It’s a big “duh” to say that brakes are vitally important to your driving safety.

Yet, while hydraulic brake systems have been around for over a century now, if you’re thinking about buying or restoring a classic vehicle, there are still some very important questions to consider:

Does it have a dual- or single-circuit hydraulic brake system? And what does that mean to the vehicle’s drivability?

We’ll explore the answers in a moment—but first, some history.

Early Automotive Brake Systems

At the dawn of the automobile, brakes were alarmingly basic.

How basic? Some simply had a hand lever that would push a wood block against the wheel hub (yikes). And you could forget about having brakes at all four wheels, many of the first cars had just a single set of friction brakes on one axle.

Even with the advent of drum brakes at each corner, these early brake systems were completely mechanical, often connected via a cable or bands. And anyone who’s ever fiddled with a wonky parking brake cable knows that those are prone to stretching, seizing, and braking…err…breaking.

Adequate for something like a 20 horsepower Model T, but perhaps a bit sketchy for a Flathead V8-powered 1932 Ford.

Introducing Hydraulics

Meet Blaise Pascal, a French physicist born in 1623. In addition to being one of the fathers of the modern computer, he figured out some key concepts in fluid mechanics. His work gave way to a string of advancements in hydraulics, which culminated in the first patent for a hydraulic automobile braking system by Malcolm Loughead in 1917.

In a vehicle’s brake system, hydraulics had a ton of upside. Thanks to the force amplification behind Pascal’s Law, it made the pedal easier to press. Better still, it exerted pressure evenly, and the hydraulic system was compact and relatively easy to integrate into a vehicle chassis.

Problem was, it was tough to get right.

Seal materials, pressure fittings, chemistry—it took several manufacturers working to perfect hydraulic braking over the next two decades before hydraulic brakes found mass adoption. Once they nailed it though, consumers immediately felt the advantages of the improved hydraulic brake design.

It should be noted that we’re still mostly talking about drum brakes here. While several manufactures (cough*Crosley*cough) had experimented with hydraulic disc brake systems, drums were the most common, by far. We’ll get to disc brakes a bit near the bottom of this article.)

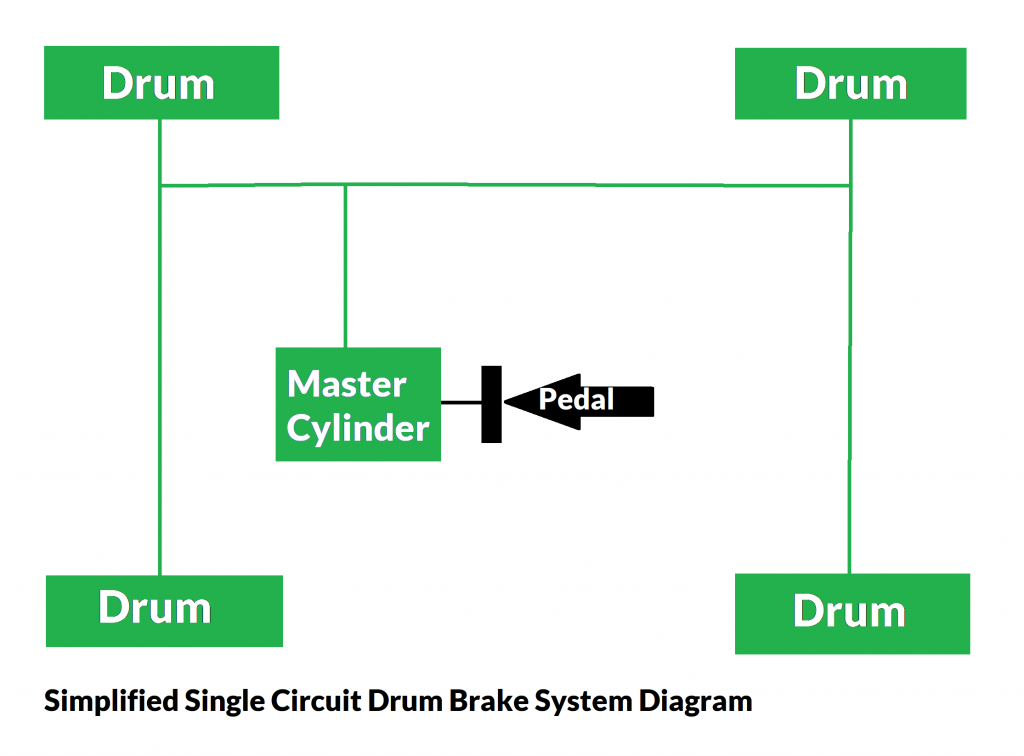

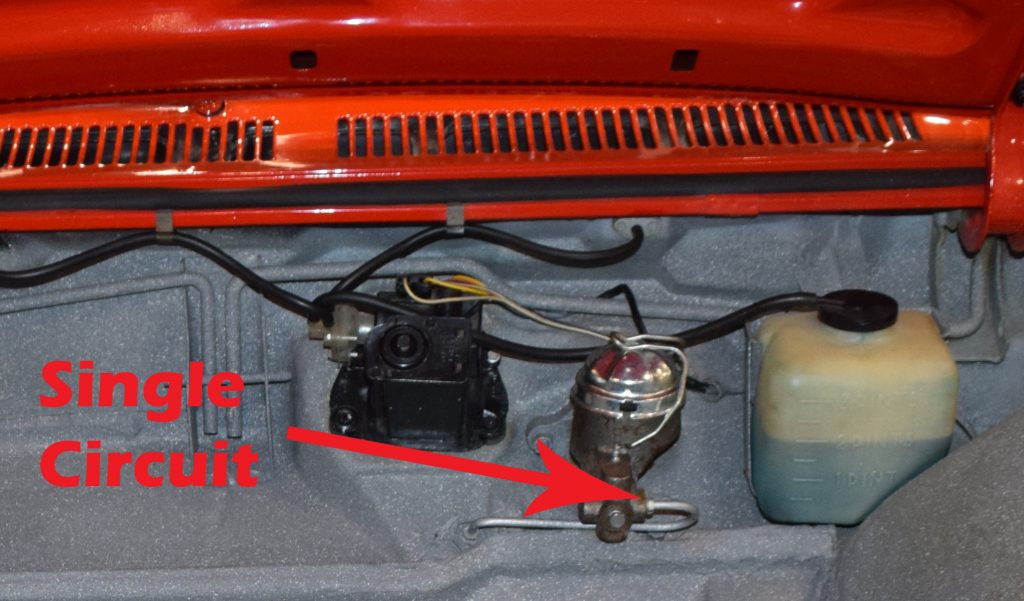

What is a Single-Circuit Hydraulic Drum Brake System?

Single-circuit brakes use a single system of brake lines, all connected together, actuated by a piston within the brake system’s master cylinder. When the brake pedal is applied, the piston is pushed into the master cylinder, which, thanks to that Pascal guy we talked about earlier, will transfer the pressure evenly to each of the four drum brakes.

Now, the illustration above is simplified…but it ain’t that simplified. The lines were typically joined using basic T-fittings and, save for the use of residual valves to maintain slight pressure at each wheel, each brake line terminates at the drum’s wheel cylinder.

While this single-circuit setup was effective, it had one serious problem—and it’s a flaw inherent within any hydraulic system. When you lose hydraulic pressure, the system is almost immediately rendered useless. So, say you’re driving along in a 1950s-era cruiser, you tear a brake line on a piece of road debris and, after a couple of stabs on the brake pedal, you’ve got little to no stopping power.

That’s why many hydraulic systems build-in some sort of redundancy to prevent against a total pressure loss.

And that’s…

Why Automakers Switched to Dual-Circuit Drum Brake Systems

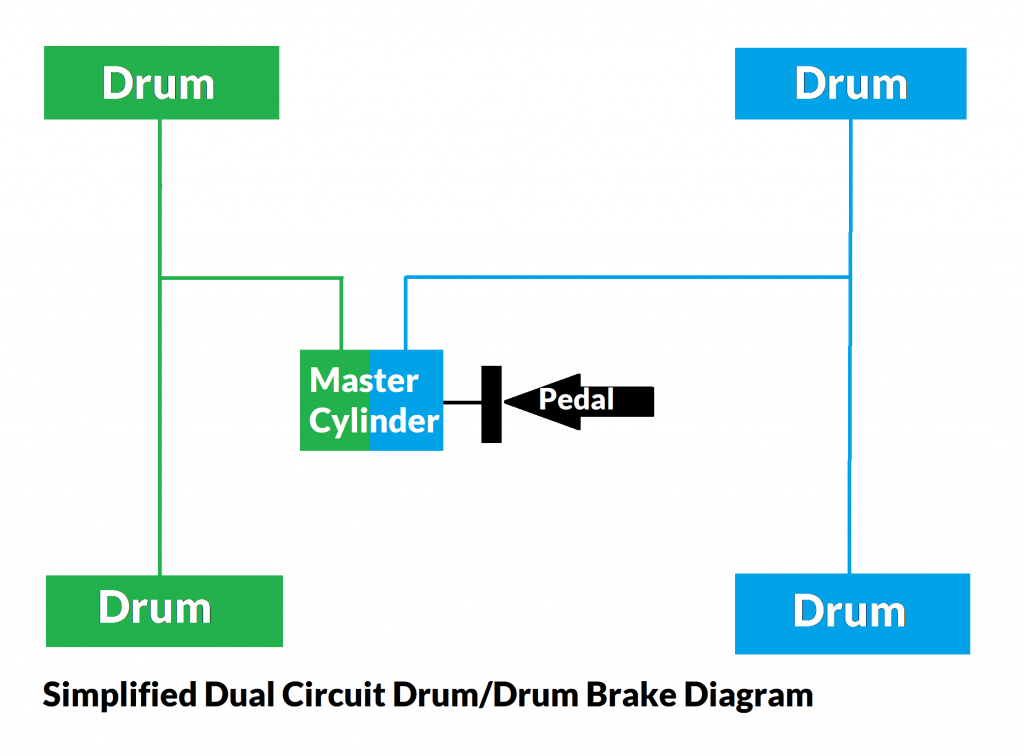

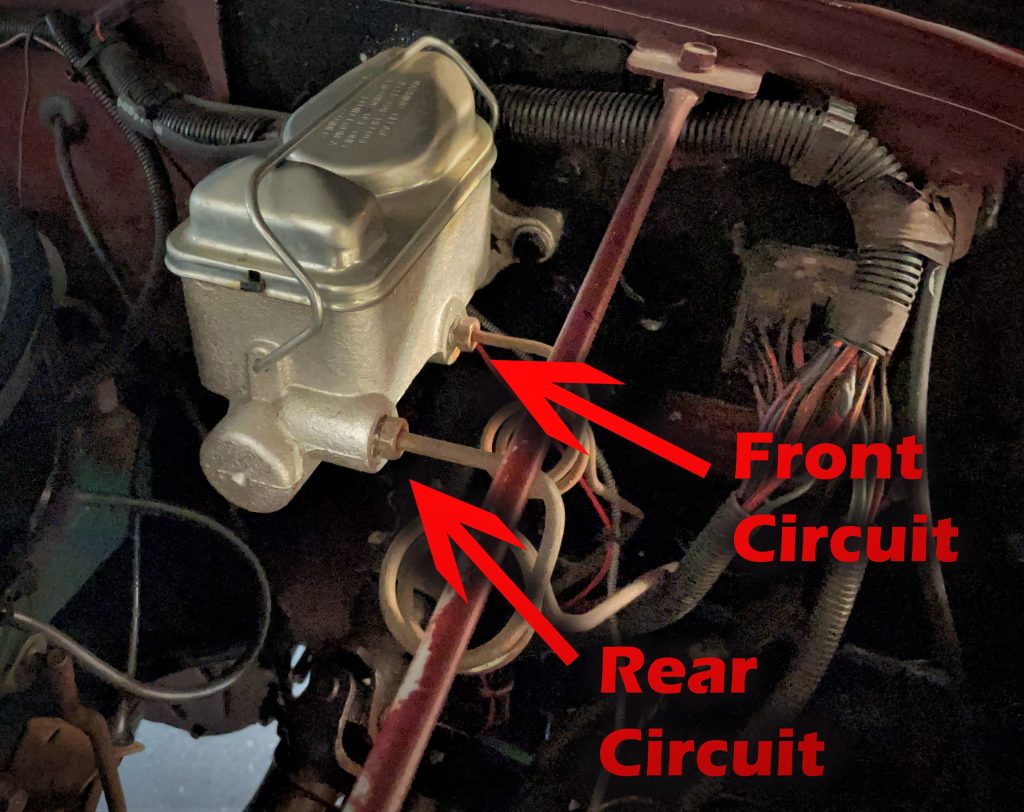

The obvious play here was to build in some sort of redundancy to the hydraulic brake system. But running a complete parallel system would’ve added a significant layer of complexity to the automobile, so engineers devised a simple solution: Treat the entire brake system as two distinct pairs of independent circuits.

Often times—but not always—in a dual-circuit brake system, the front hydraulic lines and brake components are completely isolated from the rears. That means, if the front brakes suffered a catastrophic pressure loss, the driver could still rely on the rear brakes to bring the vehicle to a stop, or vice versa.

While there’s still a noticeable loss of stopping power, it’s way, way better than losing all hydraulic pressure. And since the driver can instantly sense there’s something awry, it allows them to safely slow the vehicle the minute a problem is detected.

Diagonal Split Dual Circuit Brake Systems

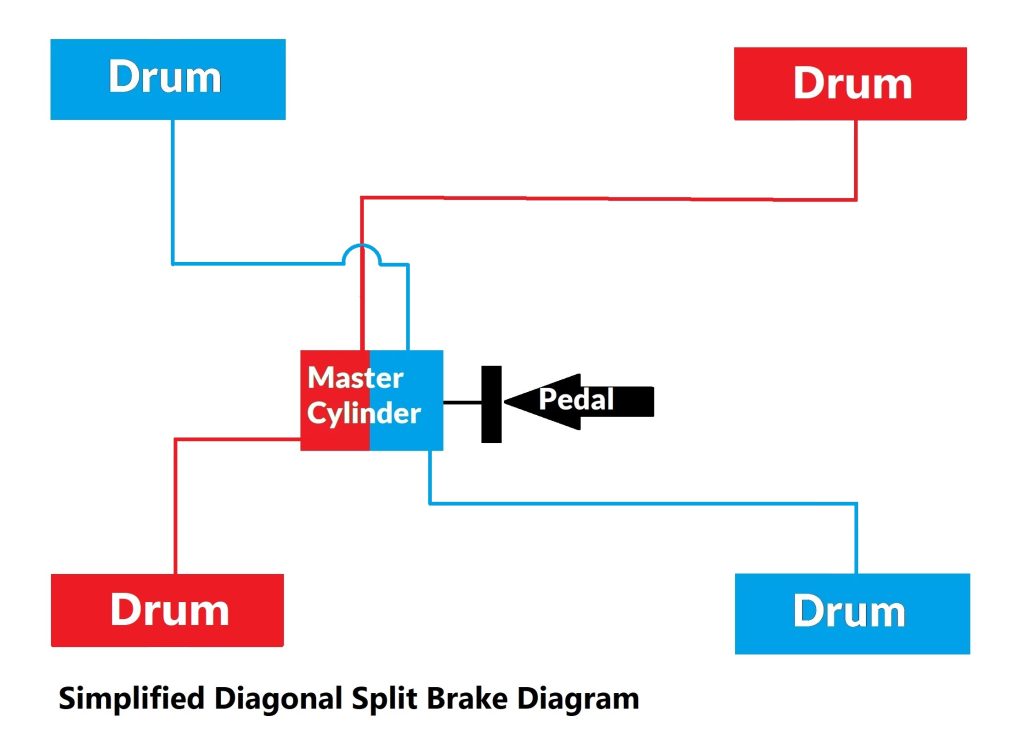

There’s another style of dual circuit brake systems that’s worth mentioning too: diagonally split systems.

As the name implies, instead of splitting the front and rear breaks into distinct circuits, a diagonally split system pairs the front right and rear left brakes, and vice versa. While slightly more complex than a front/rear split, a diagonally split system means that stopping power is more evenly distributed in the event of a failure.

And believe it or not, both front/rear and diagonally split brake systems are still very much in use today—albeit tweaked somewhat when disc brakes became the preferred front brake design. So let’s talk about that.

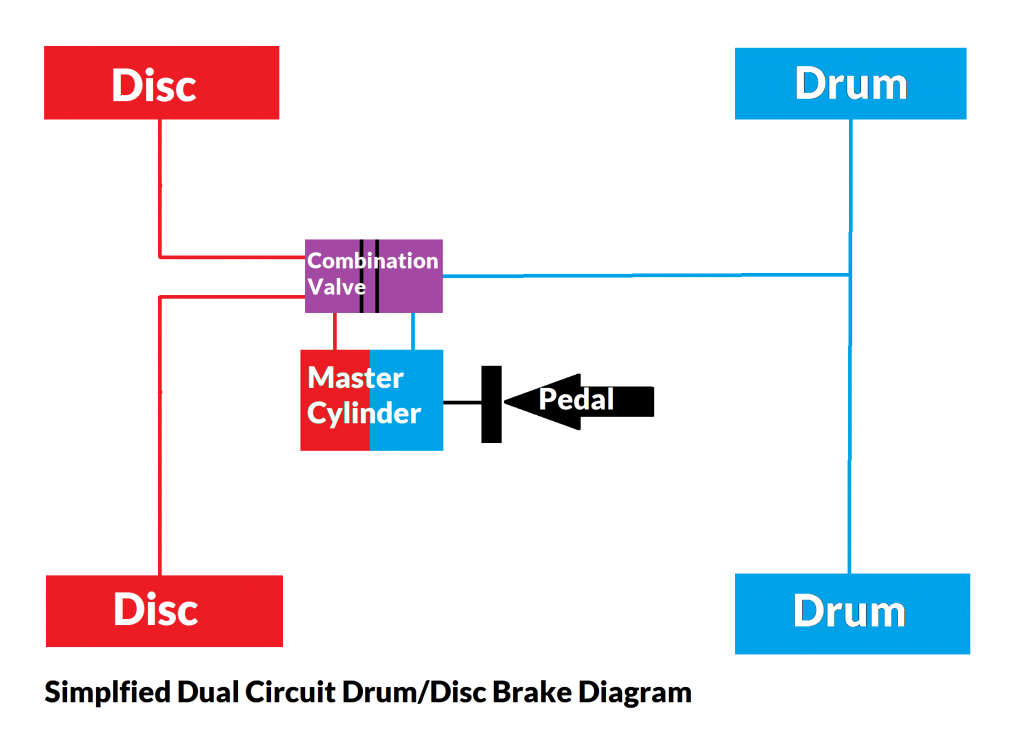

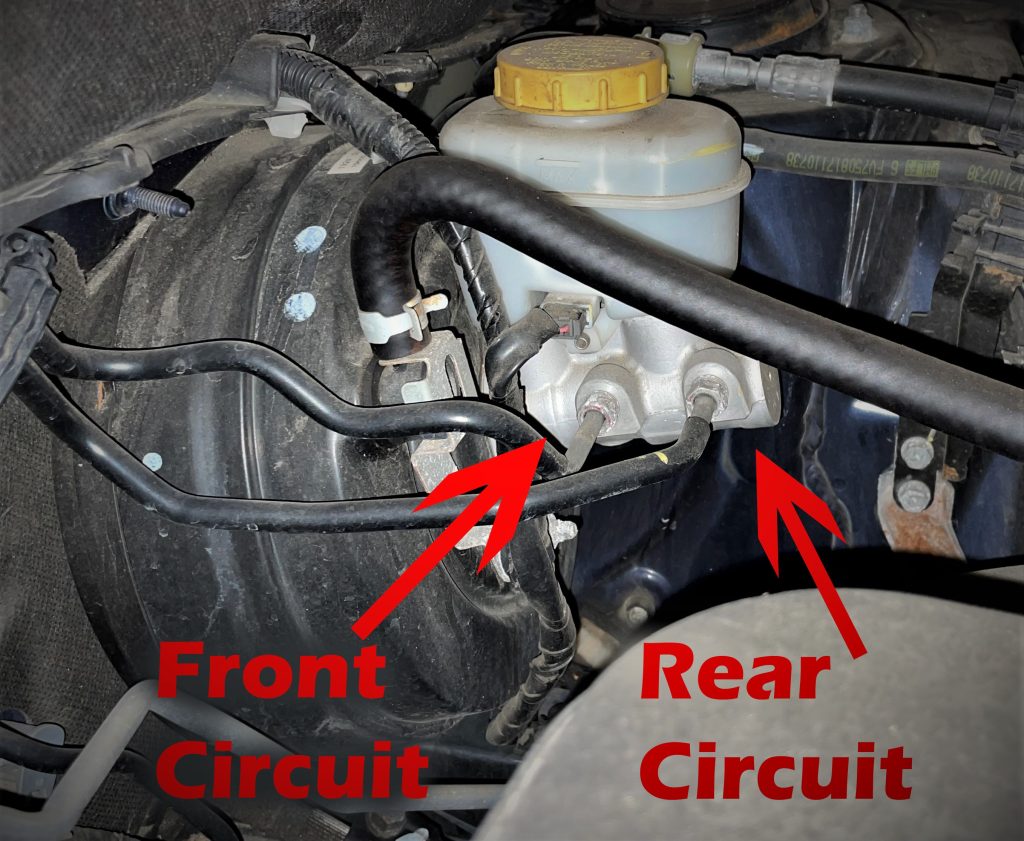

Dual-Circuit Drum/Disc Brake Systems

When automobile manufacturers begin to adopt front disc brakes in earnest during the mid-to-late 1960s, it presented a problem to the traditional dual-circuit brake system. Given the different physical operation of drums and discs, it meant that Pascal’s Law of evenly-applied hydraulic pressure hits a snag. To meet the slightly slower response of drums versus discs, engineers installed a metering valve downstream from the master cylinder. It essentially delays the discs for a split-second to allow the drums to engage at the same time.

But there was another issue too. The design differences between the two brake types meant that drums were subject to increased pressure during panic stops. This often resulted in drivers locking-up the rear drums during those hard stops. That’s a pretty big deal, because when the brakes lock up, stopping power is greatly decreased and the driver risks losing control of the vehicle.

A brake proportioning valve addresses this issue. Like a metering valve, it’s put downstream, immediately after the master cylinder. The valve decreases brake pressure to the drums during high pressure spikes (like when you stab the brake pedal in a panic stop).

You’ll typically find a brake proportioning valve and metering valve in vehicles with a disc front, drum rear setup–often combined into a single valve assembly. While they’re technically called combination valves, you’ll likely hear them simply referred to as proportioning valves.

On stock setups, the proportioning valve is usually permanently set from the factory. But for performance- and race-oriented vehicles, proportioning valves are often adjustable. That capability allows the driver to fine-tune the vehicles’ front/rear brake bias.

How do I Know If I Have a Single- or Dual-Circuit Brake System?

In 1967, the U.S. federal government mandated dual-circuit brake systems in all new vehicles. So, if your car is a 1967 model year or newer, then it’ll likely have a dual-circuit brake system. But even before that, some vehicles had begun using a dual-circuit setup. The good news is, if you’re unsure, it’s probably going to be really easy to check.

Pop your hood and find your master cylinder. It’ll typically be bolted to the firewall near the brake pedal (on the opposite side). Once you locate it, take a look at how many brake lines exit the assembly. If there’s only one, then you’ve got a single-circuit system, if there’s two, then it’s a dual-circuit system.

It’s worth pointing out that earlier dual brake systems often maintained two distinct fluid reservoirs within the master cylinder housing. This meant that you’d have to monitor both brake fluid levels. While this dual-reservoir setup was, at worst, a minor inconvenience, disc/disc vehicles nowadays usually just have a single reservoir that both circuits draw fluid from.

I Have a Single-Circuit Brake System, Should I Change it to a Dual-Circuit System?

For starters, do you drive the vehicle often? If it’s a regular cruiser than you should seriously consider retrofitting a dual-circuit brake system. It’s a vital and sensible modification that can go a long way towards mitigating a catastrophic brake failure. While all vehicles are different, in many situations, the conversion is relatively straightforward, so don’t expect to chop up your vehicle body or drill a bunch of extra holes. And there will be very little visual impact—if you’re worried about the vintage aesthetic of your engine bay, a dual-circuit master cylinder swap is relatively innocuous.

Again depending on your vehicle, a dual-circuit conversion could be as simple as replacing the master cylinder and running some extra hard line. That’s assuming, of course, your vehicle has a drum/drum brake setup. Obviously if you’re contemplating a disc brake conversion kit, you’ll have to upgrade to a dual-circuit system anyway.

Honestly, the only real reason we can think of to retain a single-circuit brake system is in situations were originality or period-correctness is critical. You probably don’t want to upset the originality of something like a high-dollar concours car. But for most classic cruisers, a dual-circuit brake system is almost always a sensible, prudent upgrade.

[…] fusion: the classic lines of a vintage truck coupled with the modern drivability of things like dual circuit brakes and solid state ignitions. Add excellent aftermarket parts support and dead-nuts simple repairs, […]

[…] because a hydraulic clutch and a brake system rely on the same basic principles of hydraulics and share many similar system components. In fact, […]

i think the labels are switched. the primary system (front for f/r split which is closer to the brake booster) goes to the front. the secondary system, the system away from the brake booster goes to the rear

Oh wow–you’re exactly right. Good catch. We’ve made the adjustment and updated the images. Thanks for the heads up!

Enjoyed the article I recently converted my 91 c1500 to 4wheel disc brakes and replaced the M/C and the combination valve as well but had to change fitting to fit the combination valve after that it was fairly easy oh Thanks for your article on the brake system.

I thought at one time the dual brake system combined a front left and right rear brake in one circuit and front right and left rear in the other circuit. The thinking the loss of one circuit would not be as significant as having only rear brakes. True?

Darn good question–and you’re exactly right. While we can’t recall every application, some automakers use(d) a “diagonal split” system instead of a front/rear split. We’ve seen that setup on some AMCs, and late model Dodge/Chryslers, specifically front-wheel drive vehicles. Very good observation and we’ve updated the story to add some more info on that setup. Thank you for reading and leaving the comment.