What do we want? Boost!

When do we want it? Now!

How much do we want to pay? Very little!

Such is the conundrum experienced by fellow performance enthusiasts, I mean who doesn’t love the idea of having a boosted LS, right? The only problem is boost makes speed and speed costs money, so how fast do you want to go?

Finding Boost on a Budget

Obviously starting with a junkyard LS is taking the low-buck approach, but how do we add an equal helping of low-buck (junkyard) boost?

The answer comes in the form of a factory Eaton M90 roots supercharger that came as original equipment on seemingly millions of 3800 V6 GM performance motors. Popular applications for the supercharged version of the 3800 included the Pontiac Grand Prix GTP, the Buick Regal GS, and even Monte Carlo SS. Bonnevilles, Rivieras and even Holden Commodores (Aussie, Aussie, Aussie) sailed on with supercharged power too.

There were actually several different superchargers (including smaller M62s) employed on various generations of the engine, but we knew the hot setup was to get the Gen. V blower used on post-2004 L32 3800s. The Gen. V blower improved flow and boost from a revised discharge and larger factory throttle body. The L32 3800s also featured a few internal engine mods to raise their power output from 240 to 260 horsepower, but we were unconcerned about those since we only cared about the cheap blower for our LS. (Fear not, if you can only find the early L67 blowers, these will work too, albeit with slightly reduced flow.)

Adapting the Blower for V8 Power

To get things started, we snagged one of the used blowers from a local wrecking yard—there should be plenty to choose from, just make sure to look for the later Gen. V blower (which are easy to spot with the unique drive-by-wire throttle body).

A cheap blower is all well and good, but naturally the 3800 V6 blower was never designed for use on a bigger, more powerful V8, right? Did it flow enough to even work?

One thing for certain, we knew it would not work on our 4.8L V8 test motor with the stock blower pulley. Simply put, the airflow and eventual boost supplied by the positive displacement roots blower was a function of three things, the size (or displacement) of the blower, the speed of the blower (relative to the engine), and the power output or airflow needs of the motor we applied the supercharger to.

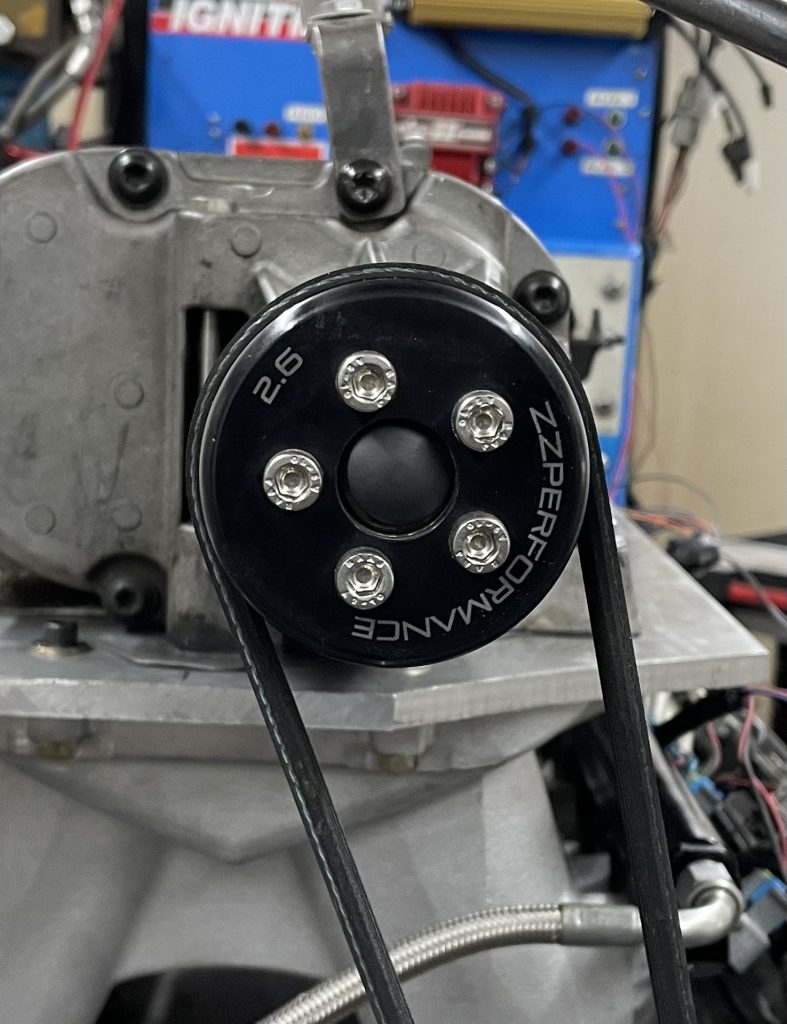

Bigger blowers supply more airflow, as does spinning the blower faster relative to the engine. Recognizing this, along with the fact that we had stepped up the flow requirement of our naturally aspirated motor (from roughly 200 hp on the V6 to 375 hp), we opted to swap out the factory 3.8 inch blower pulley for a smaller 2.6 inch pulley. When combined with the (near) 7.5 inch factory truck damper on our LS motor, this pushed the blower speed over 18,500 rpm at 6,600 rpm (engine speed). Any small increase in power we might have received from the low boost supplied by the stock blower pulley should now be much more significant.

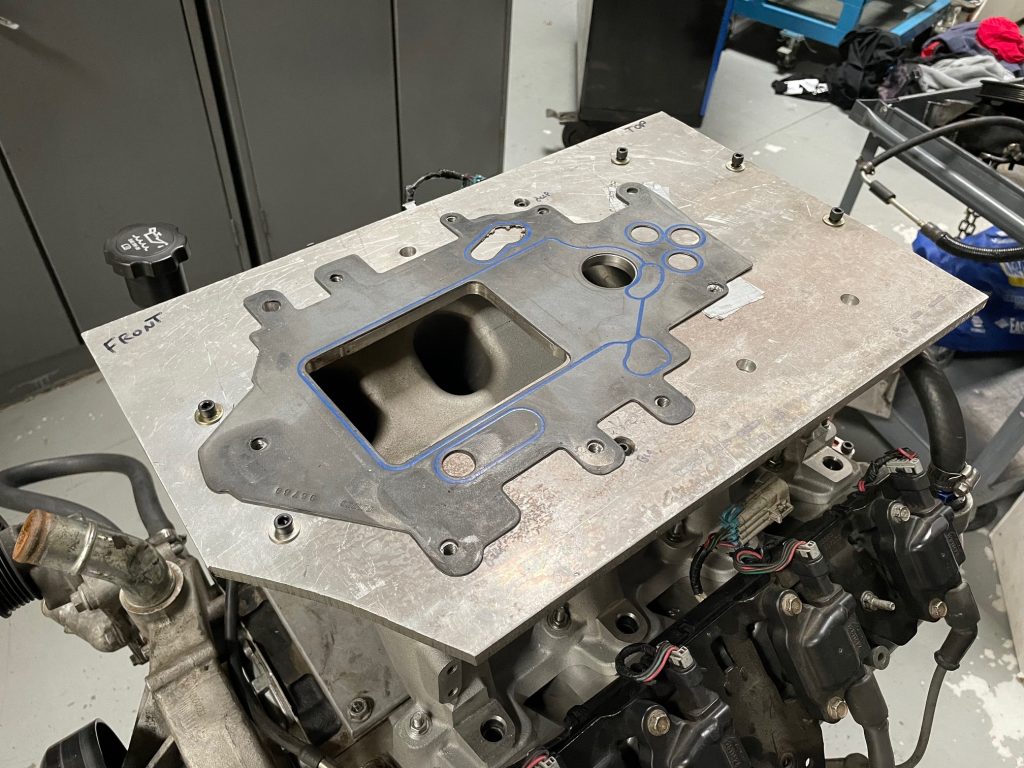

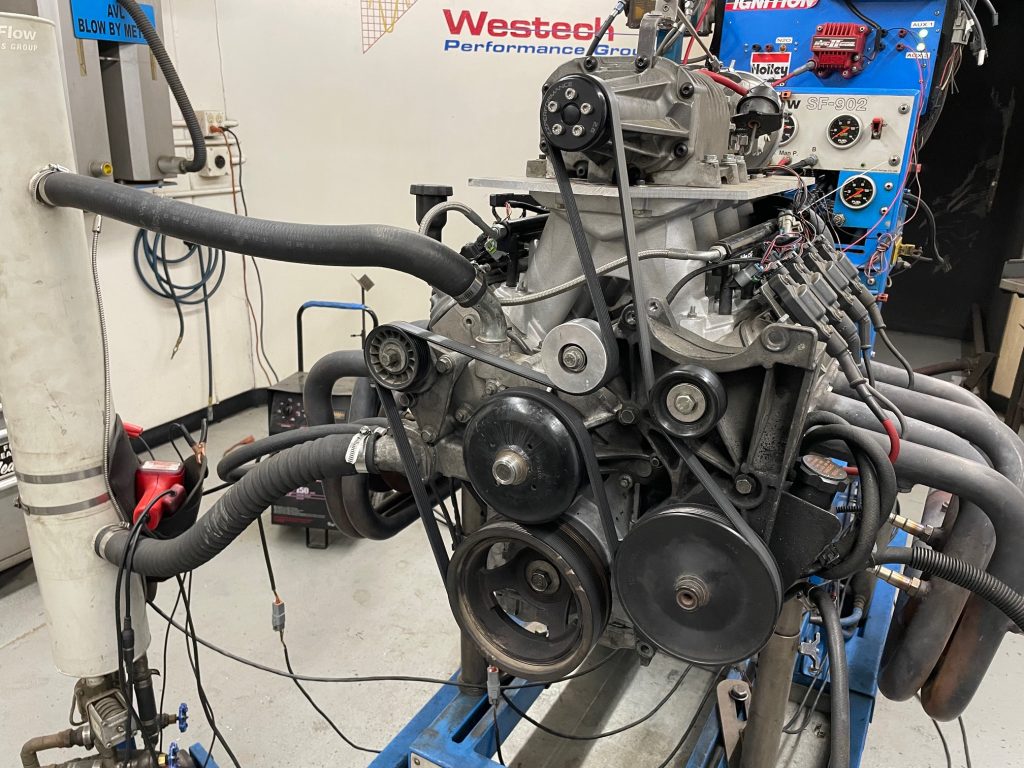

Because the 3800 V6 supercharger was not equipped with some sort of universal mounting flange, it was necessary to make a dedicated adapter plate. In our case, we opted to mount the Gen. V blower to a Hi-Ram Holley intake manifold, though it will also work on a Low Ram, since the two have identical intake flanges. Compared to the typical roots blower intakes (including the factory V6 lower intake), the Hi-Ram offered longer runners, though nowhere near as long as the factory 4.8L truck intake. The runner length should help with torque production, though we suspected the boost would produce ample torque.

Engine & Blower Mods

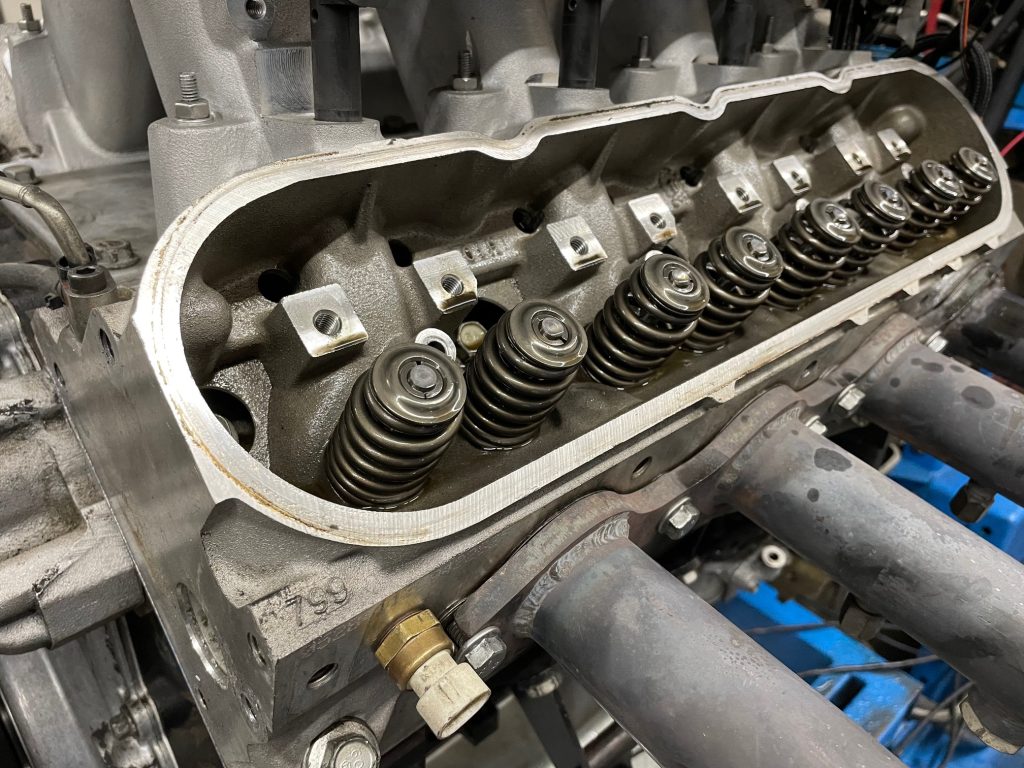

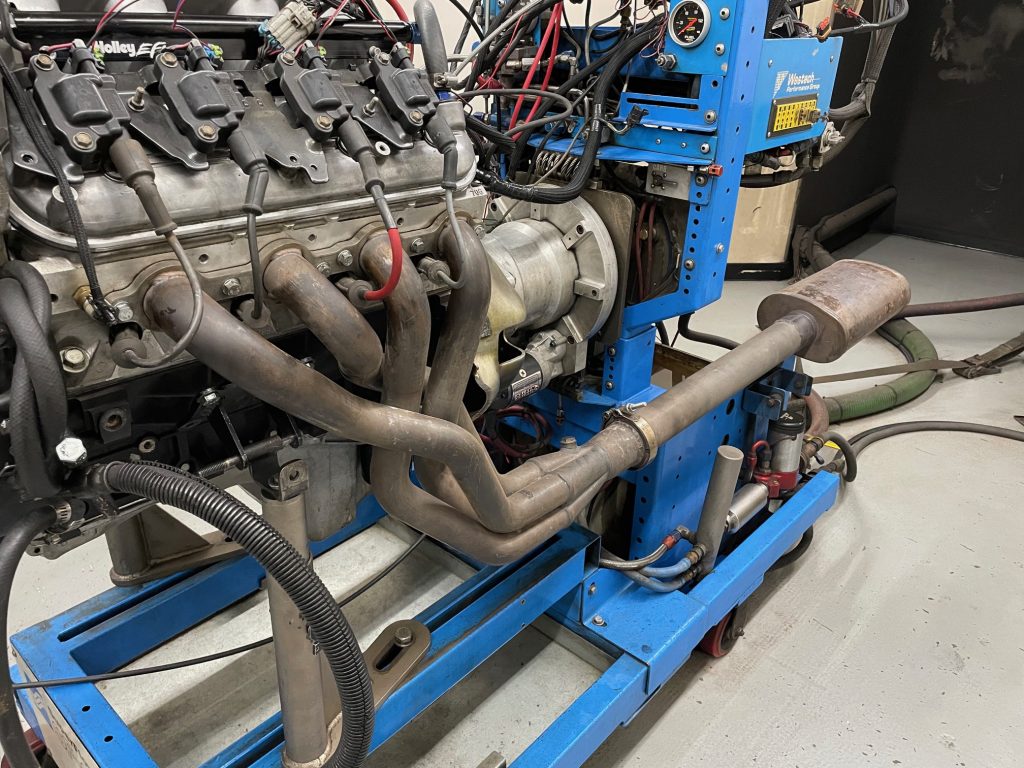

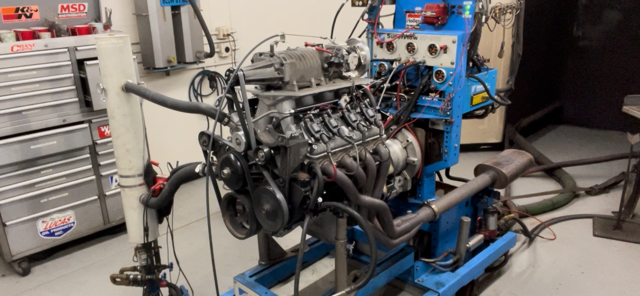

Modifications to the 4.8L LR4 LS motor used in this test included a cam upgrade (but stock springs) and long-tube headers. For a cam, the 4.8L was previously equipped with a Truck Norris NSR cam from Brian Tooley Racing. The cam offered 0.498 inch lift (same on intake and exhaust), a 212/22X, duration split and 107.5 degree LSA.

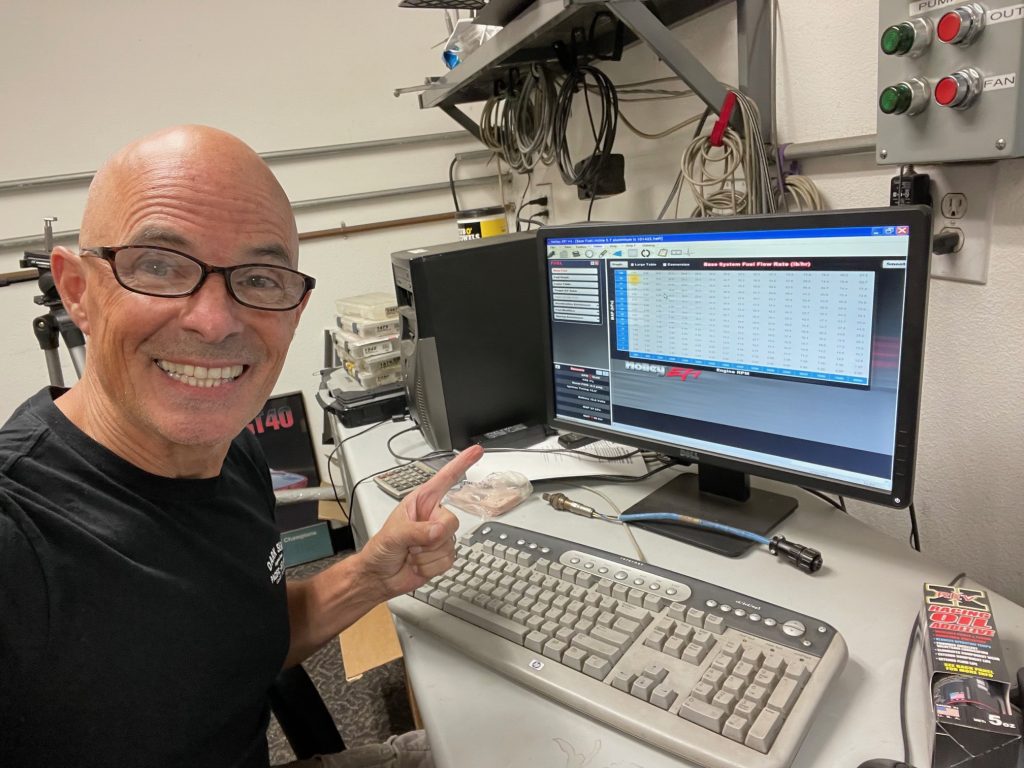

This junkyard blower did not need, nor was it given any type of dedicated “blower” cam. This means you can run just about any type of cam with great success, from the stock 4.8L LR4 cam up to the many performance grinds offered by the various manufacturers (including Summit Racing Pro LS grinds). The BTR cam was run simply because it happened to be in the motor at the time. For this test, the 4.8L was equipped with a set of 1-3/4 inch long-tube headers with collector extensions, though it would later be tested with larger 1-7/8 inch headers and mufflers. The supercharged motor responded very well to the large headers, longer extensions, and free-flow Magnaflow mufflers. All tuning was through the Holley HP engine management system, using E85 and 80 pound Accel fuel injectors.

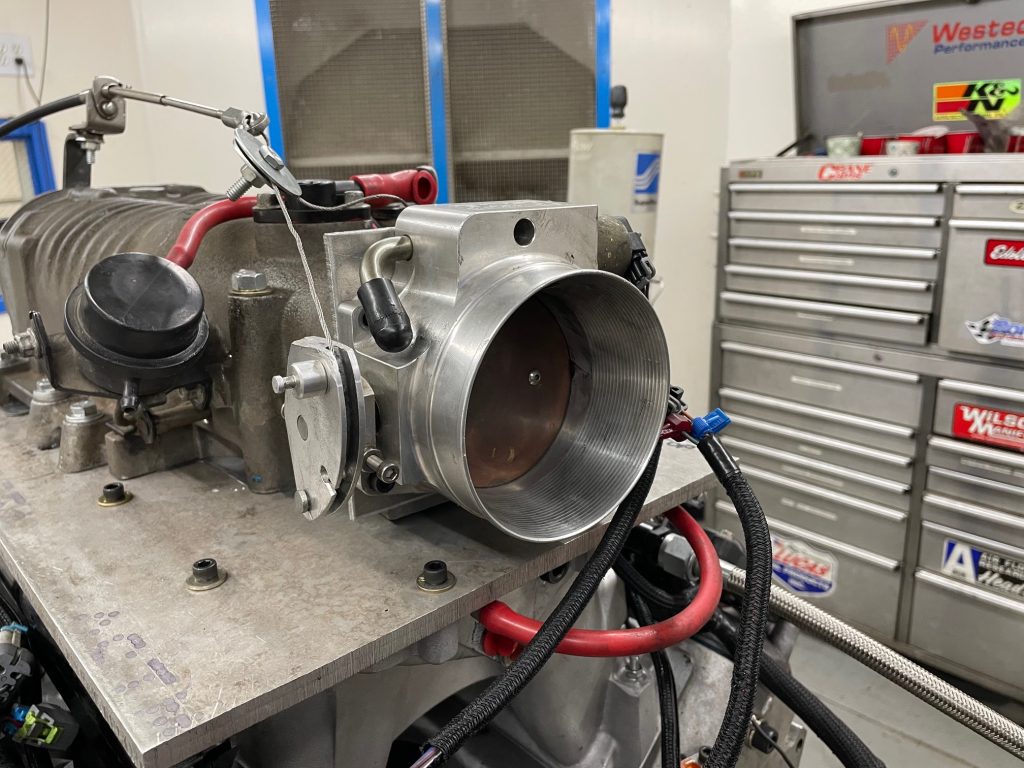

Before running the 4.8L, we made one final modification to the blower. To further improve the flow rate, we ported the throttle body entry. Because the factory V6 DBW throttle body did not have provisions for the IAC and TFS (plugs on our Holley LS Harness), we opted to run an LS throttle body.

In order to do that, we made an adapter plate with the two different mounting flanges, then port matched the opening from its original 75mm out to the 92mm throttle body. We never actually went all the way out to 92mm, so there was still a mismatch between the 92mm throttle body and the smaller (roughly 85mm) opening. We even employed and tested a fully-radiused air entry, but the bottleneck was still in the opening of the blower past the ported section.

Blower Test Results

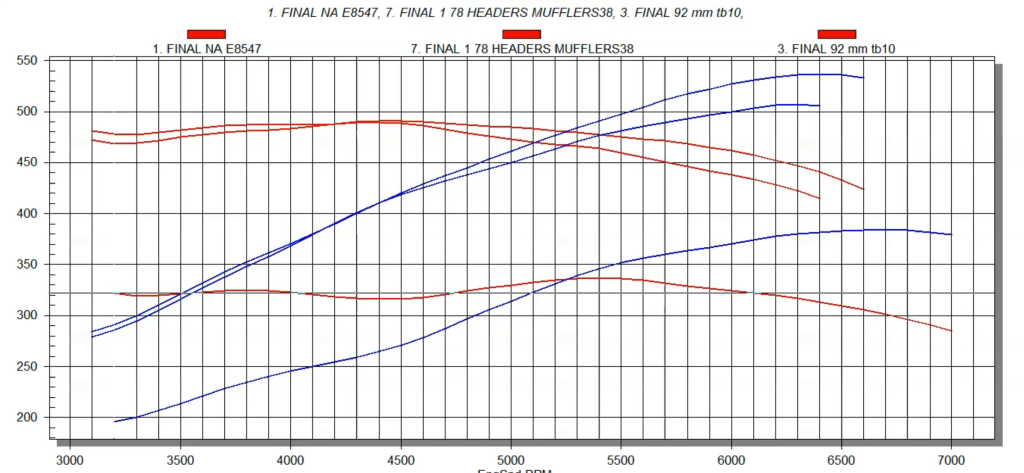

To illustrate the gains offered by the blower, we first ran the mild 4.8L in naturally aspirated trim. Run with a Holley lid and 102mm throttle body (overkill on this 4.8L), the NA 4.8L produced 385 hp at 6,700 rpm and 336 lb.-ft. of torque at 5,400 rpm.

After installation of the Eaton M90 and adapter plate, the peak numbers jumped to 507 hp and 490 lb.-ft. of torque at just under 9 psi. These numbers were pushed slightly higher to 537 hp and 491 lb.-ft. with the installation of a bigger Hot Rod cam (from BTR) and a set of 1-7/8 inch headers with mufflers.

For LS guys looking to add some cheap torque, Tom Demuse of Demuse Engineering should have M90-to-Hi/Low Ram adapters plates ready to go by the time you read this.

Can this set up work on a 5.3 if not what kind and 4 cheap.