Using a leakdown tester is one of the best ways to assess the health of your engine.

Easy to use, a leakdown tester measures how much cylinder pressure is escaping from your cylinders, showing how efficiently your piston rings and valves are sealing the combustion chamber, along with your head gasket. With street engines, ten to twenty percent leakdown is typically acceptable. For race engines, the acceptable leakdown is one to ten percent.

If you have one or more cylinders that have out of spec leakage, this points to a problem with sealing in the engine and usually requires disassembly to properly diagnose and repair. If you’ve just built a motor, doing a baseline leakdown test before it has run is ideal, so you can track your engine’s performance and wear over time.

Here’s how to do a leakdown test of your engine:

I have been using a lead down tester all my life in the aircraft industry. You failed to say that with air going into the cylinder the engine will try to turn over. You need to hold the crankshaft in place to take a reading also you can rock the crank to bring the pressure reading up a little, just make sure you return it to tdc for the reading. Listening at the intake, exhaust and case or block breather will tell you where the problem is.

Old school technology coming around that the auto industry!

Dude

Go back and read step one…he did jut that

[…] compression test. All cylinders should read close to the same. If compression checks out okay, do a leakdown test to make sure the piston rings have seated and there is no excessive […]

[…] you want to start a big discussion on any engine-building forum—ask about leakdown testing. Everybody offers opinion but few facts. Let’s deal in […]

[…] Start by checking each cylinder for leakage. […]

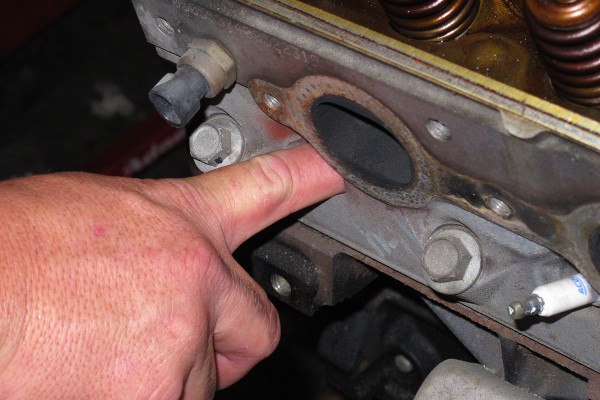

[…] disassembling the engine, Matt did a leakdown test. He found 20 to 75 percent leakage in all cylinders thanks to badly pitted exhaust valves and […]

2006 model Subaru when warm noticeable misfire at idle, computer is picking up cylinder number two misfire fault, did depression test on that cylinder just to eliminate obvious bad failure, which compression was fine, put leak down tester on top that center and got decent results. 95 PSI in 70 PSI out, did the cylinder next to it, Cylinder number four, got 95 PSI in and 35 PSI out, verified that it wasn’t me or something I did, went back to cylinder 2. Got the same reading. What this is telling me is not what the computer is telling me even at an idol. My scanner shows a problem on number two cylinder and misfire, haha little bit of something for everybody to think about. Have a nice day!…