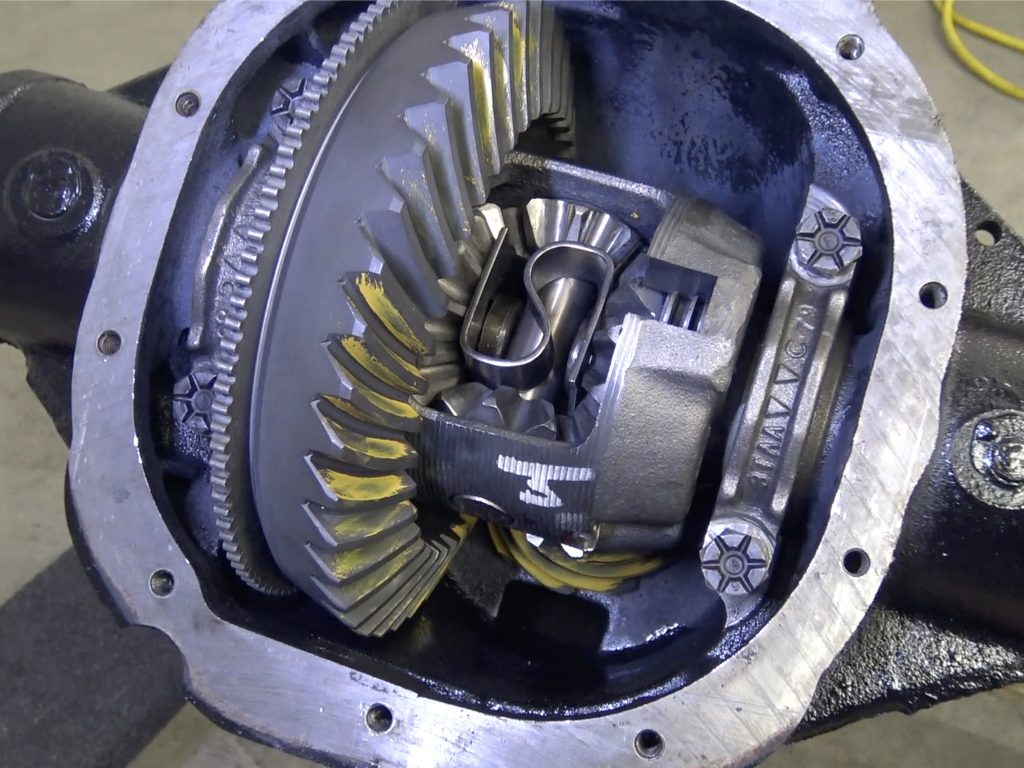

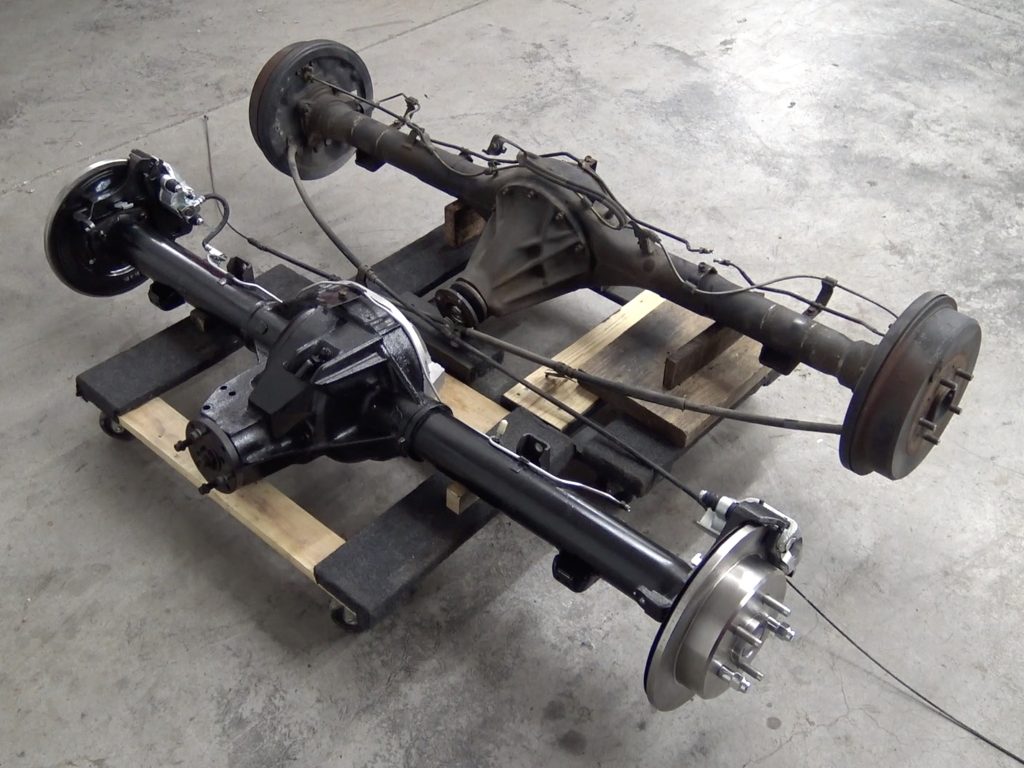

A couple of updates ago, you saw me load up our junkyard Ford 8.8 that was removed from a semi-cooperative 2001 Ford Explorer. I originally kicked around the idea to go full DIY on this diff rebuild but decided to leave it to the pros this time around. So along with the diff, I sent over the good stuff: a 3.73:1 Summit Racing ring and pinion set, ring and pinion installation kit, and differential support cover, which is strong and looks fantastic!

Driveshafts — the unsung hero of millions of vehicles roaming the Earth. Without them cars and trucks would just sit motionless, pointlessly revving their engines in a desperate attempt to move. Since we’ve changed everything when it comes to our Tacoma’s drivetrain, we need a strong, custom one built for Project Firebolt. I splurged a bit on a carbon fiber driveshaft, which offers many benefits including additional strength with less weight and better shock and harmonic absorption compared to steel or aluminum.

After tackling a variety of small “punch list” jobs, our final task in this update was to finish our turbo-back exhaust. I welded in a Summit Racing 3.5″ V-band clamp right before the muffler so I can have the option of swapping in a different muffler setup someday or maybe even bolting in a simple straight pipe, if I really want to wake up the neighborhood.

…

- Part 1: Project Firebolt: The LSX Turbo Tacoma (Part 1): The Master Plan and Engine Arrive

- Part 2: Project Firebolt: The LSX Turbo Tacoma (Part 2): Engine Teardown Time

- Part 3: Project Firebolt: The LSX Turbo Tacoma (Part 3): Engine Mods & Reassembly

- Part 4: Project Firebolt: The LSX Turbo Tacoma (Part 4): The Teardown

- Part 5: Project Firebolt: The LSX Turbo Tacoma (Part 5): Engine Assembly & Test-Fit Time

- Part 6: Project Firebolt: The LSX Turbo Tacoma (Part 6): Engine Accessories & Transmission Arrive

- Part 7: Project Firebolt: The LSX Turbo Tacoma (Part 7): More Tear Down, Steering Relocation, & 8.8″ Rear End

- Part 8: Project Firebolt: The LSX Turbo Tacoma (Part 8): The Turbo Arrives & Exhaust Build Begins

…

…

…

…

…

…

Comments