Though a wheel’s style and finish are obviously important considerations when choosing a new set of custom wheels, don’t overlook the specific wheel’s lug pattern, backspacing, and offset specs too.

Outside of the width and diameter of the wheel, those are the three most-common measurements used to match the right wheel size to a particular vehicle.

So to help you select the best custom wheels and tires for your vehicle, here’s a handy 101-style article on wheel sizing and measurement.

3 Key Wheel Measurements You Need to Know (Beyond Width & Diameter)

- Lug Pattern. First off, you need to know your wheel’s lug bolt pattern. And that’s simply the number and spacing of your wheel studs that secure the wheel. It’s a pretty straightforward measurement, and you can learn all about it in this companion article: How to Measure Wheel Bolt Pattern and Backspacing

- Wheel Backspacing. Note that in the link above, we talk about backspacing too—so it’s a good read for more details on that topic as well. But in a nutshell, a wheel’s backspacing is the distance between the back of the rim flange and the mounting pad (where the hub attaches).

- Wheel Offset. Though it’s similar to backspacing, wheel offset is the distance between the centerline of the wheel and the hub mounting surface. Admittedly—the distinction can get confusing, so let’s break down the difference between offset and backspacing in a bit more detail…

Wheel Offset vs. Wheel Backspacing

As we alluded to above, Offset and backspacing are similar measurements.

While backspacing is the distance between the back of the rim flange and the hub mounting surface, offset is the distance between the centerline of the wheel and the hub mounting surface.

Measured in millimeters, offset is the measurement of choice for many custom wheel manufacturers—and it’s described as either positive, negative, or zero offset.

Positive vs. Negative Offset

A wheel can come with a zero offset, positive offset, or negative offset.

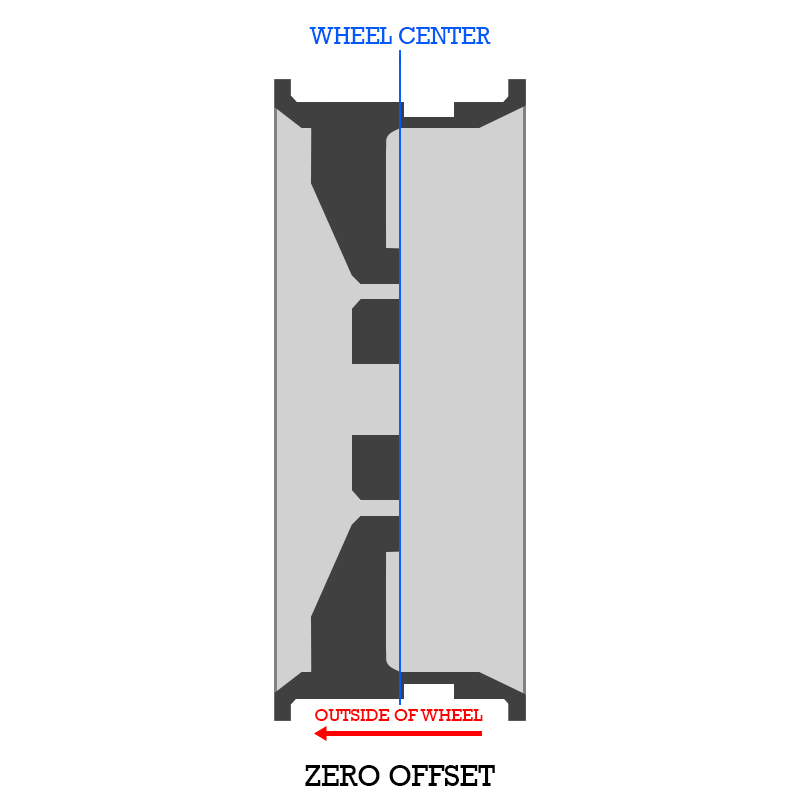

Zero offset occurs when the hub mounting surface is even with the centerline of wheel.

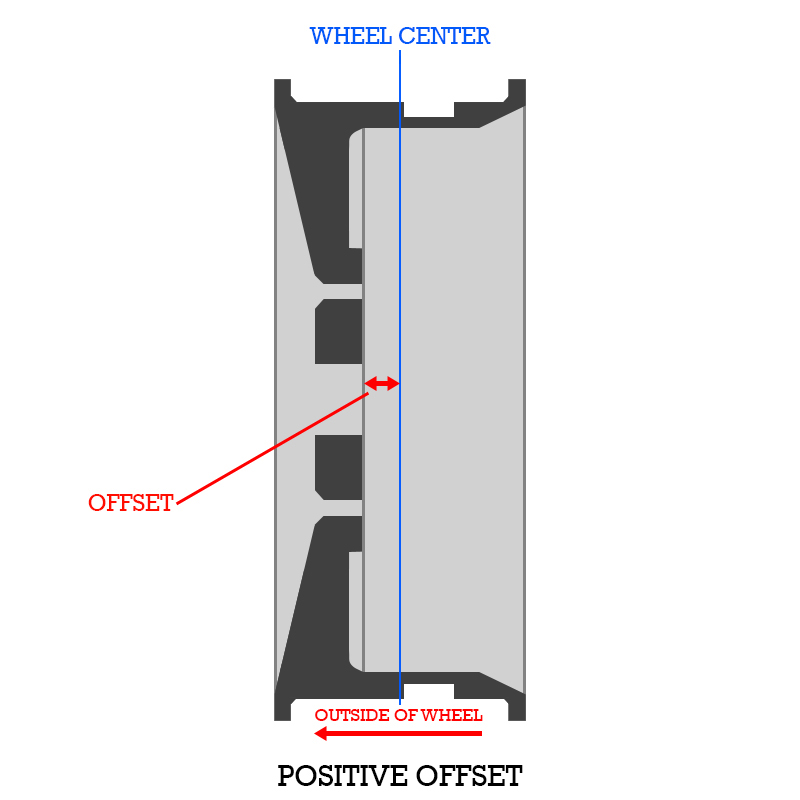

Yet most factory rims come with a positive offset, which is achieved when wheel manufacturers place the hub mounting surface to the street side of the centerline.

Often time, you’ll find that front-wheel drive vehicles use positive offset (or dished-out) wheels; conversely, many rear-wheel drive vehicles are equipped with negative offset wheels.

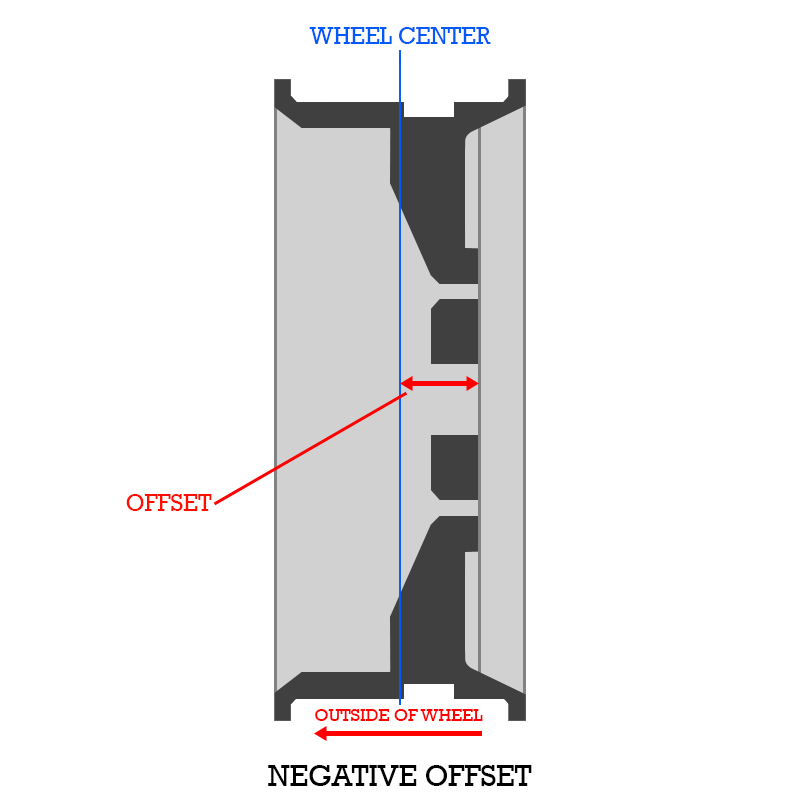

Negative offset wheels locate the hub mounting surface to the brake side of the centerline, giving them a “deep dish” appearance.

A Visual Comparison Guide to Positive, Negative & Zero Offset Wheels

Thanks to our pals in the Summit Racing tech department, we’ve got a trio of easy-to-understand illustrations that perfectly demonstrate the differences between positive, negative, and zero (neutral) offset wheels.

Special hat tip to the gang over in the Summit Racing Tech Center for letting us use the images here.

Choosing the Right Offset

As you’d imagine, wheel offset is something you absolutely must get right.

If your wheel offset isn’t correct, not only will you risk rubbing or interfering with the vehicle body, brake caliper, or chassis components—there’s a good chance your handling will be adversely affected too.

For example, excessive negative offset can cause steering wheel kick-back and place additional stress on your vehicle’s entire suspension.

Have questions about your car or truck’s specific wheel size and fitment requirements? Contact the Summit Racing Tech Department and they’ll help you get the exact size wheel and tire package you’ll nee.

[…] this quick quide to measuring wheel bolt pattern and backspacing. Along with our articles on wheel offsets and wheel/tire plus-sizing, this information will help you take essential steps toward selecting the […]