Automotive oil filter magnets have been around for nearly as long as the internal combustion engine—so what makes us skeptical of their purpose?

They can be expensive for one thing. They must also be transferred from the old filter to the new one every time you change oil. They are not always completely understood.

Are Oil Filter Magnets Worth the Investment?

We can tell you oil filter magnets are worth the investment in what they provide in engine and driveline protection. They capture ferrous metals (iron and steel particles) in the filtration process to keep harmful magnetic metal particles away from your engine’s precious moving parts. They’re also perfect for driveline components.

FilterMag tells us with the tight tolerances of today’s engines and transmissions, normal wear and tear generates iron and steel particles that remain suspended in oil. These particles are so small they can pass through the best oil filters. As hot oil circulates back to the oil sump, these iron and steel particles are carried back into the engine’s oiling system. With an oil filter magnet, these particles become trapped on the inside wall of the oil filter and are thrown away when you change the filter.

It has been proven the removal of very small iron and steel particles (10 microns) from lubricating oil has a very positive effect on engine life. The finer the filter element, the more beneficial good filtration is for longevity. Add a filter magnet and the result becomes even more beneficial.

How Do Oil Filter Magnets Work?

In order to understand what filter magnets do, you must first know something about metal. Not all metals are magnetic, meaning they are “non-ferrous” metals. Non-ferrous metals are aluminum, copper, lead, zinc, tin, gold, silver, and even some diecast. These metals are not magnetic and cannot be trapped by a filter magnet.

Ferrous metals, with a few exceptions such as some stainless steel alloys, are magnetic and can be trapped by a filter magnet. Steel alloys consist of a cocktail of metals designed to make steel stronger. We create a steel alloy via the infusion of chromium, nickel, titanium, and other metals to get greater strength and durability. Titanium enables us to produce lightweight steel, which is especially important in aviation and racing for both strength and weight reduction. Stainless steel is an alloy produced using chromium primarily. It is typically non-magnetic depending upon the alloy mix and it is corrosion resistant.

Just plain old-fashioned steel is made from iron with a carbon mix to harden the iron. This process begins by heating and melting iron ore in blast furnaces. The melted steel comes out of the furnaces and is poured into molds to form ingots used in the manufacture of steel products. High carbon steel has a higher carbon content compared with other types of steel, which makes it stronger. Cast iron used for engine blocks, heads, cranks, and even camshafts comes from raw iron, carbon, and silicon to give it strength. There are several forms of cast iron depending upon the strength desired.

Stray iron particles from castings can eat away at bearing and journal clearances, score cylinder walls and piston skirts, damage piston rings, score cam lobes and journals, and eat away at the oil pump. Iron particles originate primarily in poorly cleaned and serviced iron castings and parts. At that, you can be thorough in your cleaning and still wind up with destructive metal particles floating throughout your engine’s oil system, which is all the more reason to use a filter magnet.

Popular Types & Uses of Magnetic Filter Metal Catchers

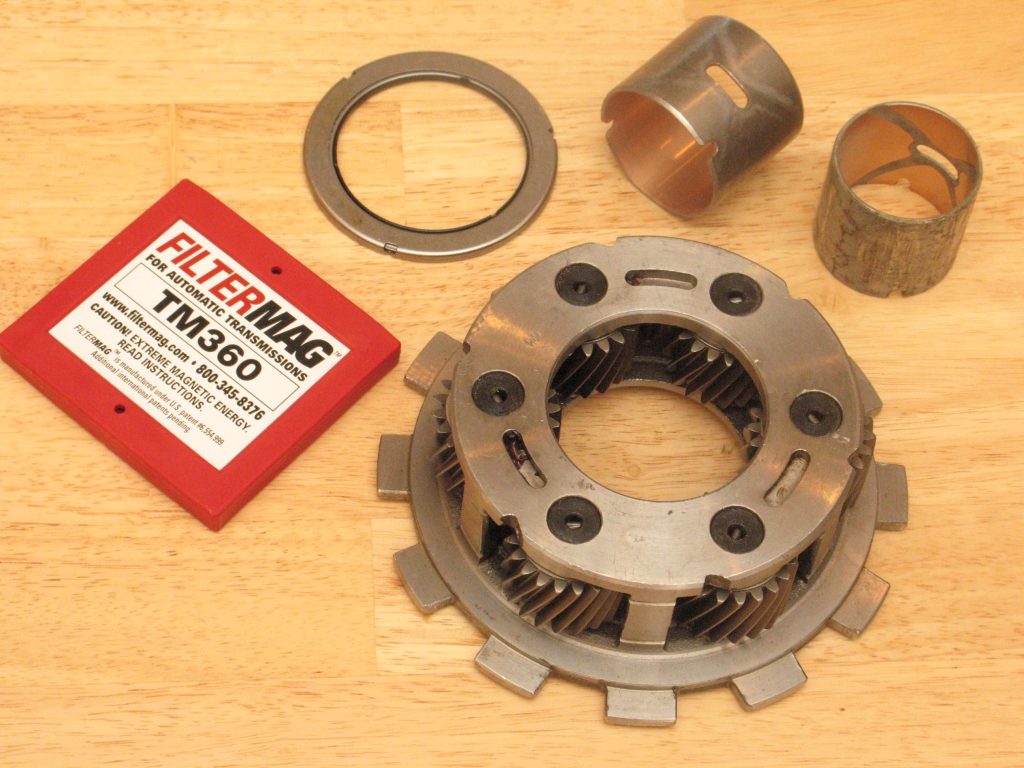

Filter magnets are available for a variety of purposes—oil filters, transmission fluid, and power steering filters along with transmission, engine, and drive axle sumps. You can place them anywhere you want protection. And this isn’t just about filter magnets, but any magnet you can place at the lowest point in a component to keep metal fragments away from moving parts. Automakers place magnets in automatic transmission sumps to catch harmful magnetic contaminants. You can place a magnet in your engine’s lowest point in the oil sump for protection.

Cruise the web and you will see all kinds of metal entrapment devices for both filtration and simple trapping at the lowest point in the oiling system. There are inline magnet filters for transmission and power steering cooler lines which are very effective. They don’t just trap debris, they catch ferrous metals that can do damage.

The most common name out there is FilterMag, which is available for virtually every application imaginable. FilterMag is a high-power magnet that “grabs” the outside of your oil filter—and any ferrous metal particles that happen to pass through it on the inside. Cut your oil filter open at the next oil change after installing FilterMag and you will see fine metal particles on the filter shell.

You will want to place FilterMag at the lowest spot on the oil filter, which keeps iron and steel debris well away from the oil pump. FilterMag also offers magnets for automatic transmission sumps, which are best placed toward the rear of the sump or at the lowest point to catch ferrous metals.

There is also MagnaFilter for engine oil filters and Magnefine for transmission and power steering fluid cooler lines. The Magnefine inline filters are installed in the return side (low pressure) side of the system to capture any debris on its way back to the pump. Magnafilters are installed between the oil filter and the engine’s oil filter mounting location. The magnetic disc structure of the Magnafilter provides for a regular replacement interval of 50,000 miles, which guarantees oil flow even under the harshest conditions without disrupting oil flow.

In short, external filter & pan magnets simply don’t work. When I apprenticed as a transmission tech, the boss decided to put magnets on the pans of our rebuilds. By chance, I was using a Trans pan for a parts bin during a rebuild. With a magnet on the outside, one would expect a gaggle of 1/4″ ball bearings would congregate over the magnetized portion. That was not the case. It had no effect. The metal of the pan simply disrupted the magnetic field. Thus, just another “snake oil” automotive product.

Yup, the magnetic flux wants to travel through the closest, most permeable medium it can find. If a magnet is stuck to something permeable that’s where the flux goes, not into the air or oil on the other side. There is a way around this, but I don’t know if “stick ons” would work. If the magnet is quite stong and/or the wall is thin enough, the permeable medium will saturate and some flux will jump into the less permeable medium. Maybe on a filter with rare earth magnets? I’ll do a test…

Welp, these things *might* work on oil filters. Using a 1/2 inch rare earth magnet I was easily able to pick up a #4×6″ center drill through .025″ of carbon steel. I could still feel it through .75″ plate, but it wouldn’t be strong enough to pull anything out of suspension. Tested a few different sizes; depending on how stong the magnet is it *could* be effective up to .06″ but I think fluid flow would likely just keep the particles in suspension.

How do they work on plastic housing?

I don’t think I’ve seen a disposable canister-style spin-on oil filter with a plastic housing–most I’ve come across have a steel shell. In those instances, the FilterMag simply attaches to the outside.

…

But, I’m guessing you’re referring to an engine with perhaps a composite oil or transmission pan? In which case, you’re right, those flat FilterMag designs likely won’t work. In those scenarios, an inline filter like the MagneFine option might be a better choice.

The 2011 Toy.corrolla has a plastic oil filter housing that houses a filter element. There are other Toyota models the same way.

Since I was testing out this concept anyways, I grabbed some plastic and gave it go. Good pull up to .135″ thick but it won’t stay in place on its own, and I’m still not convinced these work. If you’ve ever seen someone mess around with ferrofluid (basically metal in oil) it does some neat stuff, but the magnets never pull the particles out of suspension, the oil and particles just move together (but… those particles are a lot smaller than the target size of this thing, so… maybe?)

Where can I find the oil filter magnet? I have a 08 mustang GT

Hey Kenneth, I’ll include some handy links in my reply.

…

But first, FilterMags come in 3 basic sizes: small, medium, and large. And the one you’ll need is entirely dependent on your oil filter type.

* The Small FilterMag size fits 2.5″ to 2.8″ diameter filters

* The Medium FilterMag fits 2.9″ to 3.4″ oil filters

* The Large FilterMag fits 3.5″ to 4.0″ oil filters

…

For example, using a 2008 Ford Mustang GT with a 4.6L V8, a WIX filter #51372 measures 3.68″ OD, which means you should use a Large FilterMag. A similar Fram filter for a Ford 4.6L measures 3.65″ so again, it’ll use a “large” FilterMag.

…

So if you’re using a similar filter with a 3.6(ish) inch diameter, you can buy a Large FilterMag here at SummitRacing.com.

…

Thanks for reading, hope this helps.

Great product. Should always be used.

I’m 51 yrs old, and as far as I’m concerned, my father was the best mechanic/ machinery operator around.(ofcourse)People would say “if Roy can’t fix it, it can’t be fixed” and they were right. You could put wine glasses on top of the 390s and 428s he love to rebuild and soup up. Always the fastest around, yet managed to get milage and longevity out of everything he built. Obviously the Ford fan he was….he never did this. ( not that I was aware of anyway) I’m surprised he hadn’t thought of it knowing all the other tricks on how to make an engine reach its max.

As a verry young mechanic/ machinery operator myself, I didn’t try this little experiment until my mid 20s. I used a very strong magnet my grandfather had gave me, to put on the bottom of my oil pan. The results would of been catastrophic to my SBCs. As much as I raced around, and all the 1/4 milers my buds and I did, allowed my quit a bit more race time. I still use magnets on everything I can stick one too. I’ve even thought of several inventions for engine longevity. Probablly ones the old man already thought up yrs ago.

You definitely need the engine oil filter magnets for ford engines because they tend to blow up.

Hahahaha, agreed.

One thing to mention is that, excessive heat will also disrupt the magnetic field of certain magnets. FilterMag uses Neodymium magnets instead of strontium and various others. Because of this, the oil filter heating up will not weaken the magnetic field of those magnets used. Once you actually slap one of those beasts onto a filter you’ll see what im talking about. Having done some experiments of my own with clear oil, worn filings, some 20oz pop bottles, and heat you can see the difference between certain magnets used. I run them as simple cheap insurance along with my regular scheduled maintenance…

What about hard disk magnets? Old hard disks have two pretty strong “)” shaped neodymium magnets inside them, wondering if I could use those as I have a ton of old broken hard disks laying around