If you’re researching electronic fuel injection (EFI) systems, you’ve probably come across the terms speed density and mass air flow (MAF).

These are the two most prevalent types of fuel injection metering methods that an EFI system uses to calculate air/fuel ratio. (Some vehicles even use a combination of the two.)

Though there is other technology out there, in this story we’re just going to focus on mass air flow and speed density because they are the most common.

Here’s a very quick, basic rundown on how each system works, so that you can better understand some terminology when you’re shopping for fuel injection systems and related components.

Mass Air Flow

Electronic fuel injection systems using MAF metering have a mass air flow sensor.

The MAF sensor is typically found in the air intake tube, before the engine’s throttle body. The sensor measures the air coming into the engine, and the EFI system’s computer uses that information to determine how much fuel to deliver into each cylinder.

Now, the air intake information provided by the MAF sensor isn’t the only data the ECU uses to makes its fuel delivery computations—it will pull in data from other sensors to account for engine speed, temperature, exhaust flow, etc.

What makes a mass airflow system appealing (and why it’s common in OE applications) is its flexibility. The ECU is always working to deliver the optimal fuel delivery based on the actual airflow data coming into the engine, not a pre-determined set of data tables. That means it can compensate for things like ambient air temperature, altitude, and other external factors.

But, while common in newer vehicles, MAF systems don’t always make the best retrofits for older vehicles not originally equipped with fuel injection, simply because of the nature of the system design.

Routing air intake tubing for mounting the MAF sensor into a manifold designed originally for a carburetor can cause space and fitment issues, which means a MAF-based EFI conversion can involve a lot of custom fabrication and additional parts.

Speed Density

Speed density systems count on air pressure (as opposed to air flow) and engine speed (rpm) to compute fuel delivery.

Also known as a manifold absolute pressure (MAP) system, the ECU uses air pressure data and engine rpm to determine engine airflow which, in turn, is used to calculate how much fuel to send into the cylinders.

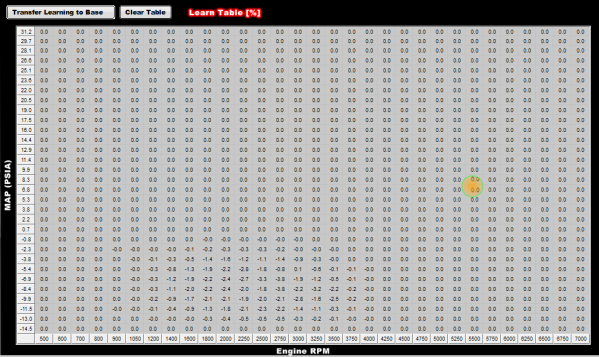

The speed density system’s computer is loaded with pre-determined data tables to help it make those computations.

These systems can also rely on several other sensor inputs to home in on the optimal air/fuel mix, along with large data tables and custom ECU tuning. Many systems utilize a sensor in the exhaust system that allows the ECU to “check its math” and make any necessary adjustments.

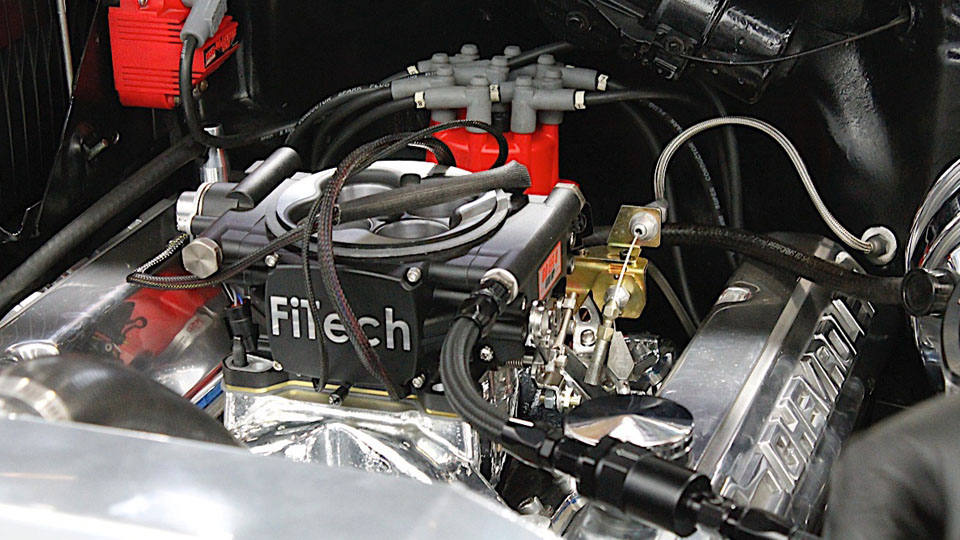

One of the reasons speed density systems are so popular in the aftermarket is that they’re ideal for folks who want to switch from a traditional carbureted setup to fuel injection.

If you’ve ever seen one of those EFI conversion kits with a throttle body that looks like an old-style four-barrel carburetor, there’s a good chance that it’s a speed density system.

So, Which is Better — MAF or Speed Density?

Honest answer: it depends.

If your vehicle was made in, say, the last 15 years, it’s probably equipped with a MAF system. It’ll work fine in stock and most performance situations.

In the early days of EFI, racers preferred speed density systems because they responded better in high-rpm, high-horsepower engines and you didn’t have a MAF sensor to disrupt intake airflow.

But the aftermarket has stepped up, offering MAF sensors and housings optimized for improved airflow and performance. Nowadays, MAF systems are widely used on many performance applications outside of the most extreme mega-horsepower, track-only vehicles.

For folks looking for the reliability and driveability of EFI in an older carburetor-equipped vehicle however, speed density setups offer some advantages. Better still, most modern speed density systems often come with pre-loaded tunes to make them practically plug-in-and-go. They even incorporate self-learning capability to calibrate themselves to the perfect air/fuel mix just by driving around.

All good information thanks it makes

my decision easier

Well said.

Breaking things down. I owned a ’90 mustang lx 5.0 5 speed notchback. I could do anything to that car, and the system would reset just by holding 2,000.rpm for one, or two minutes then let it idle until the computer relearns. Adding headers, cams heads etc was easy. I own a 2011 Dodge Charger R/T. Anything slight you do you have to have a hand held tuner, and pray that it works. Just adding a cai, headers, and corsa gt exhaust i had to get it “tuned” I don’t see where a speed density system is better. Unless I’m missing something.

John, your 90 Mustang is MAF sensor equipped, so its pretty much the same system as your 2011 charger. The mustang stopped speed density in 1987.

speed density was used in 88 in all mustangs,

but the cars for cali were came mass air

better make sure that joker is all the way TURNT up jack! and run octane booster

How does the MAF compensate for altitude? Is it in an airplane? The word you’re looking for is elevation.

Does the ecu read those in open loop ???

I have an ’87 Lincoln Mark VII 5.0 H/O in my ’66 Bronco.

Is it MAF or speed density system?

need more info on speed density system. 90 corvette.how to trouble shoot. car starts, idles. give gas, stalls.has code 34 maf system.. doesn t have maf sensor,so must have speed density. now what?