LS engines respond well to cam swaps.

It’s probably the #1 upgrade for any LS, because the gains can be dramatic. The reason is that the LS engine family, from the 4.8L up to the 7.0L, lack only one thing to make serious power — cam timing.

Factory equipped with impressive induction systems and plenty of head flow, all that’s missing is cam timing. Replacing the factory cam in a 4.8L, 5.3L, or 6.0L will make an extra 40, 50, or even 60 horsepower.

No other single change to the LS motor will gain you as much power, until you start talking about power adders.

That fancy set of CNC-ported heads is hardly worth the effort if you don’t have a good cam in the motor — the same for upgrading the intake.

The key component in any LS motor is the cam, and this holds true even after adding boost. It can be argued that the right cam is even more beneficial with the presence of positive pressure.

To illustrate that boosted LS engines respond favorably to changes in cam timing, we set up a test with a Summit Pro LS Stage 3 turbo cam.

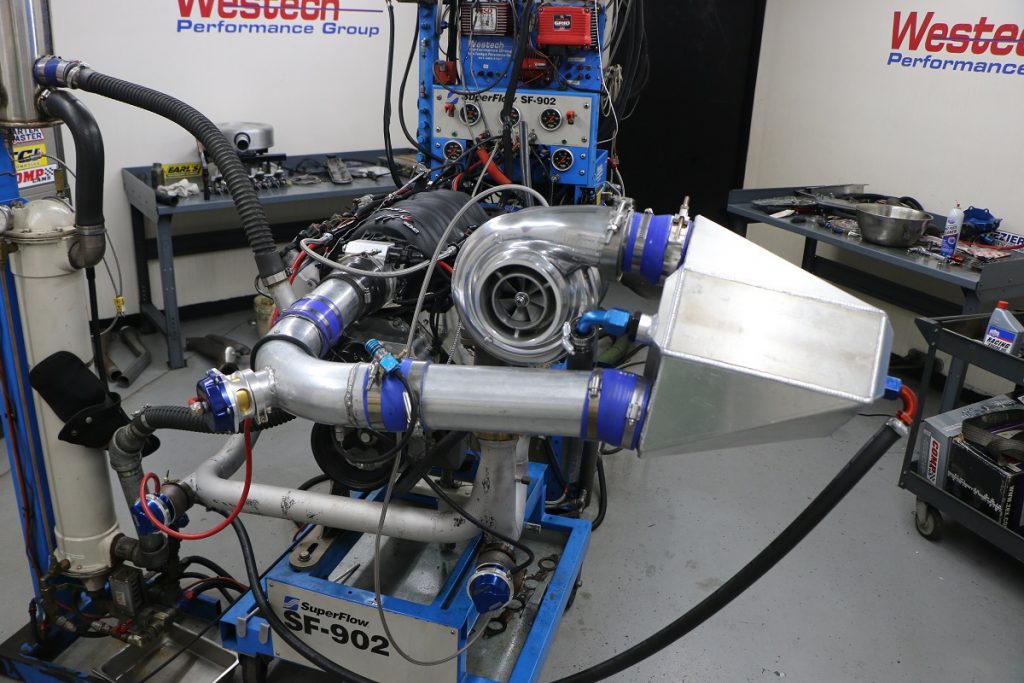

The test involved running a turbocharged 5.3L on the dyno with the stock cam, then again after swapping in the stage 3 turbo cam.

Why choose the 5.3L as the test mule?

The 5.3L is the go-to motor of choice for LS enthusiasts, primarily because it is the most available and most cost-effective.

Many people want an LS7, LS3 or even an LS2. Heck, most would take an L92, L76 or even an iron-block LQ4 for that matter.

The problem with these engines is that they’re hard to come by in wrecking yards, and usually command premium prices.

By contrast, the LR4 4.8Ls and LM7 5.3Ls are a dime a dozen. Complete motors can be had from the local scrap yards for a few hundred dollars.

Never has selecting a “race” motor been easier or less expensive. For this reason, we chose the 5.3L displacement for our test, though not necessarily a ratty junkyard version.

As luck would have it, we had a premium power plant at our disposal, thanks to our good buddy and fellow engine builder David Freiburger.

Freiburger’s 5.3L featured a stock block and crank, but was upgraded with forged K1 connecting rods and Wiseco pistons. The motor also sported Trick Flow cylinder heads, designed specifically for the small-bore 5.3L block.

Though the combination wasn’t stock, the results of the cam swap would be nearly identical on a stock motor at the tested boost and power level. The one final upgrade we made, mostly because it was already together and ready to bolt on from a previous test was a FAST LSXR intake and matching 102-mm throttle body.

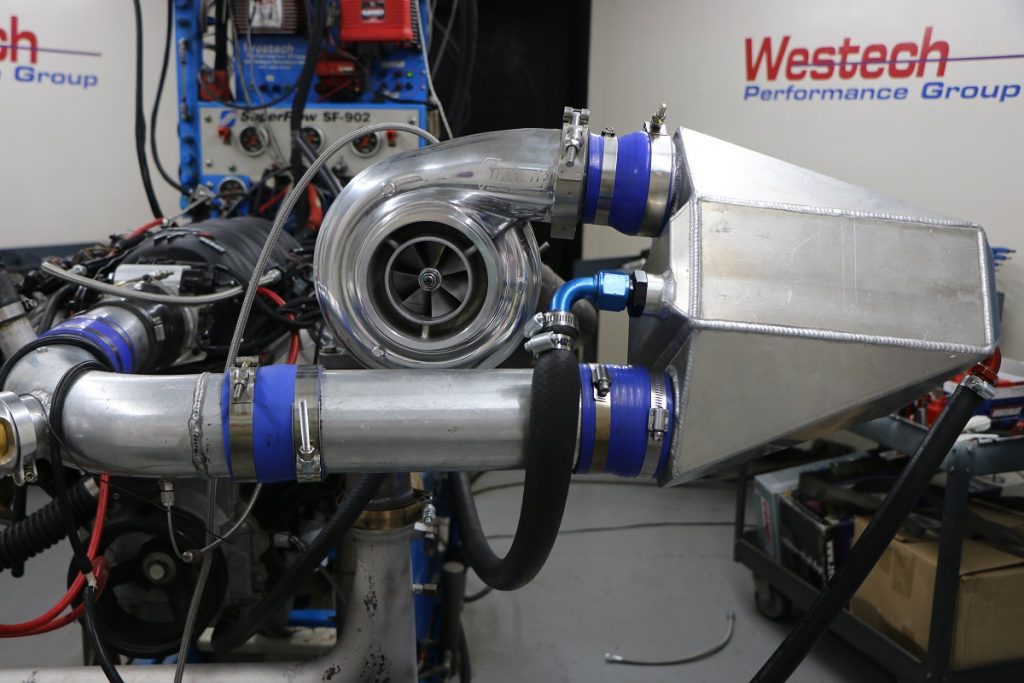

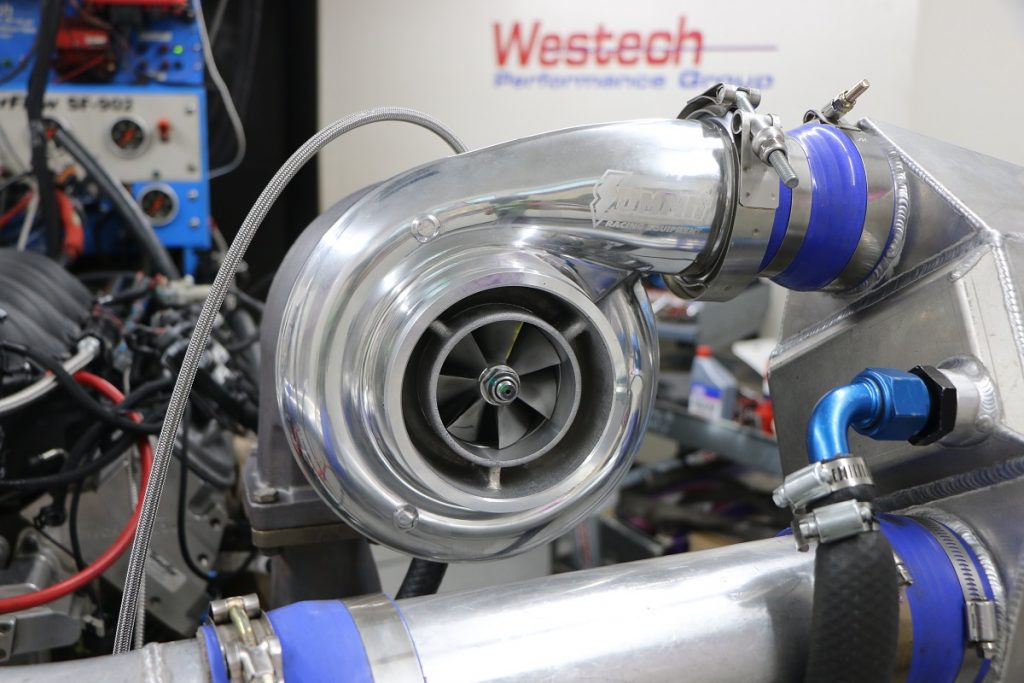

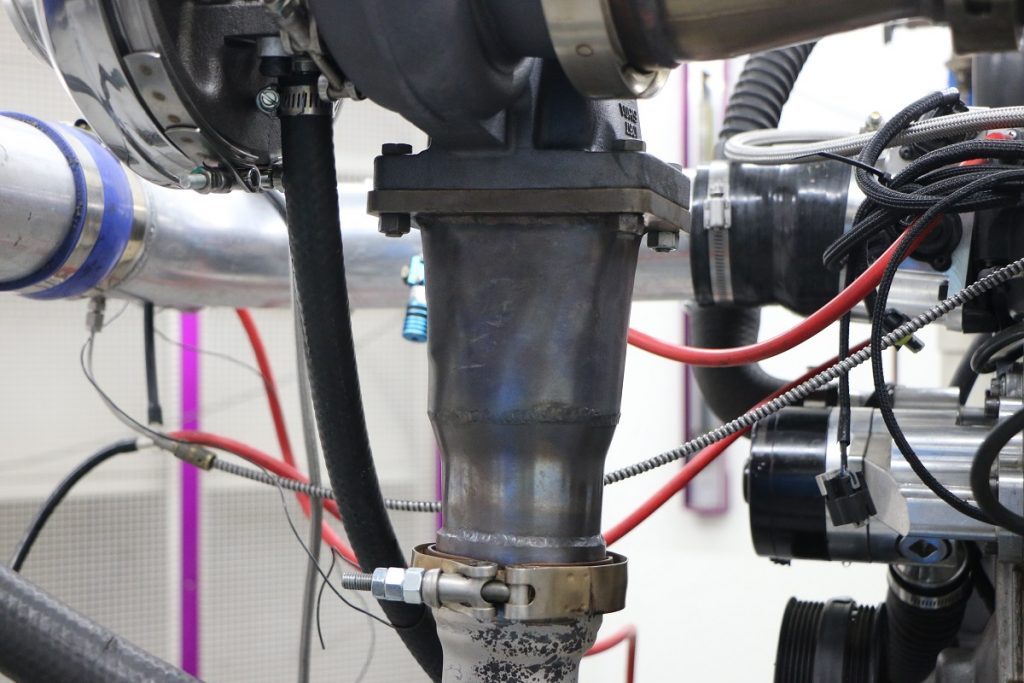

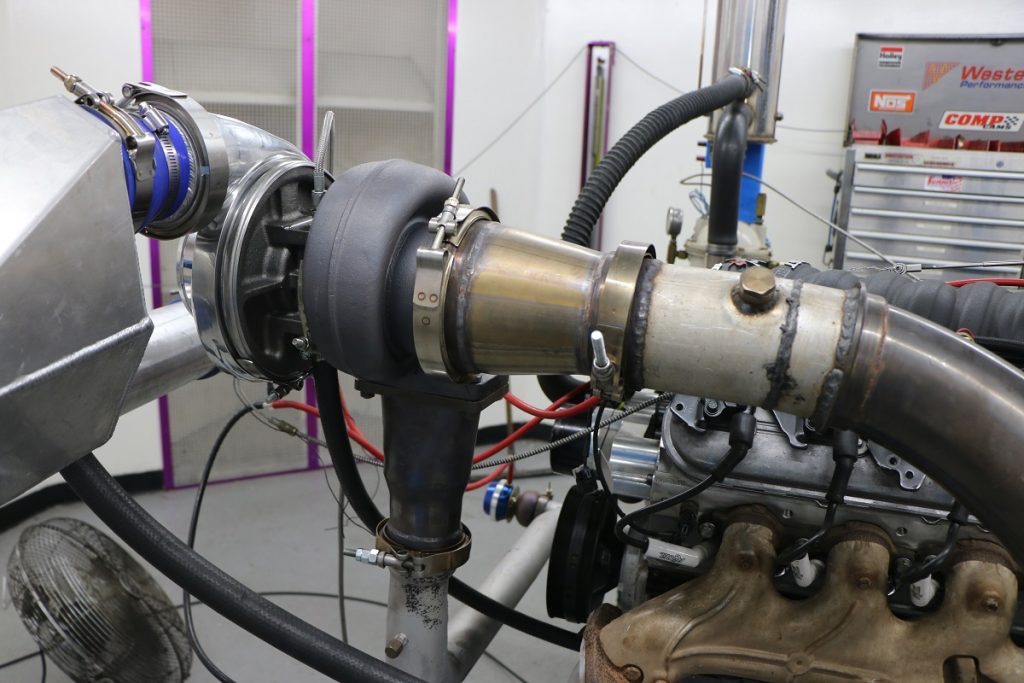

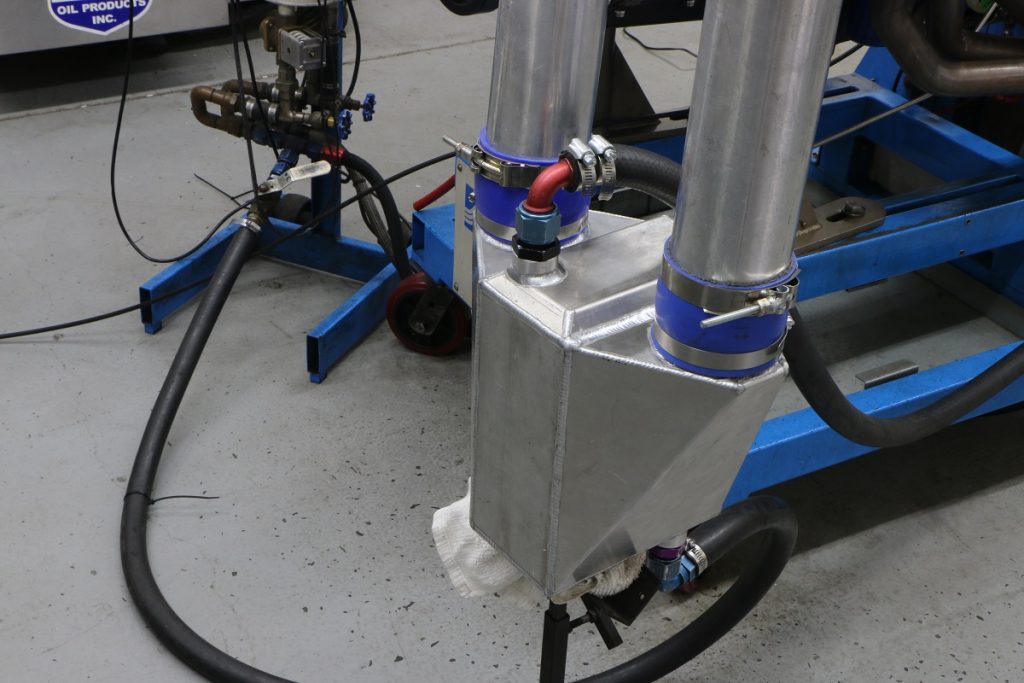

To start the test, the 5.3L was first equipped with the stock LM7 cam and supplied boost by a DIY turbo kit that featured the stock truck exhaust manifolds. The truck manifolds fed a custom Y-pipe that allowed us to mount the T6 S475 turbo from Summit Racing. Boost was controlled by a pair of Turbo Smart Gen-5 waste gates, then cooled through an air-to-water intercooler from ProCharger.

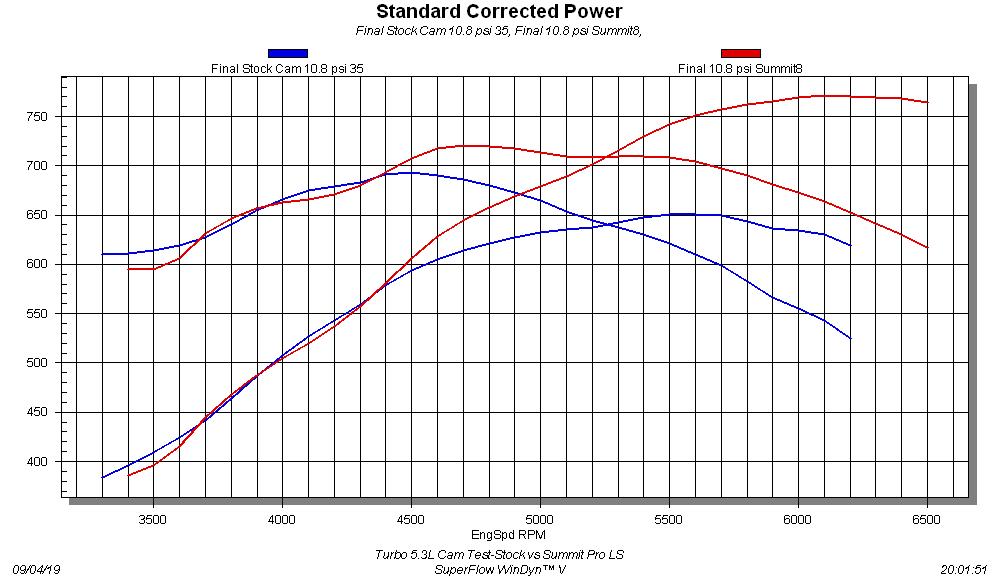

Run with the stock LM7 cam, the turbo 5.3L produced 651 hp at 5,600 rpm and 694 foot-pounds of torque at 4,500 rpm. Using a manual waste-gate controller, the peak boost reading registered 10.8 psi, but dropped slightly to 10.6 psi at peak horsepower.

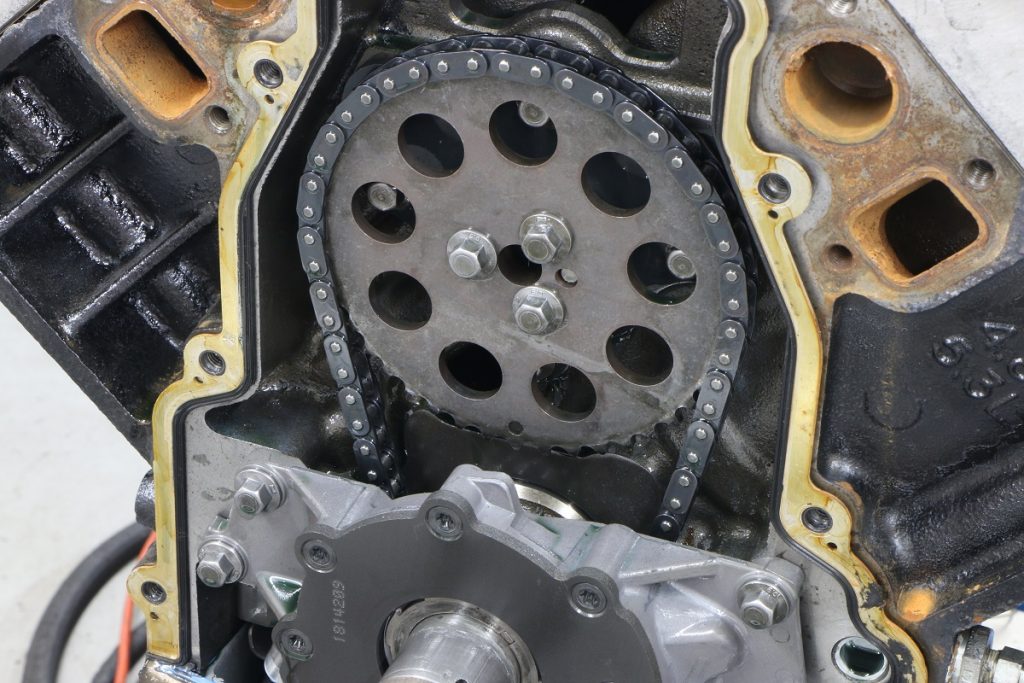

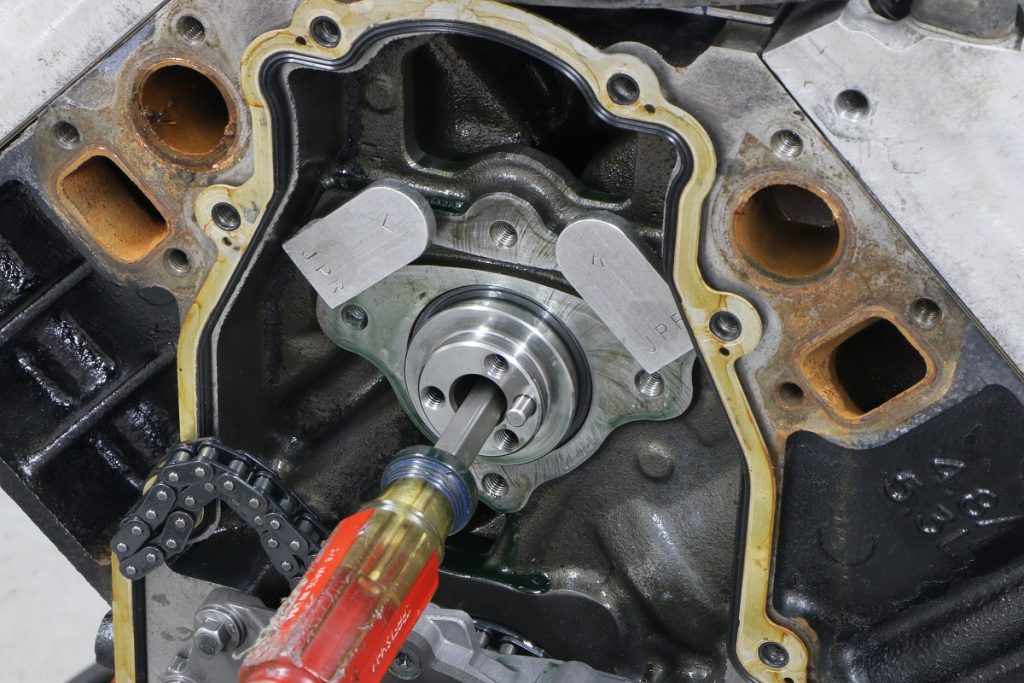

After running the stock cam under boost, we quickly swapped in the Summit Pro LS Stage 3 turbo cam.

This cam offered a .600/.575 lift split, a 231/234-degree duration split, and 115 +5-degree duration split.

This was a significant step up from the .457 lift, 191/190-degree duration split and 114-degree LSA specs offered by the stock LM7 cam.

Swapping cams was easy on the engine dyno, even with the turbo system in the way.

After installation of the Summit Pro LS Stage 3 cam, we ran the motor once again at the same AF ratio and timing as the stock cam. Equipped with the new cam, the power output jumped to 771 hp at 6,100 rpm, and 721 ft.-lbs. at 4,700 rpm.

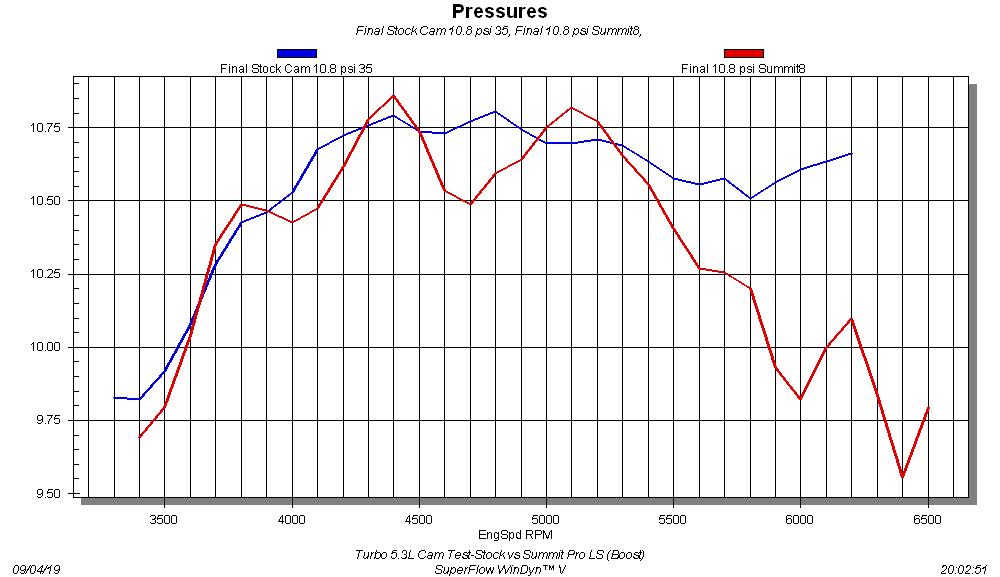

Note that our manual waste gate controller did not allow us to duplicate the boost curve exactly. The peak boost during the run with the Summit cam was an identical 10.8 psi, but fell off to 10.0 psi at peak power.

The increased power output of the new combo no doubt increased the back pressure, which in turn opened the waste gate at a slightly lower boost level. Despite the missing .6 psi of boost at the power peak, the cam swap netted a gain of 120 hp on this turbo LS application.

If you plan to run even-higher boost and power levels, the gains offered by this Pro LS Turbo cam would be greater.

The only thing better than a cam swap on an LS is a cam swap on a turbo LS.

You can make power by adding a turbo to a stock 5.3L, but why would you?

A simple cam (and spring) swap can be worth an extra 120+hp, and those gains came running a low boost level of just over 10 psi. The gains get even greater at higher boost levels. On our modified 5.3L test motor equipped with the Summit Racing S475 turbo, the stock cam produced 651 hp and 694 ft.-lbs. of torque at 10.6 psi (at the power peak). After swapping in the Summit Pro LS cam, the power output jumped to 771 hp and 721 ft.-lbs. The gains would be slightly more (by 12-15 hp) had the boost not fallen to 10.0 psi at the power peak. Despite the slightly lower boost level, the cam swap still netted an increase of 120 hp!

These graphs show the changes in the boost curve crated by the cam swap.

We ran the Summit S475 with a pair of Gen V waste gates from Turbo Smart. The boost level was controlled by a manual waste gate controller with 7-psi springs in each gate. Turning up the boost to a peak of 10.8 psi resulted in these curves. The additional power offered by the cam swap increased back pressure in the exhaust (before the turbo), which in turn opened the gate at a slightly lower boost level with the Summit cam. The result was a peak boost reading of 10.6 psi with the stock cam at the power peak, while the boost dropped to 10.0 psi with the Summit turbo cam. This can be solved with an electronic waste gate controller to regulate boost at a desired level, but know that the gains offered by the cam swap would be slightly greater (by roughly 15 hp) had we been able to match the boost precisely.

…

Please Post a link to some Good,safe timing tables for a Turbo Gen 3 ls, with Stock cam and maybe popular aftermarket cams, using the China gt-45,s-475 !!!

im hoping the platform is old enough for this to become public knowledge!-Thank You

RICHARD HOLDENER for the Many years of informative aricles and comparison studies!-it’s been a blast!