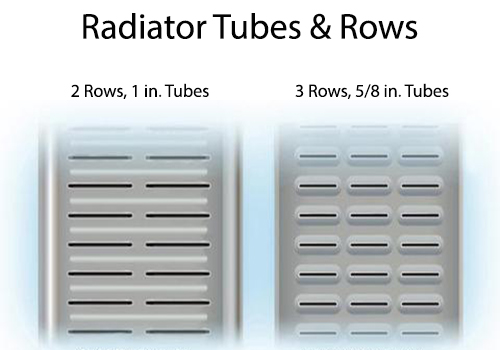

Cooling Basics – Row Quantity vs. Tube Size

In the radiator core, coolant flows through tubes. The tubes are joined together by the fins. More heat can be exchanged when there is more tube-to-fin contact area.

One way to increase the contact area is to use more tubes. This is accomplished by adding another row. Another way is to use larger tubes.

Row Quantity

The number of rows is often referred to as the core number. For example, a 4-row radiator can be called a “4-core” radiator.

- A 1-row radiator has one row of tubes.

- A 2-row radiator has two rows of tubes.

- A 3-row radiator has three rows of tubes.

- A 4-row radiator has four rows of tubes.

Tube Size

The tube size listed is the width of the tube. Wider tubes have more surface area. This means they can dissipate more heat.

How does this affect performance?

In the old days, with copper/brass radiators, more rows meant more cooling. However, it also made the radiator thicker which adds air restriction, making it less efficient. It is also harder on the fan. For mechanical fans, this means more parasitic power loss.

More rows also means the rear tubes are less effective than the front ones. As air flows through the core, it picks up heat. By the time it gets to the back row, it is warmer than when it started. This means less heat can be removed from the rear tubes. As more rows are added, this becomes a bigger issue.

Aluminum radiators have helped to solve these problems. Because aluminum is stronger, the tubes can be wider. This means more contact area without significantly increasing the thickness of the radiator.

For example:

- A 2-row radiator with 1 in. tubes will have more tube-to-fin contact than a 3-row radiator with 5/8 in. tubes.

- 2 in. vs. 1 7/8 in.

- The radiators will be about the same thickness.

- The 2-row radiator will be less restrictive to airflow.

In this example, the 2-row radiator has more cooling capacity than the 3-row.

…

This is another in a series of weekly Q&A Mailbag sessions with Summit Racing‘s tech department, in which there are hundreds more. Click here to see them all.

[…] Cooling Basics – Row Quantity vs. Tube Size In the radiator core, coolant flows through tubes. The tubes are joined together by the fins. More heat can be exchanged when […] Read full article at http://www.onallcylinders.com […]

Got a question for you I have a 65 Mustang with a 302 engine in it. The motor is board 40,000 over, running 8.5 to9.0 compression. Motor seems to run hot. I had a champion 2 core Radiator . It seemed the flow of water too fast to where the water will go right through the motor. Change thermostat to 180. Didn’t help changed water pump to an eight blade high-performance. Seem to help end up having a new or three core copper seemed to slow the water in it Engine runs about 204205 consistently is there anything else I can do to enhance my cooling. I’ve also changed to a high flow electric fan which flows about 2600 CFM

You want to see a drop in engine temp relocate the oil filter to the inside frame on the drivers side. Major drop in temp. I did this on my 91 5.0l it made a huge difference.

What about staggered 4 row? You have only listed CT cores

They are CT cores but what about a staggered 4 row tubular core?