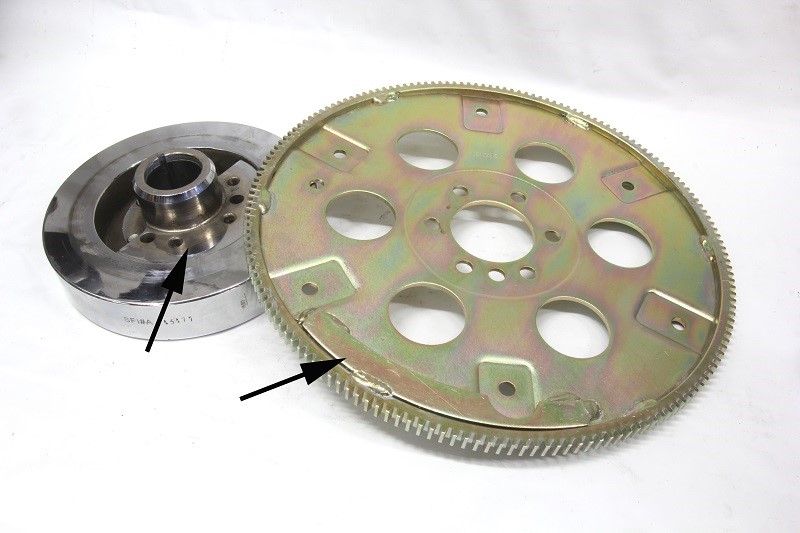

This photo illustrates the offset weight found on a flexplate and the harmonic balancer for an externally balanced big-block Chevy 454 as indicated by the arrows. On a flywheel, the offset weight is often a series of drilled holes around the outside of the flywheel instead of a fixed weight. (Image/Jeff Smith)

I am looking for the right flywheel for my Gen VI 454 engine. The date code on the block is K106, and the engine casting number is 12550313.

I purchased the economy version of the engine with a flexplate. I have a cast iron crank casting number 10114188 and I’d like to run a manual transmission now.

From all the research I have done, I cannot get to the right answer. I have found that there is a difference between the flywheels between cast and forged steel cranks, but I cannot find the part number for the flywheel that would mate to my cast crank. I hope you can clear this up. — R.O.

…

Jeff Smith: There appears to be a very slight difference between the forged steel cranks used in Chevrolet Performance’s Gen VI ZZ454 and 502HO engines and the cast crankshafts used in regular production replacement 454 Gen V and VI engines. The difference is 0.8 of an inch/ounce external weight. This represents less than 2 percent.

First, as followers of this tech column already know, we should dive into the basics.

In this case, we’ll limit this discussion to just the externally balanced big-block Chevy. When Chevrolet built the original 396 and 427 c.i.d. Rat motor, they designed the rotating assembly to be internally balanced. This means the harmonic balancer and flywheel/flexplate are zero balanced.

When the 454 came along, there was no room left inside the crankcase to fit larger counterweights on the crankshaft to accommodate this engine’s larger bore and longer stroke. To make all this work, Chevy engineers added the additional counterweight externally on the flywheel and harmonic balancer as eccentric weight. This created what is called an externally balanced engine. The production 400 c.i.d. small-block Chevy is also externally balanced engine.

The original spec for this external balance was called out as 33.0 ounce-inch. An ounce-inch is defined as the moment of force of one ounce acting at a distance of one inch from the centerline of movement. So this particular spec would be the equivalent of 30 ounces of eccentric weight placed one inch from the crank centerline.

This external weight called for a different flywheel or flexplate for the original 454 compared to the original 396 and 427 Chevy big-blocks.

To make things a bit more cumbersome, the crankshaft bolt pattern remained the same between these two applications so you really needed to be sure about the rotating assembly before bolting on a new flywheel or flexplate.

Then, to add further to the variables we must keep track of, Chevy redesigned the big-block as the Gen V in 1999 and later as the Gen VI. These versions eliminated the original two-piece crankshaft flange, replacing it with a one-piece rear main seal. This one-piece configuration made it impossible to include the small eccentric weight next to the crank flange. This increased the external balance offset from 33.0 to 42.5 ounce-inch. However, the crank flange bolt pattern remained the same so now we had yet a third different flywheel spec.

Then, when Chevrolet Performance came out with the 454 HO and 502 c.i.d. Gen VI engines, these engines used forged crankshafts that called out a yet different ounce-inch spec, changing from 42.5 to 41.7 ounce-inch. While this is a very small change, our friend Will Baty at Centerforce told us that not only is there a weight difference, but also the location of the weight shifted slightly. The combination of These factors makes it important that the proper flywheel is used.

Even small imbalances can be felt at almost any engine speed but it becomes a much more serious difference as rpm increases.

To put this in perspective, there are 28.3 grams in an ounce. One ounce of imbalance located one inch from the crank centerline will create an imbalance force equivalent to 31.9 pounds at 6,000 rpm. At 2,000 rpm, it would be 3.5 pounds of force. It’s possible that you could feel that imbalance even at 2,000 rpm.

This has probably been the long way around the answer, but it would appear from this information that you will need to find the proper flywheel for your engine. Essentially you will be looking at a choice of two basic flywheel materials. A stock flywheel that would accommodate your flywheel is normally offered as a nodular iron piece for normal street driving. This would be a 42.5 ounce-inch spec externally balanced offset weight.

The second option is a SFI-spec steel flywheel. Most of the high performance clutch manufacturers would offer one. As an example, Centerforce lists an externally balanced, 36-pound steel SFI-spec flywheel made from high quality steel and legal for use in NHRA drag racing and but may be a bit overkill for a mild street application. For a stock replacement flywhweel, we found a LUK version at Summit Racing that would work that is less expensive.

A new flywheel is best matched with a new pressure plate and clutch assembly. It’s also a good idea to break-in the new friction surfaces with easy driving for at least the first 200 to 300 miles and avoid towing until sufficient heat has been built into the clutch. While this might sound like a bunch of extra work and expense, the result will be a smooth operating clutch and flywheel assembly that will work well for a long time, long after you’ve forgotten the slight sting of the added expense.

This doesn’t tell anyone if they have a 400 flywheel, or a 454 flywheel. It also doesn’t tell anyone how to weigh the flywheel they have, or where on the internet to go to find out the right flywheel and I D it. This info ought to be written in the bible by now. We don’t need a link to Summit000000000000000000

Not all internet sources agree on this subject , the 502 /454ho there are at least 3 different flywheels maybe more ..

there is a 42.54 in oz and 41.95 in oz that I am familiar with .. I can tell you from experience balancing crankshafts , there are not too many aftermarket flexplates that match the OEM .. Best bet is to rebalance the flexplate or flywheel to the old one ..

Thanks for posting, I agree! Converting To a manual. I pulled a 42.54 flex plate off my factory zz454 according to this article I’d need a 41.07 flywheel. Interesting enough that’s what most sources say and that’s what I was sold. I called engineering at gm, they said they are not in the business of correcting sites like summit. So to be clear you can have a forged crank with 42.54 imbalance according to GM and manual for zz454 that came with my engine

I have a vortec 454 that I’m trying to put a 700r4 transmission behind. The problem is the torque converter won’t bolt to flywheel. The holes are more inward towards the center on 700 torque converter. What can i do

i have 2000 vortec 454 and trying to bolt up a 700 r4 , the bolt holes dont lineup with the torque converter

How is it possible to type such a long answer without even coming close to answering his question.?

Hi Jeff can you tell me if there is a difference in balancers between a steel crank gen 6 454 and a cast crank gen 6 454 Thanks

I’m looking for the same answer. I have a 2000 L21 454 from a GMC 6500 truck that I would like to use a manual transmission with. From what I have read these motors have a forged crank k. Do I order a Flywheel for a L29 with a cast crank or is there a different part number for the forged crank k?

Hi Jeff

Paul here

Was told it was a 66 396 that I swapped into my 70 ss

Now that installed starters don’t mesh with flex plate with out noise wtf. At least it starts now.

#2. Have a slight vibration at idle,seems to be firing fine

Can the vibration coming from the flex plate ..? If my engine is a 454?

Couldn’t identify it with any numbers that didn’t look like a original stamp

Thanks

I have a gen 5 454 with an iron crank I was told the imbalance was 41.7 for iron crank I read so many articles

That give different Inbalance numbers can you give me the correct number?

Also I am trying to find the right harmonic balancer and can’t get an answer

The motor has a vibration and I hope I don’t have the wrong flywheel and balancer

I hope you can clear this up for me thanks Pete

I have a Gen 6 454 vortex 7400 L29

Cast # 10237297

I need a flex plate

I don’t know what crank shaft I have

Cast or steel.

I need help

I have a VI BBC block that needs a new crank. Is the best going forward plan to buy a BBC V crank and matching Balancer and flywheel. And would I need to replace the pistons and rods?

How to tell the difference between a external & external flex plate?

Hey Bill, do you mean internally/externally balanced engines? Here are two articles that explain the differences in detail:

…

Key Differences Between Internal & External Engine Balance

…

What’s the difference between internal and external engine balance?

I have a quick question about painting the crankshaft. I understand that the bearing journals need to be taped to prevent over spray, but my question is,will painting it help to increase the ability to “disburse” the oil from the throws, and are there any significant gains in performance