A rusted, seized bolt or nut can turn an easy project into a nightmare.

In fact, mechanics have been known to hold a lucky rabbit’s foot or refuse to work on Friday the 13th for that very reason.

But removing a stuck bolt doesn’t rely on luck—it relies on the proper preparation and tools.

***

Story Summary Overview:

- Rust & corrosion can seize a bolt, nut, or other fastener

- Using excessive force can damage, round, or break the fastener, leading to a much bigger problem

- Some careful preparation & techniques can improve your chances of successfully removing a seized bolt

- Planning ahead with proper preventative steps can reduce the risk of a fastener seizing

- The story offers some helpful tips & advice for removing a stuck bolt or nut

***

OnAllCylinders contributor Jim Smart wrote an in-depth article that covers a lot of the stuff we mention here, but goes deeper into the topic of thread repair. You can check it out here: Taking The Sting Out of Damaged Threads

Plan Ahead.

If you have the luxury of planning a bolt removal in advance, then take advantage of your head start by spraying the bolt with penetrating oil.

A quality penetrating oil does two things:

It will act as a mild solvent to eat away at rust, plus it will lubricate the threads, which will make for an easier extraction (and mitigate the risk of snapping a bolt due to corroded threads.)

Some folks will make their own blend of penetrants using common garage substances like automatic transmission fluid, acetone, and candle wax—but we’re inclined to trust the off-the-shelf stuff.

Start several days in advance, spraying the bolt or nut every day with a fresh blast of penetrant.

Don’t be stingy—really soak the nut or bolt down. Allow the penetrating oil a good chance to creep in to the bolt threads.

If the bolt or nut is located in a tight space, try to remove as many obstacles (brackets, panels, etc.) as you can to ensure your socket and wrench/breaker bar has enough room to seat and turn properly on the fastener’s head.

Use the Right Tools.

When it comes time to remove the bolt, take your 12-point socket and hide it in your sock drawer next to your four-leaf clover—you won’t need either one.

Use a 6-point socket for a traditional hex-head bolt. That will reduce the chance of accidentally rounding the head or nut.

If your bolt in question is an Allen or Torx, make absolutely-positively sure you’ve got the right-size bit. (AMC and Jeep folks know what we’re talking about.)

Take a wire brush and knock-off any corrosion on the bolt head. You want to ensure your socket is seated fully onto the fastener.

Don’t lead off with an impact wrench or breaker bar. Instead, try to see if you can break the bolt free with your trusty socket wrench. You don’t want to risk shearing the bolt head off with unnecessary force.

Greek History Time!

If, after all that, your bolt is stuck—call Archimedes.

Archimedes was an ancient Greek gearhead who was the first to mathematically explain the mechanical advantage of a long lever. In other words, he helped invent the breaker bar. Applying gentle force, use the bar’s leverage to apply more turning strength to the bolt head. Feel is important, and if you think you’re going to round or shear the bolt head, back off the fastener.

If a breaker bar still won’t release the bolt, it’s time to contact Prometheus.

In Greek mythology, Prometheus stole fire from the gods and gave it to the mortals. Now, thanks to him, you can use that fire to un-stuck your bolt.

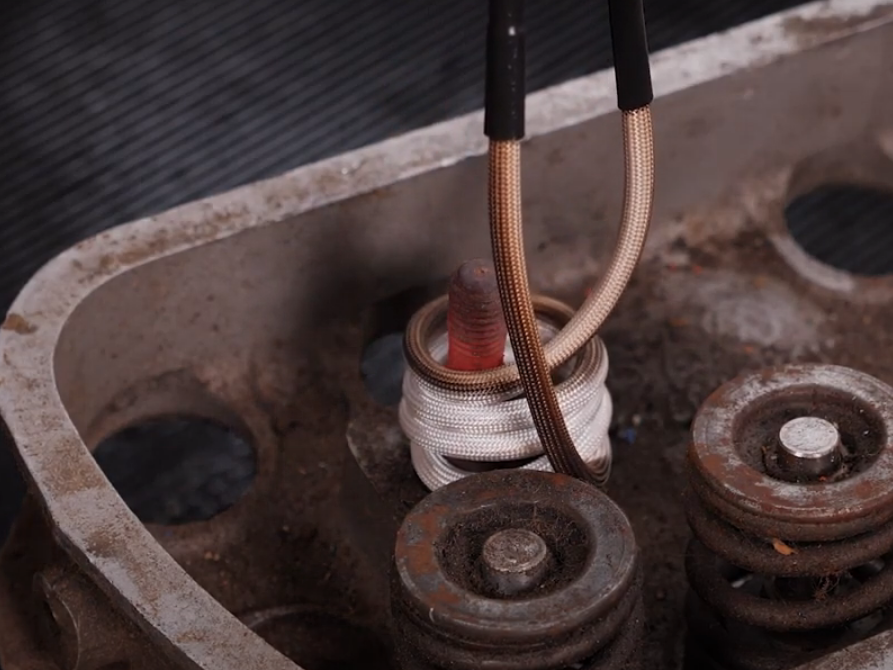

Using a torch, heat the bolt head or nut. Due to thermal dynamics, the bolt or nut will expand. The hope is that expansion and contraction process will also un-seize the bolt, breaking the corrosion that grips the threads.

Obviously, you’ll want to take great care to avoid any damage caused by the intense heat. Clear away any solvents, and make sure you’re not using your torch near a fuel line and oil-weeping gasket. Your torch will also quickly melt plastic and rubber, so be mindful of bushings, mounts, and boots. (Mini torches and induction tools are really handy for this sort of job.)

Keep the heat centered precisely on the bolt head or nut for about 20-30 seconds, and then let it cool.

Though opinions differ, we recommend waiting for the fastener to cool back down before you attempt to turn it. Again, the magic of this method occurs in the expansion action breaking loose the corrosion.

Impact Play.

An electric or air-powered impact wrench is the stuck bolt’s arch nemesis. If you’re lucky enough to have one, remember to try to loosen the bolt by hand first—too much torque too fast can spell disaster to a rusted fastener.

In addition to the rotation strength of the wrench, the impact action will help shock the bolt free, loosening corrosion that may be gripping the bolt.

Preventative Maintenance.

There are several things you can do to help prevent the bolt getting stuck in the first place.

- Proper Torque. Avoid over-tightening bolts.

- Thread Lubricant/Anti-Seize. Apply a quality thread lubricant to the bolt or stud to prevent seizing caused by galvanic corrosion.

- Paint the Fastener Heads. A simple coat of spray paint will keep rust and corrosion off the fastener head, and prevent moisture from creeping into the threads.

- Brush Up. Don’t be shy about occasionally using a wire brush on the fastener head. It will keep muck and moisture out of the threads.

- Add a Coat of Grease or Oil. If you’re unable to paint the heads, then periodically spraying them down with a penetrating oil or applying a small dollop of grease will work just as well. It’s also smart to do the same thing to the bolt’s threads, if they’re exposed behind a bracket.

A Lucky Turn?

Hopefully, following these tips has been helpful, and your bolt or nut is lying harmlessly on the cement in front of you.

If it isn’t, and you’ve rounded your fastener head or sheared it off completely, don’t despair.

There are products out there to remedy a rounded nut and extract a broken stud—and none of them involve knocking on wood, wishing on rainbows, or crossing your fingers.

Good article. One thing that i would add is whats helped me many times. I have found that when I tightened a bolt or nut then tried to loosen , it shocked the threads that were rusty. As I loosen it , if it starts to get tight i tighten then loosen again. I use plenty of wd40 while going through the whole process. Saved me many times using the repeated back and forth motion. Also if you can get to the thread on the back side of the bolt whire wheel it or brush the rust off.

Right. You can easily use a breaker bar or a box and ranch two quickly apply Force back and forth to loosen things up.

Box end wrench … For chrissakes.

too funny!

You can use a hammer and hit the head of the bolt after it cools to free it from rust.

Altho the article’s author says he trusts commercial products more than homemade concoctions,but doesn’t share his reasoning. There was an article in a machinist magazine that scientifically tested commercial products versus a 50/50 mix of acetone and ATF on rusted bolts and nuts and the upshot is that the acetone/ATF mixture beat all the commercial products, although some came close. My own experience is the same. If a penetrant will work, the homemade works rather quickly (10-15 minutes). I don’t buy commercial penetrants any more as the homemade works better.

Hey John, sorry about the late reply. My logic in that statement is for simplicity’s sake. A lot of folks may not have surplus acetone or ATF on the shelf, whereas a can of the spray penetrant can be sourced at any hardware store for a few bucks. By all means, if you’re comfortable enough and have the raw materials to make a homebrew, then proceed.

I’m not sure why older posts like this one just appear out of the blue and display on my eye phone. It might be a good omen about the usually simple task of changing the plugs on my GTP that I will be doing tonight.

The article did have a few good methods of dealing with stubborn fasteners. The Greeks were historically the first to curse to their Gods in frustration about rusted and eventually stripped small block Chevy exhaust manifold threaded fasteners.

I’ve tried calling Archimedes as suggested in this story, for help with my Roman Chariot restoration project. But his abacus pulsed cell phone is ancient at best and the micro internal sundlal speed fluctuations are incompatible with the afterlife internet.

I’ll call on “The Golden Greek” next time. Chris is much more contemporary than Archie.

And the beat goes on….

Humor is free and always an excellent additive – I’m sure Archimedes n Prometheus (sp?) applied all types.

[…] penetrating oil is a must-have. Every once in a while, it is good to spray locks and bolts to avoid rusting and seizing up. In the event, of course, that the bolts do seize up, penetrating oil will fix the problem […]

I’ve been using 50/50 mix acetone with atf fluid for over 25 years always with great results. Although the past ten years the mixture doesn’t mix well, eg it congeals, so I mix a small amount as and when needed. Doesn’t smell too good but it beats anything I’ve ever used even spanner in a can which is very expensive. I remove injectors from the infamous M9r engine and it works really well if left overnight after a drenching. The acetone is an excellent penetrating fluid by itself and mixed with a light oil atf it’s an excellent penetrating fluid all in. Keep your pleasant smelling penetrating fluids that don’t do swot I’ll stick to the smelly working stuff.

Thanks so much for the suggestion of 50/50 mix of acetone and ATF, worked like a charm when everything else I tried wouldn’t budge it!

…And sometimes, nothing works. I have an ’08 F-350 that I’m currently deleting (July 2019). EGR cooler bolt (that’s right, just one) wouldn’t come out. Tried everything shown above many times over a couple weeks’ time–nothing. Took it to a mechanic who ended up using an acetylene torch to get it out. Cost me $350, and that’s all labor.

[…] paint scraping, home improvement, upcycling, decorating, thawing frozen pipes, bending plastics, loosening rusted bolts among other […]

Just wondering what is the smartest thing to do about rusted bolts nuts in my rack which I carry wood and kayaks all the time and need to desolove the rust on them I don’t want them to break I’d rather save them from snapping got a great idea please help??? Thank you very much!!!

Hey Jim, I’m not sure if you’re asking how to prevent it or how to remove ’em.

…

If you’re removing bolts, have you tried any of the above techniques? You may just need to cut them off with a wheel and get new bolts. (Dunno what your strength requirements are, but you could go stainless, or step up to zinc-plated Grade 8 if need be.)

…

What I can advise is, when you re-install your bolts, make sure to use a good anti-seize thread lube. Then, you can hit the tops (and backs if possible) with a shot of spray paint or WD-40 to shield against corrosion.

…

^^That’ll make them easier to remove in the future.

[…] A few years ago, we ran a tech article about removing stubborn bolts. […]

[…] most gearheads know that heat is one of the best ways to free a stuck nut or bolt, many of us are understandably hesitant to shove a blowtorch down into an engine […]

Hopefully someone gets to this soon I rounded off a oil drain plug and the tech previous has overtorqued it I tried solvent , but extractor sockets channel locks as its in tight spot vice grips were a big mistake and a pipe wrench . Chisel as well nothing

You said you tried nut/bolt extractors like these? If those didn’t work and locking pliers didn’t work, you’ve only got a few options.

…

While I don’t know your space constraints, you can try to use a rotary cutting tool to cut the bolt head down better for a better grip with pliers or an extractor. You may also be able to weld on a piece of metal stock to the nut.

…

As a last resort, you can drill out the bolt enough to drain the oil, drop the oil pan, remove all the metal filings and debris from the original drain plug, and replace the pan, drain bolts, and gasket. Depending on the vehicle, that may be difficult. But on some FWD cars I’ve seen, it’s an easy, 10 minute job. Or, if you don’t mind a mess, you can remove the pan without draining the oil, which can give you the space needed to move the stuck bolt (or even get at it from behind), and eliminte the hassle and worry of removing the metal shavings.

Hi, Guys!

Any thoughts on loosening the engine block drain plug on my ’95 Honda Civic LX?

I bought Kimball Midwest’s penetrating spray at the recommendation of a nice and experienced older gearhead at Advance Auto, for almost 20 bucks. It’s apparently a professional-grade go-to for shops around here that buy as much as they can get. I’ve had trouble ensuring that the spray, through the straw as well as the wider tip application, is saturating and creeping in behind the flanged bolt head. I need to reapply, but the guy at Advance said that this is the best product he’s ever used and it worked within minutes, albeit on a tough but entirely different job. I have no trouble believing him, but after one dousing and nearly a day of being allowed to sit, I have a breaker bar that flexes without so much as the tiniest hint of that simultaneously unnerving and satisfying “SNAP!” you get when a miserably stubborn fastener releases in that split second where you wonder whether you broke IT or the bond.

I’ve used the Acetone-and-ATF blend in the past, but I can’t swear to its efficacy, as it was used in the wake of other products. I’ve used it solely, as well, and it seemed to work. I want to believe in its legitimacy, and it may be a contender in this fight.

I took a cold-weather leap of faith in using TITAN Sealer’s polymer-based head gasket repair formula rather than to take the head off to replace the gasket — and I had no red-zone overheat. I have reasonable garage access for the first time in my D.I.Y. life, but it needs to be emptied before use, it’s unheated, and I THOUGHT that the sealer would take less time and cold-weather discomfort. I’m on borrowed time with a Subaru my cousin has graciously let me use for a now-lengthy run.

I removed the thermostat, used TITAN’s system cleaner, and power-flushed the system with a garden hose, but there’s always a little bit of fluid left in the engine. I want all solution out for this treatment to stand the best chance of working, as I am now among the 2% of customers that TITAN says require a second and generously free application to achieve a full repair. There is expired product from the first treatment that I can’t fully remove, and I’m wondering if a ‘clean’ but not thoroughly flushed block is keeping me from realizing a full seal. Hence, my intent to remove the block’s drain plug, which is even recommended in the glove-compartment Owner’s Manual as proper procedure for a full clean-out and replacement of coolant.

Sorry for the ramble, but in short, I was wondering about how forceful I could be, both with major leverage and in applying heat to this area. It’s the block, so I think that impact force is unwise, and heat that exceeds operating temperatures may be too harsh. I need to get this completed. I don’t want to wait and re-apply penetrating fluids for a week to see if that’s the silver bullet, only to find that I still have a bolt that won’t budge. It looks like syringe- or eyedropper-applied Kimball or Acetone/ATF and gradual breaker bar persuasion may be the greatest hope. I doubt that this bolt has been out in the car’s 27-year life, so we all know what I face. I want this done correctly: the bolt has to come out. I’ve rinsed and replaced coolant before, but it wasn’t done this thoroughly. I want a clean environment for this sealer to do its job effectively, and I want to flush the product well — although the company’s mechanic and tech advisor says a pristine flush isn’t necessary.

Elsewhere I read a concern about corrosion perhaps causing material loss and leaks upon reassembly. I’m weighing the idea of borrowing a 3/4′ drive and see if a bit more bulk and might is all I need to get this simple but so far time-robbing and now stalled project done. Thank you for enduring my ramble, and thanks for ideas. Later!

Wondering what the magic is in ATF fluid and note there are several different formulations of that. My 06 Lincoln needs Mercron 5, tranny is shuddering and was looking at a 09 transplant, it takes a different fluid. I think Mercron 7. GM takes a different fluid ??? Wondering if Marvel Mystery Oil or 3in1 oil would mix better with acetone. Always liked the smell of 3in1 🙂