Most gearheads are familiar with traditional liquid-to-air engine oil or transmission fluid coolers.

In a nutshell, it’s a heat exchanger design that moves your fluid or engine oil through a network of small tubes. Fins connected to those tubes absorb the heat from the fluid and, thanks to the increased surface area and airflow through the cooler, that heat is dissipated to the ambient air, hence the name: liquid (oil or ATF in this case) to air.

This tube-and-fin system works pretty well, but it does have some drawbacks—primarily a relatively large size and the need to be located in a spot that gets good airflow.

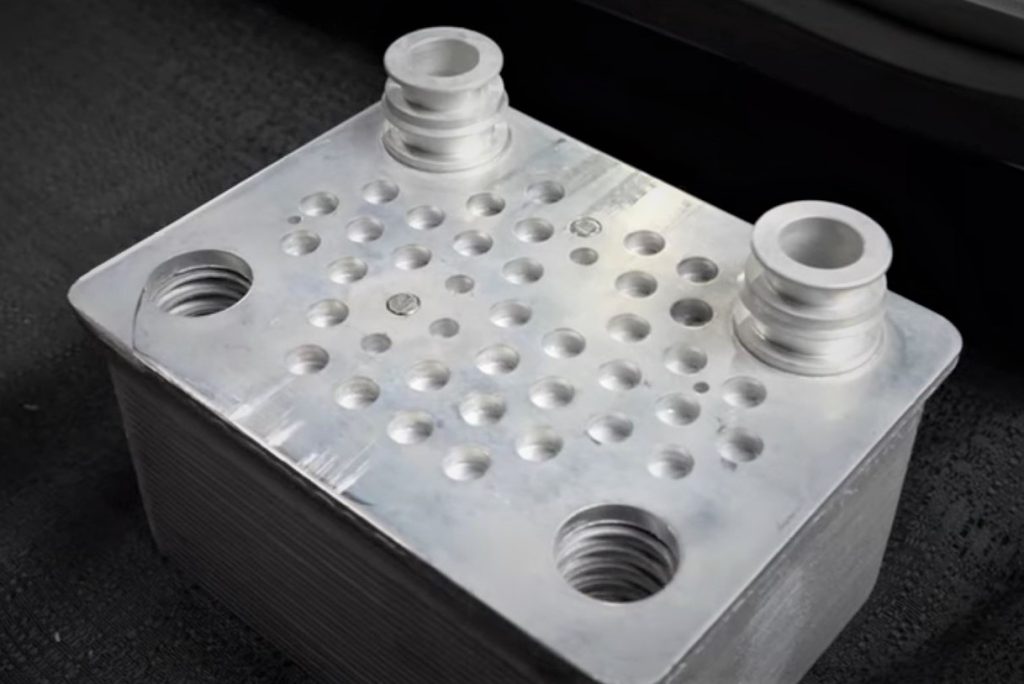

That’s why many OEs are switching to liquid-to-liquid fluid coolers. They tend to be smaller, and better still, can be placed pretty much anywhere that you can route the fluid and coolant plumbing.

The heat in the liquid (engine oil or ATF in this case) is absorbed by another liquid (your engine coolant), so that’s why it’s called a liquid-to-liquid heat exchanger.

As an added benefit, since it is plumbed with engine coolant, a liquid-to-liquid cooler like the one pictured can actually act as a gradual heater to warm-up your fluid quicker too. That can be really handy for folks in northern climates, where getting engine oil and transmission fluid to operating temperature more quickly can be very beneficial.

For a closer look, the cooling experts over at Mishimoto made this quick video that explores some benefits of liquid-to-liquid fluid coolers in greater detail. It compares some pros and cons of these coolers to their liquid-to-air counterparts, the traditional tube and fin fluid cooler. And it’ll show you some good use cases and applications for a liquid-to-liquid fluid cooler).

Check it out:

Cooling fan broke down but did not change the ATF. Affected oil did nothing to my transmission !!!