Is it better to run one big turbo or two smaller turbos?

This is a very common question among enthusiasts, and while it usually comes down to packaging, a single vs. twin turbo setup also makes for an interesting test. Especially when you compare popular, affordable turbo choices, such as the single Summit Racing S475 T6 turbo to a pair of GT3582 turbos from CXRacing.

The S475 and GT3582 turbochargers are common, and we selected them for this test because it’s an interesting comparison.

Is There a Cost Benefit to Running Single or Dual Turbos?

In addition to the obvious peak power and torque numbers, things like price and response rate also come into play. Not surprisingly, each of the smaller (universal, non ball-bearing) GT3582 turbos costs less than the larger S475 turbo from Summit Racing.

But remember, twin kits require two GT3582s—so right off the bat, boost from the twin turbo setup was more expensive.

Other Variables in Comparing Single & Twin Turbo Setups

In theory, comparing the two different turbo setups should be as easy as running the two at the same boost, air/fuel ratio, and timing, then reviewing the data.

As always, things are easier said than done, as turbo motors have a way of making things difficult.

Case in point, the intercooler. We chose to run an air-to-water intercooler on our turbo testing, but the single inlet and outlet used with the single turbo could not be run with the twins. The only way to facilitate that would be to run a Y-pipe from the outlet of the twin turbos to feed the single inlet.

Rather than do this, we elected to run a dual inlet and single outlet air-to-water intercooler with the twin turbos—but did the dual core offer more cooling than the single core used with the S475?

The inlet air temp readings (run with ambient dyno water) showed this not to be the case, but it is worth noting as a possible difference.

Along with the intercooler, another potential variable came from the possible difference in boost supplied by the turbos, as wastegate control is a function of backpressure, which can often change when making dramatic changes in turbo sizing.

As with all of the obstacles, we had a cure for this problem as well.

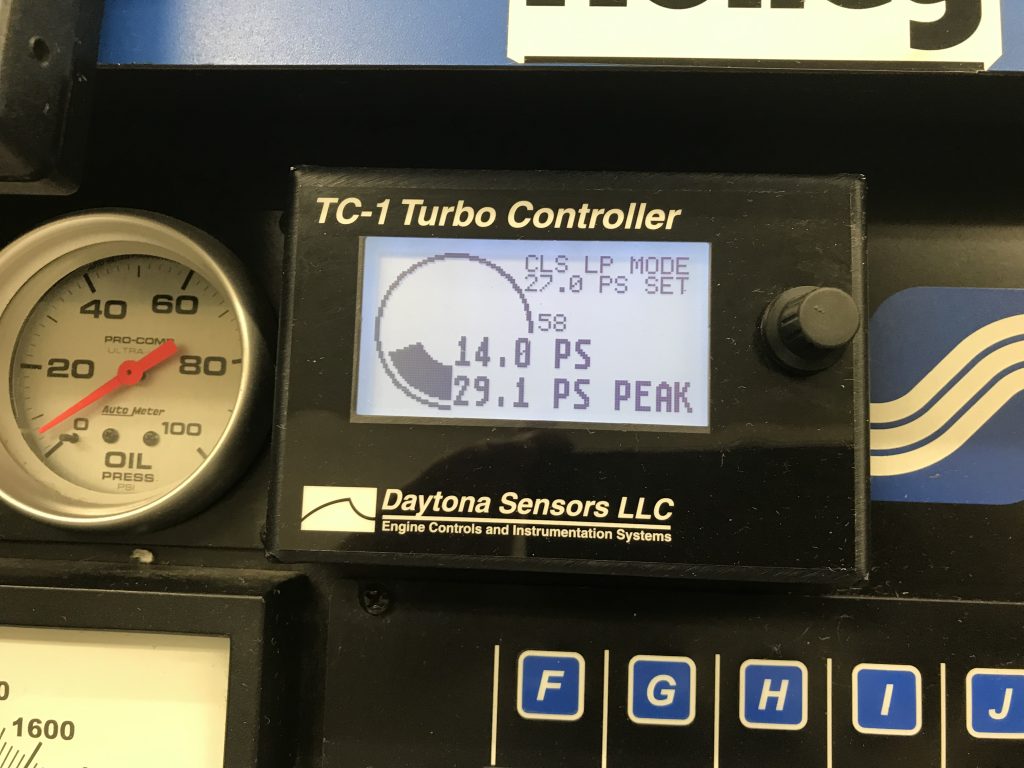

To cure the potential difference in boost pressure supplied with each system, we elected to run a TC-1 electronic boost controller. Unlike a simple bleed valve (manual controller), the TC-1 not only controlled maximum boost, it provided a consistent boost curve from each setup too. The consistency of the boost curve was obviously dependent on the response rate of the turbos themselves, but after reaching the designed boost level set by the controller, the boost remained consistent through the remainder of the curve.

The controller ensured, and data logging verified, that we received the same boost for each combination at each desired setting level, starting at 7 psi, then going up in 2 psi increments to a peak of 13 psi.

Trying to adjust a manual controller to duplicate these results would be both time consuming and problematic, as it would be nearly impossible to duplicate the same boost curves offered by each turbo setup. Backpressure has been known to play havoc on the boost curve. Unfortunately, backpressure tries open the gate prematurely, the greater the backpressure, the earlier the opening of the gate at any given boost pressure.

The 4.8L LS Test Engine

With our boost variables eliminated, we installed each turbo system on our 4.8L LS motor for testing. The 4.8L featured a stock block, crank (gen 4) rods, and forged JE Pistons. Topping the little motor was a set of factory 706 heads equipped with a dual spring upgrade from Brian Tooley Racing. The spring upgrade was necessary to work with the JFR cam that offered .595″ lift, a 224/228-degree duration and 112-degree LSA.

Also present on the 4.8L was the production (early truck) intake, a manual throttle body and a set of Snake Eater Performance (SEP) 1500cc injectors. The large injectors were chosen to work with the E85 fuel we supplied for the turbo motor. Naturally, each turbo combination was run with the same air/fuel ratio (11.5:1 gas scale) and timing values (21 degrees) to ensure consistency.

Testing the Single Turbo Setup

Run first with the Summit Racing S476 turbo, the power output of the 4.8L jumped up from 411 hp and 367 lb.-ft. of torque (NA) to 633 hp and 592 lb.-ft. of torque at 7 psi. Stepping up to 9 psi brought 671 hp and 624 lb.-ft. of torque, while 11 psi pushed the combo over the 700-hp mark to 706 hp and 666 lb.-ft. of torque.

The final jump to 13 psi had the single turbo 4.8L pumping out 751 hp and 702 lb.-ft. of torque. Now it was time for some twins!

Testing the Twin Turbo Setup

After running the big, single S475 T6 turbo, we installed the twin GT3582 turbos. Like the single turbo, the twins were run with the stock truck exhaust manifolds, but instead of feeding a common Y-pipe, the twins each received their own up pipe and 3.0-inch exhaust. Because the turbo mounts were originally designed to run T4 turbos, we attached the smaller (T3) GT3582 turbos using T3-T4 turbo flange adapters.

Boost from the twin GT3582s was run through the dual-core, air-to-water intercooler, then out to the throttle body. Like the core used on the single, the dual core was fed a steady diet of ambient dyno water. Controlled by the TC-1 boost controller, the twin turbos produced 613 hp and 560 lb.-ft. of torque at 7 psi, then 645 hp and 592 lb.-ft. of torque at 9 psi.

These numbers stepped up to 683 hp and 626 lb.-ft. of torque at 11 psi, then to 719 hp and 660 lb.-ft. of torque at 13 psi.

The Verdict?

Compared to the big, single S475, the smaller twins were down on power (751 hp to 719 hp) at the same boost level. While we might all be tempted to conclude that a single makes more power than twins, the reality is that the difference can be attributed only to these specific turbos.

Either way, adding boost and massive power to your LS has never been easier.

[…] Is it better to run one big turbo or two smaller turbos? This is a very common question among enthusiasts, and while it usually comes down to packaging, a single […] Read full article at http://www.onallcylinders.com […]

[…] with a set of stock 706 heads featuring a valve spring upgrade to go along with the mild JFR cam (from a previous turbo test). The JFR cam offered .595″ lift, a 224/228-degree duration and 112-degree […]

i have a ls 6.0 i was asking for more power 1 or 2 turbos