I was wondering if you could help me. I have a ‘99 Chevy S10 with an LS1 engine that has a long crank and iron heads. We are trying to put a 4L60E trans in it, but the torque converter flange is too long. Do you have a part number for a torque converter that will fit without having to mill the converter? Thanks,

C.C.

To bring everyone else up to speed on this question, the LS1 you refer to is more than likely an LQ4 iron block/iron head 6.0L truck engine from 1999 or 2000. These were the only engines to employ the extended crankshaft flange that you describe. The extended crank flange was used so that it the engine could be used along with a 4L80E automatic overdrive in larger trucks and vans. The 4L80E is, simplistically speaking, an electronic overdrive TH400 transmission. It uses the same bellhousing flange and bellhousing bolt pattern layout as a small or big block Chevy. GM extended the crankshaft flange on these early iron 6.0L engines to place the torque converter in the correct orientation to bolt up to the 4L80E transmission.

The 4L60E is also an automatic overdrive transmission but is smaller and different than the 4L80E. The 4L60E is basically an electronic version of the older 700R-4 four-speed automatic overdrive. The 4L60E began life in 1993 mainly in GM medium-duty trucks using a bellhousing and converter position designed to bolt on to a small block Chevy. When we compare the small block Chevy to the newer LS engine, the LS uses a crankshaft flange that is essentially flush with the bellhousing flange. Small and big block Chevys actually place the crankshaft flange about 0.400-inch farther rearward than the LS engines.

The iron 6.0L LQ4 engine you have is a two-year oddball with an extended crank flange.

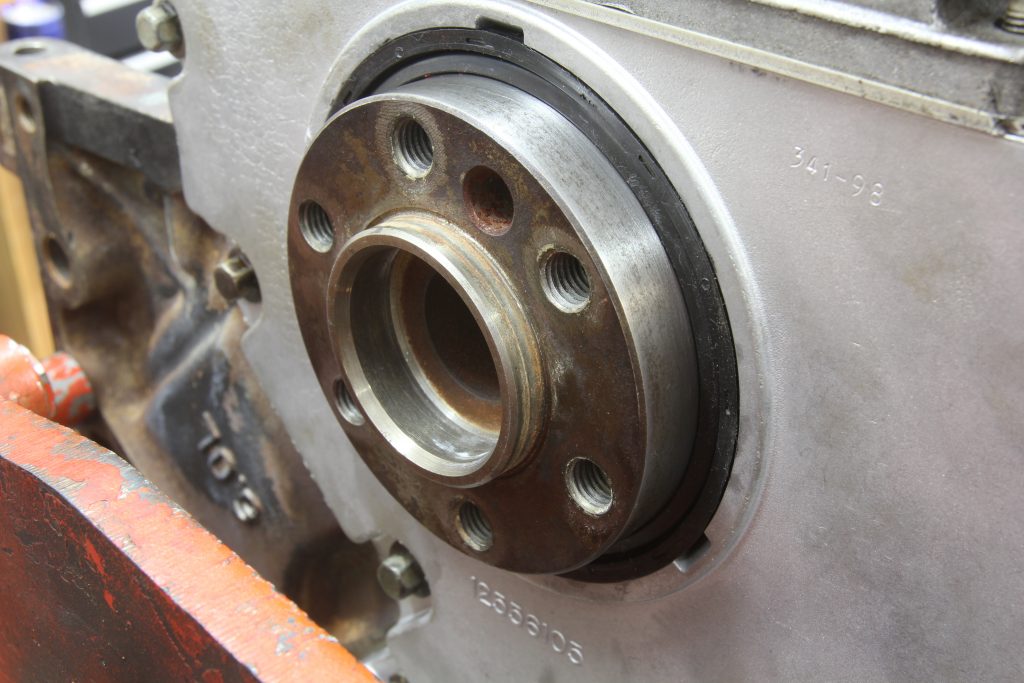

Next, I will assume that since the torque converter on your 4L60E hits the crankshaft flange before the bellhousing flange is flush with the block, this tells me you have a late model LS-style 4L60E transmission. One quick way to tell if you have this later style 4L60E is to look to see if there is a bellhousing bolt hole at roughly the 2:00 o’clock position (as viewed from behind the transmission, see the photo at the bottom of this article) where a standard small or big block Chevy bellhousing bolt would normally be located.

If the bellhousing flange on your 4L60E is missing this bolt hole, then you have the later 4L60E transmission designed strictly for the LS-style engines with a flush crankshaft flange.

Since your early iron 6.0L engine uses the extended crankshaft flange, it won’t be compatible with the LS version 4L60E trans as you have discovered. Yet there’s an easy (but not necessarily inexpensive) solution.

There is no modified torque converter that I’m aware of that will produce the desired result. The quickest and easiest resolution to your dilemma is to find an older 1993-99 4L60E transmission used in the pickups and many other applications that is designed to be used behind a Gen I small block Chevy. This is a relatively plentiful transmission so it should be easy to find. Because this 4L60E is designed to be bolted to the back of a small block Chevy, it will be compatible with the extended crankshaft flange on your ’99 iron 6.0L.

This small block version 4L60E will bolt right up to the LS bellhousing flange with one missing bolt at that 2:00 o’clock position. This is not an issue. You will need to use the stock 1999 6.0L flat flexplate in order to allow a stock LS starter motor to work. Next, you will need to find a torque converter flex plate pattern that will align with the torque converter’s 3-bolt pattern. This should not be difficult.

The older 4L60E uses the same wiring connectors as the later LS-style transmission, so that will not be an issue. I think even the case length is the same as the later LS version transmission you have now and the output shaft spline count is the same—one less problem to deal with.

This should create the solution you’re looking for with a minimum of hassle to solve your dilemma.

[…] I was wondering if you could help me. I have a ‘99 Chevy S10 with an LS1 engine that has a long crank and iron heads. We are trying to […] Read full article at http://www.onallcylinders.com […]

It might be easier than that. Most if not all 4L60E transmissions built since 1998 have had removable bellhousings. Find one that matches the Gen 1 depth and it should bolt on his current transmission.

I have the same setup noted in the article and was able to get a torque converter made from art carr transmission in california. They shipped it direct to me.

There is a 4.8 that also has the extended crank flange. express vans with the 80e.

I have an old ford pinto 2.3 turbo and I want to put it behind a turbo 400. I found a company that makes such an adapter kit. Will I be fortunate enough to bolt up and go? Or would anticipate me running into issues?

What torque converter should I use with a new ls3 gm creat and a 93 to 99 4l60e transmission 430 hp I put a 2200 and it dies when put into gear

I have a small engine model is 170f7.5hp crankis65mm/2.55

I have the oddball 99-00 long crank 6.0 I installed in a 2000 RCSB was wanting to run the stock 4l60e but that was going to be to much of a hassle… so I guess my question is I’m going to do the 4l80e swap do I need to get transmission, Torque Converter, and flexplate specific to that year engine block with long crank or would any 4l80e trans and converter work from 99-06 work I know I will need the Flat flexplate but can’t get a forsure answer on trans and TC

As mentioned in the story – the small-block version 4L60 was designed for the small-block Chevy’s extended crank – the same depth as your 1999 engine – so a small-block specific trans and converter will work just fine. The flexplate will have to be specific to your 1999 engine in order to work with the starter motor.