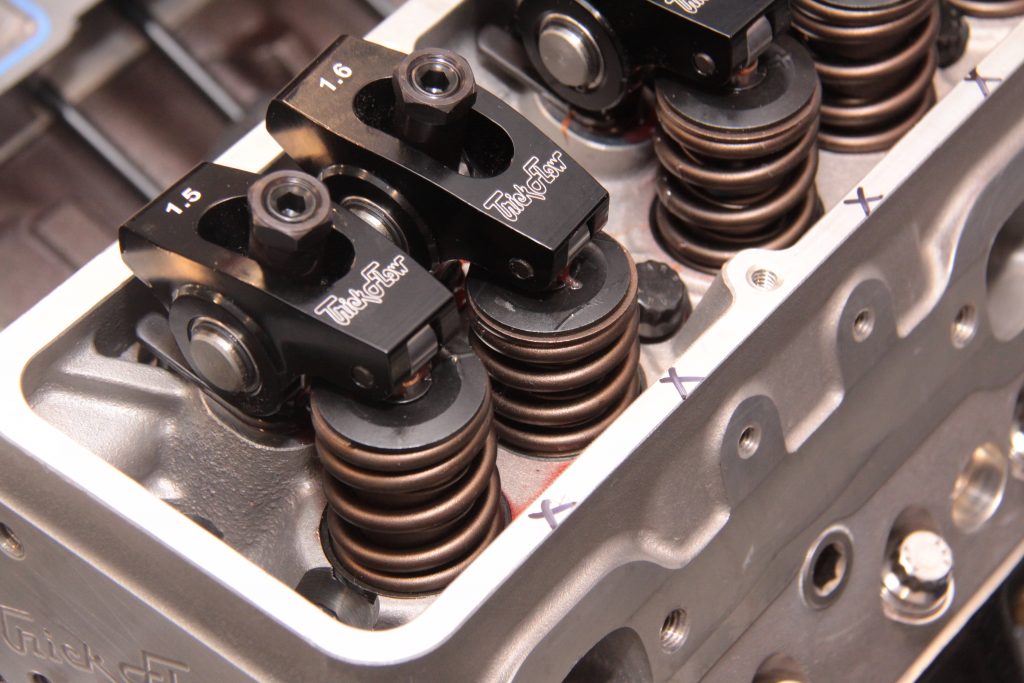

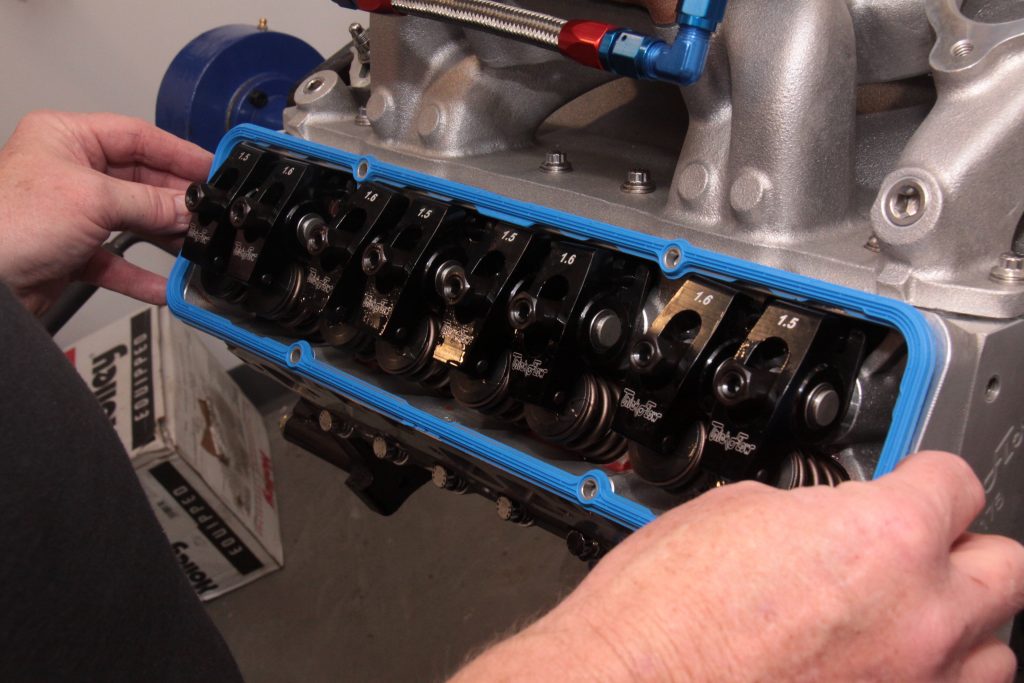

Because these Trick Flow heads are super efficient at more than 75 percent efficiency intake vs. exhaust, Jeff chose a single pattern Crower hydraulic roller cam with 228/228 duration on 108 degree lobe centers. And because this engine will still have more exhaust cam than it needs, Jeff went with 1.6 ratio Trick Flow rockers on intake and 1.5 on the exhaust. Because this is a hydraulic roller cam, it requires a cam button. Jeff opted for a cool aluminum timing cover.

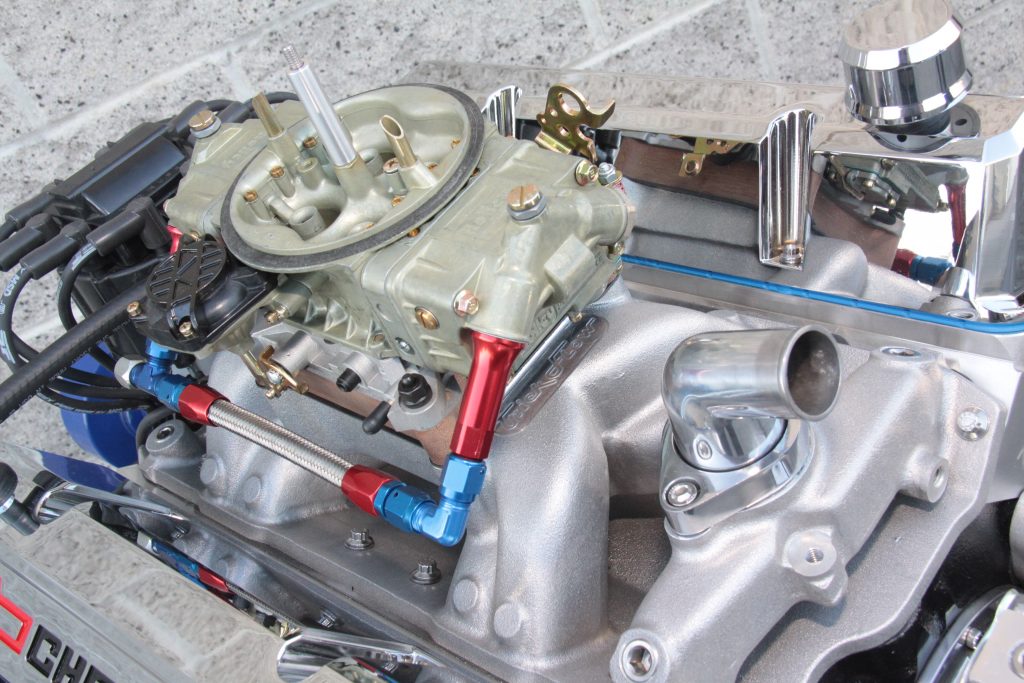

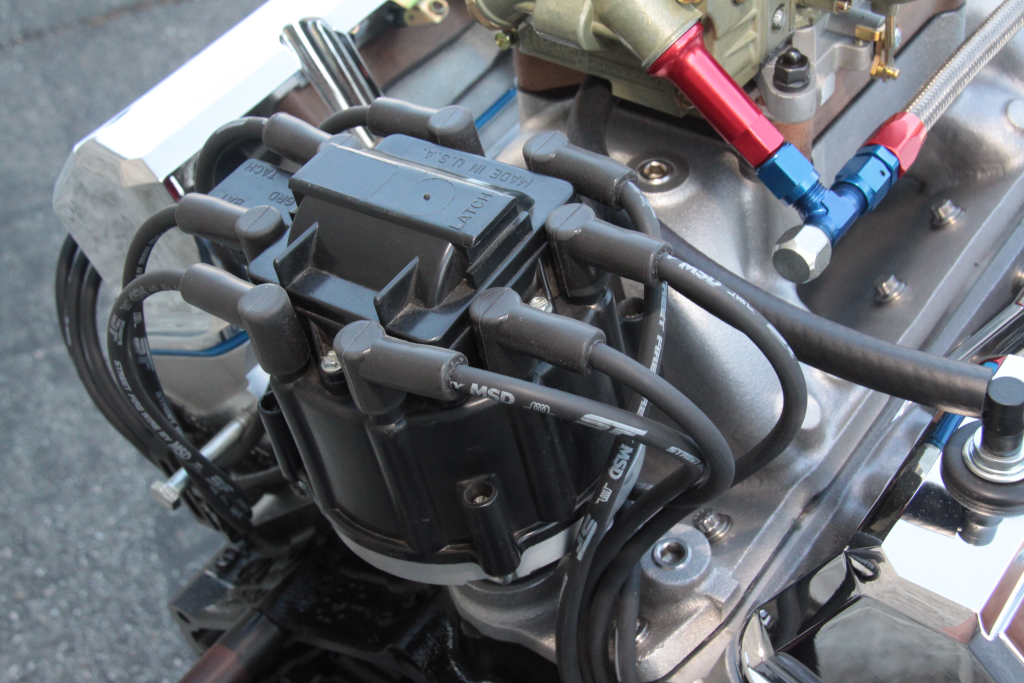

“The block was going to be close to zero deck with a 0.030 inch thick head gasket,” Jeff comments, “That made for a real tight quench that improved efficiency.” Jeff chose ARP fasteners for added security. Jeff started off with a 750 cfm Holley HP carburetor with vacuum secondaries and a GM HEI distributor modified with MSD ignition components.

The 307’s First Dyno Session

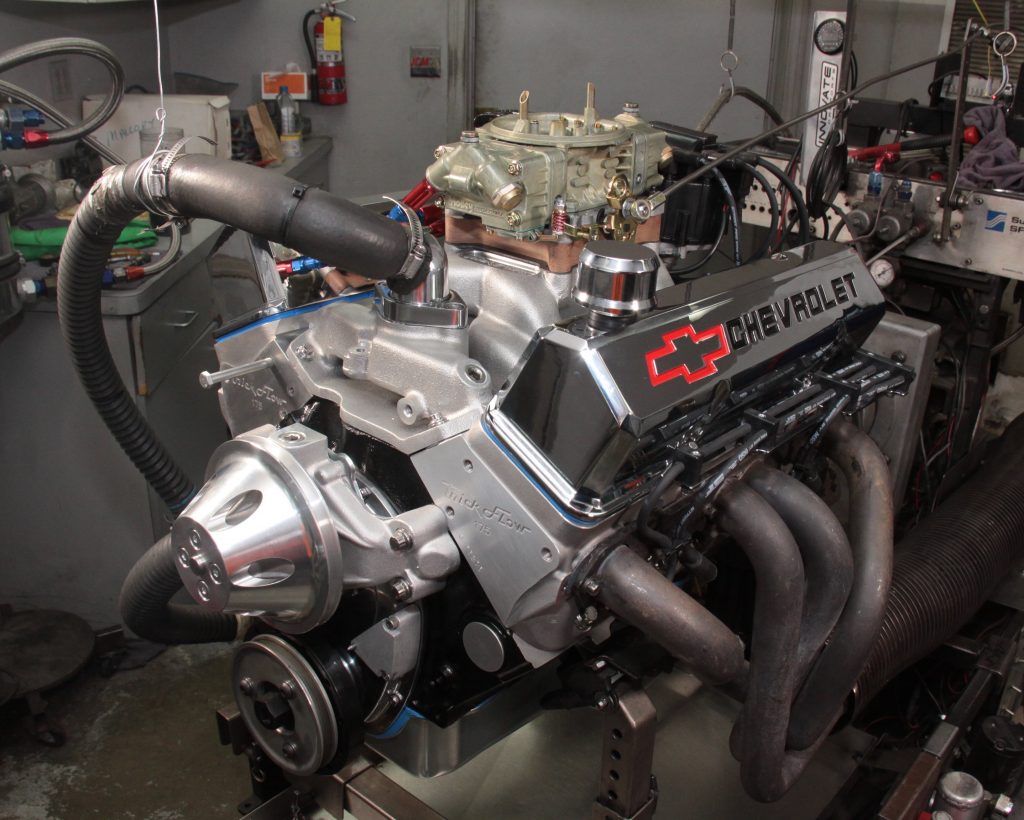

Jeff’s first trip to the dyno netted 401 horsepower at 6,400 rpm and 372 lbs.-ft. of torque at 4,600 rpm, which doubled factory 200 horsepower ratings. His efforts proved out as predicted at twice the factory numbers. Despite Jeff’s best effort, he understood there was a lot of power sleeping in the petite Chevy small block—more than he even knew or expected.

What Jeff did know during that first dyno session was he didn’t have enough cam to make real power. He performed a simple cam swap to a Comp Cams 242/248 duration (0.576/0.562 inch lift intake/exhaust) with 110 lobe centers (#12-443-8) and an intake swap to an Edelbrock single plane Victor Jr. with an in-depth port job along with a Wehr’s carb spacer and a Melling billet one-piece oil pump with Shark Tooth Technology. He managed a whopping 70 horsepower increase. That netted 471 horsepower at 6,500 rpm with torque coming in at 409 lbs.-ft. at 5,500 rpm. That indicated 1.5 horsepower per cubic inch.

A Quest for 500 Horsepower

Being this close to 500 horsepower, Jeff wasn’t lifting now. The 311ci engine was already producing more than 1.5 HP per cubic inch. That’s when he became hell bent to pass the 500-horse mark. Jeff put his years of engine building experience to work. It was his belief we needed more rpm to pass 500 horsepower. He substituted the hydraulic roller tappets with mechanical solid rollers from Comp Cams with the hydraulic roller cam he already had. “The hydraulic cam does not have clearance ramps so I set the lash at zero cold. I installed new valve springs with titanium retainers that would tolerate the higher rpm ranges expected. The greater spring pressure and solid rollers would allow the engine to rev higher than before.”

Jeff admits he became greedy about power. He wanted more and without pulling the heads. He had the intake manifold ported a bit more and added half a ratio to the rockers—1.6 intake and 1.5 exhaust. “Since the cam had lash it became slightly smaller. I was trying to help it to stay closer to the way it was before lifter change. We also added a complete MSD ignition system to keep everything lit at high revs.”

Dyno Run #2

Upon the next trip to the JGM Performance Engineering Dyno, the upgraded 311 came up a bit short at 486 horsepower at 7,200 rpm with a loss in torque to 390 lbs.-ft. peak.

That’s 20 lbs.-ft. off in torque from where it was with the hydraulic lifters on same cam. Horsepower was up 15, but shy of the mark at 486. Jeff was going to close the gap.

“What I feel I learned at this point is that because the cam was essentially the same specs as before, the torque number should not have dropped that much. That’s when I concluded the additional port work on the intake manifold hurt velocity because the engine was small at 311ci,” Jeff commented, “With the goal of 500 horsepower so near, I was always aware we would lose torque in the process.”

Jeff went on to say, “I switched to a different Victor Jr. with only port matching to get velocity and torque up. There was also a last minute cam change from 242/248 on 110 lobe centers to a Comp Cams solid roller cam—254/260 on a 110 lobe centers. I also changed rocker ratio to 1.5/1.5 intake/exhaust.” He added, “I also added a better Canton oil pan with a windage tray and full kick out from Canton.”

Third Dyno’s a Charm

Jeff went back to the dyno with fresh 5w30 Mobil1 synthetic, then warmed up the engine. That first pull was 498 horsepower at 7,200 rpm—mighty close to our goal. Jeff knew it was going to take higher rpms to achieve 500. He dialed in 35 degrees of total timing and pushed it to 7,400 rpm and got 505.5 horsepower and 394 lbs.-ft. of torque at 5,900 rpm.

“Very pleased with the results,” Jeff told us, “We’ve made more than a hundred horsepower from the 307/311 without ever pulling the heads.”

“Throughout the process, we performed several timing test pulls. Total timing of 35 degrees BTDC was all it needed. This, combined with the small chambers, gave us nice tight quench with flat top pistons, which made this engine very efficient, Jeff told us, “The long 6.250 inch Crower rods had the pistons dwelling much longer at both TDC and BDC. We ran two different Holley Carbs to check out the differences. One was a Holley HP 750cfm with vacuum secondaries while the other was an 830 cfm HP.”

He added the two highest horsepower numbers were with the 830.

“In my opinion, the best combination was when we made 471/409 horsepower and torque. That would be best combo to use on the street for both the commute and play,” Jeff commented, “I believe if I put the hydraulic roller back in it with the better valve springs and the Canton oil pan, we would conservatively make 475+ horsepower and 410 lbs.-ft. of torque. Not bad for the little 307 Chevy.”

Jeff went on to say “with the smaller 750 HP with vacuum secondaries, it would use less gas than a 350. Good for the street. The most impressive part of this engine making so much power is that the bore is so small at 3.905 inches and the intake valve equally as small at 1.940.”

Closing Thoughts on the Chevy 307 Engine Build

Jeff reflects on this purely experimental project.

“This project was never meant to be a budget build. It was darned expensive. It goes without saying if I had done a similar build with a larger engine like a 350 or a 383, we would produce much more power. My objective was to make something special out of an odd-duck, no respect engine that has been normally cast aside for one of its bigger brothers. We wound up with 1.625 horsepower per cubic-inch! This is a street engine with only 10.75 to 1 compression, which will run well on pump gas and nobody will ever believe it’s a 307.”

If we hadn’t seen it ourselves, we wouldn’t have believed it.

Impressive build.

Loved the article. Very informative. Makes me want to build a 307 just to have someone ask What Are You Running for a engine??? Very nice build. Thank you

This hits close to home. My ‘69 Chevy C10 has the original 307, 2 barrel with an HEI system and I’ve always felt like it has a lot more “tiger in its tank” than I’m giving it credit for!! Thanks for sharing

With those heads and a mild cam – .420 lift it would make a great cruiser. That and a freeflowing exhaust with 3.08s and a 4 speed.

David Vizard could have told you exactly which cam you needed for this engine, instead of trying 2 or 3 different cams.

David vizard is badges my brother built a 307 back in the day he revved at 7200 RPM big cam big heads offenhauser high-rise tunnel ram different cams different carbs ended up with a 830 started out with a 750 then a 780 and a dual point Excel distributor he played with the dwell and the springs he always wore it made close to 500 horsepower he beat many a big blocks that were built up 73 LT RS Camaro in the low 12s with a dinky little 307

Es la información que buscaba, es algo económico y gran rendimiento, para un che de calle, el mío un Malibú. 81 Chevy 305 y caja de 4 gracias

My name is Bill Cannon and I own AwesomeEngines from Delaware. What I can say is uou have a very nice turd that does not smell to bad but your gonna have to hunt real hard or to try to give it away now.

I love doing these types of engines when the customer pays me to. I would of done it differently and I never use silicone on a rear main seal or the deck. My CNC race preps a block in 30 minutes and that is bored, and decked in perfect 45 degree bank angle as well as bored on that degree perfectly.

I would have sped up the piston speed with a 5.7 connecting rod and that is even to long. The custom pistons are pricey as well as those connecting rods. I would of never done a full port on the Victor Jr.

With the small bore, that really backfired on you and I never use an HEI unless the msd box is in between it and controls the coil. The pickup in the HEI and big cap work better than you think and you used the MSD anyway.

The small journal crank was sweet but the Hp and torque you done were impressive.

Either way I am not going to start to building 307s because there is plenty of them, for anyone.

With that power your block is suspectable to splitting. I would of filled the block to 1-1/2″ from the deck and plate honed it for sure. I would have just put the black mamba lifter in with a cam not like yours but for sure used a 106 lobe separation. Either way, nice job

Maybe we will see your build up here next, I would like to see the numbers in comparison

wow , lighten up , brainiac.

Building any small block with less than a 4-inch bore is senseless.

A better small engine would be a 3-inch stroke crankshaft in a 4-inch bore block with 5.98-inch long rods. Better selection of heads. Uses stock 350 pistons. More horsepower same torque.

Over and over again. Many dyno tests have proven that long rods are a waste of money. No difference in performance.

Jeff I live in colorado and I need my pickup engine rebuilt. It’s out of my 1971 k10. I’d like to keep original engine in it, but would love around 375 hp, I don’t have anyone local who can build it, any ideas

What bearing spacers where used ugg trying to build this motor. Please can’t find anything on them

That distributor doesn’t appear to have a vacuum advance on it. Which one is that? All I can find have the VA on them.

Had lots of cars with 307s, love ’em. Stock 200 hp pulls 80mph in first with 2:78 gears. The 307 is a large-journal 327 with 1/8 inch smaller bore. You can use 1.94 or 1.84 intake valves in a good set of heads WITH SMALL CHAMBERS.: anything will do from power packs to 305s. Just add a Q-jet on a stock manifold and it will surprise you. All it needs is compression and enough mixture, dual exhaust with stock headers and all is good. In a mild climate delete the exhaust flapper valve. That’s all and you have 240-250 hp and GOOD TORQUE that idles and runs nicely with your auto or manual tranny. Use 3:08 gears, and everything is good. The secret is in the velocity and turbulence of the fuel/air mixture. You can just match up the heads and manifolds, but if you polish the runners, mixture turbulence is affected. And use 98 RON, don’t penny-pinch on the fuel! If you want a cam for a bit more hp, go for a torquer and avoid anything that just moves things up the rev range. If you want to race, build a race car.

This article is very instructive about what gets you where, most interesting. I have often wondered how light you can get a SBC and still GO. I’d start with a small journal 327, .030 over, a pair of those nice alloy Trick Flow heads, mild torque cam, Q-jet on an alloy speed-bore intake manifold, and shorty block huggers. This would trim 100 lbs and more from the motor so you could stick 300 hp in a European sport car or a Toyota Celica, perhaps? A Celica 5-sp will cope with 300 hp. Hauling around an Impala? – well, a 307 will also do that pretty well.

How much would it cost to build the 400 hp version and would you be interested in building one for me?

Good job guys,all these haters.I like odd combos.any body can buy and build 327s,350s.again great job.

yes.

What fuel pump ?

I have a 68 chevelle with a stock 307.i never thought of it as a slouch.i did read somewhere that the block has high nickel content and the bores wear quickly,soft material.however the car has 43000 miles on it and has been tore down for a ground up resto.i would love to keep the 307 and add some power adders

Could you please contact me about this build. If you are interested, i have a running 307 in a 1970 Malibu and would be interested in you using my block to build something for this car. My name is Dale i can be reached at 407 699 0041. I understand this would be a expensive build. Not a problem please contact me.

I had heard that it replaced the 327, not the 283. Late 68 the 307 appeared and the 327 was dropped.

The 327 was still around in ’69 yet. Had a ’69 Impala with a 327 in it years ago.

Hi, any chance you can share the way you built up the heads? Brand and parts used?(hardened seats? Spring pressures used? Stuff like that) Any additional work done

great article. think i’ll go out to the shop and uncover that 307 in the corner.

Engine builds are interesting, but I don’t see that ‘307’ being anything but resident in a trailer queen show car for the specs/build. What made the 283 and 307 good was reliability being thrashed whether in a light Nova or heavy Impala. I can imagine this 311 engine spread along the Florida turnpike one late evening.

Anyone selling one or does this kind of build?? Kuntahall@gmail.com hit me up

I think it would be cool to see this block done with the same pistons, a 6.125″ rod with a 3.48 crank and a 6″ rod with a 3.75″ crank. I know it’s a little silly since one could do all this it with a 3.48″ at 355/372vi or a 3.75″ at 383/406ci but plenty of those have been built and hardly any 336ci or 362ci with a 3.905 bore have been done.

Have a 68 nova with mild built 307 would like to step it up to 400 hp plus .great article jim

Awesome build. I’m build a 307/311 for my boat. Flat tops 488 lift 112 lobe separation 64cc heads 1.95-1.50 valves performer intake 650 holly probably go 750. Hopefully make some good hp. Looking for 375 to 400 hp

Very interesting build. The GOAT Smokey Yunick said “Always use the longest damn connecting rod that you can fit in the engine”. Factory block heights are short for packaging reasons in production cars. The purported gains in torque on a 3.48″ stroke engine were 7-10 ft. pounds with an increase from 5.7″ to 6″. Perhaps at a higher rpm, but with today’s transmissions, regear the car. Piston velocity is increased, increasing port velocity, or allowing for a bigger port and/or cam. Side loading on cylinder walls is decreased allowing for a smaller skirt size and lighter piston. No good reason for short connecting rods on any performance engine. Factory forged cranks go to 570 hp. Put Smokey in the NASCAR Hall of Fame.