The LS engine remains the darling of the performance world, but does that mean all LS owners are looking for the same thing when it comes time for upgrades? Obviously not, or every LS story would be about adding a cam, springs and a turbo, but that’s not the case.

While some may be probing the limits of the stock short block, others want nothing more than to have eight cylinders all firing in order, as God and nature intended.

Between these two extremes is where most LS owners actually reside, but for today, we are looking into the specific needs of LS truck owners. Not those over-the-top, Optima Challenge, road-race kind of trucks, but real trucks, the daily driven kind, the kind used for hauling 4 x 8 sheets of plywood, or towing that family ski boat. You know the kind, trucks that need boatloads of extra torque, especially those saddled with the smaller, base 4.8L or 5.3L (LR4 or LM7) engines. To all the daily drivers out there looking for more torque, we salute you with the following cam test!

…

By now its no secret that all LS motors respond favorably to cam swaps, in fact we have seen massive improvements on the right application, but the majority of the power gains come higher in the rev range. While an extra 50 hp, 60 hp, or even 70 hp (or more) is certainly desirable for an LS owner looking to improve quarter-mile times, even significant gains that come at 6,500 rpm are of little use to a daily driven truck when lugging a trailer up a steep mountain pass.

Though it is possible to reprogram the ECU to alter the shift points, most LS trucks up-shift near 5,500 rpm, meaning few would ever take advantage of extra power that came at 6,500 rpm anyway. Even if the shift points were raised, what truck owner wants to constantly rev the motor that high to enjoy the extra oomph?

Though wilder cam timing can improve power, the ideal situation for a daily driver, would be a cam that not only offers more peak power at the top of the rev range, but one that adds some much-needed torque at the bottom. Enter the Torque cam from Brian Tooley Racing (BTR), designed specifically for truck guys (and gals)!

Though BTR offers a wide variety of different cams for LS applications, including turbo, blower and NA cams, as well as Stage 1-4 truck cams, this BTR Torque cam was something new.

The low-lift (.507) meant the cam could be used with stock LS3-type springs, while the single-pattern and mild duration figures (202-degees @.050) provided a near-stock idle vacuum of 21 inches.

The tight lobe separation angle (LSA) of 111 degrees meant the cam offered significant torque gains, even down low, without concern for power production above 6,500 rpm.

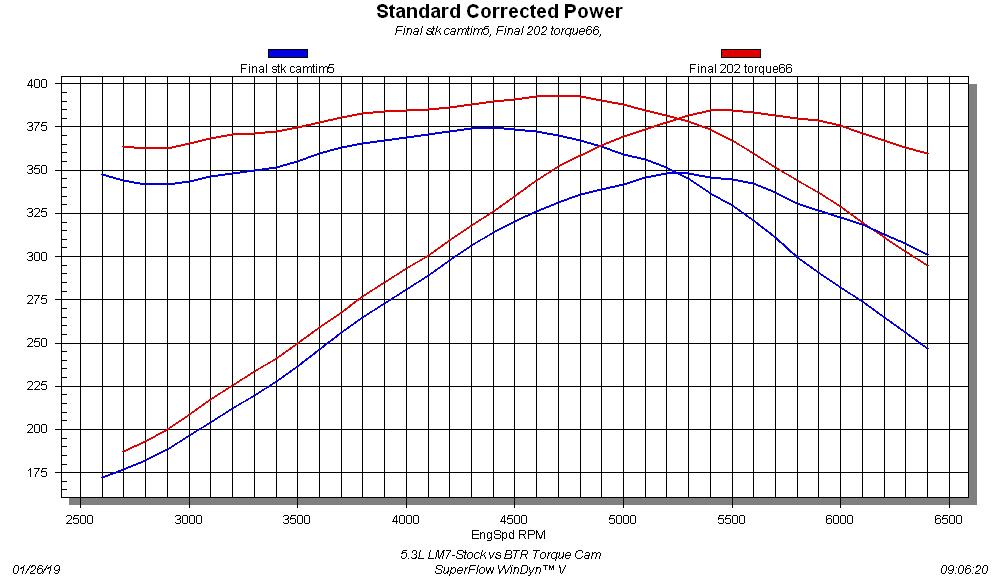

Even this mild cam improved the power output by 59 hp at 6,400 rpm, but did so with an extra 20 ft.-lbs. of torque between 2,500-3,000 rpm. Had we loaded it lower on the dyno, the gains would continue down as low as 2,000 rpm, but how often is a truck owner at wide-open throttle (WOT) at 2,000 rpm anyway?

Having run literally hundreds of LS cams through all manner of engine combinations, extra power is easy above 4,000 rpm, but rarely are the gains much to talk about below that engine speed — until now.

To put the new BTR cam to the test, we set up a suitable test motor.

…

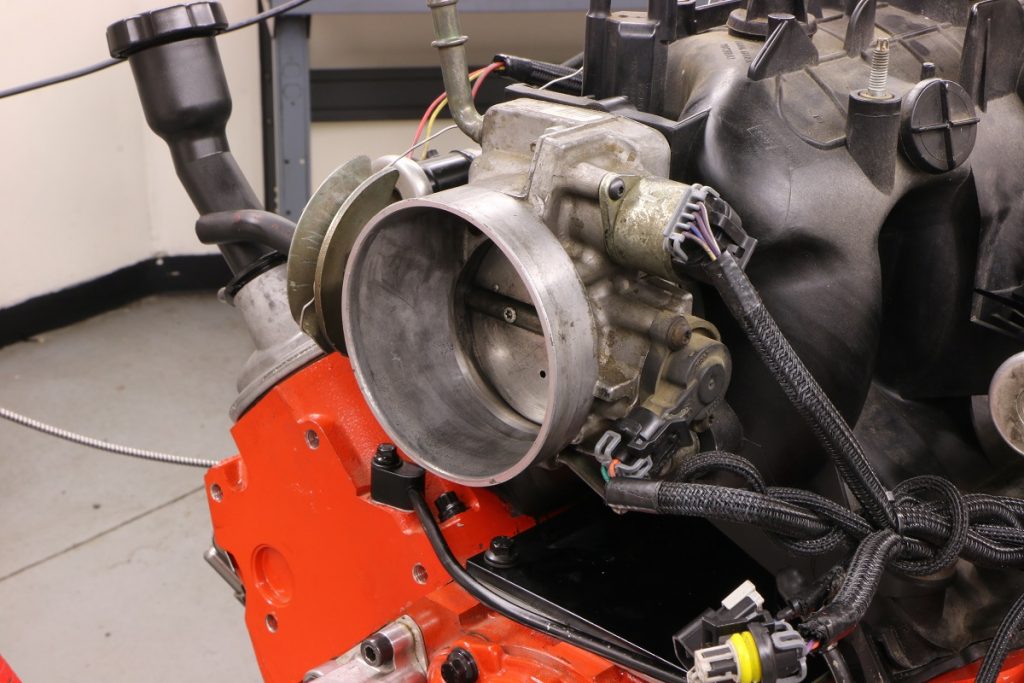

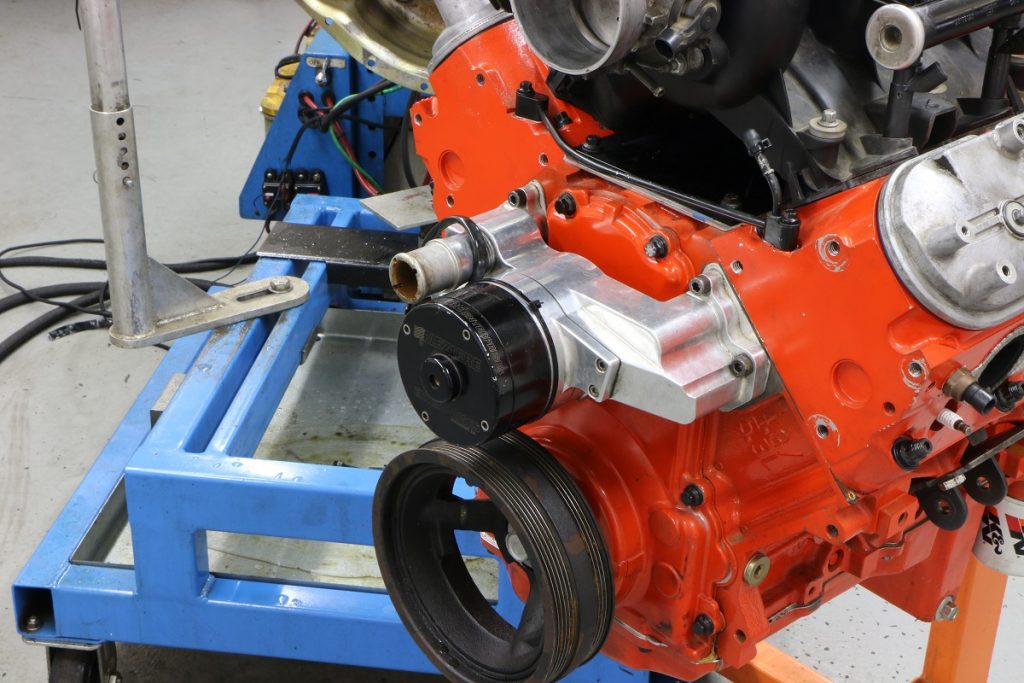

Though sporting a Chevy-orange hue, the 5.3L was surprisingly stock, including the short block, 862 heads, and composite truck intake. A few notable exceptions should be mentioned, which included fresh (factory) head gaskets, ARP head studs, and hardened pushrods (factory length).

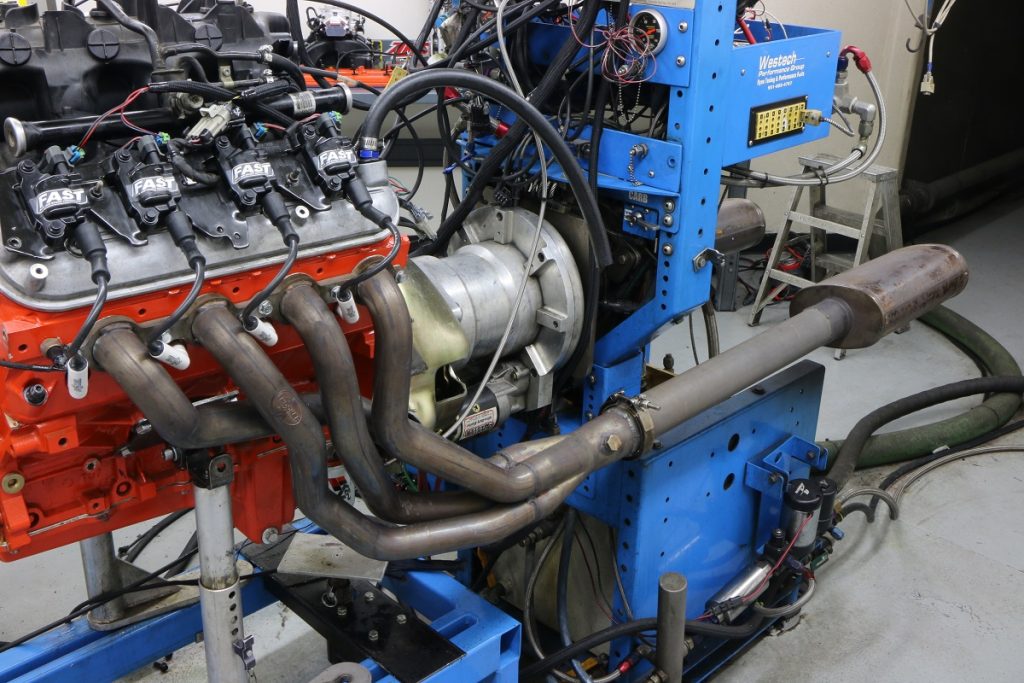

The test motor (with both cams) was run with a set of 1 7/8-inch Hooker swap headers feeding a 3.0-inch dual exhaust that included MagnaFlow mufflers. Smaller primary headers would be preferred on this mild motor, but both cams were run with this setup. All of the testing was run with a Holley HP management system and 60-pound injectors (installed for future testing). Equipped with the stock LM7 cam, the 5.3L produced 348 hp at 5,200 rpm and 374 ft.-lbs. of torque at 4,400 rpm.

After installing the BTR cam, the peak power numbers jumped to 385 hp at 5,500 rpm and 393 ft.-lbs. of torque at 4,700 rpm. As indicated previously, the cam offered gains as high as 59 hp at 6,400 rpm, but for truck owners, the real story is the extra 20 ft.-lbs. of torque offered from 2,500-4,500 rpm. Combine that with an idle vacuum of 21 inches, and you have a winning combination for real truck owners.

…

This cam test was run in an effort to maximize torque gains for real-world, LS-powered truck applications. Huge gains are available on any LS application from a cam swap, but not everyone wants big power at 6,500 rpm. Most truck applications shift at 5,500 rpm, so having extra power at 6,500 is of no use for most daily-driven trucks.

What guys really want is extra torque in the 2,500-3,000 rpm range. Replacing the stock LM7 truck cam with the BTR Torque cam improved not just the peak power and torque, from 348 hp and 374 ft.-lbs. to 385 hp and 393 ft.-lbs., but improved torque production through the entire rev range.

The BTR Torque cam improved low-speed torque by 20 ft.-lbs. where truck motors spend the majority of their time.

I have a 99 chevy z71 with the 5.3 and haul wood and the camper. This cam sounds what I need to keep up with my 78 chevy in the woods. Lol. Do you have a part # for this cam. Thanks

https://www.summitracing.com/parts/btc-30202111

Good points are made in this article like how what works great at the drag strip isn’t always the best for the street and trails. Especially for a heavy truck, improving low-end is the way to go.

I’m going with Summit’s cam https://www.summitracing.com/parts/sum-8719/ but I will have to upgrade valve springs too…so it’s not for everyone.

Keep on truckin’ !

I love cams that increase low end torque, should feel great when you put your foot down. Do u have a company and part number for those lifter retainer rods shown in one of the photos? I don’t trust those plastic retainers. And if you pull the cam and the lifters slip down then heads and pan have to come off. No fun

If the trays are so loose as to let the lifters slip out, they are too worn to use. Too loose and the lifter can rotate in the tray, destroying lifter(s) and cam

“The LS remains the darling of the performance world “. That’s the somewhat presumptuous introduction to another new story about the same old broad. I’ve been an active participant in the performance world for 50 years and I see the LS darling as the star Drag Strip Doll in the low budget movie with the same name from the sixties. She’s the main event in the pits as the hour is getting late on Saturday night. Just one mans opinion. Others may and most certainly will vary.

Like it or not, the LS IS currently the darling of the performance world, having replaced the Gen I small block Chevy. And I’ve been around to know what the small block was. I’m 67 years old.

The majority of opinions will vary from yours in favor of the LS. To each their own but the LS is my own…

I would like to see how this cam would respond to a turbo. I’m looking everywhere and cant seem to find a cam springs and turbo for a 5.3 tahoe daily driver with power between 2k-5k any advance would be great.

How would this cam do in a stroked LS3 and 11:1 compression?

Tengo un stroker 410 sbf 11.7:1 rc cabezas afr 185 rpm air Gap intake carburador 750 secundarias de vacío turbina 2500 paso 4.11 en una camioneta la uso solo fines de semana y carreras de fin de semana que árbol de levas me recomiendan

Can you keep the factory VVT with this cam?