While most gearheads probably already know the difference between a leaf spring and a coil spring in a car or truck suspension, we wanted to provide a simple 101 for folks just getting into the wrenching hobby. So let’s bounce right to it.

What is a Leaf Spring?

A leaf spring is the earliest form of vehicle suspension spring. They were seen on horse drawn carriages, buggies, and steam trains, so it’s no surprise that when the first automobiles debuted, they were wearing leaf springs too.

In an automotive context, leaf springs are designed to suspend the weight of the vehicle and help suppress the effects of road imperfections. A leaf spring generally consists of multiple strips (leaves) of steel, fiberglass, or composite plastic, arranged in an arc, and clamped together to form a single spring.

For automotive applications, the leaf spring is typically attached to the vehicle frame with a solid mount and bushing on one end and a leaf spring shackle mount and bushing at the other. The shackle affords the entire spring assembly some movement and makes installing/removing the spring a bit easier.

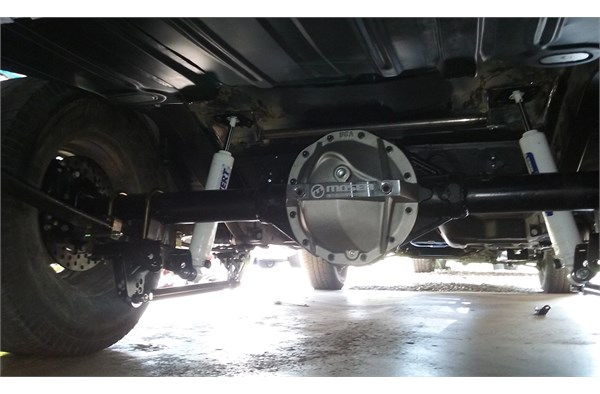

It should be noted that leaf springs do more than suspend the vehicle, they keep your axle centered in the chassis, ensuring things like your driveshaft, pinion, and rear wheels stay where they’re supposed to.

Leaf springs are a bit more complex than coil springs and, as such, require some basic maintenance–often just a periodic coating of lubricant to ensure the individual leaves don’t squeak against each other.

Leaf springs were prevalent on the body-on-frame vehicles that were common before, say, 1980. A typical setup for a passenger car was to have coil springs in front, leaf springs in the back.

While most two-wheel drive trucks adopted the coil front/leaf rear setup in the 1960s and 70s as well, some four-wheel drive vehicles maintained leaf springs front and rear into the 1980s. Heck, the Jeep Wrangler YJ rode four leaf springs all the way until 1995.

Nowadays with the advent of unibody design, leaf springs are largely the domain of heavy duty trucks, commercial equipment, and trailers.

But here’s an interesting footnote. While most leaf springs are installed in-line with the vehicle frame, some cars had the leaf spring mounted transversely—notably Corvettes. Starting in 1963, Corvettes featured an independent rear suspension instead of a solid axle. To achieve this, Chevy engineers mounted a single leaf spring sideways to secure the axles and differential housing. GM (and some European manufacturers) used this transverse leaf spring setup in other vehicles too.

What is a Coil Spring?

As alluded to above, coil springs are now very common in both passenger cars and trucks. That’s because a coil spring suspension offers a few key advantages over a leaf spring setup, namely in the areas of range of movement, adjustability, and size.

In the context of a car or truck suspension, a coil spring is simply a helix of hardened steel. You’ll typically find a single coil spring at each vehicle wheel.

Coil spring suspensions have been around for decades. As coil spring adoption grew, coils springs first appeared in the front suspension of the vehicle, then eventually the rear. This largely followed the transition from a body-on-frame to unibody vehicle design and was a vital step for vehicles moving to independent front or rear suspension configurations (aside from a few applications, like described in the Corvette footnote earlier).

Manufacturers like coil springs because they’re more compact, making it easier to design a vehicle around. They’re easier to assemble too. And perhaps most importantly, they’re lighter than leaf springs, which improves both performance and fuel economy.

As mentioned above, most light duty vehicles on the road nowadays feature a coil spring suspension front and rear.

Given their body-on-frame design that continues to this day, trucks were slower to adopt coil spring suspensions, at least in the rear. Yet as coil spring technology develops to allow for increased towing and hauling capabilities, more and more trucks are using heavy duty coil springs out back as well.

Signs of a Bad Leaf Spring or Coil Spring

Think you’ve got a failing (or failed) suspension spring? There are some obvious clues to watch for. Some symptoms of a bad leaf or coil spring include excess body bounce, lean, or roll. You may also notice your vehicle sagging more, particularly when heavily loaded or pulling a trailer, which puts more stress on your vehicle suspension.

Worn spring bushings can introduce unpleasant jolts and vibration into the cabin as well.

Are Coil Springs Better than Leaf Springs?

It depends on how you use your vehicle. For most passenger vehicles, coil springs are a simple, compact suspension solution. On performance-oriented cars and trucks, coil springs, in the form of a coil-over suspension, offer adjustability and a modular, compact footprint.

Yet for heavy-duty trucks and commercial vehicles where cargo and towing capacity are really important, leaf springs are often the go-to choice, thanks to their durability. Off-roaders often like leaf springs too, given their ability to maintain axle position and driveline geometry.

Remember, a lot of cars made before 1980 with a solid rear axle will likely have a leaf spring setup as well. That means there are still plenty of leaf spring cars out there, which also means there’s a ton of upgrade and replacement parts for leaf springs being made too.

More importantly, don’t think your leaf-spring equipped car is inadequate for today’s roads. Properly maintained leaf springs are every bit as safe and reliable as their coil spring counterparts.

I recently installed traction bars and a rear sway bar to my ’95 V8 S10

with 8.6″ 4:11 geared rearend. What a major difference in handle, launch, and overall driveability.

Yes, you can make your leaf spring car or truck handle race-worthy for less than $500. I’m pleased with my investment.

[…] too long ago, a strut or shock absorber was a separate component, divorced from either the coil or leaf spring. But on lots of modern vehicles nowadays, you’ll likely find your strut or shock combined […]

This image (https://www.onallcylinders.com/wp-content/uploads/2021/03/19/Stock-vs-aftermarket-leaf-spring.jpg)

These leafs are entirely different and entirely different applications. The ‘performance’ leaf spring is just that ‘performance’ and I suspect you’re looking for the ability to race. The second leaf spring is meant to take a load, the second leaf has more leafs at different strength tolerances to accommodate heavy loads. You cannot relate the two at all, period. They serve entirely different purposes. The ‘arc’ in a leaf is there due to engineering…. it allows for a leaf to deflect weight. Deflection. Going back to the amount of leafs which provide strength, the arc allows for deflection.

Next time provide relevant photos similar to each other to describe what you’re attempting to explain. A sloppy leaf will be nearly out of arc and worn (tired) out versus a new leaf which will display an arc. All of which depend on their engineered rating and purpose.

Hello Todd. Thank you for reading, and you’re exactly right. As mentioned in the article, the top spring is a Hotchkis Performance Spring for a second-gen Camaro with a variable rate from 150 to 180 lb./in. The lower spring is a worn, sagging spring from a 1981 Camaro. We simply used the two side by side to demonstrate that springs can have different arcs, along with the importance of assessing the condition of old bushings. The photo was part of an earlier project to upgrade the suspension on a second-gen. F-body, you can learn more about that particular project in that article here.