What does every boat on the lake have in common with every car on the road? The obvious answer is that they all need (say it with me) MORE POWER! Mas rapido, por favor!! Yes, my friends, every boat needs exactly what every car (or truck, or ATV, or submarine) needs—proper motivation.

“I wish my ride was just a little slower.”

No One, Ever

If there was one universal reality that binds all of us enthusiasts together, it’s the need to improve performance. We might choose different motors and different methods, but in the end, we all choose to want MORE! Such was the case with the improvements made to this already stout GM CT525 LS3-based crate motor.

Exploring the GM CT525 LS Circle Track Crate Motor

Chock-full of all-aluminum goodness, the 6.2L already had a lot going for it. But like every motor, it needed just that little something extra. Besides, every boat motor needs two things: zoomie, over-the-transom headers and a dual-quad tunnel ram!

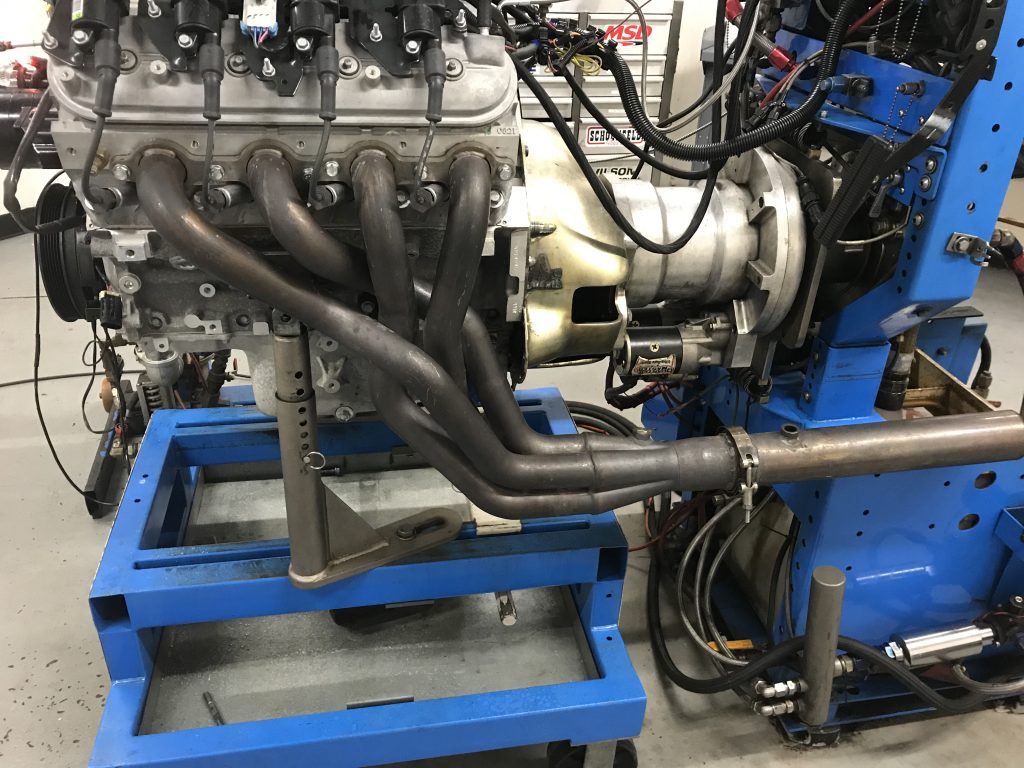

Looking at the photo of the motor and the boat (photos at the bottom of this story), we can see the exhaust was already on point.

With the exhaust portion of the equation taken care of, the induction system was next—but not before we take a look at the specs offered by the basic GM crate motor.

Though the LS engine family was offered only in fuel injected form in production vehicles, GM recognized that man does not live by fuel injection alone. There are plenty of guys out there wanting carbureted performance. What could be better than combining the advantages of the LS platform with old-school carburetion? To that end, the put together a carbureted crate combo based on the already potent 6.2L LS3.

Looking at the specs of the LS3, we find an aluminum block and heads to reduce curb weight (less weight is the same as more power). The short block combined a 4.065-inch bore and with a 3.622-inch stroke to produce a total displacement of 6.2 liters (376 cubic inches). Included in the mix was a static compression of 10.7:1, a set of rec-port heads that offered intake flow numbers of 315 cfm (enough to support over 650 hp on the right motor) and a GM ASA cam that offered .525 lift and a 226/236-degree duration split. GM topped the CT525 crate motor off with a single-plane, 4150 carbureted intake.

The Holley Hi-Rise LS Intake Manifold & MSD Ignition

As appealing as the CT525 crate motor was on paper, the single-plane intake just wasn’t going to the job done on this 1976 Rogers Bonneville TR Jet Boat.

Come on, it’s a jet boat, and the motor needed to not only offer plenty of performance, but it needed to look the part! After all, said motor was exposed for all to see, why not give them something to look at?

To that end, the GM Performance CT525 crate motor was treated to not just a Holley Hi-Ram carbureted intake manifold, but also a pair of Holley 650 XP carbs. Sure, a single 850 or 950 would suffice for the eventual power level, but why settle for just one carb, when your tunnel ram was designed to support dual quads?

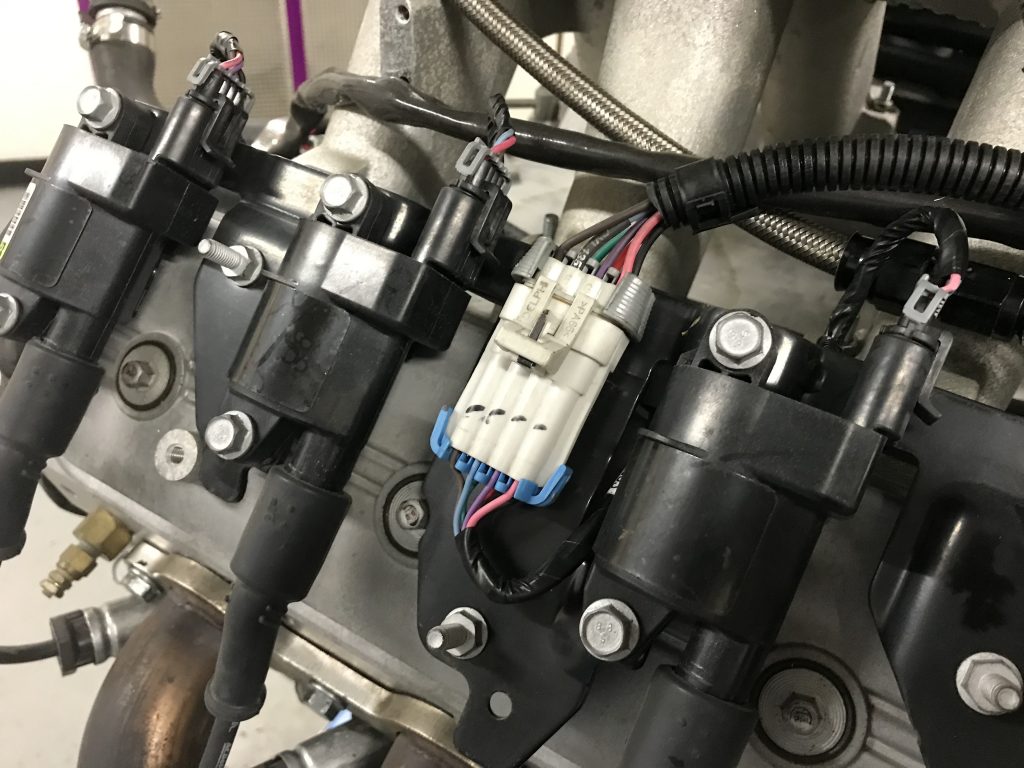

The single-plane was quickly ditched in favor of the dual quads, but, since this LS motor was originally designed for factory fuel injection, running carbs required another simple upgrade. Running carbs on the LS (any carbureted LS) was a simple matter of installing the MSD ignition controller. MSD offered controllers for either the early 24X (and 1x cam) or the later (like this LS3) 58x (and 4x cam) trigger patterns. Every bit as important was the fact that the MSD controller allowed us to dial in the desired timing curve at every rpm (including changes to map-based load).

Dyno Testing

With everything set, the Hi-Rammed LS motor was installed on the dyno and finally run it in anger.

Equipped with the dual-quad injection system and a set of 1-7/8-inch dyno headers, the all-aluminum 6.2L responded with peak numbers of 570.1 hp at 6,600 rpm and 499.4 lb.-ft. of torque at 5,400 rpm.

Yes, we know, the 499.4 lb.-ft. reading missed the 500 lb.-ft. mark by a scant 0.6 lb.-ft., but we report what the dyno showed. You can always tell your friends it was 500 lb.-ft. (and we are sure from the passenger’s seat, it will feel like 500 lb.-ft.). We like the fact that not only did the 6.2L produced 570 hp, but also that this combo was not some peaky race motor.

The worth of the motor is not measured in peak numbers alone, but in all-important average power production.

Torque production from the 6.2L exceeded 450 lb.-ft. from 4,100 rpm all the way through 6,600 rpm. In fact, the torque output hovered near 445 lb.-ft. even down to the load-in point. The Holley tunnel ram looked racy, but worked very well on this all-aluminum boat motor.

Out on the water, this carbureted LS combo should have no trouble delivering the goods, and look good in the process. In fact, the only thing that might make this combo even more impressive are twin turbos-and that is exactly what it got right after this test…

…But that, my friends, is another test for another day!

Comments