What does every enthusiast have in common?

No matter what car you drive, what motor you like, or how old you are, we all share the same desire to make more power!

Lucky for us, an entire industry exists that caters specifically to our more-power needs. And it’s as diverse as we are.

Not everyone wants the same car, engine, or even power improvement.

Some want a little, others want a lot. No matter what you want, chance are you want it to be distinct.

We’re are all individuals. And our vehicles, even the performance mods we choose, express our individuality.

Some follow the crowd, some blaze their own path, and some are a complex mix of both.

The internal combustion engine is well-suited for expressing this individuality, as the paths to performance are as varied as us vehicle owners.

Some choose basic bolt-ons. Others increase displacement. But a select few of us throw caution to the wind and combine both, with a side order of forced induction!

Adding power to any engine is easy, and can be done with bolt-on basics, like cylinder heads, a camshaft, or intake manifold.

Minor mods are also possible, using things like headers, throttle bodies, and cat-back exhaust systems. But for this test, we went whole hog on not only a dedicated build up, but one with boost.

Executing the Plan: 5.3L Iron Block

The best results come from a well-executed plan, but the plan itself must first be sound.

Knowing that power gains are available from bolt-ons, displacement, and boost, we decided to hedge our bets and combine all three.

We built an engine not only capable of harnessing boost, but one that embraced it.

The best boosted engines start out as solid naturally aspirated engines.

The more non-boosted power you make, the more power you will make under boost!

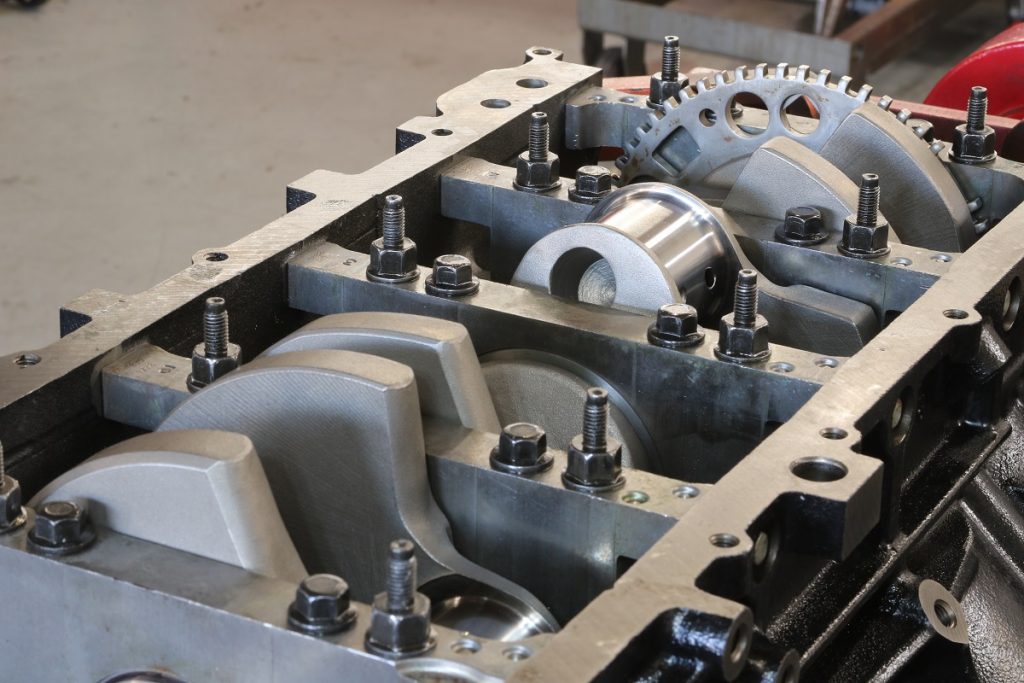

Since the easiest way to make power was with displacement, our boosted LS build started out as a stroker. Starting with a 5.3L iron block, we first bored it to accept 3.905 forged Wiseco pistons, which we chose in order to keep compression down (below 9:1) for pump gas use. Then we combined them with K1 forged 6.125-inch rods and a matching K1 4.0-inch stroker crank.

Once assembled, the forged rotating assembly was ready for almost any amount of boost we could throw at it.

With strength taken care of, it was time for the power producers.

Looking to feed the extra inches, we first selected a suitable camshaft. Destined for street use, we chose a healthy profile from COMP Cams which offered a .617/.624 lift split, a 231/239-degree duration split and 113-degree LSA.

We paired the cam with new lifters, lifter trays, and a double-roller timing chain. We then topped the cammed 383 with a set of CNC-ported Trick Flow Specialties GenX 215 cylinder heads.

The heads offered plenty of flow for the 383, and the chamber dimensions (not just volume) were ideally suited for the 3.905-inch bore 383. These Trick Flow heads offer full CNC porting of the intake, exhaust, and combustion chambers, along with a 2.04/1.575-inch valve package.

We chose an MSD Atomic intake manifold and 105-mm throttle body to feed. The MSD intake was perfectly suited for the rpm and power needs of the stroker.

Intake manifolds are best thought of in terms of rpm, as runner length determines the effective operating range. The Atomic was a good match for the combination of cam timing and head flow offered by the COMP cam and Trick Flow GenX heads.

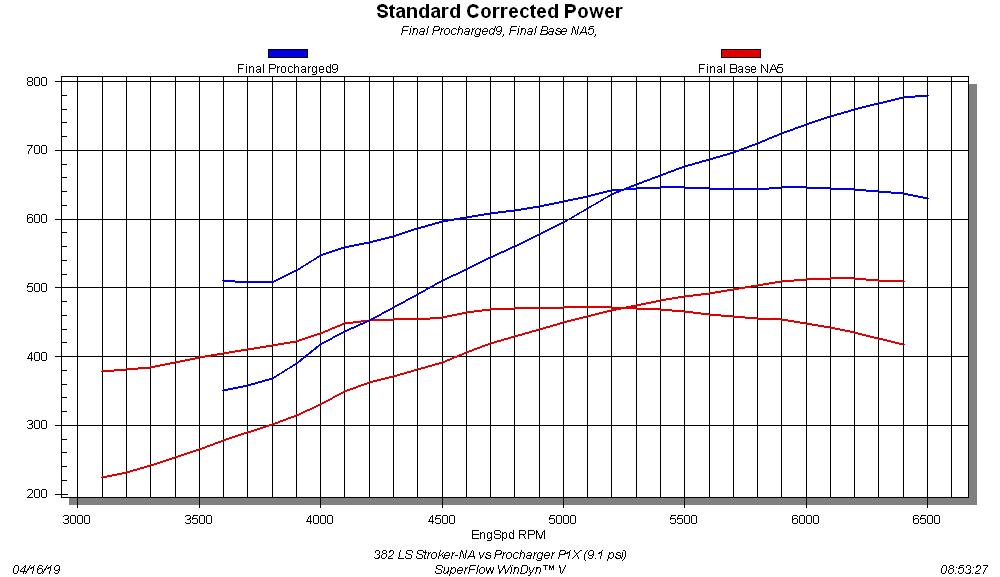

Run in naturally aspirated trim, the low-compression 383 produced 516 horsepower and 472 foot-pounds of torque.

Now it was time for some boost.

Adding the ProCharger to our 516 HP 5.3L

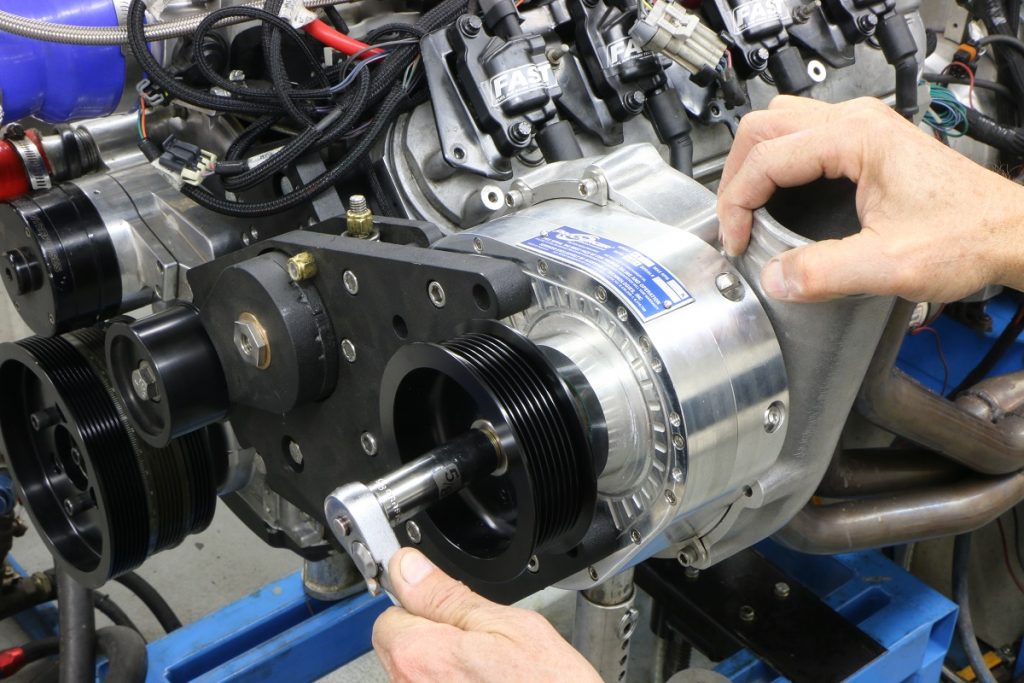

Our bolt-on boost came courtesy of ProCharger.

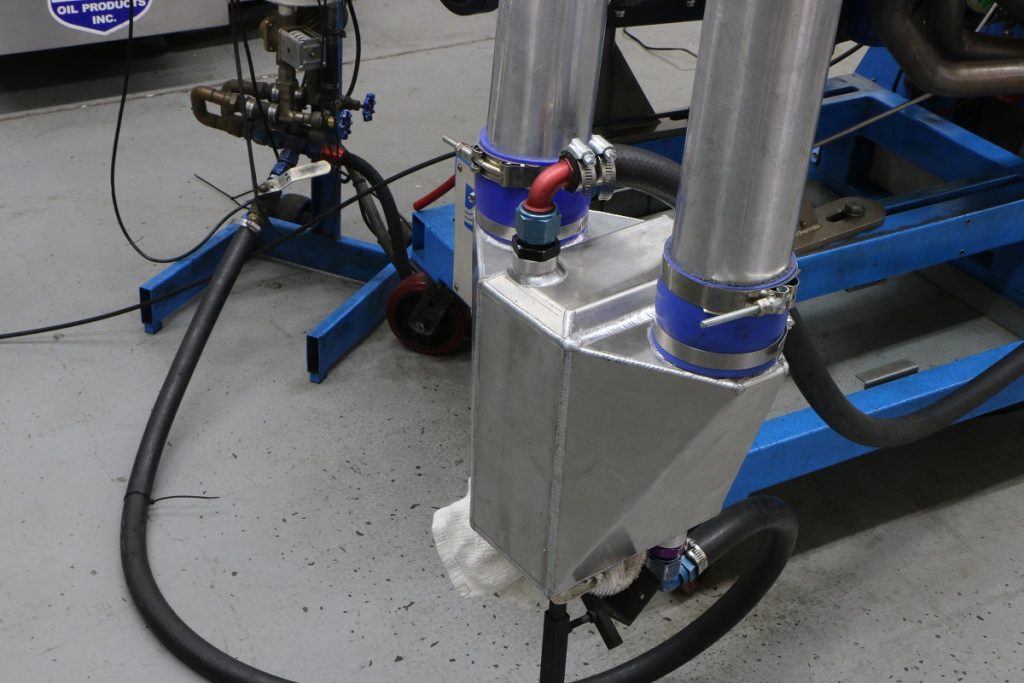

For this mild, street stroker build, we selected a D1X supercharger. The centrifugal supercharger was teamed with an air-to-water intercooler, though we purposely kept the boost pressure reasonable on this 383.

Using the Holley HP management system, we slowly dialed in the supercharged combination at each rpm and boost level.

After we completed the tuning, we were rewarded with peak numbers of 780 hp (779.9 hp) at 6,500 rpm and 646 ft.-lbs. of torque at 6,000 rpm (at 9.1 psi).

In typical centrifugal supercharger fashion, the rising boost curve pushed the peak power numbers higher in the rev range.

Run naturally aspirated, it made peak power at 6,200 rpm and peak torque at 5,100 rpm. With the blower, peak torque now occurred at 6,000 rpm, while peak power occurred at 6,500 rpm, but that was our self-imposed shut–off point.

The HP curve was still climbing. The D1X certainly had more to offer, and the stroker would certainly take much more, but we called it quits here, as 780 hp was deemed more than sufficient for this supercharged street stroker.

…

[…] What does every enthusiast have in common? No matter what car you drive, what motor you like, or how old you are, we all share the same desire to make […] Read full article at http://www.onallcylinders.com […]

Would like 1 for a new GM pickup truck

Would like won for my 1978 z28 Camaro would really wake that car u with the right rear end gear I have a stock 350 8.1 compression engine a has I think 255 gear

’78 Z/28’s were factory equipped with 3.73’s when ordered with a stickshift, or 3.42’s with the automatic.

An Eaton Limited Slip Differential was standard with either trans.

Would you guys to the same w a 6.2. Thanks, Roost