Brake line tubing is commonly 3/16-inch or ¼ inch, is usually annealed and today, stainless is very popular.

Fair enough, but there’s a hitch: A lot of tubing is sold in rolls. Sometimes, a pre-cut straight section of tubing will have a “bow” in it. Both rolled tubing and bowed tubing spell trouble (sometimes BIG trouble) if you’re building brake lines from scratch.

Honestly, we’ve witnessed (and tried over time) a few different “fixes.” One involves clamping the tubing between a couple lengths of lumber.

For smaller pieces, the same process is used, but in a bench vise with something soft protecting the tube. Neither of those fixes work very well and to be honest, they’re awkward when working with long runs of tubing. Plus, if you get too aggressive with the clamping or the vise, the tube is vulnerable to damage.

Fortunately, there’s an easy fix, and it comes in the form of an uber-cool tubing straightener from Earl’s Performance (039ERL).

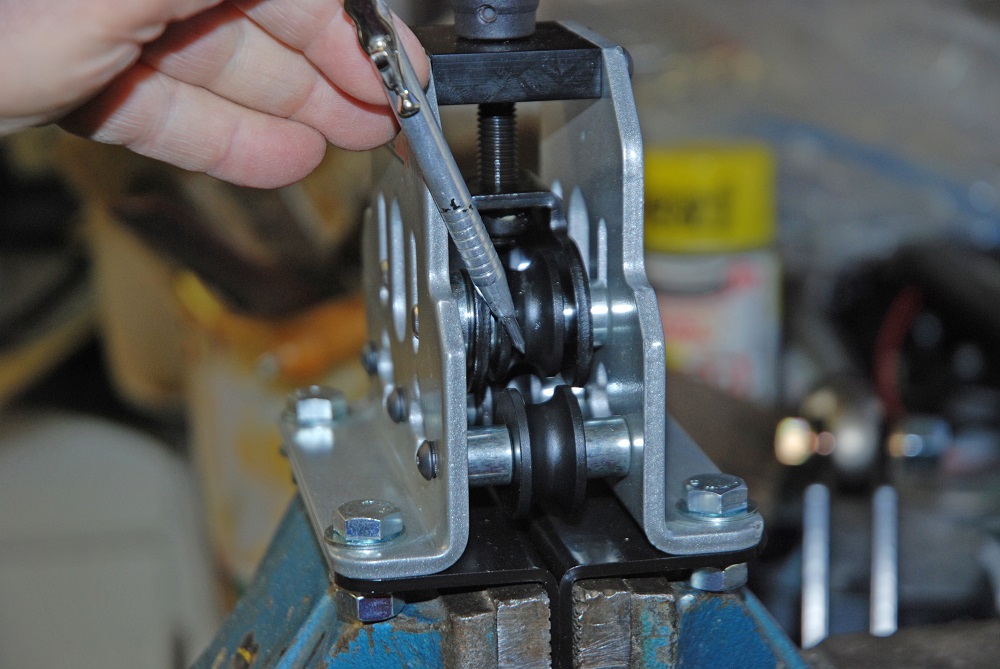

The tool is designed so that it can be bolted directly to your workbench top or held in place by a bench vise (by way of an optional mount kit, part number 040ERL).

To use the tool, hand-straighten (uncoil) the end of a coiled tube and insert into either side of the tool. Use the adjustment knob on top to bring the rollers into position and feed the tube through the rollers.

Once there is a sufficient amount of tubing clear of the tool wheels, begin to pull the tube through with constant pressure. Use the adjustment knob to fine tune the alignment for your tube, and pull the desired length of tube through the tool. Bingo. The coiled section is now straight.

What about straightening a shorter pre-cut length? It’s just as simple: In order to straighten a pre-cut length, simply push the piece of tubing through the alignment wheels and work it back and forth. You can fine-tune the adjustment knob until all bends in the piece have been straightened.

One big secret behind how this tool works so easily is the material choice for the rollers.

According to Earl’s: “Coiled-tube straighteners with steel rollers can become pitted by contact with the leading edge of stainless steel tubing. The result is unsightly specking along the tubing being straightened, or worse, damage to the protective coating found on some brake tubing. Our Brake Tube Straightener uses hard polymer rollers to prevent tube surface damage.”

Some tube straighteners have a tendency to flatten the tubing (for example, the home-brewed jobs mentioned previously). The design of the polymer rollers is such that flattening the tubing isn’t an issue. Another big reason this straightener works so smoothly and effortlessly is because Earl’s uses ball bearings on the rollers. Tubing pretty much glides through it.

In terms of materials you can use, the Earl’s tubing straightener works for 3/16-inch or ¼ inch tubing. It functions perfectly with stainless steel, aluminum, copper, copper-nickel, or conventional steel tubing. The bottom line here is, this is a simple, robust tool that works (provided you follow the directions!).

Fund here are the experts do it