Let’s face it, some tests are just cooler and more fun than others!

Just what constitutes a cool engine build, you ask? Well, you start with a pinch of Stroker displacement, toss in, say, wilder cam timing and head flow, then finish it all off with boost from a turbo or turbos! Heck, let’s toss a blow-through carburetor into the mix, just to spice things up!

Lesser enthusiasts might be satisfied with any one of these components, but that’s not how we roll here at Summit Racing. If one or two of these things might be good, then all of them are definitely just right. It is with this wretched excess in mind, we decided to bring you a pair of boosted, blow-through (carbureted) Stroker tests.

In truth, we wanted to illustrate how effective blow-through carb combos can be, but why stop at just one test when two really brings the message home? Remember, there is no reason that the EFI guys should get all the love. Enthusiasts have been running boost through carbs long before EFI came around, and the thing is, it still works!

Follow along while we cover the blow-through boosted results on a 347 Ford and a 383 LS Stroker.

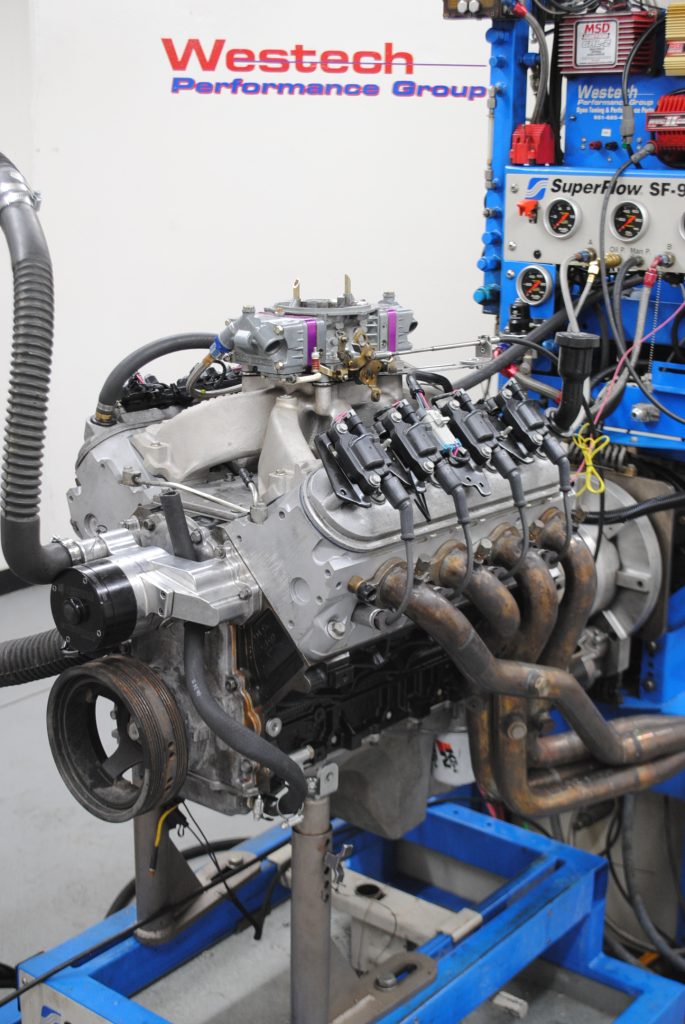

Test Motor #1: Turbo, Carb 383 LS Stroker (13.4 psi)

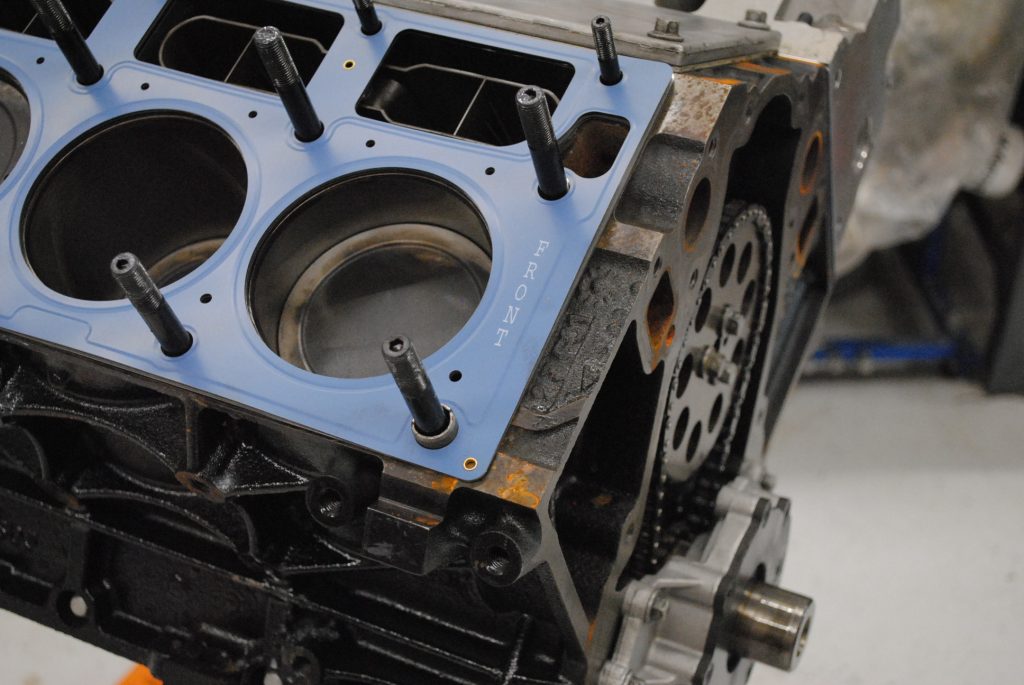

Before adding boost, we decided the first thing the boosted LS combo needed was more displacement. The 4.8L/5.3L iron block was taken to L&R Automotive in Sante Fe Springs, California for machining which included cleaning, boring, and honing to a final LS1 over-bore size of 3.905 inches (up from 3.780).

To this we added a 4.0 inch forged steel SCAT Stroker crank, a set of 6.125 inch 4340 forged rods from K1, and flat-top forged pistons from JE. In addition to being plenty strong, the JE pistons featured sufficient valve reliefs for our Stage 3, hydraulic roller cam from Brian Tooley Racing. The BTR Stage 3 Turbo cam offered 0.609/0.610 lift split, 230/235 degree duration split, and 114 +4 degree LSA.

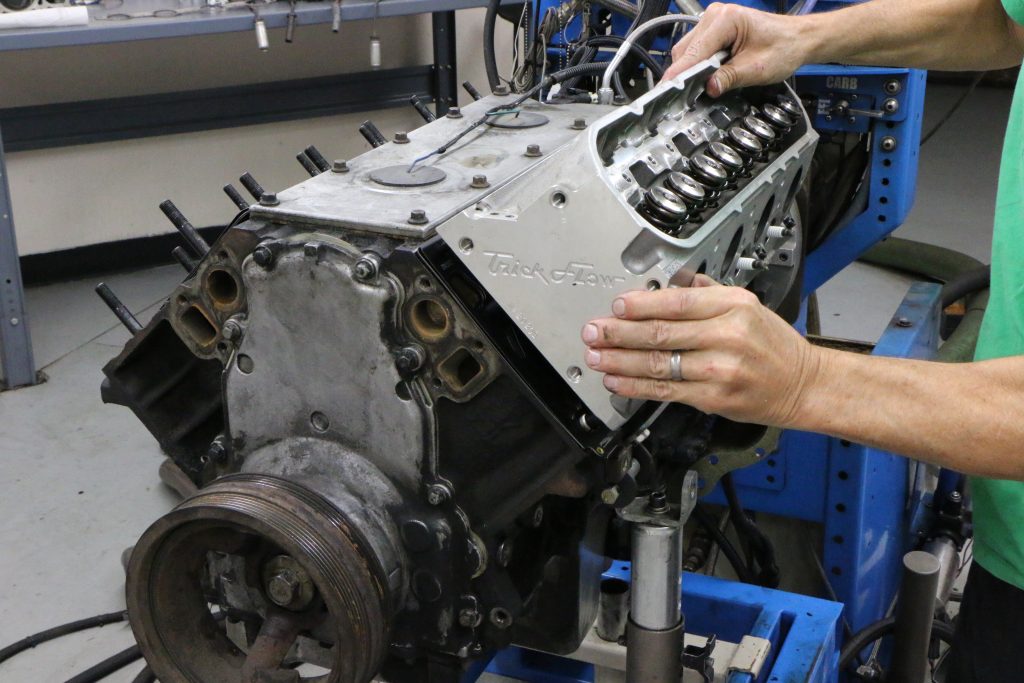

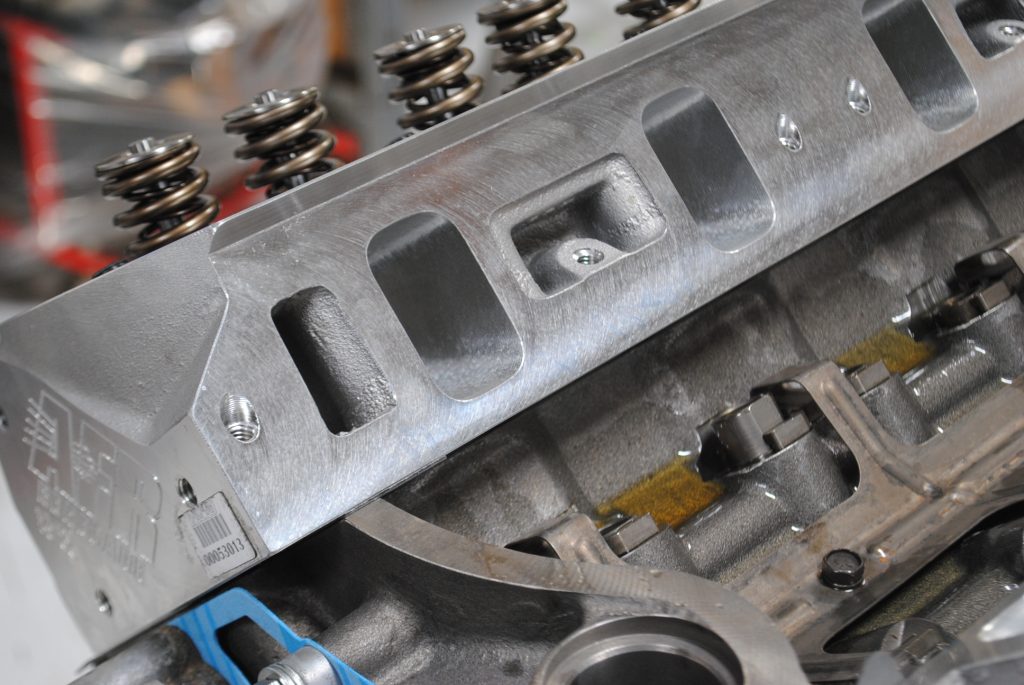

Working with the BTR cam was a set of Trick Flow Specialties GenX 215 heads. What was special about the GenX 215 heads, you ask? How about revised valve angles (from 15 to 13.5 degrees), full CNC porting, and a 2.05/1.60 stainless valve package?

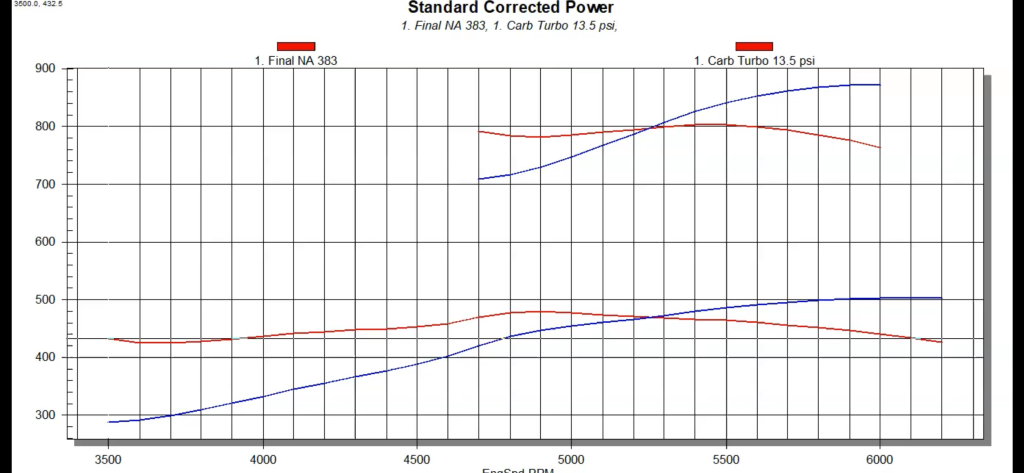

Feeding the ported heads and BTR cam was a single plane Edelbrock Victor Jr. Intake and (for the NA motor) Holley 750 HP carb. The MSD ignition controller was used to dial-in the timing curve on the carbureted combo. Run with 1-7/8 inch headers, the 383 combo produced peak numbers of 504 hp at 6,100 rpm and 479 lb.-ft. of torque.

Now it was time for some boost.

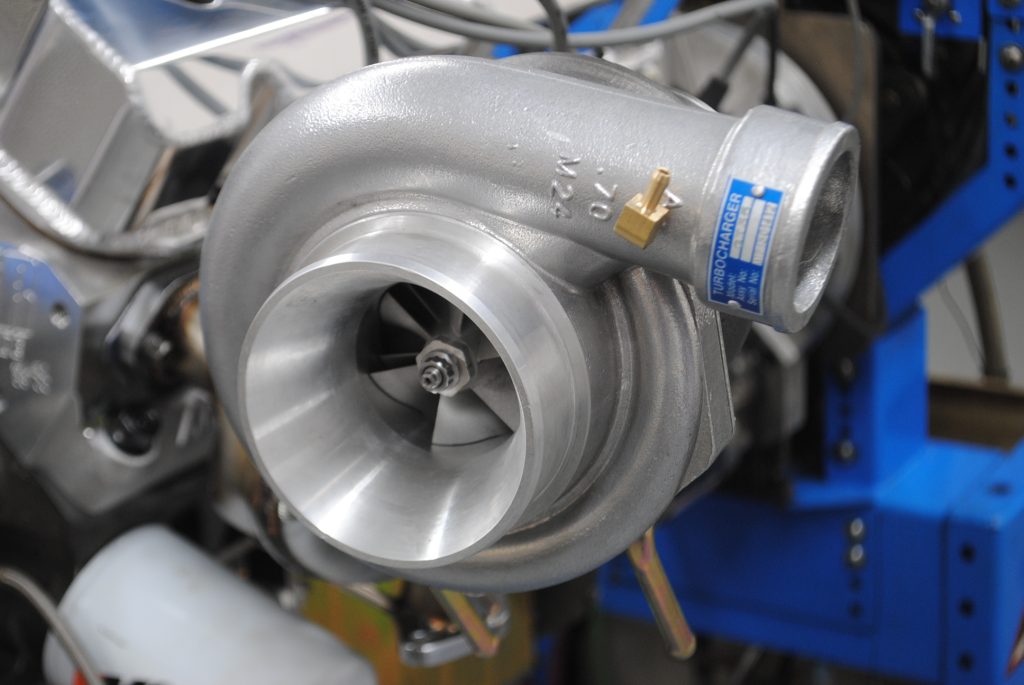

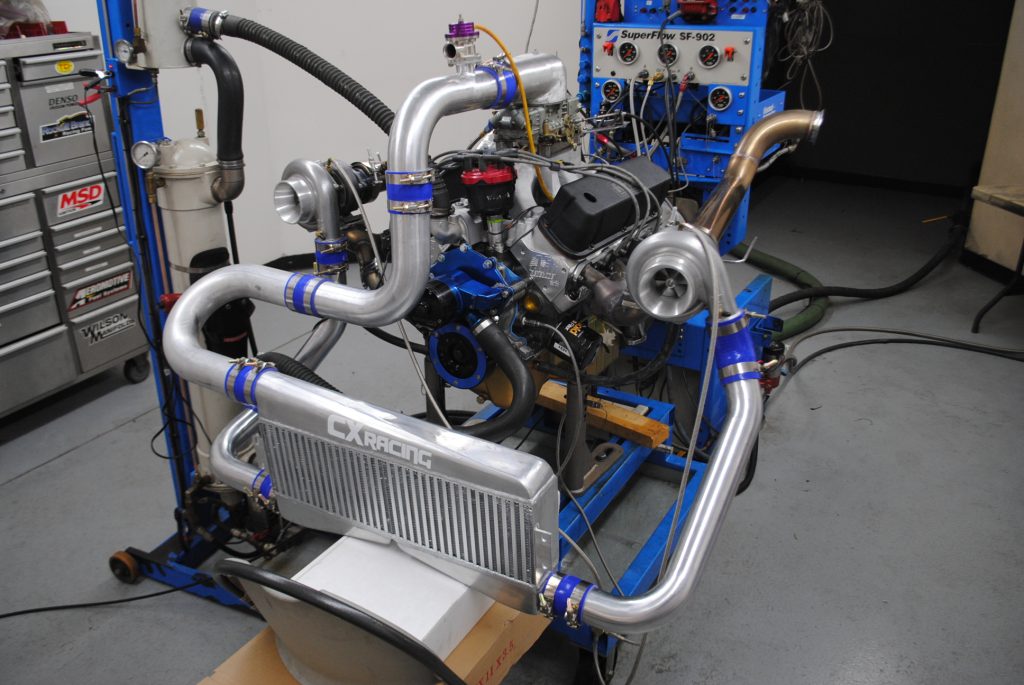

The LS turbo kit from CX Racing included tubular exhaust manifolds, Y-pipe, and a single 76mm turbo. The kit also featured its own wastegate, which we controlled with a simple manual wastegate controller (bleed valve). The kit was designed to accept a T4 turbo, but we replaced the supplied 76mm turbo with a larger GT45-style turbo. The V-band clamps allowed easy hook up, but it should be noted that the proximity of the exhaust tubing to the spark plugs and wires on this kit was less than ideal.

We ran this turbo system through a CSU blow-through 850 carb. Thanks to jetting and boost-referenced power valves, optimizing the carb was no more difficult than jetting the NA version. The blow-through, turbo 383 was run with no intercooler on 100 octane race fuel. Run in this manner, the turbo 383 produced 872 hp at 6,000 rpm and 803 lb.-ft. of torque at 5,400 rpm at 13.4 psi. Run at this boost and power level, we suspect we were nearing the absolute limit of the turbo, as the combo produced a falling boost curve. We would later run this 383 with EFI and a larger Precision turbo to the tune of over 1,000 horsepower, but the carb combo worked well on this 383 LS Stroker.

Test Motor #2: Turbo, Carb 347 Ford Stroker (12.4 psi)

To test the merits of a blow-through set up on the Ford, we built a 347 Stroker with forged internals that included a 4340 forged crank and rods combined with forged flat-top pistons from JE. With sufficient strength and displacement, we added the necessary power producers, including heads, cam, and intake.

AFR supplied a set of new CNC-ported 205 Renegade cylinder heads which were combined with a COMP XFI hydraulic roller cam and single plane, Funnel Web intake. Effective for both normally aspirated and boosted combinations, the Comp XFI cam offered a 0.579 Lift, a 236/248 degree duration split, and 114 degree LSA. COMP also supplied the necessary lifters, double roller timing chain, and hardened pushrods.

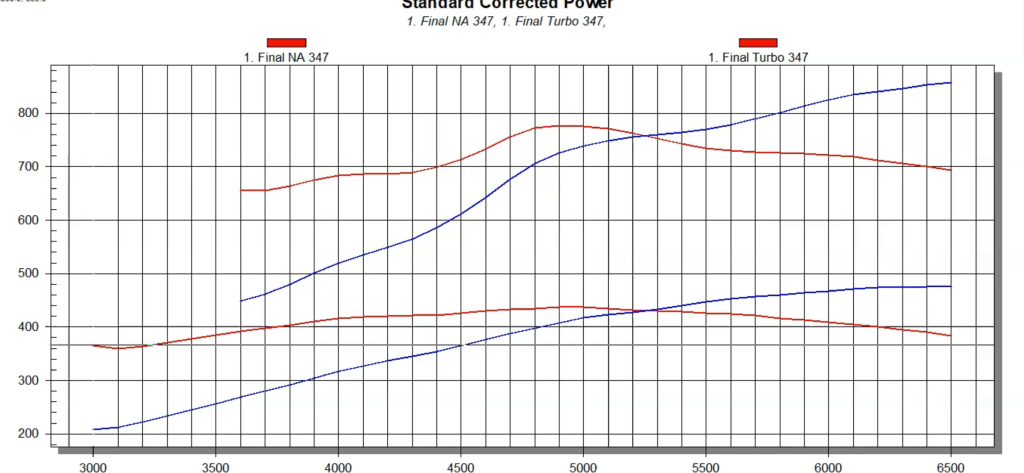

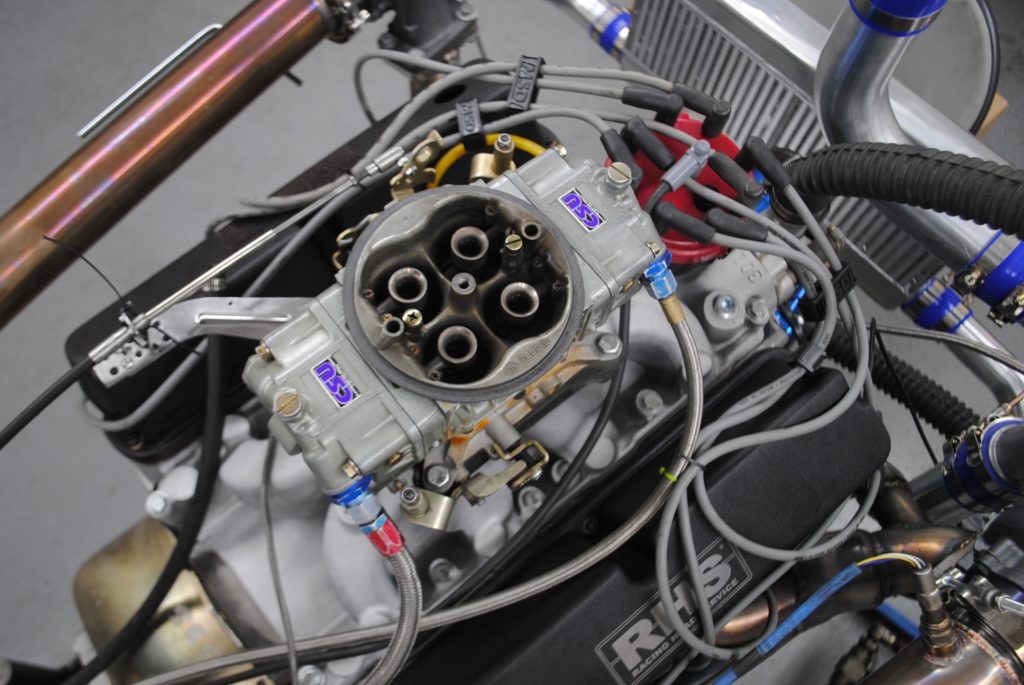

The AFR Renegade heads offered flow rates exceeding 330 cfm, or enough to support over 660 (normally aspirated) horsepower. They were obviously more than enough for our 347. Ensuring plenty of high-rpm power, the single-plane, high-rise Funnel Web intake was fed by a Holley 950 Ultra HP carburetor and fired by an MSD billet distributor. In normally aspirated trim, the 10.8:1, carbureted 347 Stroker produced 476 hp at 6,400 rpm and 438 lb.-ft. at 5,000 rpm.

Turbo time!

The Ford twin-turbo kit unit included stainless exhaust manifolds & tubing, aluminum intake tubing, and all the clamps and couplers to connect the system. The kit also featured all the oil feed and drain fittings, braided oil feed (but not rubber drain) lines, and a sizable air-to-air intercooler. The exhaust manifolds were designed to accept T3 turbine housings, meaning they will accept any size T3 turbo. We installed a pair of GT3582 turbos from Max Speeding Rods. Each Max Speeding turbo was capable of exceeding 500 hp, so they combined to provide over 1,000 hp worth of flow potential.

Before running in anger, it was necessary to orient the compressor and turbine housings to line up the oil feed and drain fittings. Once oriented, we bolted the turbos to the T3 flanges. The wastegates were also mounted to the provided wastegate flange on the manifold, but this was later modified to accept a pair of larger 45mm Hyper-Gates from Turbosmart to properly control the boost.

All the boost was channeled through the air-to-air intercooler and finally to the awaiting CSU blow-through carb. After installation of a pair of Max Speeding GT3582 turbos and CX Racing air-to-air intercooler, the blow-through 347 produced peak numbers of 858 hp and 777 lb.-ft. of torque at 12.4 psi.

Another win for the blow-through carb contingent!

Graph 1: 383 LS Stroker-NA vs. Blow-Through Turbo (13.4 psi)

Graph 2: 347 Ford Stroker-NA vs. Blow-Through Turbo (12.4 psi)

Comments