Why were we so excited about swapping cams on the all-aluminum L92?

Many reasons.

The first was that we had previously run the Summit Stage 4 Pro LS cam (SUM-8711) successfully on a smaller 5.3L. In fact, we broke the 500-horsepower mark with that cam on the little LM7, so we naturally had high hopes for the larger 6.2L.

We also liked the fact that the cam test on the 5.3L was run with ported cathedral-port heads, while this 6.2L L92 featured factory rectangular-port heads.

There is a lot of misinformation about cam profiles favoring one head design over another and it would be interesting to see how well these cam specs worked on each application.

In addition to the difference in displacement and cylinder head design, we enjoyed the refreshing change from running another junkyard 5.3L. The all-aluminum LS engines are hard to come by in the junkyard, as they are quickly snatched up by savvy enthusiasts and resell companies. Most of all, we were excited to see if the extra displacement and head flow allowed the healthy Summit cam profile to shine.

Full disclosure, the L92 test mule did not belong to us, though our good buddy Jason Trejo at Fort Meade, FL-based JTFab, gave us permission to go wild with it.

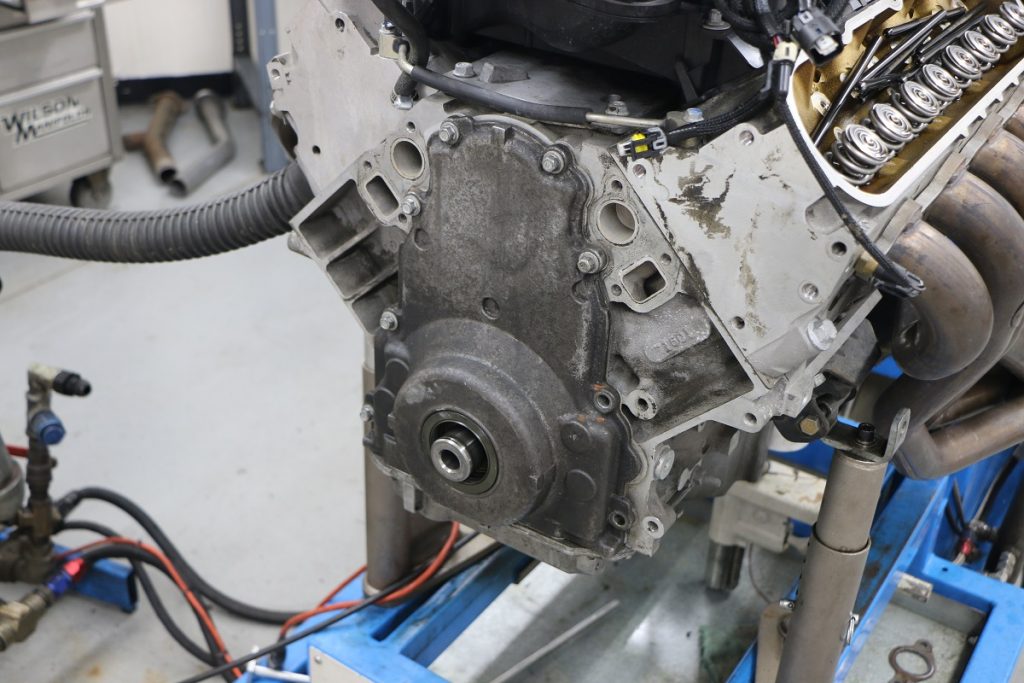

We’re sure he had boost and/or nitrous in mind, but we decided to start on the mild end of the destructive scale, with a simple cam test. After all, even though the L92 offered plenty of displacement and head flow, it, like all LS motors, was in dire need of a cam swap. Even if nitrous and boost happen to follow, every motor deserves to produce decent power before the adders come into play, right? To prep for our test, the loaner L92 required a few changes, namely removal of the VVT and DBW throttle body.

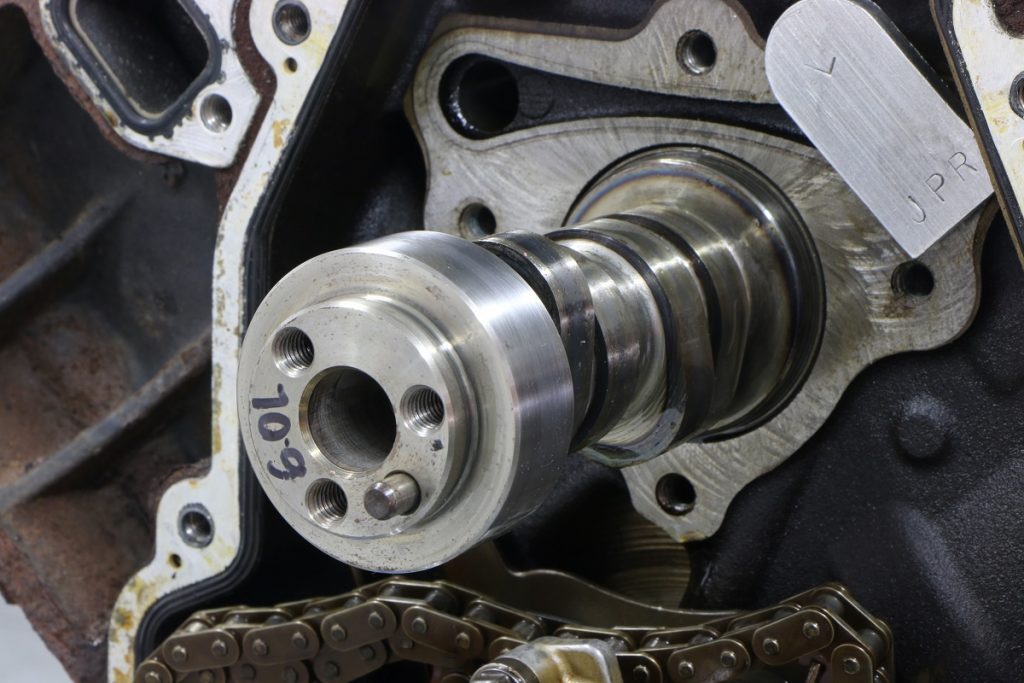

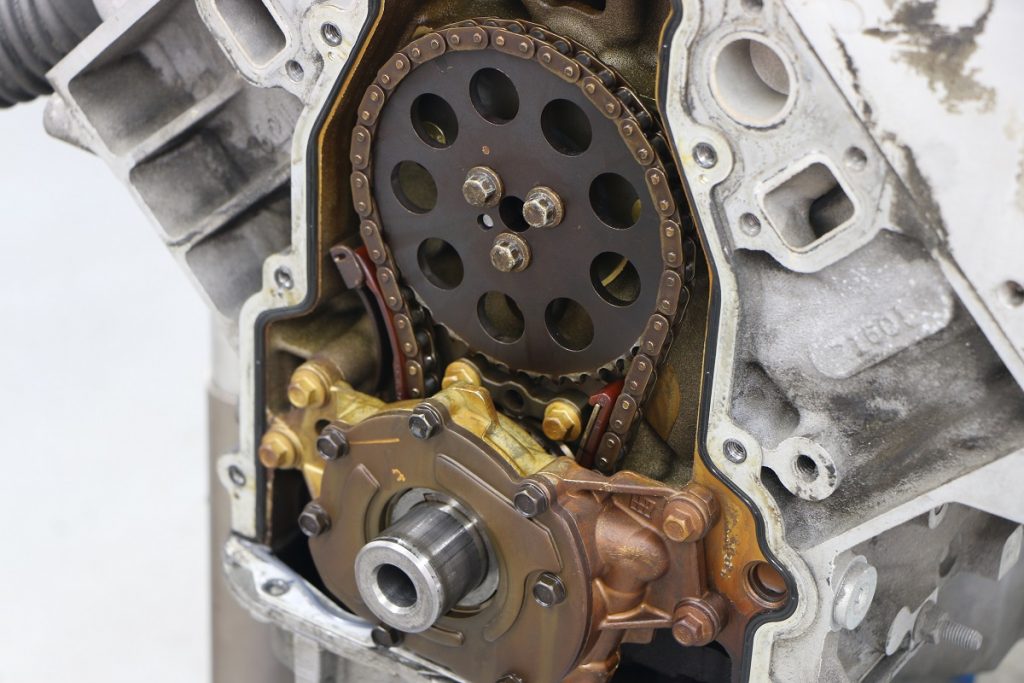

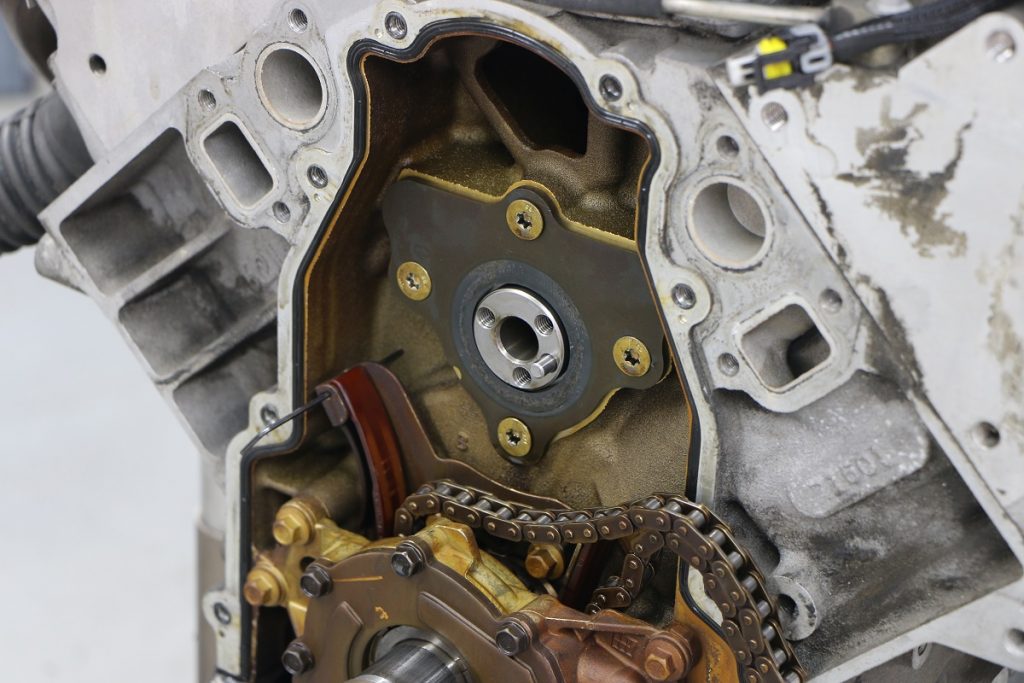

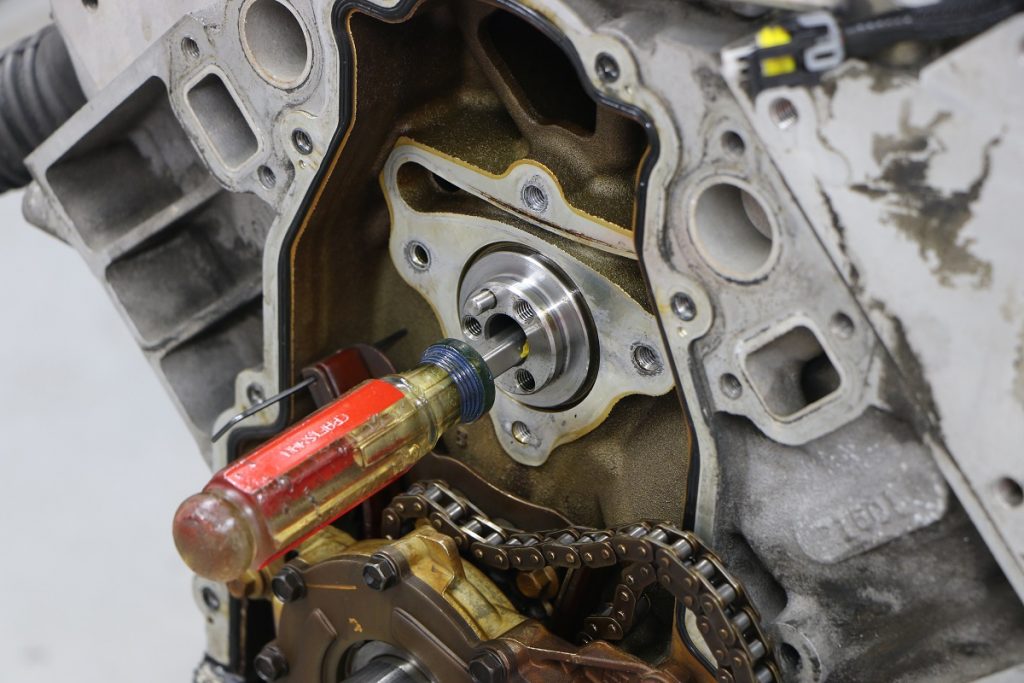

The Holley HP management system did not allow us to run the variable cam timing so it was replaced by a fixed LQ4 cam. Likewise, the DBW throttle body was ditched in favor of a manual 92-mm FAST throttle body. The final two changes prior to testing included replacement of the factory exhaust manifolds with long-tube headers and the installation of a dual valve spring kit from COMP Cams. The healthy Stage-4, Pro LS cam certainly required a spring upgrade.

After our changes to the stock engine, the rest of the test was a breeze.

All that was necessary was to dial in the tune on the LQ4 cam, then perform the same procedure after swapping in the Summit Stage 4 cam.

Speaking of the Stage 4 cam, the Summit grind was a healthy customer with a .625/.605-lift split, a 234/247-degree duration split, and 113+3.5 LSA.

Summit offers two different Stage 4 LS cams.

Compared to the slightly more aggressive Stage 4 LS grind (SUM-8709), which offered .625/.605-lift split, a 237/246-degree duration split and 113-degree LSA, the Stage 4 LS3 cam (SUM-8711) offered slightly more (.015) piston-to-valve clearance.

This is important for LS guys looking to mill their heads.

Initially, we chose the Stage 4 LS3 cam to ensure adequate piston-to-valve clearance and to work with the LS3-style heads. The increased piston-to-valve clearance was a given but, given the success of the LS3 cam on the cathedral-port 5.3L, our concern for matching the cam profile with the respective port style seemed all but unwarranted.

Could it be possible these cams work well on both heads? There we go, opening Pandora’s box!

By no means was the LQ4 cam an exact replacement for the stock VVT cam.

First, the fixed cam didn’t benefit from the extra power offered by the advance/retard features of the VVT, but we needed a starting point for our cam test.

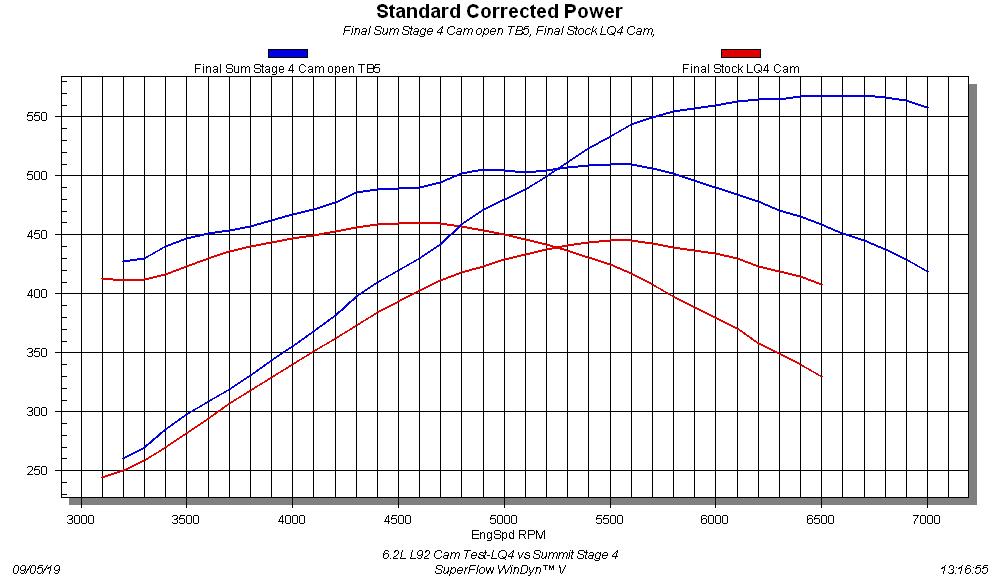

The Holley HP ECU wasn’t able to control the VVT cam, so we swapped it out for the LQ4 to establish our baseline. Run with the 1 7/8-inch headers feeding the 3.0-inch exhaust, the LQ4-equipped L92 produced peak numbers of 445 hp at 5,600 rpm and 460 (459.9) ft.-lbs. of torque at 4,600 rpm.

With our baseline established, it was time to upgrade the cam.

With the Summit Pro LS Stage 4 cam, the peak power numbers jumped to 568 hp at 6,700 rpm and 510 ft.-lbs. of torque at 5,500 rpm.

Note that the wilder cam timing pushed peak power higher in the rev range, but did so without a loss of low-speed torque. The Summit cam out-powered the LQ4 cam even down at 3,200 rpm.

This doesn’t imply that the more-aggressive Summit cam will offer the same idle vacuum or torque production at 2,000 rpm, but it does show the versatility of the bigger cam.

Upstaging a stock cam with big power gains is always welcome, and adding 123 hp certainly qualifies as big, but the gains are even more impressive when they come with no loss in power down low.

To get 445 HP and 470 torque out of a stock cammed engine is insane! That is a tall order to gain an additional 123 HP! And to do so without sacrificing and trade off down low is impressive.

I chose to run the sum stage 3 turbo cam (.600/.575, 234/237, 115+5), and currently will be flogging the car NA and with Nitrous.

How will the turbo cam like the nitrous? Engine is a 6.0, iron block LQ4, carb intake and MSD, Stinger 2 plate kit.

Keep in mind, there are no accessories on Richard’s dyno test engines. Use numbers ONLY for comparison within the same dyno test.

Do a milder cam. Like a sloppy stg2 or a little milder. Give vacuum at idle too

What pushrods were used? I’m doing this exact swap and there’s no mention of that in the article.

Best to ALWAYS utilize a pushrod length checker. A good quality stage 1 cams on an un-milled head can be ok to run the stock takeouts (cleaned out). IMO, bigger cams or not a high end manuf., have a length checker to be safe. They’re cheap!

How much for part and what’s are the prices?

What’s Price the 120+ Hp. I’m 6.2 Chevy

wondering what my L86 will put out, it has 1-7/8 long tube headers, cold air induction ported 95mm TB and Brian tooly stage 2 cam springs, and 1 pc push rods. 4:10 gears with posi. in a 2014 Sierra 4×4