When your race car is staged and the last yellow light blinks off, the car experiences a number of forces — all of which you must control for at least 1,320 feet. These forces include:

- Engine Torque

- Rear-End Wrap Up

- Rear-End Torque Rotation

- Chassis Sway

- Track Irregularities

- Aerodynamic Loading

Engine Torque

According to well-respected chassis expert Jerry Bickel, you must always take Sir Isaac Newton’s Third Law of Motion into account. This simply means that for every action, there is an equal and opposite reaction.

“If a gun is fired, it must kick back with an equal and opposite force to that which is applied to the bullet,” Bickel said. “The [race car] engine exerts similar forces and counter-forces that affect the operation of the race car.”

As each cylinder in the engine fires, the pistons and rods apply a force to the crankshaft. The crank rotates and obviously applies a clockwise twisting force (when viewed from the front). Fair enough, but then our pal Mr. Newton’s Third Law of Motion enters the equation. As the crank spins, an equal amount of torque is applied in the opposite direction. It rotates counter clockwise within the block in response to the crank rotating clockwise.

What this all means is the chassis of the car eventually has to absorb what can turn out to be considerable counter clockwise rotation. Racers tend to call that clockwise force “chassis roll” or “roll rotation.”

Bickel notes that there are only three methods you can use to control roll rotation: proper suspension geometry, chassis pre-load adjustment, and the use of a rear stabilizer bar. Keep in mind that you need all three of these methods to control roll rotation.

That’s not the end of it, however.

Rear-End Wrap Up

You have to consider the driveline.

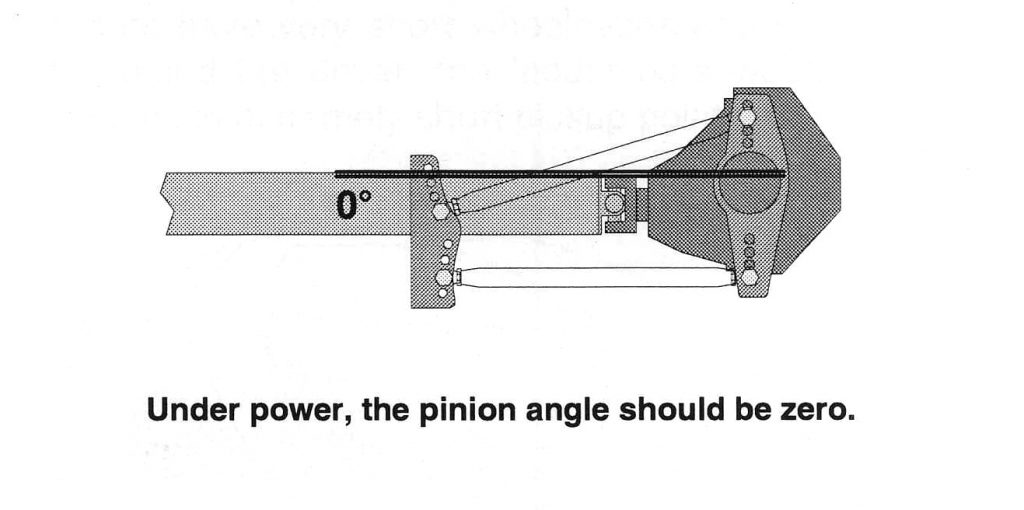

The driveshaft in your race car rotates 90 degrees to the axles. To get there, the driveshaft spins the pinion yoke. The pinion yoke in turn twists the pinion gear, which is meshed with the ring gear. That allows for the 90-degree change in direction, which provides power to the axles. Remember, as the engine spins the pinion, torque is multiplied by the transmission. That serious torque coupled with equally serious (sticky) back tires causes the pinion to attempt to climb the ring gear rather than turn it. This force causes the rear-end to rotate upward. This is what racers call “wrap up.”

Remember that Third Law of Motion? The torque required to wrap up the rear-end is equal to (but opposite of) the torque that is applied to the rear wheels.

According to Jerry Bickel, uncontrolled wrap-up on acceleration would allow the rear-end to rotate upward, placing the driveshaft out of proper alignment. Bickel is referring to the U-joints, which operate best when they’re aligned (straight). When they operate in an angular motion, the U-joints transmit an uneven turning motion (often referred to as a non-constant velocity), which usually translates into driveline vibration and even worse, driveline carnage.

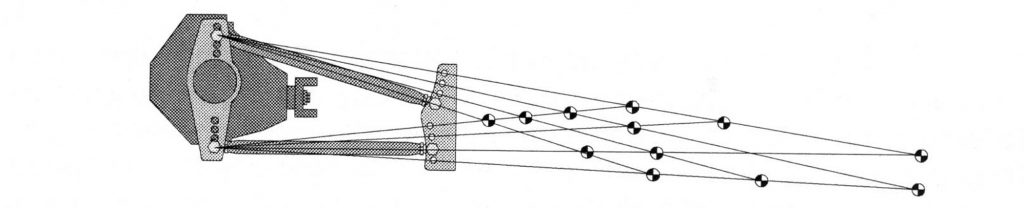

Acceleration wrap up is most often controlled by something like a four-link rear suspension system in the race car. Those four simple links connect the rear-end housing to the brackets welded to the chassis.

Rear-End Torque Rotation

You must also factor rear-end torque rotation into the equation.

“The rear-end pinion gear cannot be turned without resistance as the weight of the car must be accelerated,” Bickel said. “Think of the rear-end as an airplane propeller. As the driveshaft is rotated clockwise, the propeller will be rotated the same way. Likewise, as the driveshaft delivers engine torque to the rear-end, the housing will attempt to rotate in the same direction as the driveshaft. This is called “rear-end torque rotation.”

Rear wheel torque rotation tends to increase left rear wheel traction and decrease right wheel traction, pushing the car to the right on acceleration. Since chassis roll (caused by engine torque) is equal and opposite that of rear wheel torque rotation, you’d think those forces would cancel out one another, allowing the race car to run straight down the drag strip.

The trouble is, it’s not a perfect world.

As Bickel tells us, no chassis is 100 percent rigid. Plus, you have consider that chassis roll actually upsets four-link geometry. To get it to work right and simultaneously make the car run down the track straight, you have to adjust spring and shock rates, wheelie bars, four-link intersect points and manage engine torque.

Chassis Sway

Next on our list is chassis sway.

Chassis sway is the sideways motion of the body (and chassis) on the wheels. This sway can cause the body to touch the tires, and it can also have a very adverse effect upon the car down track.

Part of the sway issue is caused by coil springs. Coil suspensions of one form or another are found on the vast majority of door slammers. Bickel notes that a coil spring is very effective at resisting forces in compression, but it’s not so effective when it comes to combating lateral forces. One method of controlling sway — and most likely the best one in a dedicated drag car — is by way of a wishbone bar.

The wishbone connects to a pair of brackets on the chassis and one on the rear-end housing. In Bickel’s opinion, if you mount the wishbone over the rear-end housing, you have far better access to the rear-end, simplifying the removal and replacement of the center section. In either case (top mount or bottom mount), two rod ends allow the bar to pivot as the chassis moves up and down in relation to the rear-end housing. The single rod on the wishbone telescopes in and out as the chassis moves up and down, but the motion is restricted to up and down. As a result, the body cannot move sideways in relation to the rear-end housing as the car goes down the track.

The bottom line here is sway is eliminated.

Track Irregularities

It’s no secret there is no perfect track. That’s why suspension systems must be engineered to allow the wheels and tires to move up and down in concert with any track regularities. It’s also the reason pro racers spend a huge amount of time examining the track.

The coil springs found on most race cars do a great job when faced with the task of dealing with up and down movement; however, coil springs do have a tendency to oscillate. If you don’t control this repeated bouncing, the tires will lose contact with the racing surface.

That’s where shock absorbers come into play.

Shock absorbers control spring oscillation. In a simplified view, shock absorbers consist of a piston within a cylinder. As the shock absorber is compressed, fluid inside the shock absorber must pass through small internal valves. This valving causes resistance that effectively dampens the spring oscillation. Most drag shocks are designed to offer a greater resistance in one direction (usually on the extension side); however, you can purchase a drag shock with external adjustments that allow you to set the valving for specific conditions. These adjustments allow you to tune the chassis to the various irregularities found on the racing surface.

Aerodynamic Loading

The last force that affects your race car is aerodynamic loading.

At speeds that can exceed 200 miles-per-hour, air can exert many hundreds of pounds of force to the race car body. This aerodynamic loading of the chassis is controlled in part by the use of a front spoiler and a rear wing.

The function of the front spoiler or air dam is to force the air around the sides or over the top of the car. That’s a good thing, because air that goes under a car creates lift on the front-end. (That’s pretty much how and why airplanes fly.)

“The shape of the car, while not a perfect air foil, is relatively flat on the bottom and curved on the top,” Bickel said. “As it pushes through the air, substantial lift is also created. The front spoiler (air dam) can reduce or eliminate lift by keeping the higher pressure air from getting under the car. Because the top of the car is not smooth, certain areas of high and low pressure are created.”

Lift at the rear of the race car can be eliminated by installing a wing. The wing works by catching the air moving down the back of the car. This pushes down on the wing and, in turn, the car. The rear wing can also reduce the turbulence created when this high pressure air mixes with the low pressure behind the car. Some chassis builders even add a couple of NACA ducts into the middle of the rear wing to help deploy the drag chute. A NACA duct is an aerodynamic slit that can allow air to pass through with minimal turbulence.

As you can see, there are a large number of forces present in a race car. It’s up to you to control them with the proper race car chassis tuning. And it’s not that tough when you figure out what each piece of the puzzle accomplishes.

For more info, check out the chassis setup links below:

Thanks for sharing.

Very informative. My question is about a gm a-body stock type rear control arm suspension with double adjustable rear shocks. Shouldn’t the right rear shock be adjusted more stiff on compression than the left one? The normal torque reaction wants to lift the right wheel and make the rear right squat. Right?

[…] You can read the entirety of that article here. […]