Making big power requires a big camshaft, right?

I mean, it makes sense. For years we have been taught that the internal combustion engine is nothing more than a giant air pump. The very basic premise being, the more air you put into the motor, the more power you get out of the motor.

The oversimplified air processing scenario notwithstanding, the foundation is sound. Big power requires big cylinder heads with lots of flow potential, ditto for the intake and, last but not least, a big, nasty cam profile to tie it all together.

While there is certainly some truth to this—just look at a Pro Stock or Pro Mod motor—the bigger is better theme just doesn’t carry over to a typical street/strip turbo LS. In fact, a solid argument can be made that the opposite is true when it comes to boosting a junkyard LS motor, especially one that sees any type of street driving, where high rpm and maximum power take a back seat to boost response.

For most folks (without excessive converter stall speeds, 2 steps or quick-spool valves), how a junkyard turbo LS performs in the first 1,000 rpm of the power band is way more important than how it performs in the last 1,000 rpm. Getting a turbo LS to make big power is the easy part, now let’s look at how to make that power sooner.

Improving a Turbo’s Response Rate

Truth be told, there are several things you can do to improve the response rate of the turbo, the very first being sizing the turbo correctly.

While it stands to reason that a smaller turbo will spool quicker, the vast majority of turbo LS folks want 1,000 horsepower. We will sidestep the reality that most don’t have a suitable 1,000-hp transmission or the ability to hook that amount of power up, let’s focus on getting the big (1,000 hp) turbo to spool.

If we assume a big turbo on a junkyard 4.8L or 5.3L (the most common—but a 6.0L would also help spool rate), we need to take a look at the camshaft.

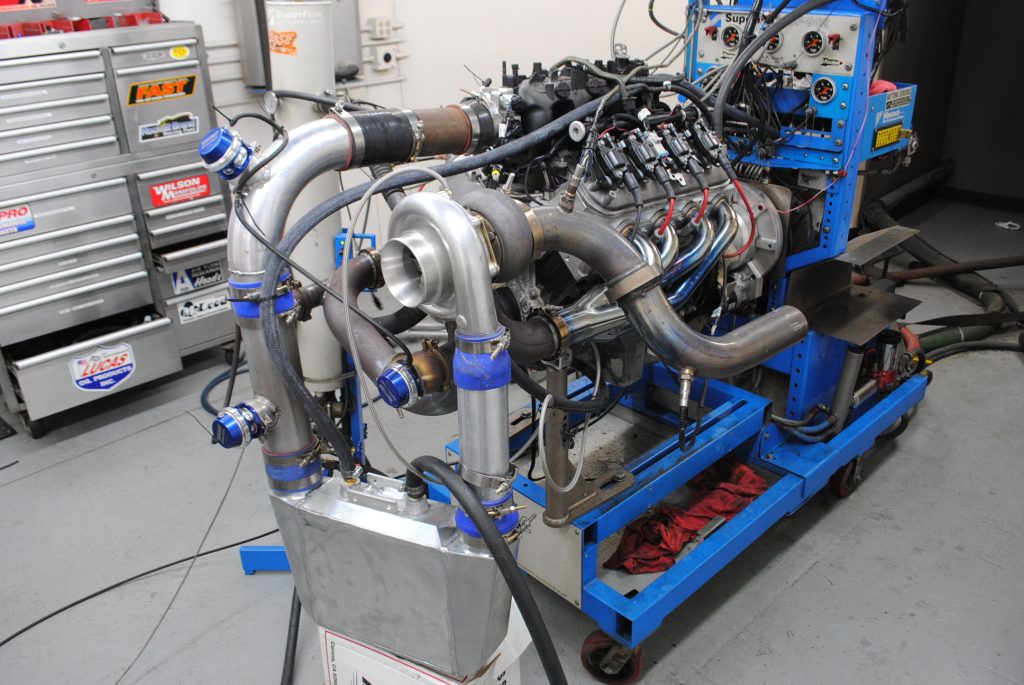

Quick side note: A long runner intake (like the truck intake used on this test), is another great way to improve spool rate.

The 1,000 hp goal is what causes most of the problem as people think that lofty power goal requires things like ported heads and intakes and (for this discussion) wild cam timing. The most important thing you can learn here is that the turbo (not the cam) determines how much power a turbo LS makes.

You can literally run any of the hundreds (really, thousands) of different cams with your 1,000 horsepower turbo (like the S475 used in this test), and you would be able to make 1,000 hp. Again, the TURBO decides that, not the cam.

The cam helps decide how early in the rpm range you start to see boost!

Understanding Cam Profiles for Turbocharged Engines

Once this reality sets in, you start to understand the potential benefits of running a cam profile that improves low-speed torque, as this helps boost response (boost response is a function of the low-speed torque output and attending exhaust energy and flow).

More low-speed torque equals more exhaust energy, which in turn spools the turbo. Since the turbo decides the maximum power output (just crank up the boost), why not concentrate on getting it up on boost sooner? This doesn’t even take into account the other benefits of the milder performance cam, like stock converter usage, improved idle quality and drivability and even fuel mileage—though this rarely applies to turbo folks once they sample boost.

Testing the 5.3L LS with a “Low Buck Truck” Cam

Food for thought: LS motors respond very well to even mild cams (the Low Buck Truck tested here added over 60 hp), these gains are multiplied under boost. Unless you are trying to maximize NA power or looking for elevated rpms with your dedicated drag race turbo LS, the combination of a mild cam and boost is hard to beat.

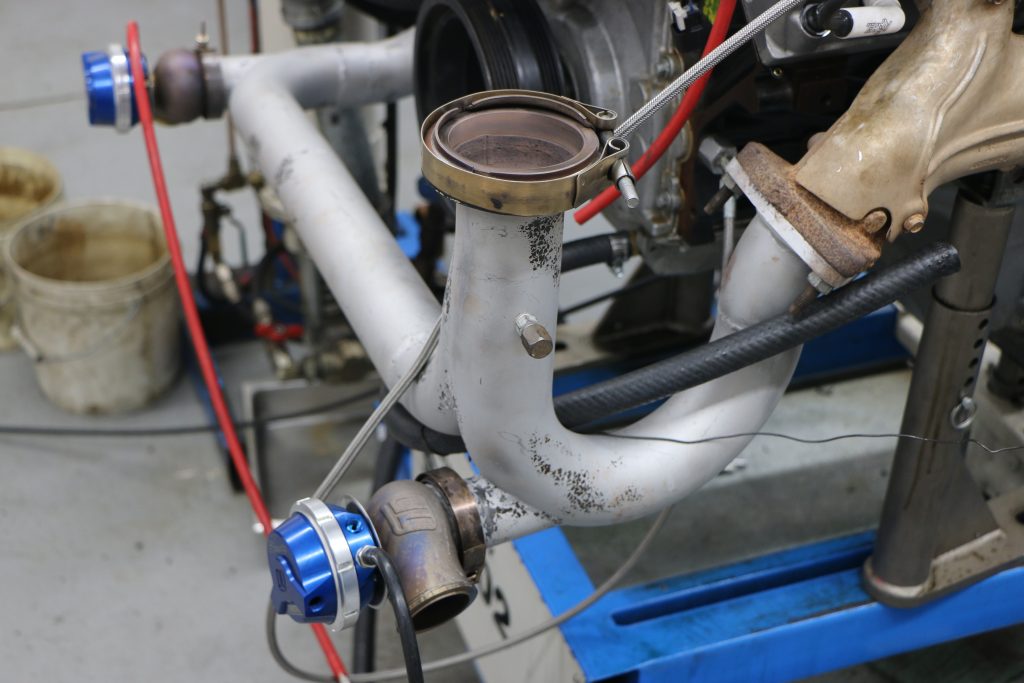

To illustrate one of many examples, we set up a test on a junkyard 5.3L LS engine using a mild cam that offered plenty of low-speed torque, without sacrificing any of the potential of 1,000 hp S475 turbo.

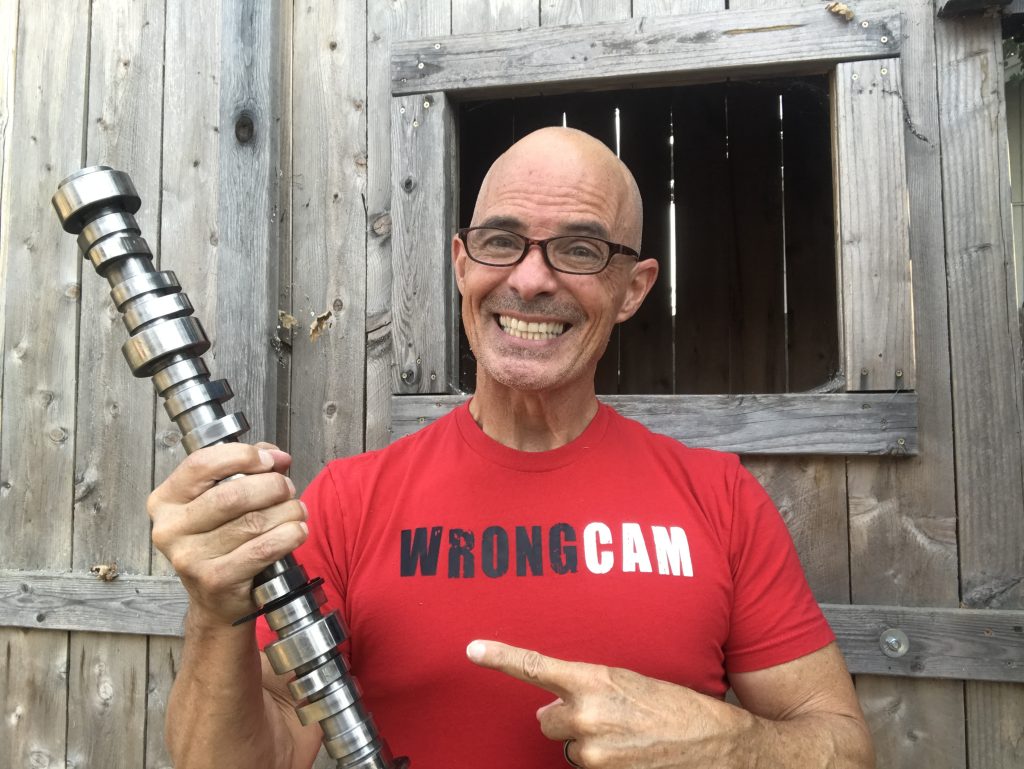

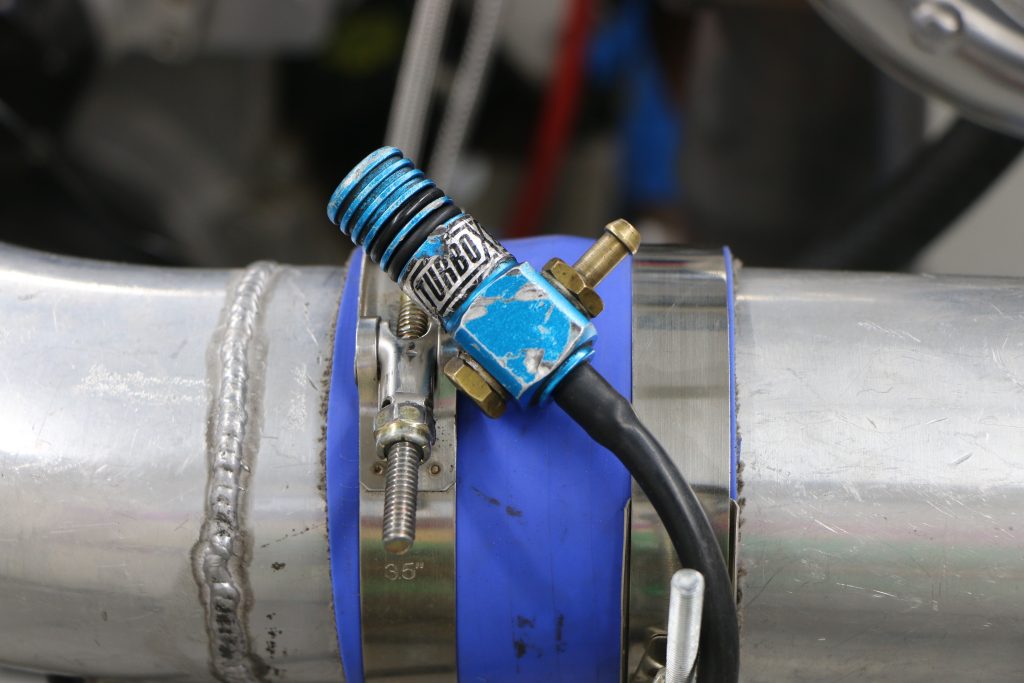

The test motor was a simple one, a junkyard 5.3L equipped with the stock internals (crank, rods and pistons), but treated to extra ring gap. The 5.3L was also sporting both factory 706 heads and the early (non-TrailBlazer SS) truck intake. The mods to the motor included a Low Buck Truck cam (0.552″ lift, 212/22x, and 107 degree LSA) and BTR valve springs.

Though the test was run with this cam, there are many, many cams (Summit Racing, Brian Tooley Racing, Cam Motion, Texas Speed) that can produce similar power curves.

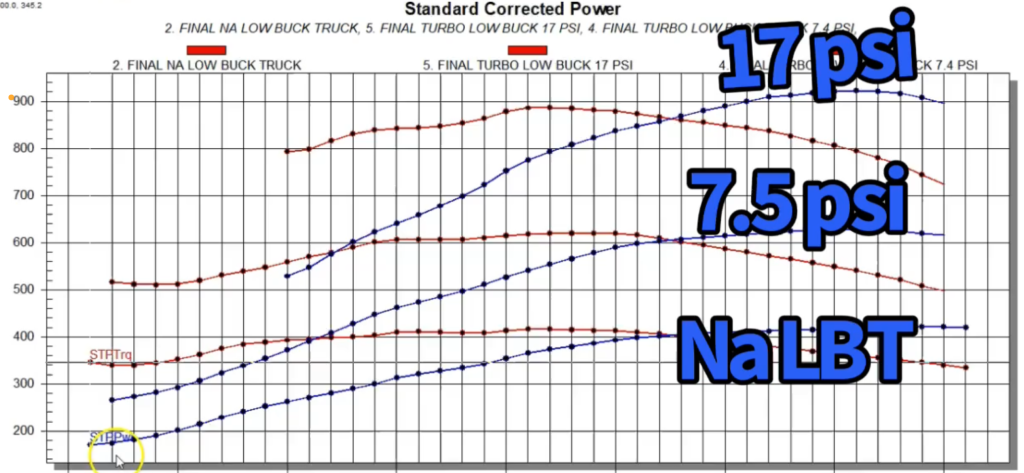

Run with Holley injectors and Holley HP engine management, the NA 5.3L produced 422 hp and 415 lb.-ft. of torque (gaining 60+ hp over the stock cam), but most importantly, the mild cam offered good torque production down low.

After the installation of the turbo system (see photos), the turbo 5.3L produced 628 hp and 619 lb.-ft. of torque at just over 7 psi. To show the mild cam could easily keep up with the turbo, we cranked up the boost to a hair over 17 psi, where the turbo 5.3L produced 923 hp and 886 lb.-ft. of torque.

With a mild cam and the right turbo, you can combine boost response and big power—what a good time to be a gearhead!

Comments