The heat generated from stop-and-go-driving, racing, and towing can kill engines. A well-designed electric cooling fan is critical to prevent engine overheating—a good fan will provide the airflow needed to dissipate excess engine heat with the least impact on horsepower and fuel economy.

Without airflow, a radiator is not much more than a holding tank for hot coolant. Optimizing the air movement across the fins of the radiator is essential to prevent overheating—a task that electric fans can often handle better than engine driven fans. The key advantage of an electric fan is increased engine cooling at idle when it is most needed. In addition, replacing an engine-driven fan can increase horsepower and improve fuel economy by eliminating the drag of the engine-driven fan.

We contacted the engineers at Maradyne to learn more about what makes good electric fan design–and what you should look for when choosing a fan. Maradyne electric fans are spec equipment for several NASCAR Nationwide and Cup Series teams—a demanding application where cooling is critical to winning. Maradyne uses that same racing technology to build electric fans for daily drivers, street rods, muscle cars and off-road vehicles.

Factors that Impact Fan Performance

According to Maradyne, factors such as blade width, blade pitch angle, number of blades, and blade velocity impact a fan’s overall performance. Taking these factors into account, Maradyne engineers calculate the optimal angle of airflow through its fan at three points—the hub, the middle, and outer blade tips.

The next step is to make the fan design fully functional by optimizing fan blade pitch at the static pressure and rpm conditions that replicate most automotive applications. Essential aspects of high performance fan design include:

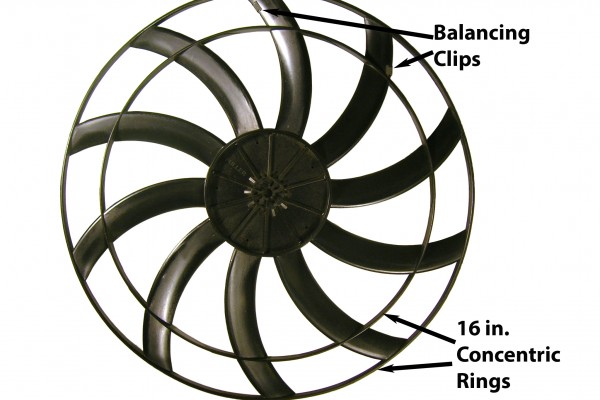

- Balanced blades to prevent additional stress and wear on the motor, which can shorten its lifespan.

- Amperage draw to achieve maximum performance using the least amount of current.

- Concentric rings to tie fan blade tips together. For example, two rings (one outer and one inner) are used on Maradyne’s 16-inch fans to add stiffness to the blades and prevent them from flexing rearward into the shroud at high rpm. Smaller 12 to 14-inch fans have one outer ring preventing blade flex and distortion. Theses rings also reduce noise by preventing harmonic vibrations that can occur when individual blades rotate at high speeds.

- Sealed motor that can withstand dust and humidity.

- Practical design and testing. This testing allows performance to be further optimized. Maradyne says its tests are made at various static pressures to measure airflow, speed, torque, and amperage draw. Validation of a fan design comes in the form of on-track and off-road racing teams.

Choosing a Fan

Here are some factors Maradyne considers important when choosing a electric fan:

- Size the fan to the radiator core. A fan must cover as much of the radiator core as possible. When measuring, do not include the cooling tanks on each side or top and bottom of the radiator. These measurements will give you an idea of what diameter fan is required. You may find that you will need a dual fan setup to cover the radiator core. • Match airflow to the vehicle. Because it doesn’t generate as much heat, a stock or mild street engine doesn’t as powerful a fan as a strong street or race engine. Maradyne fans have motors that range from 130 to 225 watts; motor power determines the amount of cubic feet per minute (cfm) of air a fan delivers. If you plan to upgrade your engine, it won’t hurt to install a more powerful fan now—you can control its airflow with a temperature sending unit.

- Pusher vs. puller. The majority of automotive fans are set up in the puller configuration to pull the air through the radiator from the grill opening area. This keeps the fan out of the natural airflow path into the radiator. If you have space issues, you can use an electric fan in a pusher configuration in front of the radiator. Some fans can be used as either a pusher or puller.

- Shrouding. A fan shroud helps improve cooling by channeling air into the radiator core. If you have room for one, Maradyne highly recommends using a shroud.

- Power draw: The more powerful a fan is, the more current it will draw from your vehicle’s electrical system. Twelve- to 16-inch fans can draw from 15 to 28 amps, while some dual fan applications can draw up to 35 amps. Make sure your electrical system can handle the addition of an electric fan.

Check out this Maradyne video that goes into more detail on choosing the right fan.

A popular modification on E36 Bmw’s is the fan mod delete, made popular by the ptg race team. This completely eliminates the engine driven fan and uses (2) lower temp thermostat’s to kick on the aux electric fan and the engines thermostat earlier as well as using water wetter. This was all fine and dandy until the past week when temps reached 100+. With that being said the first line of this article really started to radiate with me * pun intended* and also confirmed what i already knew/suspected! “Without airflow, a radiator is not much more than a holding tank for hot coolant.” Upon sitting in a fast food line for 20+ min the plastic necking on my expansion tank literally BLEW up causing massive failure. The lesson was driven home for me.. Get a good aux fan for a daily driver! A race only car may be able to handle the above modification i mentioned but for daily drivers sitting in traffic 100+ with the combination of no air flow on the rad it is impossible to keep the proper temps under these extreme situations. I am now upgrading rads as well as getting a proper elec fan.

Hi Tyler, I am C.J. Clayton with Maradyne High Performance Fans. I am sorry to hear about your cooling issue and what that has cost you. Plus I bet you didn’t get to enjoy your food. We are a universal fit fan manufacturer, the beauty of an electric fan is does not know what it is going on nor does it care but the proper fan still needs to be chosen for the application and use. Not all fans are equal even if they are the same diameter, same watt motor & similar design. If you would like some help picking the proper fan for you car feel free to give me a call at 800-403-7953 ext 208. Summit stocks and ships the full line of Maradyne HP Fans products.

Tyler, you seem to be off on a wild tangent. An expansion tank is not supposed to be sealed, has a vent valve or vents out the top. Apparently your vent became plugged and the resulting pressure buildup caused a burst. THIS IS NOT A FAN ISSUE.

A blown expansion tank also does not cause a massive failure, merely a loss of a little coolant and the need to replace the tank when it’s convenient. Remember that once upon a time ago, vehicles didn’t even have expansion tanks.

The system is designed for flow back into the expansion tank but was not working properly to relieve expansion tank pressure. It is true that keeping the radiator cooler will cause less expansion into that tank, but a higher flow fan and lower radiator temperature doesn’t actually fix the problem.

It could very well be that your cooling system was inadequate, too, and needed some review and improvement, but be sure to figure out what’s going on with the pressure relief on your tank as that’s a problem waiting to repeat itself if you don’t get that fixed.

I’m considering adding a accessory pusher fan on my Cummins Dodge because of our extreme summer heat in Arizona. 115 today. Slow traffic can be hell on the cooling system. Any thoughts,

Hi Brian, it is not a bad idea. At Maradyne we do not recommend electric fans replace your engine driven fan on diesel applications which you are not doing. You could add a pusher fan or two to the front side sure but when you go to a pusher fan I recommend running them all the time because you have obstructed the natural airflow the a/c condenser, trans cooler and radiator is suppose to see or for sure run the fan or fans with an on off switch if the temp climbs in normal condition due to the obstruction. I realize some may disagree with that as it would also depend on climate as well, I feel that way because every action has a reaction & I will not tell you I know exactly what is happening with that air at the grill once you put a fan or fans there but we know for sure you have obstructed it or changed it’s path in some manner.

Give me a call if you would like to discuss further, 800-403-7953 ext. 208. Summit stocks and ships the full line of Maradyne HP Fans.

Doesn’t BTU s need to be looked at as well?

Do you have an electric fan that can handle a Cat 3208

636 cid Allison Auto with 35000 gvw.

I have a 2001 Lincoln Town Car that I use 6 days a week as a car service here in Phx Az. The factory electric cooling fan works with ongoing as needed current(similar to Pulse Width Modulation if not same) and it does not keep the Ac temps where I would like to see them.(51-54 degrees) I have installed a complete NEW a/c system using Ford/Lincoln original parts. A/c condenser,radiator,ac lines,ac receiver drier, compressor, etc. I am considering using a BMW pusher fan to assist with the ac cooling. Your thoughts on this idea would be welcomed.

The fan is a good idea, especially if you desire this lower cabin temperature during low speed driving when air flow through the condenser is low! Thanks for reading!

I have an electric fan/shroud combo with an aluminum rad on my small block powered 1957 Chevy. It works great but is there a way to have the fan run a little longer after shutting off the engine? It comes on 185*

Thanks

Doug

I have a bigblock 460 in my 86 F250. I upgraded to dual fans on a shroud that I designed and built. The fan wiring kit that came from Summit has dual relays to run each fan independently. I wired one “hot” straight to battery power and used an adjustable thermo switch (also from Summit). It works great at keeping this big old girl of mine cooled off because of the siphoning effect that naturally occurs in most radiators. The fan would stay on for 3-5 minutes after I shut the motor off, come back on after the radiator heated back up (due to siphoning) and run for a minute or two.These cycles could sometimes go on for 20-30 minutes after driving through town on a hot day with a pretty warm engine. UPSIDE is the motor stays cool in city stop and go traffic, down side is it really taxes your battery and charging system. You’ll need to also upgrade your battery size and charging system.

[…] Download Image More @ http://www.onallcylinders.com […]

I am currently restoring a 1939 Chevy Pickup. It’s a restomod with an L58/GEN3 5.3. The problem I’m running into is the lack of room in the engine compartment. I don’t want to modify the firewall. So the mechanical fan is detached which still leaves me just enough room for the condenser on the inside. This leaves me with the option of mounting an electric fan on the outside pushing air. I live in Texas and will drive this truck often. Will this set-up be feasible with the right fan? Thanks