Custom plumbing systems for fuel, oil, coolant, power steering, brakes, and more are an essential part of many builds. The correct components not only ensure proper function, they also add some style under your hood.

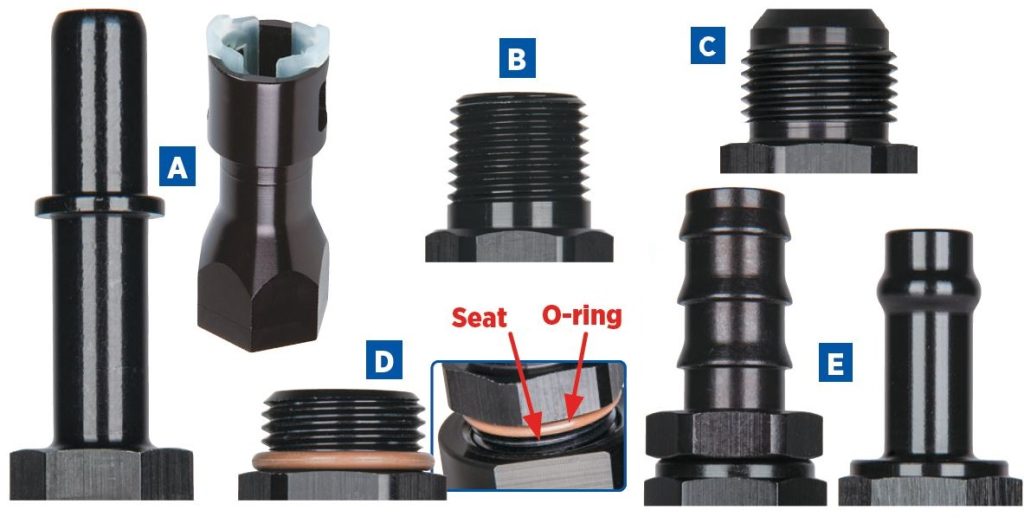

Here are some common fittings and port types for your next plumbing project. (Use the image below with each fitting’s assigned letter to reference what they look like.)

A. Quick-Connect Adapter Fittings

Late-model engine swaps often require converting from an OE quick-connect end (like on a fuel rail) to an AN flare or other common fitting type. The most popular dimensions used in factory fuel systems are 3/8″ and 5/16″ (or 8mm). While these dimensions are standardized, the connector’s locking design can vary. Always verify your fuel line adapter size and fitment type before ordering.

B. NPT (National Pipe Taper)

These fittings have tapered threads that compress together, wedging the male and female threads during tightening. PTFE (aka Teflon™) tape or paste is required to lubricate the threads to prevent damage and ensure proper sealing. The standard tightening procedure is hand tight, then add another 1-1/2 to 3 turns using a wrench, clocking as needed.

C. AN (Army/Navy)

AN fittings work by mating tapered 37 degree conical surfaces together under pressure. The seating surfaces should be clean and undamaged. Never use sealants with AN connections, and avoid overtightening, which can damage the seats. These fittings are often used as hose ends or adapters. Though they’re commonly made of aluminum, steel fittings should be used in extreme pressure applications like brake systems and power steering.

D. ORB (O-Ring Boss)

These fittings use the same thread pitch and diameter as AN fittings, but feature an O-ring on the male fitting that seats into a chamfer on the female fitting. Many fuel pumps, filters, and oil coolers use female ORB ports. An ORB-to-AN adapter is needed to attach a hose.

E. Push-Lock Fittings

Also known as “hose barb” fittings, push-lock fittings use an aggressive barb to connect to a rubber hose, providing a fast, easy, and cost-effective plumbing solution. They’re available as hose ends or adapters and are generally more compatible across different hose brands. Depending on the fitting and hose, these systems are typically rated for pressures up to 250 psi and may require an additional clamp.

Comments