Update: We found some good audio clips of this cam’s idle quality/note. We’ll post those videos at the end of the story. We also had a reader ask about torque converter choices and alternative cams. We’ll post those responses at the bottom of this article as well.

We’ve all heard the keyboard warriors:

“Overlap is the most important element of cam timing.”

“No! Duration…or lift…or LSA is the most important element in cam timing.”

The reality is, none of these are the ONLY element to consider when choosing a performance camshaft for your application.

If power is your major concern, the very best method is to look at actual back-to-back dyno results versus other cams you might be considering—as this tells you not about possible outcomes, but actual outcomes.

Dyno results on power production are all well and good—but power production is only one of many reasons why enthusiasts choose a camshaft. The other (many) elements can include price, sound (the chop), and even compatibility with a stock torque converter. Often times these elements are the deciding factor, despite what the dyno says. After all, how many people would pick a cam that makes five to ten more horsepower, when it costs twice as much as the cam that makes slightly less?

Reasons for cam choices are as varied as individuals, but today we focus on overlap and why it (despite the keyboard warriors) does not determine the effective rpm range of a camshaft.

Our L33 LS Motor for This Camshaft Test

Before testing or discussing the two Summit Racing Pro LS cams, we needed a suitable test motor. Sitting on the stand, just begging to be put back in the game, was our trusty stock bottom end 5.3L.

Originally plucked (big score!) from a local wrecking yard, the all-aluminum L33 5.3L LS engine featured the very desirable aluminum block, matching aluminum 799/243 (the most desirable factory cathedral port) heads and early (not ideal…but still good) truck intake. Though it was possible to run the cam test on the stock motor, our L33 had already been subjected to endless testing (like, hundreds of dyno pulls) and a whole slew of upgrades.

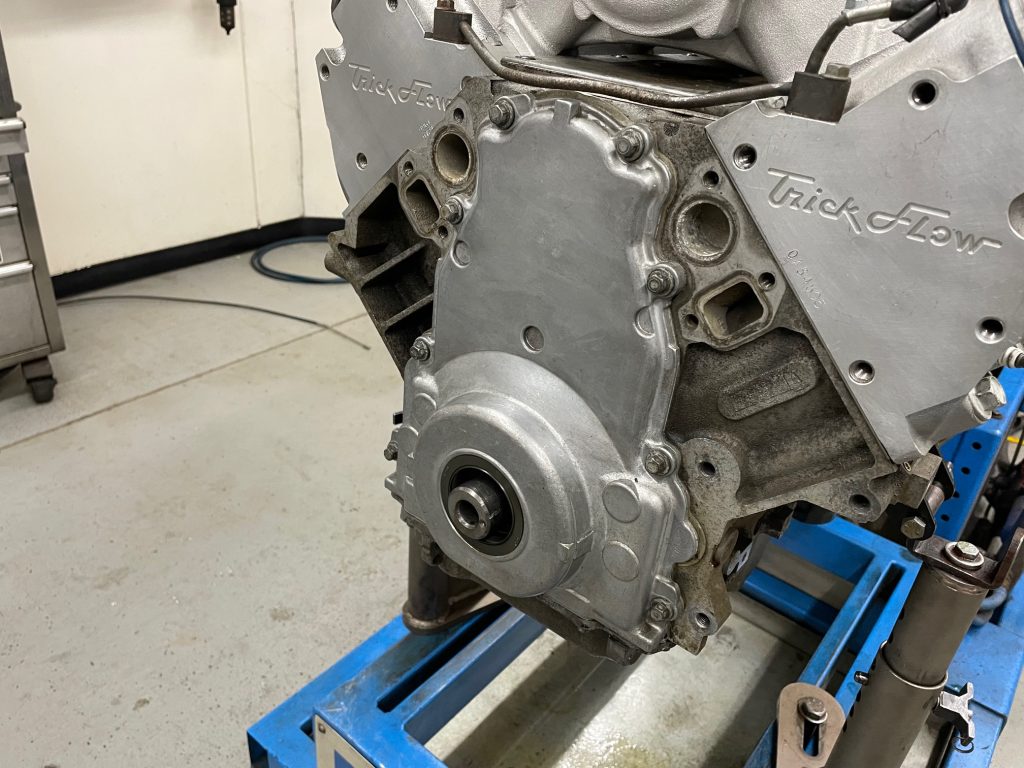

In its current configuration, the 5.3L was sporting a set of Trick Flow Specialties GenX 220 (Fast as Cast) aluminum cylinder heads for the LS. Impressive and effective right out of the box, the Fast as Cast heads were treated to further porting from the guys at Brian Tooley Racing. In addition to extensive porting, the TFS GenX heads were also milled 0.030 inch to help reduce the chamber size and increase static compression.

Because of the RPM potential of the combination, the heads also received a valve spring upgrade in the form of the BTR Extreme RPM dual spring package. The head flow would come in handy when running the Summit Racing Pro LS 8711R1 cam and short-runner intake.

The First Test Camshaft

To kick off the cam test, we first equipped the 5.3L with a Summit Racing Pro LS 8711R1 camshaft that offered a 0.625/0.605″ lift split, a 234/248 degree duration split and 113.5 + 3.5 degree LSA.

The interesting aspect of this cam comparison is that the Big Nasty 5/4 cam shared the same overlap, despite having wildly different cam specs (0.550″ lift, 218/230 degree duration split, and 105 +3 degree LSA). The folks at Summit Racing wanted to provide a cam with all the chop, but with much more low-speed torque, essentially offering a torque cam that sounded all-the-world like a nasty race cam!

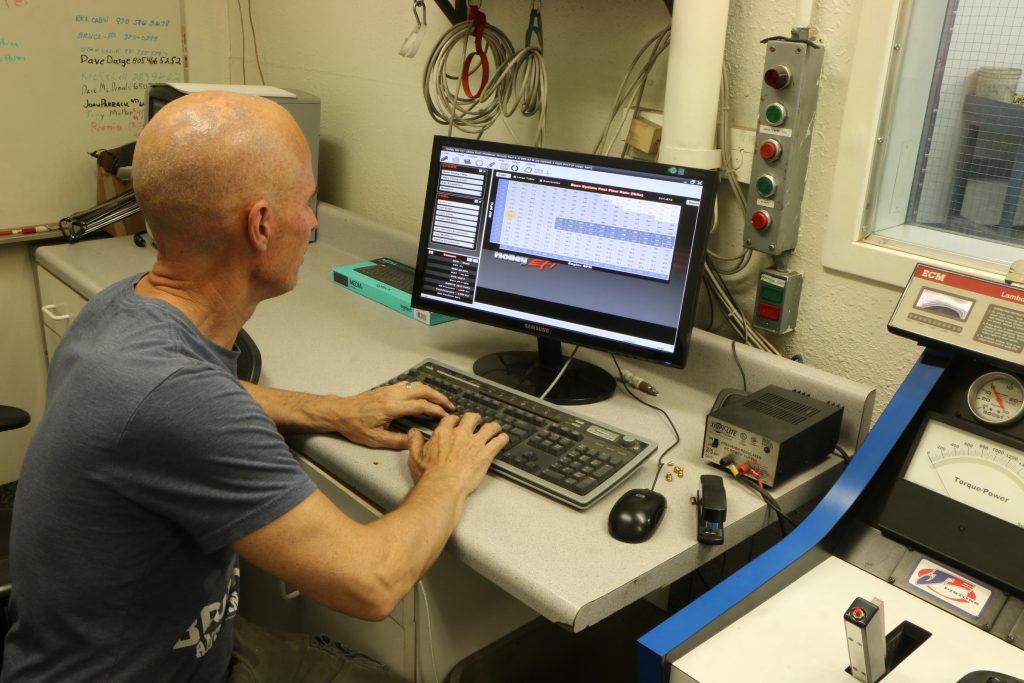

Because the Pro LS 8711R1 cam specs were optimized for higher engine speeds, we first equipped with 5.3L test motor with a short-runner intake, also designed to optimize power production at higher engine speeds. When combined with the 1-7/8-inch headers, 105mm throttle body, and Holley HP engine management system, the Summit Racing-cammed 5.3L spun right up to 7,500 rpm, run after run.

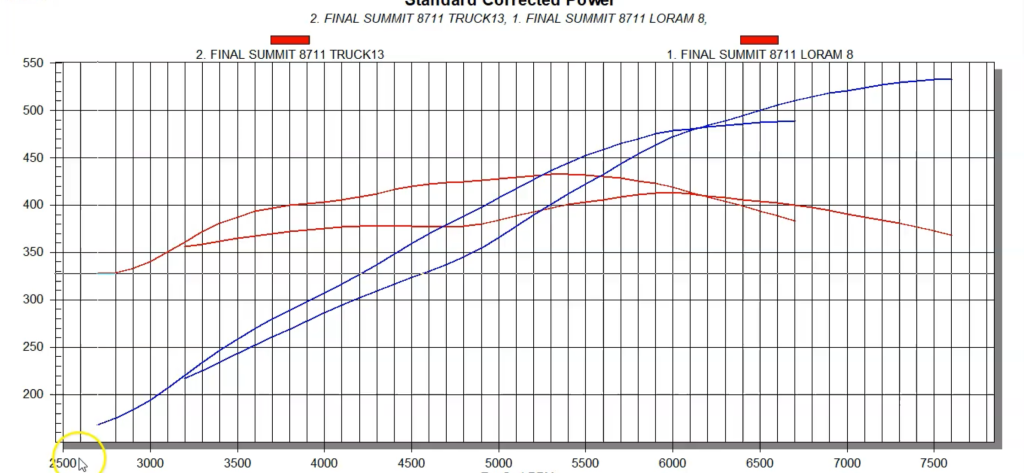

Equipped with the Summit Racing Pro LS 8711R1 cam, the TFS-headed 5.3L produced 532.9 hp at 7,500 rpm and 413 lb.-ft. of torque at 6,000 rpm. I guess the combination of wilder cam timing, short-runner intake and ample head flow allowed the SBE 5.3L to really shine on the big end.

The “Big Nasty” Cam Comparison Test

After running the Summit Racing Pro LS 8711R1 cam with the Holley Lo-Ram, we made a decision to first perform an intake swap. Despite sharing the same 14 degrees of overlap, the Summit Racing Big Nasty 5/4 race cam was actually much more efficient at lower engine speeds.

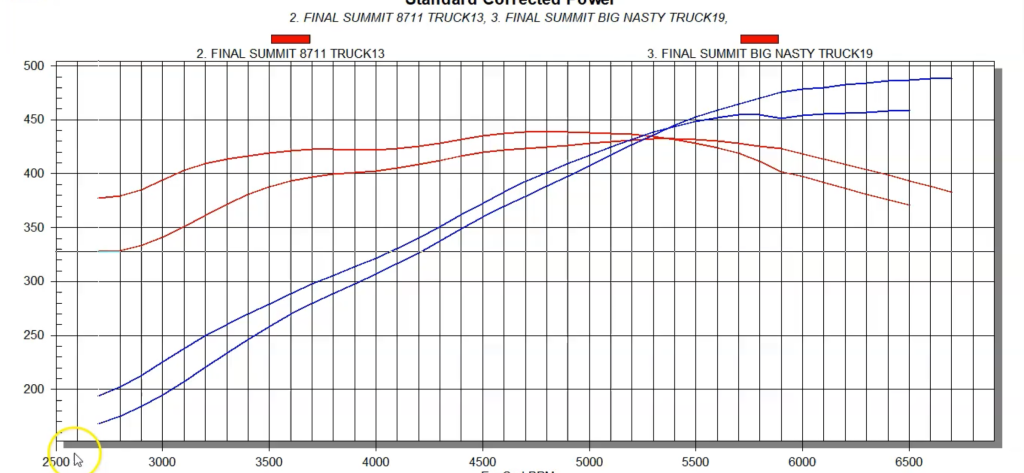

The Big Nasty would be a better match to a long-runner intake than the super shorty Holley Lo-Ram, but because we wanted a direct back-to-back test, we first ran the 8711R1 cam again with a factory truck intake. Run with the truck intake and 8711R1 cam, the 5.3L combo produced 488.5 hp at 6,700 rpm (800 rpm lower than with the Lo-Ram) and 432.5 lb.-ft. of torque at 5,400 rpm (600 rpm lower).

After running the 8711R1 with the truck intake, we tore into the 5.3L and swapped in the Big Nasty!

Equipped with the Big Nasty cam, the modified L33 produced 459 hp at 6,500 rpm and 438.8 hp at 4,800 rpm. Naturally, the milder Big Nasty produced less power than the bigger 8711R1 cam, but it did offer more peak torque (by six lb.-ft.). The minor gain in peak torque did not show the real strength of the Big Nasty specs, which came down below 3,000 rpm.

Compared at 2,800 rpm, the Big Nasty offered an additional 51 lb.-ft. of torque, and out-powered the bigger cam up to 5,400 rpm.

Remember, these two cams had the same overlap, yet offered wildly different power curves!

A Question on Torque Converter & Cam Compatibility

Q: I’m running a stock converter at the moment with the factory 4l60e. I have a built th400 with a 4k stall and trans brake all ready to install. I would say the loss of power down low from the factory converter is very minimal, definitely a ton less than any other cam I’ve run on a stock converter. It will still break the tires from a dig with a stock converter, stock 3.73 gear & a set of 20” LTZ wheels if I go wot while turning a corner. I also have 750lbs of subwoofers right over the rear axle.”

Summit Racing’s Answer:

That is Awesome and pretty amazing considering the short runner intake manifold. We designed the SUM-8728R1 Big Torkinator camshaft but limited overlap to -5 degrees to help guys out with fuel mileage…the downside is lack of big chop.

With Big Nasty, we were free to do anything we wanted and there’s a strong chance it will out torque Big Torkinator down low. In fact, it might out torque ANYthing at 2,700 rpm. The reason for this is the intake is open at 7 degrees BTDC and the valve is further open during the piston downstroke the whole way down. More air digested with the same 33 degree intake closing point as Big Torkinator means more torque.

The only downside to the overlap is it’s more sensitive to backpressure so a free-flowing exhaust must be used to compliment the cam fully if Max Torque is the goal.

Richard, what’s the idle vacuum like?