Can you ever have too much of a good thing?

In the case of boost, the answer is a resounding yes.

As we told you in Blower Basics (Part 1), boost is the amount of air pressure created by your supercharger and is the result of a combination of factors: engine displacement, blower displacement, and blower drive speed. A proper amount of boost is good—very good. A supercharger creating the optimum amount of boost can produce substantial power gains and/or improved starting and low-end performance, depending on the supercharger style.

Too much boost can be bad—very bad. It can lead to detonation, which can be catastrophic in forced induction engines. With assistance from the supercharger experts at Weiand, we’ll help you zero in on the safe, optimal amount of boost for your street application.

Compression Ratio is Key

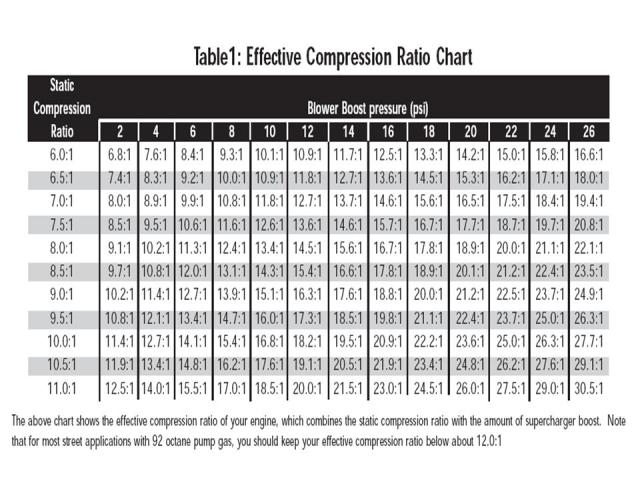

When deciding on what boost level to run, you must consider your engine’s compression ratio—static compression and effective compression. Static compression ratio is the compression ratio that is built into your engine. When you combine your engine’s static compression with boost pressure, you get the “effective compression ratio.” This effective compression factor was established to help determine your engine’s safe boost level.

So what is safe boost?

For street engines running on 92 octane gasoline, you should keep your effective compression to 12.0:1 or below, according to Weiand. Once you exceed the 12.0:1 effective compression mark, detonation begins to become more likely. Naturally, you can attempt to control detonation with boost retards and other modifications, but Weiand recommends you stay below or near the 12.0:1 range to make any detonation problems as manageable as possible.

Use the handy chart below to determine your safe boost level based on your engine’s static compression ratio. Again, if the combination of static compression and boost take you over the 12.0:1 effective compression ratio, you may find yourself dealing with detonation issues. Also, remember that low compression, high boost engines will make more power than high compression, low boost setups.

Can you run higher boost levels than those recommended in the chart? Sure. But you’ll need to make modifications (covered in our next installment) to your engine to do it reduce the chances of detonation or mechanical failure. To bring safe, practical performance increases to your street-driven vehicle, follow Weiand’s basic recommendations above.

(Supercharger) Size Matters

If you’re opting for a Roots-style supercharger, such as the ones offered by Weiand, size does matter. According to Weiand, you typically want to run larger blowers on larger engines. Assuming a constant speed ratio between the engine and the blower, a larger blower will make more boost than a smaller one on the same size engine. As engine size goes up, the supercharger will begin to make less boost; therefore, it’s ideal to use a larger blower on larger cubic-inch engines.

Keep in mind, you can make boost adjustments by running larger or smaller drive pulley sizes. You can use smaller pulleys (overdrive) to run a blower faster for more boost; you can add larger pulleys (underdrive) to run the blower more slowly for less boost. Using the popular 6-71 supercharger, the chart below shows you how pulley size can effect the boost pressure of a given blower:

It is perfectly fine to run a larger blower on a small engine as long as you use the proper underdrive pulleys to create safe boost levels. However, it is not practical to run a small, overdriven supercharger on a large engine, because you would have to run the blower very fast to create a reasonable amount of boost. At some point, the blower would become inefficient and could actually heat up the air, causing loss of boost.

Bottom line: larger blowers are for larger engines.

Boost Ranges & Variables

When shopping for a supercharger, you’ll notice boost levels are noted in ranges—as in 6 to 8 psi. This is because there are outside factors, including carburetor size, camshaft profile, and valve size, that can cause boost to vary. For example, at full throttle, your engine is going to need about 50 percent more air than it did before the blower was installed. If your carburetor is incapable of flowing the necessary airflow, you will have lower boost.

Boost readings are typically observed or measured at the intake manifold. If your engine has restricted cylinder head ports, small valves, or a non-performance camshaft, you will actually see artificially high boost readings in the higher-rpm range. This is because the boost pressure can’t get into the engine cylinders efficiently and begins to build up within the intake manifold. Although you’re observing high boost levels, the actual amount of boost pressure reaching your engine is lower and your engine’s power gains have maxed out. Conversely, lower readings on your boost gauge can mean your supercharger is making more power.

In part three of our Blower Basics series, we’ll talk about engine and ignition upgrades that can maximize the performance of your supercharger. We’ll also share some recommended modifications for running higher boost levels—all courtesy of our friends from Weiand.

[…] can read Part 2, which covers what you need to know about boost, here. // […]

[…] everything you probably don't want to read this. Compression ratio with boost | Turbobygarrett Blower Basics (Part 2): Boost and What You Need to Know – OnAllCylinders "If you can't hear it before you see it, what's the point?" – Jesse James […]

[…] The stock rad is not going to cut it. Might as well get it sorted with the hood off and the motor out aince ots probably going to be thicker and need to be mounted further forward. Blower pulleys will be in the way to move it back. Ron davis radiators is what i would go with they can custom make you something very nice. For a vette you can get and extra thick aluminum rad that will be surely needed for a 600 hp build. Pistons should work if 8:1 then just make sure your blower is in the proper range for the type pf boost needed. They come in a few different designs. Dont want one for way too much or way to little boost. Look at this when you buy your blower make sure its in range for your build. Blower Basics (Part 2): Boost and What You Need to Know – OnAllCylinders […]

[…] supercharged applications, check out our Blower Basics (Part 2) and Blower Basics (Part 3) stories for guidelines on proper boost levels and how they relate to […]

Can you give me a phone number to talk with a weiand rep to help me set up my 8-71 blower do they offer any books on it as well , thank you

[…] Basics: Part 1, Part 2, and Part […]

New to supercharger world with Whipple. If a smaller pulley is used what fuel delivery product will keep up with the thirsty sc?

Note: website below not related to sc subject

Does Weiand make a supercharger to suite a 1000cc motorcycle ?

Thanks for the information. If choosing a 1000 cc car engine to supercharge, apart from the bottom end strength would it be better to choose a 3 or 4 cylinder ? I am hoping to get in the region of 250bhp for short bursts of no more than 30seconds.

For a given amount of power the 3 would rev less but the 4 would have more valves to let the gas in and out.

I prefer Supercharging over a turbo as it is easer to map with an after market ecu. One thought is to choose an engine that already has a turbo, remove it and fit a bigger charger.

I have a stock 350 can I run a 6-71 blower with a 37 tooth top 1/2 pitch pulley with what tooth count bottom pulleys for low boostlevels. 30 or 31 tooth bottom pulley ?????

I am thinking of putting a Magnussen Supercharger on a 5.7L 2016 Tundra with 150,000 miles for a more towing FT/LBS (unaspirated = 401 ft/lbs and the with a blower = 540-ish ft/lbs). I would drive the truck normal for my age 60 yrs old and never race it around town. I need the truck to last another 100,000 miles. I only want the blower to tow a 8200 lbs RV (Tundra rated to 10,500 LBS towing capacity). Is this intelligent and realistic or do I take this $10,500 for the Magnussen and the $15,000 trade in value towards a F-250 6.3L diesel ($70,000). Would like to get 300,000 ish miles out of either. Yes, I am aware that this F-250 has 1000 ft/lbs. I value your opinion. Mike (retired navy officer and son of an auto mechanic).

Hello Mike, I had a 2013 Tundra. Great truck! Horrible MPG…15. Even if I drove it like the old man that I am…62. Sold it and bought a new 2016 Dodge 2500 Cummins diesel. Bought it for the motor. I had a 2001 2500 dodge Cummins…should have never sold it!!!! The 2016 Dodge, SUCKED!! 7 recalls. The last recall had to do with the tie rod adjuster bolt. Crappy metal so the bolt would not hold torque. Remedy…weld in place after torque. So if you ever needed alignment after the fix, you were buying a new tie rod. 2019 traded the Dodge for a new F250 diesel to pull our 28ft toy hauler fifth wheel. Worth every dollar!!! MPG 18 without trailer. with trailer, the worst was 12, fully loaded. I can’t say enough about the Ford. Only thing I don’t like is the jake brake on the Ford. The Cummins has a true jake brake, where the 6.2 ford uses the transmission to reduce speed. It’s a chunk of money to buy the F250, but for me, worth every dollar.

Hello, I’m trying to figure out how much boost my SBC, can you help? 350 CID 8:5 Static Comp with 671 & 55 top pulley & 50 bottom pulley. I understand it is underdriven but engine builer needs to know boost to gap ring gap. Thx Mike