I have a 5.7L LS6 engine out of a 2005 Caddy CTS-V that dropped an intake valve with just over 50K on the odometer. The damage was not too extensive (no damage to cylinder wall or rod), just some dings in the piston and it broke the valve and shoved the tulip sideways in the seat. I want to put this engine in a ’71 Nova I have so I’ve decided to go with a stroker setup.

I got a Scat 383 kit (stock compression), AFR 205 heads, FAST EFI intake, and I plan to install a larger throttle body, a set of Kooks long tube headers, and a lighter flywheel and clutch to work with the T-56 trans. I still want the car to be a driver that I can cruise the streets without a lot of overlap that kills idle quality and creates a peaky power curve. But I also have concerns about installing too mild of a cam as that would be a waste of a lot of good parts and perhaps not achieve 500hp. I understand I should stay away from 110-degree LSA, maybe even 112 for that drivability goal. I know that mild durations with steep ramps do make power, but they also beat on the valve train. Any thoughts on a good cam for this 383?

J.J.

We stay up late at night with thoughts on good camshafts and your requirements fit right into a new lobe design from Comp that works exceptionally well. We’ll give you a little background and then get into the details for your 383.

Introducing Comp’s Low Shock Technology

A couple of years ago, Comp’s chief cam designer, Billy Godbold embarked on an amazing technical exercise with EFI University’s Ben Strader to design a cam and valvetrain that would live at 11,000 rpm. This required an immense amount of development time on a machine called a Spintron. This machine spins an entire valvetrain and measures valve action, deflection, and a dozen other variables that affect valvetrain stability. What came out of this exercise was a family of lobes that Godbold labeled Low Shock Technology (LST).

Without getting into the complex physics of these lobes, the old school procedure was to slam the valve open as quickly as possible. One way to evaluate that was to look at the duration at 0.200-inch lift and the bigger cam was the more aggressive. The problem was these lobes also tended to be very hard on valve springs. Shorter duration cams with lots of lift are also abusive of valvetrain parts. In the past the solution to control this aggressive action was to add spring pressure. But that made life more difficult for rocker arms, pushrods, and lifters.

Now enter the LST lobe, which operates in a much different way compared to the previous designs. Instead of slamming the valve open as quickly as possible right off the seat, Godbold discovered that by more gently lifting the valve initially and then later adding acceleration, that the valve spring did not incur a severe shockwave through the body of the spring. The wave was still there, but much smaller in amplitude. This meant that the valve was opening and closing. Plus, with this greater acceleration on the closing side, Godbold was able to increase valve lift in this area where it improves cylinder filling. This combination is now capable of adding power compared to older cam designs.

Testing the LST Cam Lobe Design

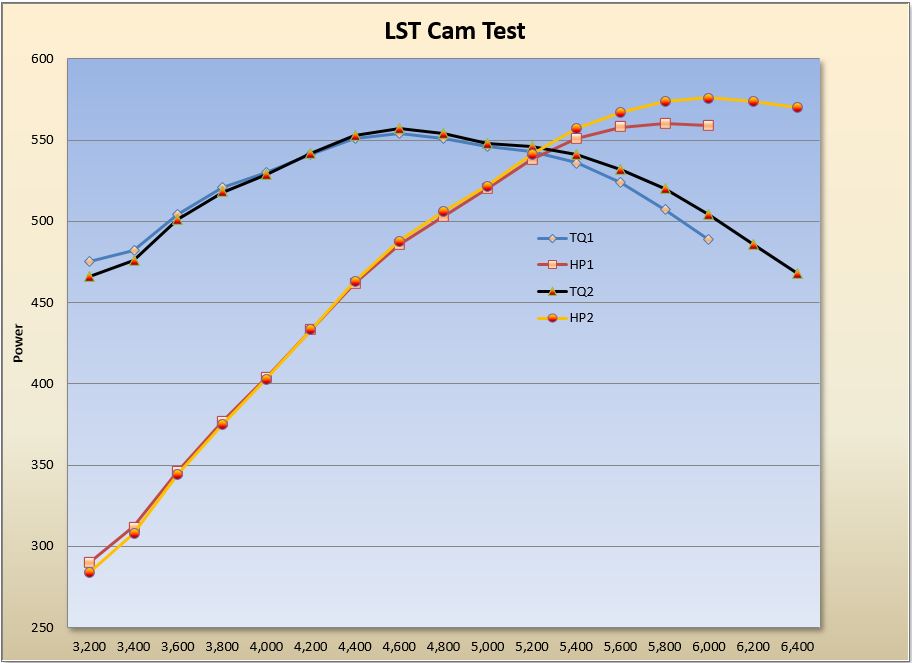

To test this idea, we took a 404ci LS stroker engine out to Westech Performance where he tested a LST cam lobe against an older LRR Comp cam hydraulic roller cam. We’ve listed the specs for both camshafts in the following chart. If you look at the duration and lift specs, you’ll notice these cams are more similar than they are different. If you were to ask an engine builder which of these cams would make more power, most would probably answer that they would be very similar. But that’s not what happened.

Our test was performed on a 404ci stroker LS engine very similar to the engine that you’re building, just with a slightly larger bore. The new cam produced slightly less torque (roughly half of one percent) below 4,000 rpm but above 4,000 the LST cam made more power with an increase of 16 horsepower at peak. That’s impressive.

If we look at the advertised specs on the LST cam versus the earlier LRR cam, you can see that the LST cam offers slightly more advertised duration compared to the earlier cam while the duration at 0.050 numbers are the same. This means the lobe is starting the lift a little earlier and ending it a little later – which makes the lobe more stable which minimizes shock values imparted into the valve.

We also need to point out that we also added Comp’s recommended dual valve spring package as part of this test. But other than the cam and springs, we did no other modifications to the engine. So by keeping the duration at 0.050 numbers the same, it’s clear that the lobe design has the effect of adding power while improving durability at the same time.

A Camshaft Suggestion

Now to address your engine, Comp has a Stage 1 LST cam for the early, 24x three-bolt cams as used in your 383ci LS stroker. You’ll find these specs in the large chart near the bottom of this post. This cam is milder than the one we used in our 404ci engine mainly because of your need to keep the cam streetable. With 223/225 degrees of duration at 0.050 combined with a wider lobe separation angle (LSA) of 115 degrees, this cam will work exceptionally well with the rest of your combination.

My guess is that this will produce very strong throttle response at low engine speeds which can be a lot of fun with a six-speed manual transmission where you can pull the engine down slightly in a taller gear and still be able to pull through with more throttle without lugging the engine. Not that we recommend you do this, of course, but with a mild cam and 10.5:1 compression, you should be able to really feel that low-speed torque especially when matched with a good set of AFR heads. You didn’t mention which heads, but a set of AFR’s 210cc Mongoose heads would work exceptionally well.

One thing that is rarely mentioned in engine combination discussions is inlet velocity. A set of cathedral port heads like your AFR’s or those from Trick Flow, Dart, and others, enjoy a substantial boost in inlet air speed that is separate from a cfm discussion that is usually used to evaluate an intake port for street engines. If we had two heads, both with the same cfm flow numbers through the entire lift curve, but one intake port was slightly smaller in terms of cross-sectional area, that head will have higher inlet velocity and will work much better for the street. So your choice of a cathedral port set of heads is a great plan.

Plus, you’re also adding the best intake manifold in that FAST LSXR polymer intake. Yes, it’s pricey but it also makes more power than any other cathedral port intake currently on the market. Your package will need larger injectors. Doing some quick math, it appears that 40 lb.-hr. or larger will suffice to flow more than enough fuel to satisfy a 550 hp goal.

Let’s also apply our simple horsepower formula to see how well your 383 will perform. We’ve seen good LS engines make more than 1.4 lb.-ft. per cubic inch. Our example 404 with the LST cam comes in close at 1.379 lb.-ft. per cubic inch. Let’s remain conservative and put your 383’s potential at 1.35 x 383ci = 517 lb.-ft. at peak torque. Generally speaking, engines lose about 10 percent torque between peak torque and peak horsepower so multiply 517 x 0.9 = 465 lb.-ft. at peak horsepower rpm. Let’s put your peak at 6,000 rpm. Then we just do the simple horsepower equation of TQ x RPM / 5252 which equals 531 hp at 6,000 rpm.

My guess is that estimate is likely conservative and that this engine could make more. But even with 530 hp, that’s strong power from a very conservative engine combination that will idle almost like a stocker and pull strong in each gear from idle all the way to 6,000 rpm.

Good luck with your combination—I think you will be pleasantly surprised with how well it runs.

Traditional vs. LST Cam Comparison

| Camshaft | Adv. Duration | Duration at 0.050" | Valve Lift | Notes |

|---|---|---|---|---|

| 281LRR HR-113 | ||||

| Intake | 280 | 231 | 0.617" | 113 LSA |

| Exhaust | 296 | 247 | 0.624" | |

| New LST Cam | ||||

| Intake | 286 | 231 | 0.614" | 111.5 LSA |

| Exhaust | 293 | 244 | 0.606" | |

| Note, that while the advertised duration is six degrees longer on the LST intake lobe, the duration at 0.050 is the same as the baseline camshaft. This reinforces the concept that the LST’s initial opening rate is slower, applying this 6 degrees of duration to both more gently open and close the valve. | ||||

LS6 LST Camshaft Suggestion

| Camshaft | Adv. Duration | Duration at 0.050" | Valve Lift | Notes |

|---|---|---|---|---|

| 278HLO15 | ||||

| Intake | 278 | 223 | 0.598" | 115 LSA |

| Exhaust | 280 | 225 | 0.600" | |

Comments