Nosebleed wheel stands are the poster children of drag racing.

Everyone likes to see them, but for the most part, they’re not all that conducive to running a low ET or even making a straight lap down the quarter mile.

The solution is, of course, the wheelie bar.

Wheelie bars have been around drag racing for what seems like forever. There are multiple configurations, including body mount, axle mount, dual wheel, single wheel, and so on. The most common setup is a dual wheel axle mount.

And that’s the primary target we’re aiming for here.

Initial Wheelie Bar Setup

Typically, wheelie bar setup is one of the last things you attend to when base-lining a chassis and is usually done after adjusting the chassis preload. Well known chassis-builder Jerry Bickel points out that the chassis pre-load (on a four-link suspension, for example) isn’t sufficient by itself to create a straight launch on a high-horsepower car. That’s because there are additional forces caused by inertia that occur only at the launch. As Bickel notes, these forces are a result of the sudden acceleration of drivetrain components, and they typically fade away after launch.

As a result of these initial forces, you shouldn’t attempt to make the car launch straight with four-link pre-load alone. If you do, then that pre-load will have an effect upon the car further down the track, with the result usually being a car that wants to steer itself off center. The solution is to use wheelie bar stagger to compensate for the sudden loading of the right rear tire. This will help to steer the car in a straight line on the launch.

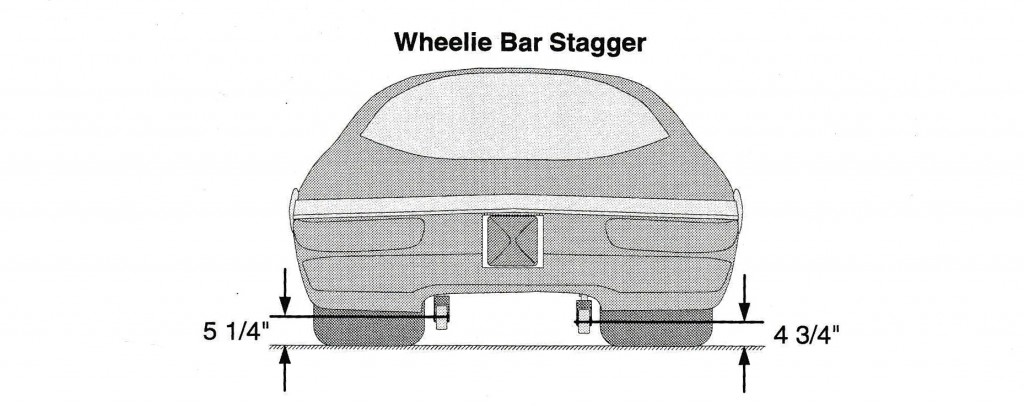

In order to set up the preliminary stagger, Bickel suggests you place the car on a flat level surface and measure from the ground to the centerline of the wheelie bar wheels (see image below).

When performing the initial setup, something to keep in mind is the way the driver’s weight affects wheelie bar height. In most cases, once the driver is belted in place, the wheelie bar height will rise slightly. This is because the weight of the driver compresses the suspension and in turn, changes the pinion angle. Because the wheelie bars are attached to the rear-end housing brackets, the bar angles change, too. Because of this, it’s a good idea to set the wheelie bar height with and without the driver in the car so that the height can be readjusted in either way.

Setting up the wheelie bar height serves two purposes: 1) Keep the car launching straight, and 2) limit the rise of the front-end. The actual height of the wheelie bar is dependent upon several factors. For example, the overall diameter of the back tires has an effect upon the wheelie bar height. When the diameter of the tire changes, then the wheelie bar height changes. As a result, you should always check the rollout (diameter) of your slicks. Remember, too, that slick rollout can change from tire to tire.

Another factor is the wheelbase of the race car. The majority of drag cars squat when they launch. The reason for this is the wrinkling of the slick sidewalls coupled with long and low Instant Center (I/C) locations. If you tune a car with a 95-inch wheelbase and you switch to a car with a 110-inch wheelbase, you’ll find the wheelie bar settings are far different. By keeping the same setting from a short wheelbase car on a long wheelbase car, you’d find that the wheelie bars will likely contact the tarmac too soon and the front tires won’t get off the ground. Consequently, you need to change your wheelie bar settings to work with different wheelbases.

Bickel tells us that wheelie bar height is also directly related to overall bar length.

“The longer wheelie bars are, the higher the static setting must be. Part of the reason for this is that wheelie bars are connected to the rear-end housing. As the rear-end pinion wraps up on the acceleration, the angle of the wheelie bars changes with it. The longer the wheelie bars are, the more the wheels move toward the pavement at launch. Chassis squat and pitch rotation also move long wheelie bars closer to the ground, increasing the static height setting requirement.”

You also have to consider wheelie bar flex and how it effects optimum height setting. For example, look at the way many Super Stock cars are set up. They’re heavy cars and many of them rotate violently on the launch. This places considerable loads on the wheelie bars, and they can flex dramatically. Some wheelie bars are designed to have some spring in them, and they’ll deflect more than rigid bars under the same load. When the bars are loaded violently and flexing, it means you should double check height measurements before each lap. It’s also a good idea to set up the bars with a lower overall height setting initially.

So where do you begin when it comes to the initial height setting?

Bickel suggests you start with ½-inch stagger but don’t exceed ¾-inch. If you find that you have to run more than ¾-inch stagger, there is something else wrong with the chassis.

“After observing the first test pass, it is likely that some changes will be required,” Bickel said. “Once you have found the sweet spot on your car, record the measurements in your chassis log book with and without the river. These are the initial settings I use for our Pro Stock cars:

- Right wheelie bar: 4¾-inch

- Left wheelie bar: 5¼-inch

Check your wheelie bar height often or after any change that has an effect upon the ride height of the car. Check the wheelie bar height after every tire change, even if your new drag slicks have the same size designation.”

With the wheelie bars setup correctly, the race car will launch straight and will carry the wheels off the ground in low gear. The higher the front-end of the car rises, the higher the center of gravity becomes. This increases the load transfer to the rear.

You’ll get a lot of arguments when it comes to how high the front-end of the car should be during a wheel stand. As a rule of thumb, the more power your car has, the lower it should carry the front-end. As Bickel points out, if a Pro Stock car or a modern Top Sportsman car had no wheelie bars, it would instantly leave on the back bumper. Bickel said he prefers to limit these cars to approximately three or four inches of front wheel carry height. If there’s more, it places excessive loads on the wheelie bars. This unloads the rear tires and actually reduces the hook.

Watch seasoned racers, and they’ll always use shoe polish on the wheelie bar wheels. This gives them an idea of how hard the car is loading each wheelie bar wheel on the pass. The more the shoe polish is worn away during the lap, the higher the load is on that wheel.

Don’t expect to see even loading on both bar wheels. Bickel notes that the right wheel will usually get the majority of the load at launch. You’ll often see professional crew chiefs watch cars ahead of them in the staging lanes. Then, they’ll go back and make a wheelie bar adjustment. The reason is, track conditions change. What they’re doing is adjusting the stagger minutely, so that the car can go straight down the track.

Bickel said he prefers rubber wheels with a slight crown, because they tend to leave the most accurate markings. He also notes that wheelie bar wheels with slight scores on the tread are softer and typically require a little more stagger to steer the car. It’s a good idea to avoid the use of flat wheels. They don’t always roll straight when staggered because the bars lean slightly to one side. As a result, they keep the bars from doing their job of steering the car straight.

Bickel gives us some insight into tuning, too.

Adjusting Your Wheelie Bar

“If your car launches to the left, the right rear tire is overloaded,” he said. “Lower the right wheelie bar a little at a time until the load on the rear tires is equalized and the car launches straight. If the car launches to the right, the left rear tire is overloaded. Raise the right wheelie bar or lower the left until the car launches straight.

Sometimes, traction improves at night as the track cools. This causes the cars to launch harder, and many will tend to go to the left. Often there is one good qualifying session that occurs when the track and the air are their coolest. Lowering the right wheelie bar a little in the staging lanes can save a run at a very important time.”

As you can see, wheelie bar setup and tuning isn’t a bunch of voodoo or tricks. It’s all based upon the way a car hooks and goes down the track. Use Bickel’s setup and tuning advice, and we’re confident you’ll get a handle on “hooking hard and going straight!”

[…] Want to learn how to properly set up your race vehicle with wheelie bars? You should read this. […]

hi, can I send you some videos please to help us do the setup?