Will a 2002 Chevy transmission work behind a ‘99 Chevy motor? Is wiring or computer an issue? I work at a junkyard and the interchange says one year only. This is for a rat rod build. Thanks. — S.S.

…

Jeff Smith: We will have to make several assumptions to answer your question.

The quick answer to your question is — it depends!

Our first assumption is that we are talking about a 1999 LS engine and not a small-block Chevy. However, there are many situations in this changeover year where the small-block was used in several GM heavy-duty vehicles. So we’ll deal with both applications but for the benefit of future questions for this column, more detailed information in the question creates a better answer.

First we’ll deal with the LS (Gen III) engines. In 1999 GM used three different displacement truck engines: a 4.8L (293 c.i.d.), a 5.3L (325 c.i.d.) and a 6.0L (366 c.i.d.). The 4.8L and 5.3L engines used a crankshaft flange that was essentially flush with the block bellhousing flange which is identical to the Corvette and Camaro 5.7L all-aluminum LS1 and LS6 engines in that year.

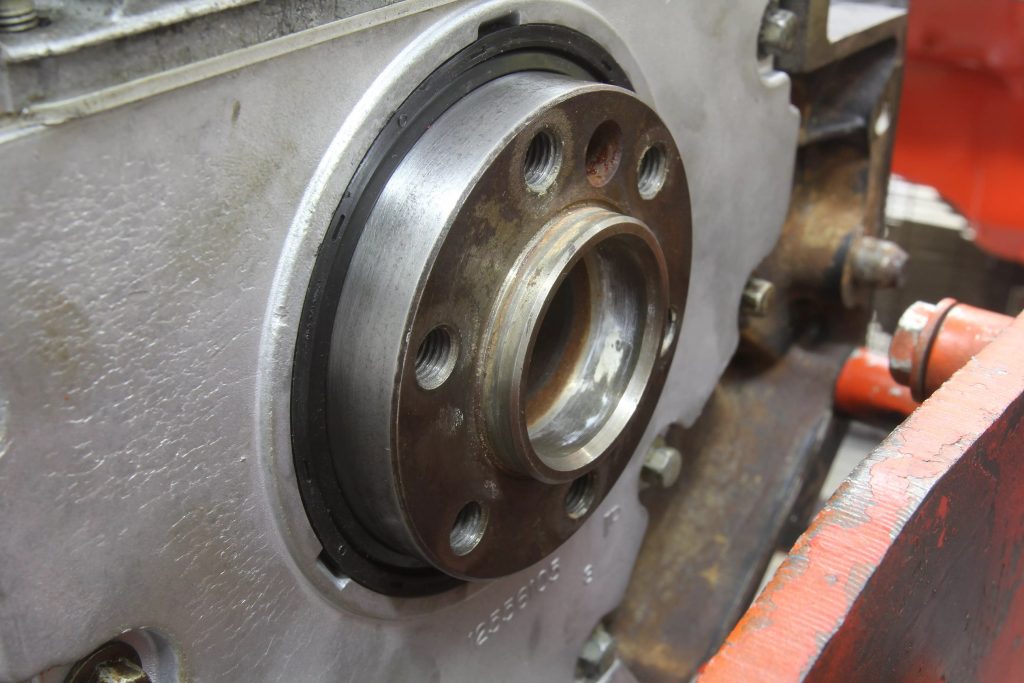

The iron-block 6.0L LQ4 truck engine found in the larger 2500 series trucks and some vans used a 0.400-inch longer crankshaft flange that protruded from the engine’s rear cover. GM used this different crank flange to adapt the 4L80E four-speed automatic transmission that had earlier been designed for use behind big-block Chevys.

The longer crankshaft flange on the early 6.0L engines were employed to essentially duplicate the crankshaft flange position of the earlier small- and big-block Chevy engines that the LS replaced. By doing this, GM employed a flat flex plate and this allowed the 4L80E’s torque converter hub to nestle directly in the extended 6.0L’s crank flange and using a flat 6.0L flex plate.

We will also assume that the 2002 automatic you refer to is a 2002 LS version 4L60E transmission used in Camaros, Corvettes, and also light duty pickups. If so, then that trans was designed for engines using the traditional LS crank flange that was essentially flush with the bellhousing flange. There is insufficient room for this transmission’s torque converter if you attempt to bolt this trans to a 1999 LQ4. On the other hand, if you are using a 1999 4.8L or 5.3L truck engine for this rat rod, then that 2002 4L60E automatic will bolt up using the stock LS engine’s flex plate and everything will work.

Now, if the engine you are using is a traditional small-block Chevy that was still available in certain Chevrolet and GM vehicles like Suburbans and trucks, then this is an entirely different ball game. This engine will require an earlier overdrive 4L60E transmission designed for a small-block Chevy. If your transmission is a 2002, then likely it is designed for an LS engine. One way to tell is to look at the bellhousing flange. A small-block Chevy bellhousing bolt pattern has six attaching bolts that are laid out symmetrically with three on each side and no bolt hole at the 12 o’clock position.

The LS version bellhousing bolt pattern is skewed with four attaching bolts on the driver side with a bolt at the 12 o’clock position and only two bolts on the passenger side. This identifies the transmission as intended for an LS engine. It gets even stranger with the Gen V LS engines with yet another change to this pattern, but we’ll leave that alone for right now.

So with a small-block 1999 engine you will need a 4L60E intended to be used with a small-block Chevy. These transmissions were used in several Chevrolet cars and trucks between 1993 and 1998.

In all of the above applications, the transmission will also require a stand-alone controller since these transmissions are electronically controlled. There are several companies that offer these controllers and they range in price from around $600 to over $1,000.

Brands like B&M, Chevrolet Performance, FiTech, MSD Atomic, Painless, and TCI all offer the controllers you’ll need.

You didn’t mention what induction system you will be running, but if it’s going into a rat rod, then likely it’s a carburetor. You will also need a separate ignition box to run the spark side of this engine. MSD now offers a universal spark box that will operate with either the early 24x crank position sensor wheels or the later Gen IV 58x wheels.

Can a 1998 4L60E trans work behind a 1999 6.0 truck block?

Will a 1999 5.3 crank/flexplate be compatible with my 2005 4l60e? I did a rebuild on a 99 5.3 and installed it with the 99 flexplate in my 2005 Silverado 1500. I have a feeling something is not right because now I’m seeing trans fluid slowly leaking by the trans bell housing. Any help would be greatly appreciated.

Those parts should be compatible. Often when changing engines it’s a good idea to change the frotn pump seal at the same time. It could be that the leak is just a weak front pump seal.

I have a long crank. I have the 4l80e that came with it. I can’t find a flat flex plate with the smaller bolt pattern for an aftermarket converter. Do I just hang out with my die grinder and massage the holes to fit. Anyone know what my options are.

I have a 2001 Chevy 3500 6.0 with the 5 speed tranny and it had the short crank flange. I put in 2000 6.0 that has the long crank flange. The flywheel teeth do not line up now.Is there a flywheel or clutch kit conversion that will work?

I’m putting a gen1 4l60e in a 99 5.3 do I need to elongate the holes in my flywheel

Hey Jeff my name is David I have a 2006 I will drive trailblazer SS I put a steel motor in it with the long crank I put the spacer behind it 400,000 with a 4L 70 I put it all back together and I’m having a problem with the starter hanging up is there a different starter that I can use it just seems like it’s not fully engage in far enoughI have done some research and they said his lawn crock long crank motors came in a two year only I was wondering if there was a difference daughter that was used for these motors is that my problem I believe I have a flat flex plate that I bought when I was doing a build I’m just at a point it starts every now and then but the start is just not engage in correctly with that 400,000 I believe that the starter should go out further

Is there any way I can use a 97 4l60e behind a 2006 4.8l

Jeff: Tracy Sandberg here, I have run into a snag and hope you can help me. I have built a 440 cu. in. LSX for my Camaro that you remember when you were driving with Dan Livesy. It has a 6 bolt pattern 58X crank and I run a Ram 3 disk Assault Weapon clutch on it. The flex plate I bought PRW # 34610 is slightly off on the bolt pattern, enough that it doesn’t look like I can just oversize the holes and make it work. I called PRW and they were not any help. I can get three of the six bolts in but the rest are off…Help!

(515) 468-8108n Thanks Jeff

Hi Jeff I have a 2002 silverado regular cab 4.3 engine with a 4l60e transmission trying to swap a 2000 lq4 long crankshaft engine will that transmission work your advice would be greatly appreciated

I have a 2003 GMC Sierra 1500HD 6.0L

I took 2004 Chevrolet Silverado 1500 6.0L

I’m swapping the motor out the 2004 n putting it in the 2003 GMC

I’m having a problem with the flywheel

The flywheel off the 2004 have three holes

2003 GMC has six holes

It won’t turn

So how do I fix it

Hello Jeff I have a 6.0 the guy told me it was a 2002 year with 317 aluminum heads with flat top pistons,the problem I m have when I try mate it to my 4L60e tranny with 300 mm converter everything bolts up but there’s a gap between torque converter holes to flexplate