When it comes to reworking the brakes on your car, two things seldom come into consideration: your master cylinder and pedal ratio. And those are two factors that are absolutely critical to your brake system performance. The brake pedal acts as a lever to increase the force the driver applies to the master cylinder. The master cylinder, in turn, forces fluid to the disc brake caliper pistons or drum brake wheel cylinders.

Take a close look at a brake pedal. You’ll find that the pivot point (where the pedal swivels) and the mounting point for the master cylinder pushrod are often rather different. If the length of the pedal or the distance between the pushrod mount–or a combination of both–is changed, then there is a change in the amount of (leg) force required to energize the brake master cylinder. This is the mechanical advantage of the lever or in simpler terms, the “pedal ratio.” There is a mathematical equation that helps you figure it out:

Input Force X Pedal Ratio / Brake Piston Area = PSI

The formula essentially figures out the amount of force exerted by you through your leg times the pedal ratio divided by the area of the brake piston(s). The force is measured as pounds per square inch (PSI), and we’re told that the average adult male can exert roughly 300 pounds of force (maximum) with one leg. That’s a whole bunch! Something in the order of one-third or one-half that figure is certainly more relaxed, even in a bad-to-the bone hot rod.

Let’s look at how all this applies to activating your master cylinder. A typical manual master cylinder usually requires something in the range of 600 to 1000 PSI to function properly. You have to figure out how to transform the 100 or so pounds of relaxed leg pressure (roughly one-third of the 300 PSI as we mentioned above) into pretty big PSI figures. This is accomplished by way of a lever (the brake pedal). In order to arrive at the pressure required, changing the overall length of the pedal is possible, although it’s probably a bunch easier and usually far more practical to simply shorten the distance between the pivot point and the master cylinder pushrod mount location. That’s how fab shops modify brake pedals.

But we’re not done yet.

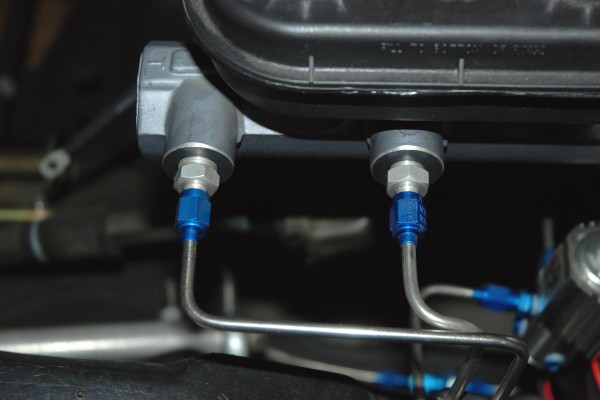

There’s something else to think about: brake line pressure. This pressure is a totally different thing than the force you apply to the pedal. That force acts in one direction and is addressed in pounds. Pressure, on the other hand, acts in all directions and is addressed in PSI (pounds per square inch). As we pointed out above, varied (pivot length) brake pedals can be used to change the force. Inside the hydraulic system, the surface area of the piston is what is affected by pressure. Decreasing the bore size of the master cylinder increases the pressure it can build.

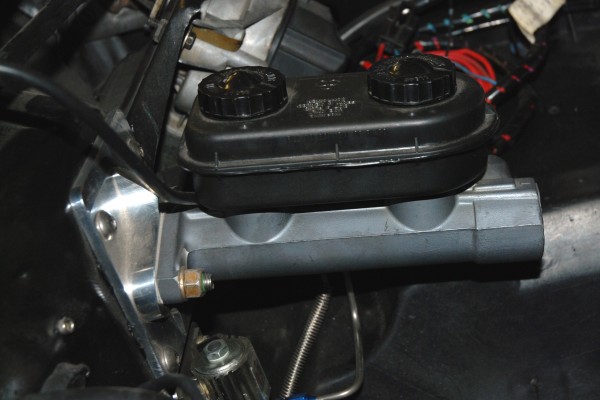

Pistons in master cylinders are specified by bore size, but there’s a catch. The area of a circle (or bore) is Pi–R-Squared. The area of the piston surface increases or decreases as the square of the bore size or diameter. The area of something like a common 1-1/8-inch master cylinder is approximately 0.994-inch. The area of an equally common 1.00-inch bore master cylinder is approximately 0.785-inch. Switching from the larger master cylinder to the smaller version will increase the line pressure approximately 26.5 percent assuming that pedal ratio hasn’t changed.

When the pedal force is increased or the pedal ratio is increased (or perhaps both at once), the stroke of the master cylinder is shortened (brake line pressure is unaffected). When the master cylinder piston size is increased, the output pressure of the master cylinder is decreased. A master cylinder with a smaller piston will exert more line pressure with the same amount of force (pedal ratio) than a master cylinder piston with a larger piston area. Because the brake line fluid pressure is working against the surface of the wheel cylinder (or disc brake piston), increasing the area of the cylinder will increase brake torque.

So, if your car needs some help in the stopping power department, or if there’s a need to reduce the pedal effort, you have a few options: A) decrease the master cylinder bore size; B) increase the pedal ratio; or C) increase the wheel cylinder bore size. If the pedal ratio is increased, there will be more travel at the master cylinder piston. If the master cylinder bore size is decreased, the piston has to travel further to move the same amount of fluid. Typically, a master cylinder has approximately 1-1/2-inch to 1-3/4-inch of stroke (travel). What you have to do is coordinate the pedal ratio with the bore size to arrive at approximately half of the stroke (roughly 1-inch) in order to make the brakes feel comfortable and stop the car safely.

I have been told, by so called experts, that the larger the master cylinder bore size would give more stopping power with less leg pressure on the peddle. If I understand this artical, my information is incorrect and a smaller bore master cylinder will give more stopping power with less leg pressure. Is this correct? Thanks

With the same pressure applied (by your leg), the smaller bore piston will have more pressure at the caliper.

right, would you walk thru mud on a soup can or coffee can? soup can provides more psi.

[…] If you still can’t diagnose the problem, then step up to a larger master cylinder bore size (we recently covered bore size in this article). A new set of brake drums and metallic shoes will also improve braking power, but you’ll […]

I have 15/16 bore MC. I have converted to 4 wheel disc brakes (67 barracuda) right stuff on the rear wilwood on the front. Cannot get a decent pedal. I feel I have a volume issue & intend to go to a 1″1/8 bore MC. Am I on the right track. If isolate front or rear lines pedal comes up good.

If volume was a thing you would have huge lines similar to fuel lines. Hydraulics is pressure. If you go to a bigger bore you lose pressure (according to the article). I too have the 15/16 MC. But I want to add a vacuum power booster to assist in my efforts.

This article is spot on!!! It has good understanding of basic hydraulics. Going on the comments, don’t people get taught anything anymore? I had this in 7th grade science.

I have a 1938 chevy pickup with 1 1/4 & 1 3/16 wheel cylinders. I converted to a dual resivor 1 ” bore master cylinder. The problem is the pedal travels to the floor before engaging the brakes. I have the shoes adjusted up far enough you can hear them drag. Do I need a larger bore master to displace more fluid ?

Sounds like you need to bleed them properly.

What is your MC stroke?

IF you have zero air in the lines and no spongy pedal then yes, you need to increase the m/c bore size to move more fluid volume to be able to move the pistons in each wheel cyl

I have the exact same issue on my 38. How did you finally fix the problem? I have 3-1/2″ of foot travel and 1/2″ of booster travel.

I am building a 4 door 32 plymouth hotrod. 560 hp want it to stop… All steel, heavier than most rods with disc brakes all around. Conversion disc brakes using 69-77 gm calipers on 11″ discs. Would like to go with manual brakes but vac assisted a possibility. Deciding on master cylinder- 1 or 1-1/8″? Pedal I have is 4 to 1 (power brake set up) Can change ratio if need be. Any input would be appreciated THANKS

Follow up question- how does a power booster affect the 600- 1000 PSI required to function properly?

I have 67 nova on grand national chassis g body every thing new stock every thing drake related rear drum new dual booster 78 blazer m/c won’t slide a tire 1/4 rear line Help. I can’t drive my 35000.00car.

I have a 97 mustang Gt with hydroboost and 1 inch bore oem master cylinder with Wilwood Big brake kit up front.The issue I have is that mine brake pedal feels to soft to Low. I will change the master cylinder to 1 1/8 bore size and hopefully it will help with the brake pedal feel. I want mine brake pedal to be more firm not soft like it is now.

i like to customize the single piston master cylinder can u help me for it to be build?

Howdy, you should reach out to the Summit Racing tech folks. They’ll be able to spec-out exactly what you need for your brake system. Click here for their contact info.

Ma car has 1 pot floating caliper 48mm diameter for a total area calculated 3619mm2, I bought 4 pot from old Jaguar xjs with 4x48mm pot, total area calculated 7239 exactly double, standard master cylinder is 22.2mm diameter, how can I calculate the new master cylinder? The pedal still remain the same, thank you

I have a 1933 Singer with a 5 to 1 pedal ratio a 1inch bore m/c 1 inch bore rear w/cyl on single leading shoes 15/16 inch front w/cyl on twin leading shoes, should this give the right balance.

I have a wilwood 7/8 bore master cylinder with 3/16 brake line and chevy meteric 2.5 inch front calipers and ford 9 inch rear drum brakes the brake pedal feel is good with one pump but gets higher when pumping the pedal but even then the vehicle does not lock up the brakes and only slowly stops can not panic stop . I have manual proportioning valves front and rear the adjustment of them makes no difference what is my problem? do I need to change the master cylinder bore?

this might just be the worst article I have ever read. caliper piston size effects line pressure? that is only the beginning. you guys really should take this down. it is only going to confuse people?

the article states master cylinder bore size affects pressure and is 100% accurate