It all started when we noticed a telltale bearing squeak in our home’s HVAC blower motor.

Then, on the hottest day of the year…Squuuuuuuueeeeeeerrrrrrk! A bearing failed and the motor ground to a halt.

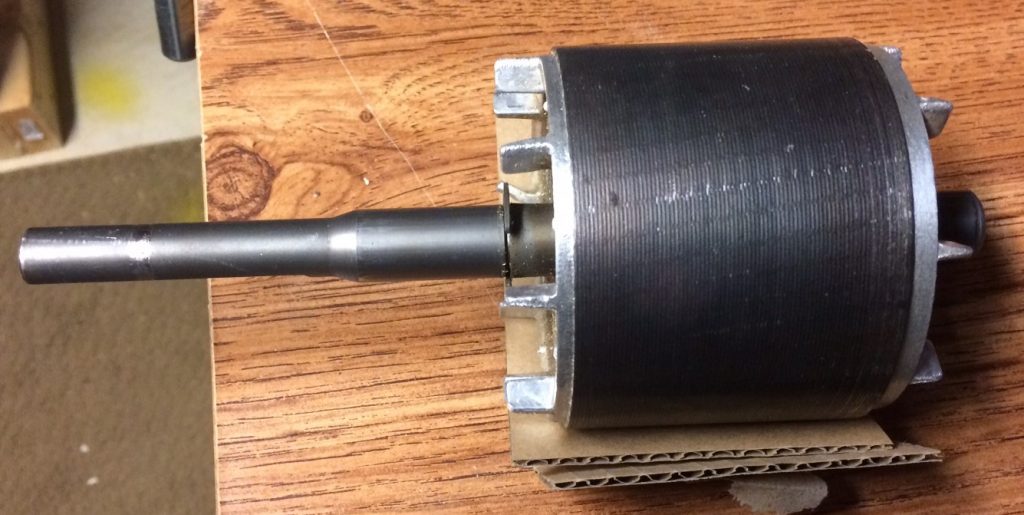

Disassembling the motor confirmed our suspicions—a roller bearing got toasted. We used a three-jaw puller to get the bad bearing off, but being a press-fit, we weren’t sure how to properly seat the new bearing back onto the motor shaft.

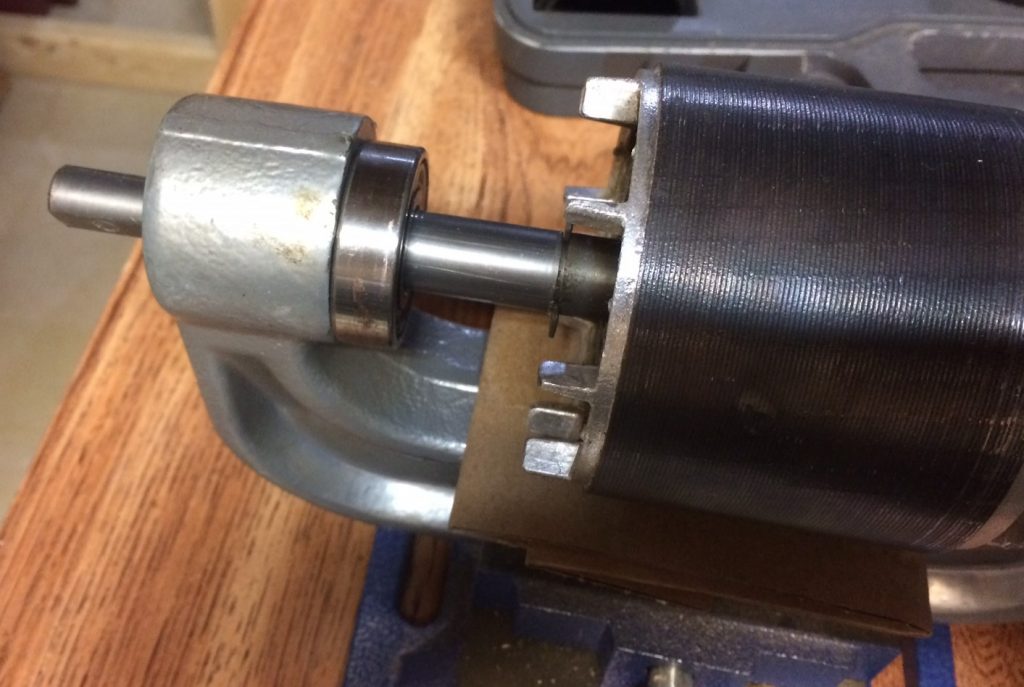

After some thinking, the proverbial light bulb popped and we grabbed our trusty ball joint press.

As the name implies, the ball joint press is a specialty automotive tool that’s designed to properly remove ball joints that were pressed-in by the factory.

…Turns out, they’re equally good at installing bearings onto electric motor shafts.

After setting up a makeshift jig using a drill press vise, we positioned the large C-clamp upright, slipped the motor’s rotor and shaft assembly through the open end of the C-clamp, and begin turning the clamp’s threaded shaft. In just a few twists, both bearings slid right on and we could reassemble the motor. An hour later, our HVAC system was blowing frosty air again.

But our little HVAC anecdote is only the beginning.

Since it’s basically a big C-clamp with a pass-through on one end, you can think of a ball joint press as a portable, yet hefty press for removing and installing small-size to medium-size bearings and bushings.

And while we delicately pressed-in our HVAC bearings using an ordinary box-end wrench, if you need more torque, you can always slip an impact driver over the nut on the end of the threaded shaft and go to town.

They’re relatively compact too, so you can often use them on individual components without having to remove a whole assembly from a vehicle.

Do a lot of woodworking? Perhaps making temporary jigs, shelves, racks, or other structures? Then you can use the ball joint tool’s pass-through as way to insert screws too. And it’s especially handy if your wood is twisted and you need to correct the warp with a strong clamp. Simply tighten the ball joint press over where you need your joint secured, and you can place a screw right inside the pass-through.

It’s worth mentioning that there are a ton of different ball joint tools out there. Most of them are sold in kits with a handful of adapters for a lot of common ball joints. More robust kits include adapters for 4×4/four-wheel drive applications as well.

All told, the trusty ball joint press is truly an unsung hero tool that can help you tackle a lot of other odd jobs besides ball joints—inside and outside the garage.

Comments