A little while ago, we ran a story that mentioned how some spark plugs use a built-in resistor to help suppress electrical interference, so that vehicle electronic components (like radios or ECUs) can work properly.

And you can include digital gauges and displays in that mix too.

So with some help from New Vintage USA, we wanted to cover the topic of electrical interference, with a nod to your vehicle’s gauges.

A lot of the information in this story was plucked right from the Technical Resources on the New Vintage USA website. You should check it out—it’s packed with tons of good tech stuff.

Too much RFI or EMI creeping into your gauges can cause erratic, inaccurate readings. Or they may simply just not work at all. If you’re dealing with some of these electrical phantoms in your ride, this article may help.

What’s the Difference Between EMI & RFI?

For starters, you’ll typically see electrical interference referred to as either electromagnetic interference (EMI) or radio frequency interference (RFI). Truth is, RFI is a sub-set of EMI. EMI covers a massive spectrum of frequencies, whereas RFI refers to interference contained within a narrow slice of the radio wave spectrum. You’ll also here interference casually referred to as electrical “noise.”

Whatever you call it, too much EMI or RFI can wreak havoc on sensitive electronic components, so you’ve got to keep it under control.

Any good ham radio operator will tell you that EMI and RFI don’t necessarily behave in exactly the same way, but in the context of locating/suppressing it for this article, they can often both be addressed using similar tactics.

But keeping it under control can get tricky—by their very nature, engines produce plenty of electrical interference. According to New Vintage USA:

“The ignition system produces short impulses that generate a broad spectrum of frequencies. Other sources of EMI located within vehicles include motors that are used for blowers, windshield wipers, buzzers used for ignition and seat belt warnings, and voltage regulators that utilize points that open and close frequently. All of these devices generate interference in a frequency spectrum from the kilohertz range up to the gigahertz range.”

Methods to Help Control EMI & RFI

Yet automakers have a couple of tricks up their proverbial sleeves to help. We’ve already heard about the resistors in spark plugs, but there are other tools like resistor ignition wires, dielectric insulators, and grounding straps that all work to suppress electrical interference.

Electrical Grounding Straps

First off, a ground strap is simply a metal strip (often something like tin-brazed copper) or braid that connects your engine block to the vehicle body or frame (and ultimately the negative terminal on the battery). It’s extremely important because it serves as a quick, direct path to common ground for all the electrical components grounded to the block. Not only does that help complete the electrical circuit, a good grounding strap goes a long way towards suppressing EMI. You can often find the ground strap near an engine mount or on a section of exhaust tubing, so if you discover yours is broken, frayed, or torn, it’s worth replacing the ground strap.

EMI Suppression in Spark Plug Wires

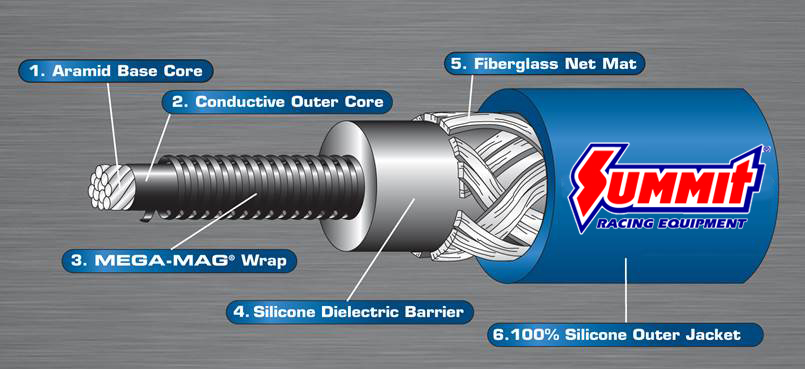

And as far as spark plug wires go, New Vintage USA offers some insight into their construction:

“Spark plug wires deliver thousands of volts to the spark plugs. To do this successfully, they need to be covered in thick insulation to prevent high voltages jumping off the wire before it reaches the spark plug and a rubber boot at each end. The boot protects the metal connectors from moisture, corrosion, oil, and other contaminants.“

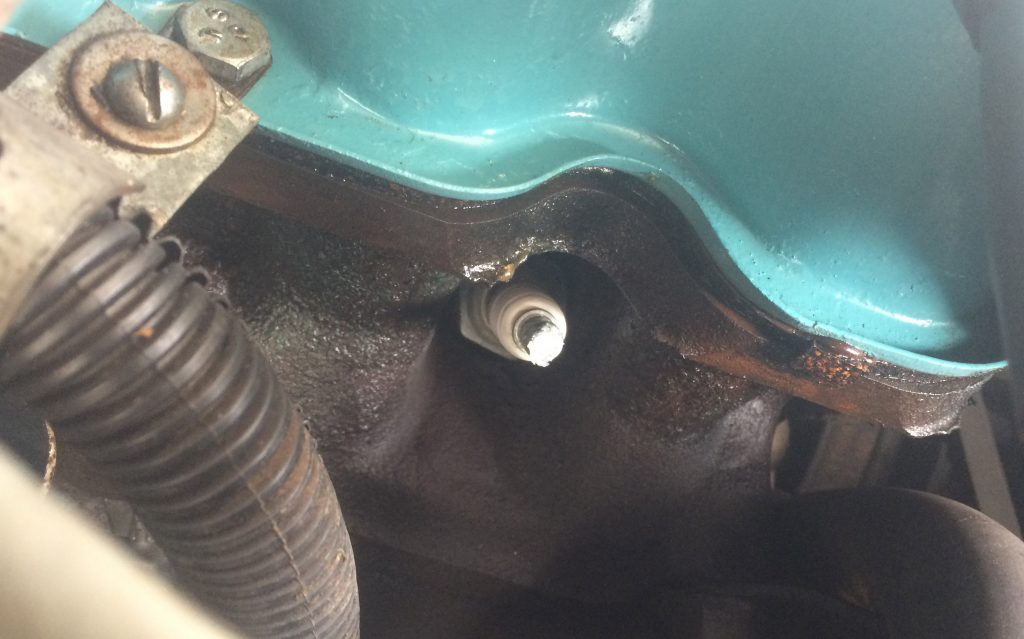

So your ignition wires and coil(s) are another good place to look if you’re battling EMI, and you can start by inspecting them for loose connections and torn insulator jackets.

It’s not all about ignition wire design and condition either—where you place them matters too. OnAllCylinders contributor Wayne Scraba wrote a lengthy article on the topic of ignition wire routing. You can read it here.

Dielectric Grease: A Little Dab’ll Do Ya

As a general rule, you’ll also want to use dielectric grease when you’re installing electrical components—and we’re talking everything from spark plugs to turn signal bulbs. We won’t spend a lot of time on the topic here, because we’ve got an entire article written about dielectric grease already. Check it out and you’ll see some other places to use dielectric grease with the goal of mitigating EMI.

Oh, and bonus points if you caught the Brylcreem reference.

Ferrite Beads Can Suppress EFI

If everything looks good under your hood, you can start addressing the individual component’s (be it a gauge, ECU, display, etc.) wiring harness. To help, the New Vintage USA folks give a special shout out to ferrite beads as a smart way to squash EMI. Here’s what they said:

“Ferrite beads prevent electromagnetic interference (EMI) in two directions: from a device or to a device. Ferrite beads are used as a passive low-pass filter, by dissipating RF energy to heat, by design. The geometry and electromagnetic properties of coiled wire over the ferrite bead result in an impedance for high-frequency signals, attenuating high-frequency EMI/RFI electronic noise. The energy is either reflected back up the cable, or dissipated as low-level heat. Only in extreme cases is the heat noticeable.”

And New Vintage USA even gives us some practical ferrite use cases too. To eliminate and reduce EMI/RFI noise you can add a ferrite bead to your wiring harness as shown:

Fighting EMI In Your Vehicle

All told, EMI and RFI are inevitable in any automobile, but it’s not too difficult to keep it from saturating your electrical systems. If you’re struggling with EMI/RFI issues in your ride, start with a close inspection of its major electrical components, like the alternator/generator, distributor, spark plugs, wires, and coil(s). If everything looks up to snuff, a ferrite bead or two can attack EMI on an individual component’s wiring harness, like a gauge, dash screen, or radio.

If you want to read more on the subject of EMI/RFI, check out this article on the New Vintage USA blog: EMI Interference (And How to Remedy It)

Do you think a ferrite bead could reduce the gremlins in my wife’s CRV Ifotainment system? (It looses its mind fairly regularly …)

If you do … Where should I put one?

Thanks!

Dave

Hey Dave, you didn’t mention what year your CRV was, or if it’s the stock head unit, but you should probably look for problems elsewhere first. Have you ever pulled the dash before, like for an HVAC service? Perhaps a connector got loose or its insulator got torn. Or maybe your ground strap was removed during an exhaust repair?

…

But! I did some quick online searching, and there seems to be quite a few folks talking online about gltichy screens in 2017+ CRVs too–so it may be a bigger problem with the infotainment system itself. Check out the threads I linked to above, does that describe your problem?

Good article on EMI & RFI

When hot rodders build a car with a standard ignition distributor and carburetor RFI is never a problem.

Non resistor spark plugs and non resistor spark plug wires deliver maximum performance to the spark plugs.

With 8mm diameter spark plug wire insulation and a large diameter distributor cap the spark plug gap can be increased to .060 inches for a good increase in performance.

The biggest mistake hot rodders make is switching from an induction style ignition to a CD ignition system.

MSD style “CD” ignitions are inferior to “Induction” ignitions below 5500 rpm. They only show an improvement above 5500 rpm.

FALSE … Most CD systems are Multi Spark until 3,000RPM . There is Definitely an Improvement of Low RPM Power as well, Main issue is the extra interference generated by the Higher & quicker voltage spikes. Throttle response is WAY more snappy with CD systems, Most who Do Not have Electronics knowledge do Not actually understand how these systems work.

Make sure you have an ignition relay