Returnless fuel systems are becoming more common in new vehicles.

As we learned in a recent Jeff Smith Ask Away! column, the increased use is due in part to tightening federal environmental regulations.

Does that mean a returnless system is better for your engine than an earlier, return-style setup?

It’s an important question to answer, especially if you’re considering an electronic fuel injection (EFI) conversion.

But before we come to a conclusion, let’s understand how each system works.

Return-Style Fuel Systems

Think of a traditional return-style fuel system as an endless cycle.

Your fuel pump (electrical or mechanical) constantly pumps gas from the tank, through a regulator, to either the injectors or carburetor.

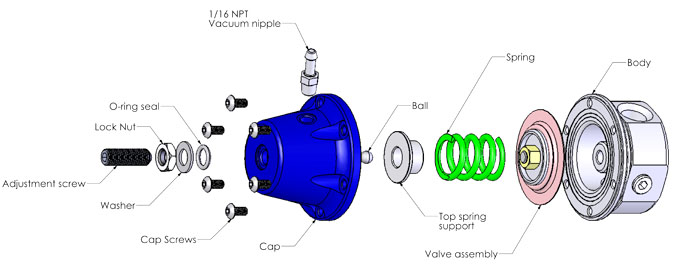

The fuel pressure regulator is charged with sending the excess fuel back to the tank. It’s a simple mechanical device consisting of a diaphragm and a spring that is typically controlled by engine vacuum. As manifold vacuum changes with engine rpm, the diaphragm moves, opening/closing a secondary passage for the fuel to exit and return to the fuel tank.

For visual learners, here’s a cutaway image of a regulator, courtesy of Turbosmart:

There are some key benefits to a return-style setup.

- Vapor lock is mitigated because the constant cycle of fuel back into the tank cools the gasoline.

- Engine tuning is easier because the fuel temperatures in a return-style system are typically more consistent.

- Fuel pressure is more stable at the carburetor or injectors because you can place the regulator closer to the delivery point.

This system does have a few drawbacks however, beyond the potential negative environmental effects.

- Return-style systems require fuel pumps to work all the time—it never shuts off as long as the engine’s running, which can shorten the life of the pump.

- Your plumbing system can become more complicated because you have to run a separate return line from the regulator to the tank.

Returnless-Style Fuel Systems

A returnless fuel system uses an in-tank pump and regulator. A single fuel line exits the tank and travels to the engine.

Pressure is controlled by a computer, which monitors a series of engine sensors to determine how much fuel to deliver.

To regulate the fuel pressure, the ECU simply adjusts the pump speed or fuel injector rate.

From an auto manufacturer’s standpoint, it requires one less fuel line. That makes it easier (read: cheaper) to design and build a car around.

It also reduces the amount of harmful evaporative emissions released from the vehicle.

So…Which One?

The short answer is a return-style system, given its mechanical simplicity and consistency.

It’s an easy question to answer on vehicles that already have a fuel return line…or at least the routing room for one. Retrofitting a returnless system can get expensive, requiring a new pump, regulator, and plumbing.

But that’s not to say your vehicle’s returnless system isn’t pretty darn good. It’s perfectly fine for OE and many high performance applications—so don’t think you need to rip out the factory setup if you’re planning some power-adders on your late model car or truck.

Replacing your OE returnless system may bring potential regulatory concerns depending on where you live— Please check your local laws/regulations.

Want to see the differences between return and returnless fuel systems in more detail? Check out this video from our pals at FAST.

My 68 440 Mopar came from the factory with a fuel return line that comes off the fuel filter canister back to the gas tank. How does that work with no regulator ( that Im aware of ?

Hey Brian, we think you’re describing a common setup on earlier vehicles. With a carburetor and a mechanical fuel pump, you’ll typically have much, much less fuel pressure, which allows the fuel filter to essentially serve as the regulator. That’s why the fuel filter in these setups is typically installed clocked with the secondary outlet (return line) above the main outlet to the carb.

The pump constantly draws fuel into the filter. When there’s excess fuel, it fills up the filter until the fuel level inside reaches the return port. When it reaches the return port, it just dumps back into the tank–super simple. Make sense?

Nothing was mentioned about system response lag when the pressure regulator / return is located back near the tank rather than up front close to the FI system.

Hey Joel, you’re correct, we only spoke in broad strokes about fuel pressure stability due to the regulator’s ability to be closer to the injectors/carburetor. If you want a more in-depth read on the fuel system stability, check out the Jeff Smith Ask Away! column we linked to in the opening paragraph.

[…] Want to learn more about return and returnless fuel setups? Read this. […]

Good morning I have a return sistum on my 2002 Expedition. How ever I have installed 2 340 stealth automotive fuel pumps because I run a supercharger. My question is what would happen if I took of the return fuel line cap from the factory.

I hope u will be able to help .

i have this PH13 Carbureted Honda SX8 1997 (return fuel system) ,coverted from mechanical pump to electric which does not have a provision for a return statem, what happens if i just t-out (use a t-coupling) from my fuel line near the carb for a return line (no regulator) would it work? would it affect fuel pressure?

any idea will be gladly appreciated

i have 2004 f150 4.6 engine 5 miles to gallon black smoke p0191 codep0451 p2196 and p2198 ireplces these still same problem Help

hello,

I googled returnless fuel system and I came hoping Id get an idea on how to overcome the problem of not being able to regulate fuel pressure on my car that has it. I want to turbocharge it and I dont know how to up the pressure, any ideas PLEASE? i cant find anything online!

Change to fuel pressure regulator. For instance bosch 3bar to a bosch 4 or 5 bar pressure regulator

Change the fuel pressure regulator. For instance bosch 3bar to a bosch 4 or 5 bar pressure regulator

I have a 72 stingray, a fuel pump with a return line. A few days ago I added a fuel pressure regulator close to the fuel rail and it helped a lot.

Heat has been a big issue and adding a heat shield under the carb helped with vapor locking. If I upgrade to a fuel pressure regulator with a return line can I ‘T’ into the return line from the fuel pump?

If so, I may put a bleed valve at the end of the carb fuel rail instead of changing the fuel regulator.

I want the gas to stay cool and plumbing is my weakness…

Hey Mike, my father has a 72 as well, ZQ3 engine, and we faced the exact same vapor lock issues that you describe (plenty other 68-72 ‘Vette owners have as well). This era of Corvette is notorious for poor venting/airflow and high ambient underhood temps, which exacerbates a lot of issues that other SBC/BBC-equipped cars of that era don’t have to deal with.

…

So before you go about re-plumbing your fuel system, let’s explore another route.

…

You mentioned heat shield under the carb, but what worked well for us was sleeving the fuel line itself. We discovered that the fuel line would droop off the Quadrajet and contact the intake manifold, which put a ton of heat directly into the line entering the carb. A heat sleeve prevented this by insulating the line to stop the direct heat soak.

…

Hope this helps.

Can you use a return style regulator without the return line (low fuel pressure) on a carbureted engine?

[…] (for a carbureted application) and no fuel is returned to the tank. It’s best to install a full return system for either carbureted or EFI as this style system offers better […]

Just installed fuel return regulator, with added fuel return line to tank, with bung. Running B/B Chevy 468, Holley elec. .fuel pump at 6 1/2 psi. With fuel pump on, it is returning fuel, and suppling fuel to carb ok, but car starts ok, runs 2 seconds,sputters for lack of fuel, and dies. Car ran fine with deadhead system before mod.

I have put an older chev truck on a 2006 Yukon chassis. I have kept all of the Yukon wiring and emissions from the 2006. There isn’t enough space to use the factory gas tank but I can get a 1995 s10 gas tank to fit. Using the s10 tank means that I need to use a different fuel pump. A 2001 Silverado fuel pump will fit in the s10 tank. The issue is the 2001 Silverado pump uses a return line and the 2006 Yukon engine/computer does not.

Can I use the 2001 fuel pump without a return line? My assumption is that the 2006 computer/sensors will tell the 2001 pump to turn on and off when the fuel rail is at the correct pressure just like it would with a 2006 pump- correct?

We make 950 rwhp in our small block turbo mustang with Holley 225# injectors. This year we have moved the fuel cell from the front engine bay to the rear spare tire well. We run a Magnafuel 750 pump mounted at the front of the car and would like keep it there. We have been running a return style system with the fuel cell in front of the car and it was very short return but now we would need to run it all the way aft, very inefficient. Can we not loop the return line back to a T fitting pre pump and have that fuel circulate at idle and use the low pressure pre pump to regulate the flow? My crew chief/mechanic is an aviation engineer and can’t understand why it needs to return all the way to the tank and this the way airplanes run their fuel systems. This is a dedicated drag car and is pushed to the start line so we don’t think heating the fuel should be an issue. Is there something we are missing?

Currently, I am running a 12-305 (255LHP) in-tank fuel pump, self-regulating to 58 PSI, no return line required. It is good for 550 HP and my engine may put out as much as 650 HP. Can I switch this pump out for a (350LPH) Fuel Pump, and will it still regulate at 58 PSI without an external regulator?

1990 Ford F150 351w E4OD Removed all computer components all EFI. Full manual position shift (micro switches on shifter, one toggle switch for O.D.) Blowhat with vortech 10 lb. boost. Fuel system vapor locked quite often. Installed fresh air system with ducting to solve the problem of heat in the fuel lines also insulated headers to help with engine compartment heat. Non-recirculating fuel system works great now. Low pressure Holley electric fuel pump with a static fuel pressure setting a 8 p.s.i. Used the o.e.m. vapor canister to keep the tank from pressurizing. High volume high pressure oil pump and two oil coolers also keeps the blower and engine heat controlled, 3 core solid aluminum radiator keeps a consistent 185 degrees O.T. Little bit of experimenting kept it simple and cost to a minimum.