If you’ve modified your fuel system and are running an aftermarket fueling setup, then you may want to think about stepping up to a high performance fuel damper as well, to mitigate the power-robbing effects of unstable fuel delivery.

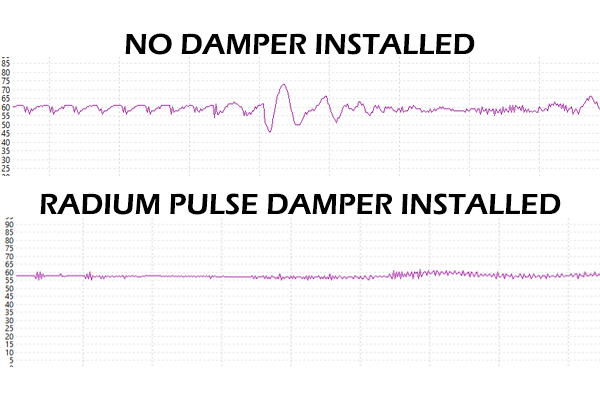

Why? Basically, the normal opening/closing operation of high flow fuel injectors can introduce ripples in your fuel pressure, which can cause problems like a surging idle, engine stumble, or a lean-running condition on certain cylinders. (You may also notice your aftermarket fuel system is a lot noisier that the stock setup too.)

Radium Engineering’s Fuel Pulse Dampers are designed to solve those problems.

Tailored precisely for high performance, high flow fuel systems, these dampers smooth out those fuel pulses to help your engine sip a steady, consistent diet of fuel across its entire powerband.

Radium’s got a lengthy blog post on the science and technology behind fuel dampers—you can check it out here.

These fuel pressure dampers feature an engine vacuum reference port too, which ensures proper operation at all RPM levels. (That’s particularly valuable if you’re running forced induction with a 1:1 rising rate fuel pressure regulator.) Radium Engineering Fuel Pressure Dampers are compatible with all types of fuel (yup, even E85), and come with a vacuum hose and Y-fitting for easy installation.

You can get Radium’s fuel pressure dampers with either 3/8″ NPT or -8 AN fittings, in your choice of anodized green or black finishes.

- RDM-20-0176 – Green, -8 AN

- RDM-20-0177 – Black, -8 AN

- RDM-20-0178 – Green, 3/8″ NPT

- RDM-20-0179 – Black, 3/8″ NPT

Comments