Try this experiment: Mention four-valve (4V) Ford to a few fellow enthusiasts and see what discussion pops up.

Oh, how quickly people forget! Time was when you mentioned 4V, people immediately thought of the 351 Cleveland, and the massive port openings offered by those amazing cylinder heads.

Compared to the pedestrian 2V versions, the mighty 4V heads (and intakes) reigned supreme, a fact illustrated by usage on all the top factory performance Cleveland motors. While Ford abandoned the Cleveland early on in the US, it continued to power hot motors down under in Australia for many years!

Today, the 4V designation best differentiates the 4.6L Modular Ford family from the lesser 2V combos, or conjures up a conversation on 5.0L Coyotes. Sure, time and technology have certainly marched on, and the modern 4V Coyote is head and shoulders more powerful than any factory Cleveland, but ask yourself (and your friends) this: How many NASCAR races have a Coyote ever won? For many, particularly the boys down under, 4V means ONE thing, Cleveland performance.

For those unfamiliar with the fabulous Ford 4V, the question has to be, what exactly made the Cleveland so special? In short, what did the 351 Cleveland motor have that the other Fords (like the Windsor), or even the competition over at Chevy and Dodge, didn’t?

The answer was simple, the Cleveland family–and the 4V version more specifically–offered massive head flow.

The 351C 4V motors, and even the smaller 1969 & 1970 Boss 302, offered head flow unmatched by any (regular) production small block Ford, Chevy, or Dodge heads of the period. To put this flow into perspective, a 1987-95 5.0L Ford (E7TE) head flowed 155-160 cfm, and a Chevy Fuelie head might flow 210 cfm.

The as-cast, production Boss/351C 4V heads flowed a whopping 275 cfm!

Combine cylinder head flow with proper cam timing and a decent inductions system, and you have the makings of a serious performer. One need only look at the current crop of modern Coyote, LS/LT and Hemi motors to understand the importance placed on head flow by the manufacturers.

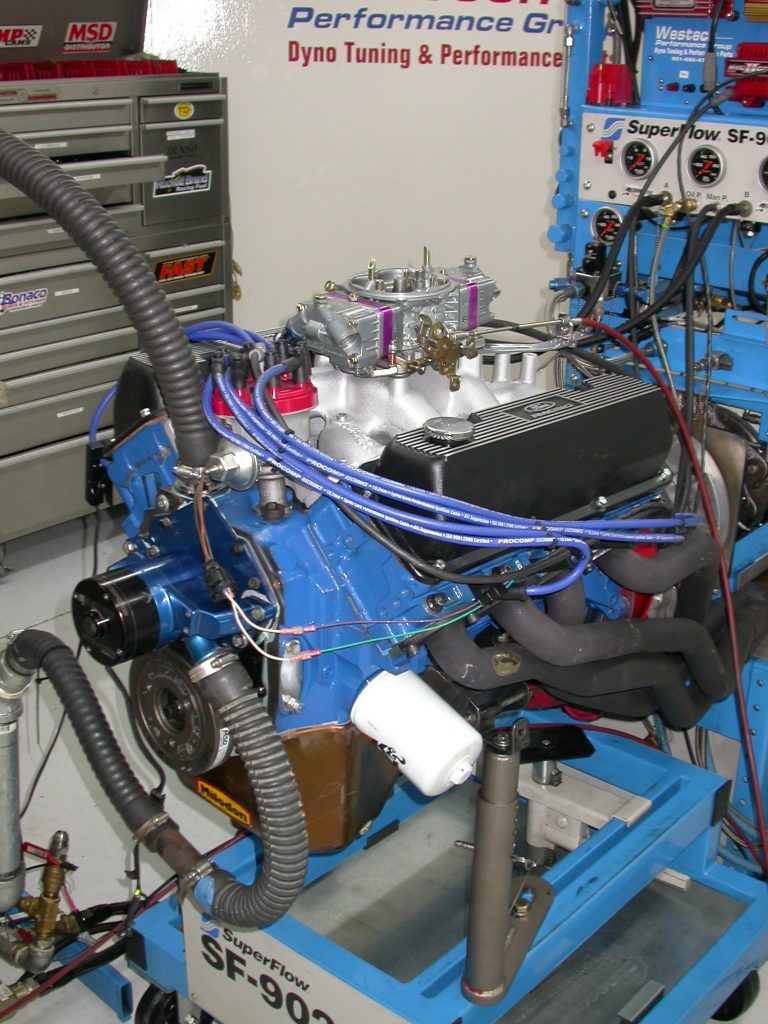

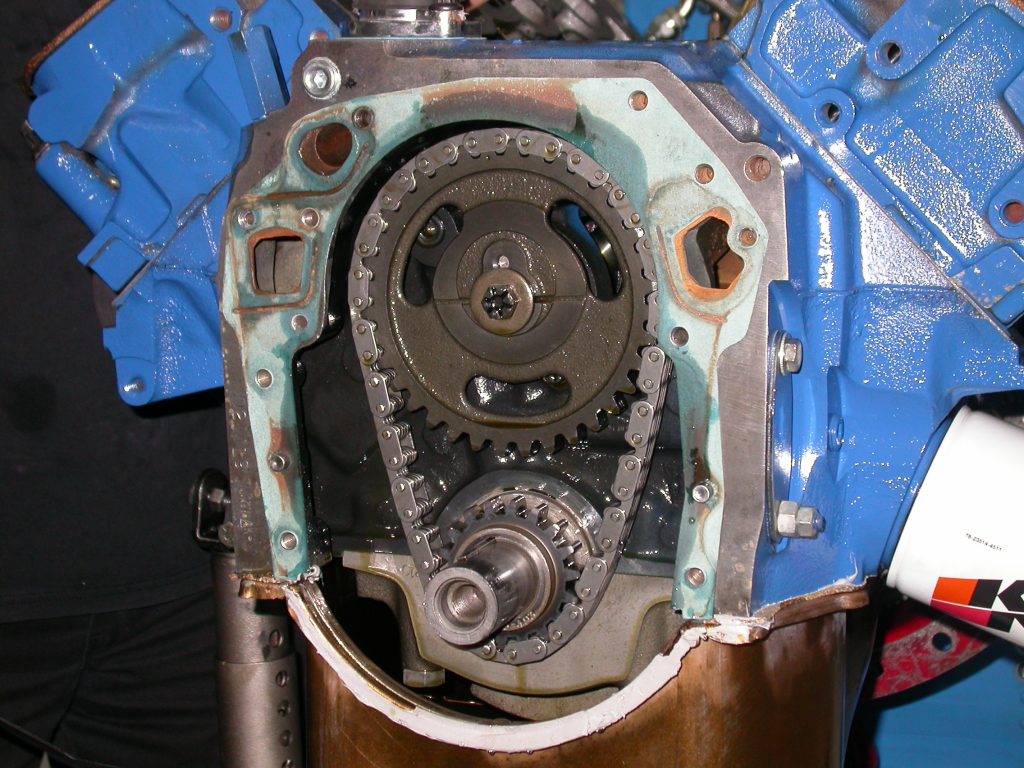

For this test, we wanted to illustrate just how much power was lurking in the massive 4V Cleveland heads, so we put together a near-stock displacement test motor. The original 4V, 2-bolt, 351C was disassembled and treated to some first-class machine work by L&R Automotive. The machine work included boring and honing the block to accept a fresh set of .030-over, forged slugs.

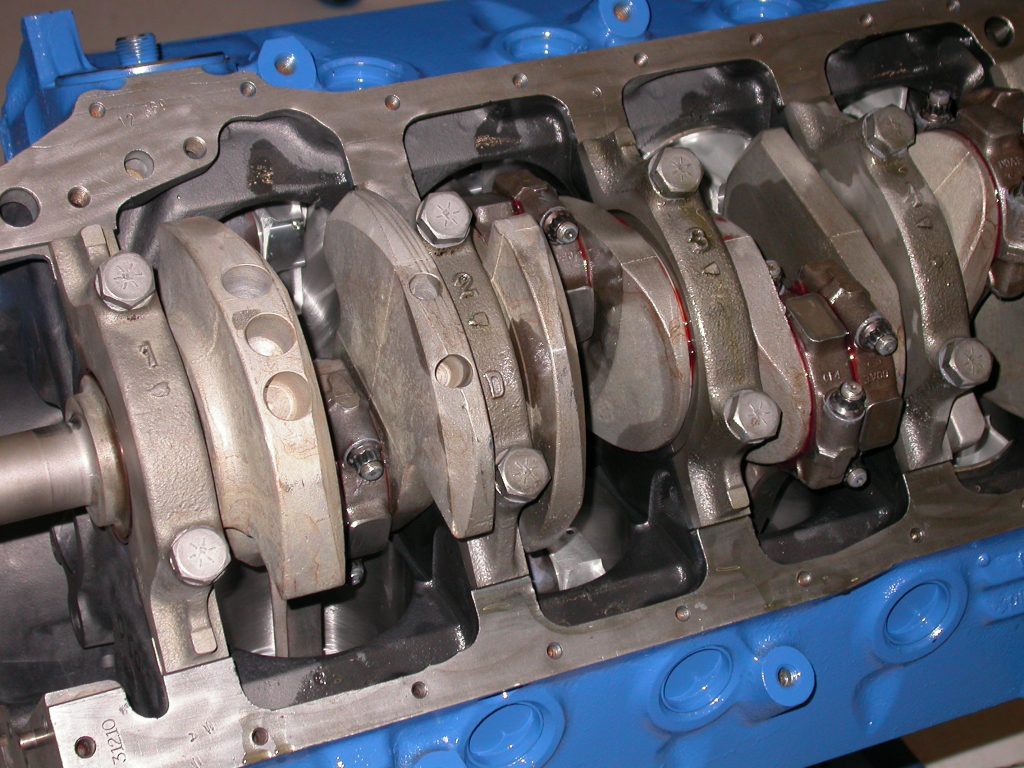

Probe Racing supplied the small-dome, forged pistons, which also featured the necessary valve reliefs for more aggressive cam profiles. The 11.0:1 Probe pistons were designed for use with the stock connecting rods. Before assembly, the stock rods were treated to polishing, shot-peening and a set of ARP rod bolts. The forged pistons and reconditioned rods were teamed with a factory cast (polished and balanced) crank. We finished up the short block with a reproduction (hydraulic flat-tappet) 351 Cobra Jet cam from Elgin.

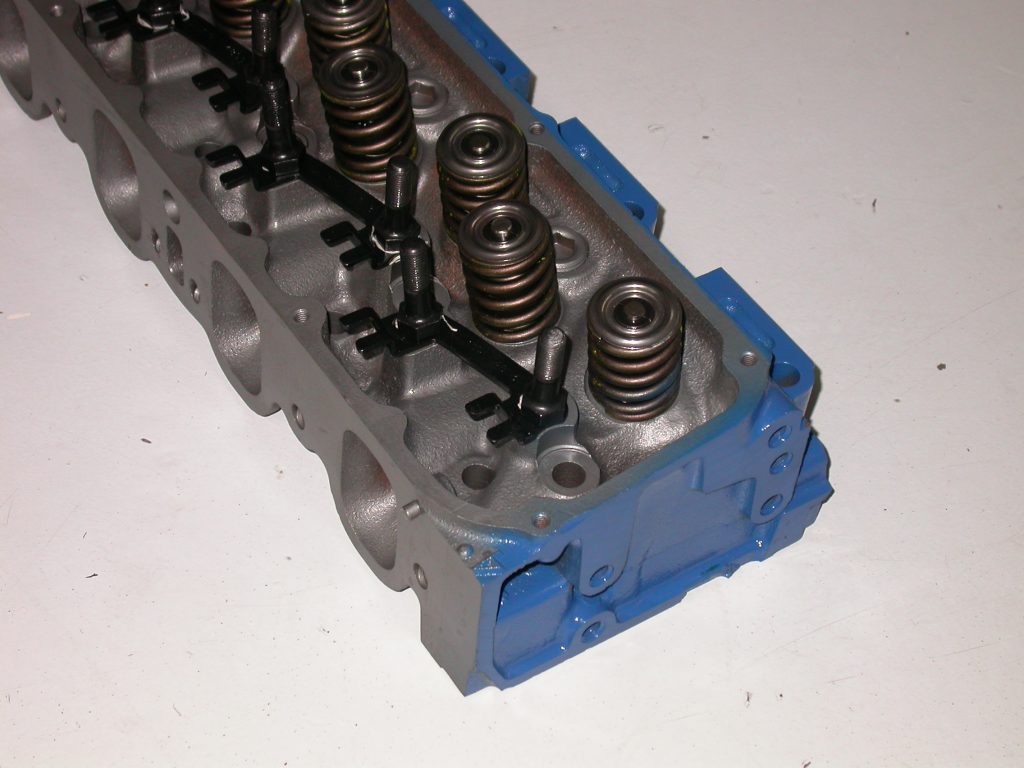

Topping our .030-over, 351C short block was the real success of the Cleveland engine family: the 1971 4V heads. These 1971 heads got us half way to our performance goal, by featuring the desirable (smaller) quench chambers. They did, however, lack the adjustable valve train offered on the performance-oriented, solid-cammed (hard to find) Boss 351 heads. Lucky for us, this was easily cured, as L&R simply machined the non-adjustable pedestals to accept rocker studs and guideplates.

True Cleveland enthusiasts might recognize the fact that we could well have run both the hydraulic flat-tappet, 351 CJ and upgraded Comp cams with the non-adjustable valve train. But we liked the idea of having an adjustable valve train and planned to run roller rockers on this Cleveland later on. The 351C 4V heads were also treated to a new set of stainless steel (intake and exhaust) SI valves, with the more-common single grove keeper to replace the factory multi-groove versions. The heads were also treated to a multi-angle valve job and surfacing (63-cc chambers) prior to installation

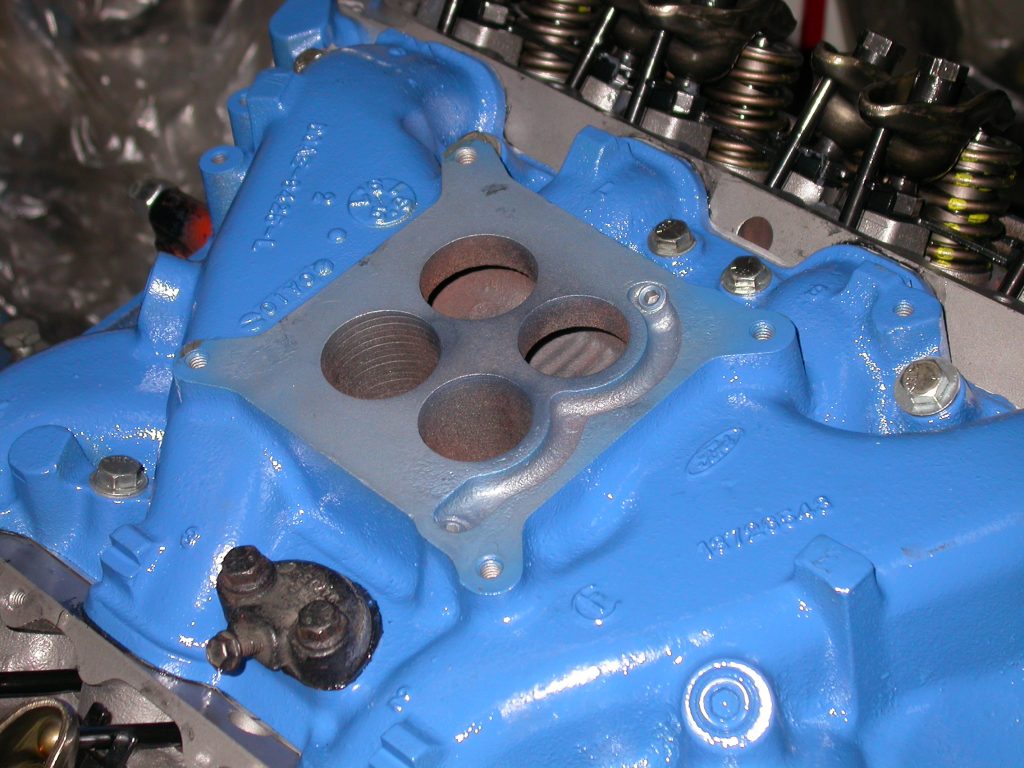

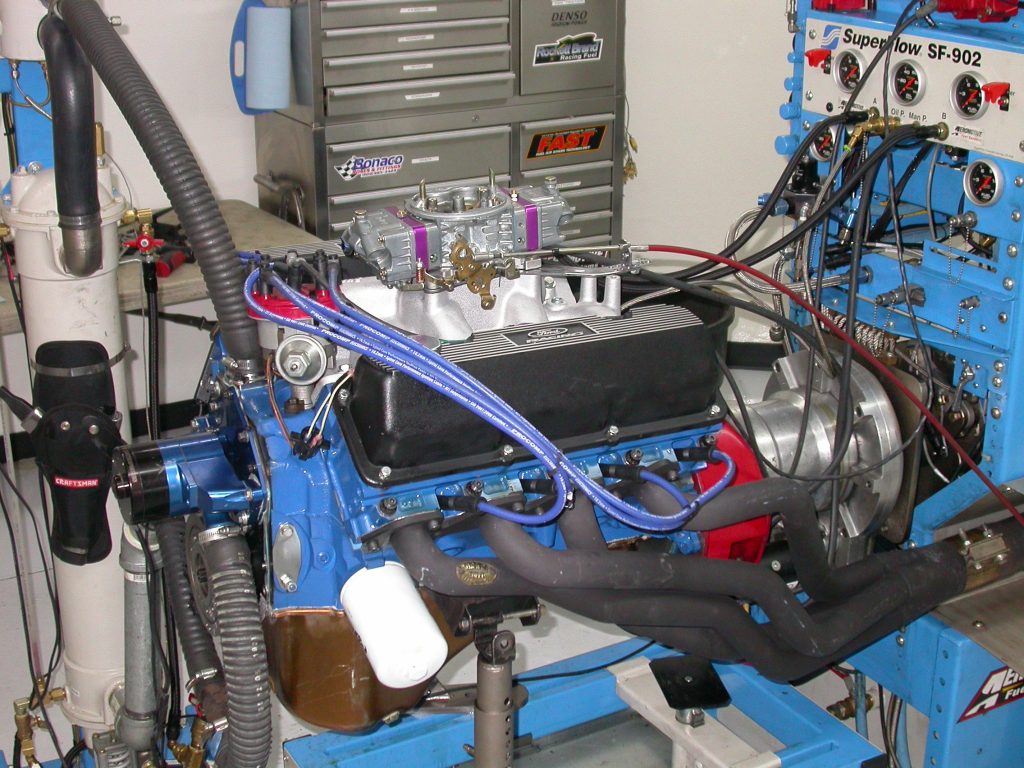

To show the stock 4V heads had plenty of offer, we first ran the Cleveland with the factory, iron 4V intake manifold and 750 Holley carburetor. The original manifold was designed to accept an Autolite carb, but the Holley carb upgrade required only the installation of a gasket and spacer. Also present during testing on the Cleveland was a Meziere electric water pump, MSD distributor and amplifier and a set of 1 7/8-inch Hooker Super Comp headers.

Run first with the stock 4V intake and mild CJ cam, the Cleveland produced 359 horsepower at 5,700 rpm and 372 ft.-lbs. of torque at 3,800 rpm. After our baseline, we replaced the Elgin CJ cam and 4V intake with a Comp XE284H cam and Edelbrock Performer RPM Air Gap intake. The Comp Cam offered a .584/.588 lift split, a 240/246-degree duration split and 110-degree LSA. The Edelbrock intake was actually designed for the smaller-port, aluminum Edelbrock heads, but worked well on the larger 4V heads.

Demonstrating that the stock 4V heads had much more power to offer, the cam and intake upgrade increased the power output by nearly 100 horsepower, pushing the peaks to 452 horsepower and 412 ft.-lbs. of torque. Given the flow rates, even this modified 351C was just scratching the surface of what OG 4V heads will support!

How is it you can easily add nearly 100 hp to your 351 Cleveland?

The answer lies in the massive head flow offered by the 4V heads. With 275 cfm at your disposal, the 351C offered the most cylinder head flow of any production small block. What this means is that they respond very well to other performance mods, like a healthy cam and improved induction system. After replacing the stock, iron intake manifold and repro-CJ cam in our .030-over 351C, we were rewarded with a jump in power from 359 horsepower and 372 ft.-lbs. to 452 horsepower and 412 ft.-lbs. of torque. As expected of a healthy cam upgrade, both peak hp and torque occurred higher in the rev range, but the new combo only experienced losses below 3,300 rpm.

Follow along with the entire process here:

[…] Try this experiment: Mention four-valve (4V) Ford to a few fellow enthusiasts and see what discussion pops up. Oh, how quickly people forget! Time was when you mentioned 4V, people […] Read full article at http://www.onallcylinders.com […]

I’ve only had the opportunity to build one Cleveland. Was a 71 cj. Done the same as article with the exception of slightly larger crane solid lifter cam & an old school torquer intake & H/S rockers . Wow no dyno but that thing pulled like a Bear 3500/ 7500ish! Very impressed. Gonna build another a little more aggressive for a road race tribute 68 mustang. Can’t wait.

It a hard ask from the get go with an old school 1970 cleveland because they weigh 720 lbs fully loaded.

The very first sentence of this article is WRONG! 4V Ford Cleveland heads NEVER had 4 valves. We all know that 4V stands for 4 venturi, a.k.a. 4 barrel carburetor. I’m not doubting that this build produced a very strong engine but, c’mon Summit…do some proof reading before posting something like this!

I shouldn’t say wrong but it IS very misleading.

Back in the day, they WERE referred to as 4V heads and it didn’t mean 4 valve as there were no 4 valve heads from anyone back then. Everyone then knew it meant 4 barrel carb head. Just saying. The article is correct.

Did you read the first line?

It mentions 4v and says 4 VALVE..

Lol cast heads have a tiny 4v on the corner of the head.

I wonder if you feel a bit stupid after rushing to judgement about 4V heads. I love internet experts

You’re right, Mike+Brown. It’s not even misleading, it is plain wrong. Maybe a little correction is in order, just for accuracy’s sake? 4V stands for “four-venturi”, not for “four-valve” as the article incorrectly states.

My God you such a good mecanic lol when we speak about 4V it’s about 4 Venturi not 4 valves get some information before making comment like that

Just because there was no 4v during those years, does not mean you cant put newer one made for it now. Right????

Fuel on the fire…what does 442 stand for?

In the Ford world, 4V has always meant 4bbl. That is, until the Coyote. 4V carbed engines became obsolete with the mass produced invention of fuel injection. 1986?

Oldsmobile 400 cid 4 barrel carb with 2 duel exhaust 442

If you have a 4V quench head to look at you will see that with the two ginormous valves there just enough room for the spark plug

Hey guys just slightly off topic but I’m building an original 351 Cleveland and having trouble getting hold of a factory iron 2V 4bbl inlet manifold to suit a 750 holley. If anyone can help it would be appreciated

What you’re looking for is an Australian 4v intake. Some were imported for resale along with the 302c closed chamber heads, but they’re hard to find.

aluminum 4 barrel carb to 2v 351c heads i have one 541 660 4446

The very first sentence is actually 100% correct, the proof is shown by your own misunderstanding of what it says and not comprehending what the article’s intended meaning was.

The offenhauser power port short runner tunnel ram with twin 600 Holley vac sec carbs, 12.4 trw pistons, and 108 lobe center sig Erson hi flow I M cam running AV gas was absolutely a rocket ship on the street. Could be duplicated better with new technology. Try it you’ll like it!

I have 351 Cleveland 1971 Mach 1 I’m looking for more power on take off what can I do ?

What ratio is your diff at the moment

What kind of fuel are you running to make this much horses

Hey Frank, I can’t speak for Richard Holdener but Clevelands are still my favorite engine to build and your question is a good one. The forged Probe pistons used for the build provided an 11:1 compression ratio with the closed chamber chamber (quench) heads. The Ford engineers did a great job of designing the small chambers and the location of the spark plug on the early 4-V heads.

During combustion the quench area promotes good flame front travel and reduces the probability of detonation.

With proper timing advance settings, the engine should run well using 93 octane pump fuel. Holdener routinely does his dyno testing at the Westec facility which provides access to race fuel which is what he typically uses for best results in all of his builds.

How do i get more hp with 351w

Charles, one of the most popular ways of increasing power is by adding more cubic inch displacement with a stroker kit rotating assembly. You can safely get 408 inches from a production 351 Windsor block and the aftermarket has plenty of stroker kits to choose from. Most of the better ones use forged pistons, rods and crankshaft that has smaller 2.750”, 351C size main bearing journals for longer bearing life.

The increased displacement will require higher flow from the heads for best results. Another popular upgrade is to build a Clevor engine which uses 351 Cleveland style canted valve heads on a Windsor block. The cylinder bore spacing and head bolt patterns of Cleveland and Windsor heads are identical which makes the better flowing Cleveland heads a natural choice.

Cast iron production Cleveland heads can be used but finding a good pair and having them machined for an adjustable valve train can get expensive. The aftermarket has a good selection of modern aluminum alloy Cleveland heads available at a reasonable price. When shopping for stroker kits, just keep in mind that Windsors and Clevelands use different piston types and will need to be specified when ordering parts.

Sell it and buy a cleveland

Clevor.

My brother has a Q code 351 clevland and he put all the goodies in it and it pulls so hard you can pull your self up to the dash.

My best friend had a stock 302 boss that came in a cougar eliminates 1970 and it would beat a 1970 454 chevells we raced 2 of them and won it was a high winding engine loved it. It still runs to this day.

I love my 351 Cleveland. Thanks for the great article.

[…] erecting one from scratch, which you can do with a Ford Performance BOSS block (M-6010-BOSS302) and Cleveland heads. You may also cruise the online auctions for a vintage 5.0L roller block (F1AZ-6010-B). There are […]

Why didn’t they do a test with the stock intake manifold and the cam upgrade? The article is all about flow rate so I don’t see how using an aftermarket intake manifold with smaller runners is going to increase the flow rate through the engine. If I am missing something please let me know.

New small runer intake manifold has new port design’s that flows more air through smaller diameters at high speeds wich improves horsepower and torque in all area’s of rpm band it actually helps the stock cylinder head make more power and torque than the 50 year old design.

The referal to 4 Valve only confuses you and others less versed in the Ford world. Is was meant that Ford guys might think of the newer 4.6L and 5.4L 4 VALVE DOHC TYPE ENGINE and that people forget about the 4V & 2V cylinder head desensitization of the 351 CLEVELAND’S. DONT CHIME IN ON CONVERSATION YOU OBVIOUSLY need to do some of your own proof reading Mr negatively. Take it easy man.

See the corner on a 4bbl Cleveland head it has a 4 cast in it , 2bbl has a 2 ,never had a V on either head !!! Please get it right or continue showing your ignorance?

Guess it’s your choice . The 4v or 2v refers to carb installed & designation on air cleaner lid . I’m done flogging the dead horse . lol

Igor a 1970 Mach 1 with shaker hood.

I want to keep the shaker filter.

EVERYONE MAKES MISTAKES LOL, LETS FOCUS ON THE SOLID INFORMATION AND THE FACT THAT RICHARD IS

SHARING SOME GOLD….

BEST WISHES TO ALL CLEVELAND GEAR HEADS AND AS A SCOT LIVING IN AUS SINCE 73 WE LOVE THESE ENGINES

I HAVE A XY GT FALCON AND WILL NEVER PART WITH IT.

Great comments!

My Cleveland, built 10 yrs ago still going.

Stock Crank and rods, 30 over trw 2348 pistons, OC heads cut .060 59cc, Ported intake and exh. 345/210@.600, 12.29 comp, Comp Hyd roller .612/245 dur (not a great cam but low DCR allows 93 octane) AWESOME sound!, Sheetmetal intake, EFI Megasquirt, 2-1050 cfm 4barrel throttle bodies, C4 with GV overdrive and 4k stall, 380 gears.

Fun and dependable 67 FB Mustang, Street Car.

What distributor are you using in your Cleveland?

Hi,

I’m getting ready to rebuild my 400, and am looking for the parts list used, and if the deck height problem was ever solved to get more than 9.1:1 compression. Or are the flat top pistons the best solution? The motor is going back in my 79 bronco, so I don’t really want a screamer, just really good power and torque.

Thanks!

The cheapest way to increase compression is to use 351C dome pistons (Keith Black KB Performance Pistons KB149.030). These will reduce combustion chamber size by 8cc. Also mill the cylinders heads down to make combustion chambers smaller. Probably can get the compression to 9.7 to 1 . You may be able to mill the deck height down on the engine block. Call MPG head service they are experts on the cleveland and 400m engines. Also Richard Holder did a video on hopping up a 400m on youtube.. Dave

I wonder what the numbers would have been if they port matched the edelbrock airgap to the heads?

Best question. Searched everywhere about port matching airgap or most modern manifolds to the 4 heads and found nothing. Seems like a testing void no one is covering. Endless clevo dyno tests but everone going with the mismatch and not expaing why.

Thanks, how can I reach author? For additional questions? Ie timing & heads.

All these comments pro and con for different combinations is good for keeping the 351C alive in todays performance scene. Speaking for myself I prefer the old school exhaust runner cut 4V heads and an Edelbrock UR-19 tunnel ram. It might be labor intensive but the idea of cobbling power out of mostly Ford parts is appealing. If you do it right you can achieve some healthy gains. I have run this setup in a ’64 Falcon Sprint drag car for years and turned many heads with mid 7 sec runs. I would say my point is no need to argue because there is power to be found in this competitive little motor without doing much of anything, all mods make power. Always be willing to listen to new ideas and test what you have. Dynos are nice but the real pudding comes out at the dragstrip! Patrick (Skid Mark) Mullins.

What are your thoughts about the Blue Thunder 4V heads that have ports that match the stock 4V heads I got a manifold from Holmon and Modey that they got for me from Blue Thunder and if Comp would send me my cam that I ordered in December of last year I would like to try it out I am going to try a hydraulic roller Thumper and see, I hope

I have wondered how to hop up an H-code 351c for street power. It’s the most common Cleveland engine and it has hidden potential. It would be instructive to show the performance gains from simple upgrades, and it’s exactly the kind of video that Richard Holdener used to do. Step-by-step; Melling MTF-2 camshaft (282°/292° 204°/214°@.050 .486”/.512” 112 lsa ) and 4v springs. 2.08″ intake valves from a 2v 460 with pocket porting. Blue Thunder and/or Edelbrock intake and Holley 4160 vac. sec. 600cfm carb. Headers. A cheap, streetable engine requiring no major machine work. Goosing a Cleveland 4v seems pointless because how many are there and would you find bigger power gains started with a 250 HP engine?