Log on to YouTube and type in engine builds. You’ll be rewarded with about 3.5 quadrillion videos on builds ranging from garden-variety American V8s to high-winding turbo engines, bike motors, exotic European stuff—the works.

Many of these videos gloss over the nuts-and-bolts of engine building and highlight the glamourous stuff like big cams, cylinder heads, induction systems, and dyno testing. Nothing wrong with that. But let’s say you want to see an engine build that covers every step from teardown to running engine. That can take some digging through the YouTube universe to find.

One channel that does these kinds of build videos is 2CarPros. Host Ryan Lavacot has posted playlists for five engine builds—a 383 cubic inch small block Chevy; a 468 cubic inch big block Chevy; a 5.3L LS; a 347 cubic inch small block Ford; and a 5.4L Ford Triton 3-Valve. Ryan covers disassembly, machining, reassembly—right down to every bolt size and every torque spec—so any mechanically-minded person can understand and be successful in building similar engines.

Here are overviews of each engine build, including links to the playlists on the 2CarPros YouTube channel and parts lists on Summit Racing’s website.

383 CID Small Block Chevy

This build was supposed to be based on a 350 cubic inch small block out of a 1972 Chevy Blazer. We say supposed because the engine had overheated and locked up, and disassembly revealed it was a total wreck. A bad head gasket allowed coolant to get in the oil and run through the engine. The valvetrain was rusted solid and number seven cylinder was full of dried muddy goo. But what damned the engine to the junk heap were very deep grooves in the number two main bearing journal thanks to a spun bearing.

Ryan started from scratch with a four-bolt 350 block he had hot tanked, align-honed, and bored .030-inch over. The reciprocating assembly includes a 3.750-inch stroke Summit Racing cast crankshaft, forged pistons, and H-beam connecting rods. All this stuff created a 10.2:1 compression, 383 cubic inch small block that made 413 horsepower with a carburetor and 416 with a Summit Racing MAX-efi 500 fuel injection system.

Other components include:

• Summit Racing™ Classic flat tappet camshaft kit, 234°/244° duration @.050-inch lift, .487/ int./.508-inch lift

• Summit Racing™ Aluminum Cylinder Heads, 64cc chambers, 200cc intake ports

• Summit Racing™ Aluminum Roller Rocker Arms, 1.5 ratio

• Summit Racing™ Stage 3 Dual Plane Intake Manifold

2CARPROS 383 CHEVY SMALL BLOCK PARTS LIST AT SUMMITRACING.COM

468 CID Big Block Chevy

This build was the first Ryan did for his channel. He wanted a big block to replace the leaky 327 small block in his 1967 Camaro. He pulled a 454 cubic inch Gen IV big block out of an old heavy-duty truck and went to work. The two-bolt block went to the machine shop to be hot tanked, align-honed, bored .030-inch over, and fitted with cam bearings.

Ryan had the stock cast crankshaft turned .010-inch under to clean up journals and the connecting rod big ends rehoned to size. His build featured SRP forged dome pistons designed for use with Edelbrock Performer RPM cylinder heads. Those pistons are no longer available, but Summit Racing has JE forged pistons that are a close match. You’ll find them in the parts list.

Ryan went with a Lunati Bootlegger camshaft kit rated at 232°/244° @.050-inch lift and .535- inch lift on a 108° LSA. This kit is also no longer available. This Howards Cams hydraulic flat tappet camshaft is very close at 235°/241° duration @.050 and .553/.533-inch lift on a 108° LSA.

Once Ryan had the 468 in the Camaro, he had hard starting and bogging issues despite having the 750 CFM Holley Aluminum Street HP carburetor professionally tuned. His solution was to replace the carb with a Summit Racing Max EFI 500 Fuel Injection System. This OnAllCylinders story outlines the conversion.

2CARPROS 468 CID BIG BLOCK CHEVY PARTS LIST AT SUMMITRACING.COM

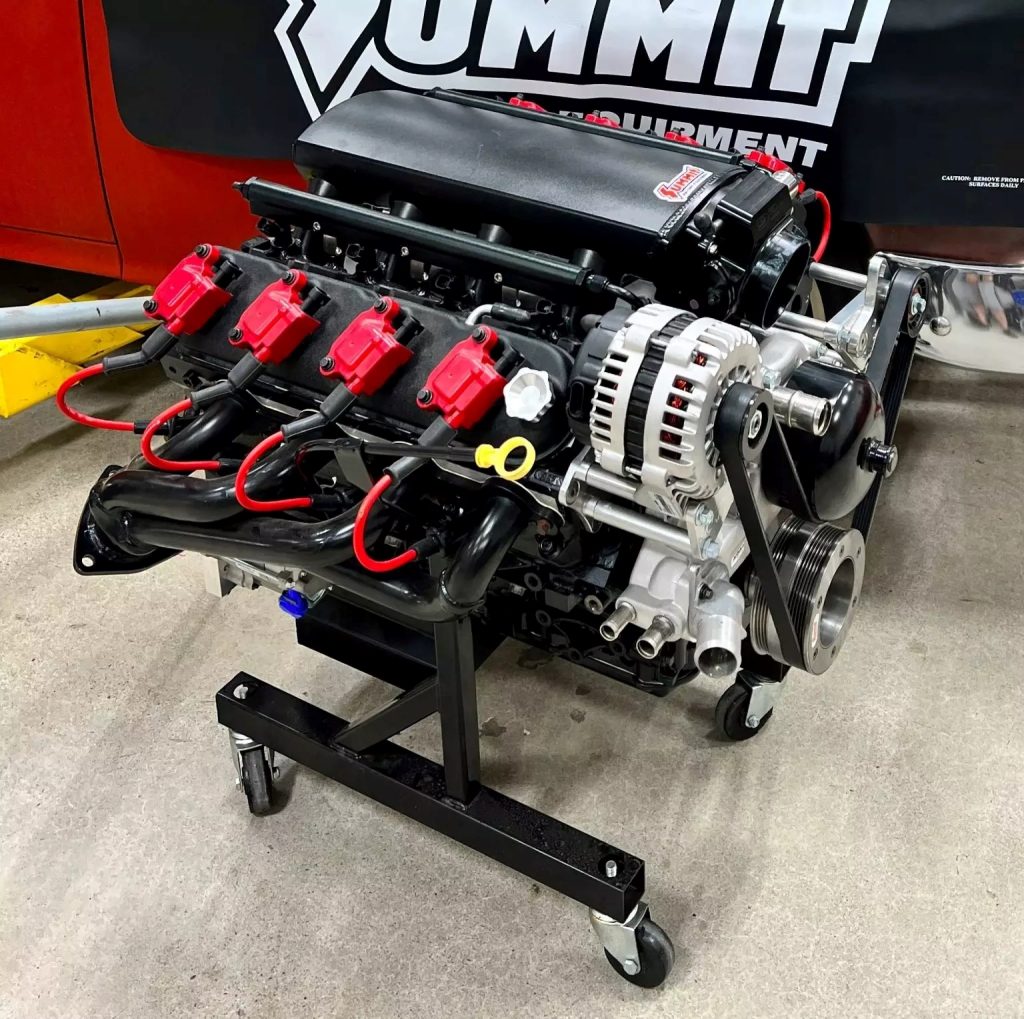

5.3L GM LM7 LS

Ryan obtained a grungy 260,000-mile 5.3L LS from a 2001 Chevy Silverado for a rebuild. The salvage yard tag on the LM7 said the engine ‘runs good.’ The water and rust in the cylinders, crud in the oil pan, the sloppy timing chain, and a bent connecting rod for the number three cylinder that Ryan found during teardown said otherwise.

The block was good though, so Ryan sent it to the machine shop to be cleaned, align-honed, bored .030-inch over, and have new cam bearings installed. He also had the shop polish the journals on the stock crankshaft, weight-match the Summit Racing™ Pro LS forged pistons and Pro LS forged H-beam connecting rods, and balance the rotating assembly.

The camshaft is a Summit Racing™ Pro LS Stage 3 hydraulic roller rated at 232°/242° duration @.050 inch and .600-inch lift. It’s a good street performance cam with a lopey idle and plays nicely with boost or nitrous.

The factory aluminum cylinder heads were reworked—ported and polished intake and exhaust ports, polished combustion chambers, and a three-angle valve job. The heads got new stainless steel valves and upgraded PAC Racing valve springs.

Set up with a Summit Racing™ Fabricated Intake Manifold and 92cc throttle body, DeatschWerks 44 lb.-hr. fuel injectors, and Summit Racing™ High Output Coil Packs, the 5.3L made 493 horsepower and 412 lbs.-ft. of torque on the dyno.

Ryan then swapped the LS into a 1955 Chevy Bel Air sedan and documented the entire process. Read all about it and access the videos in this OnAllCylinders article.

2CARPROS 5.3L LS PARTS LIST AT SUMMIT RACING.COM

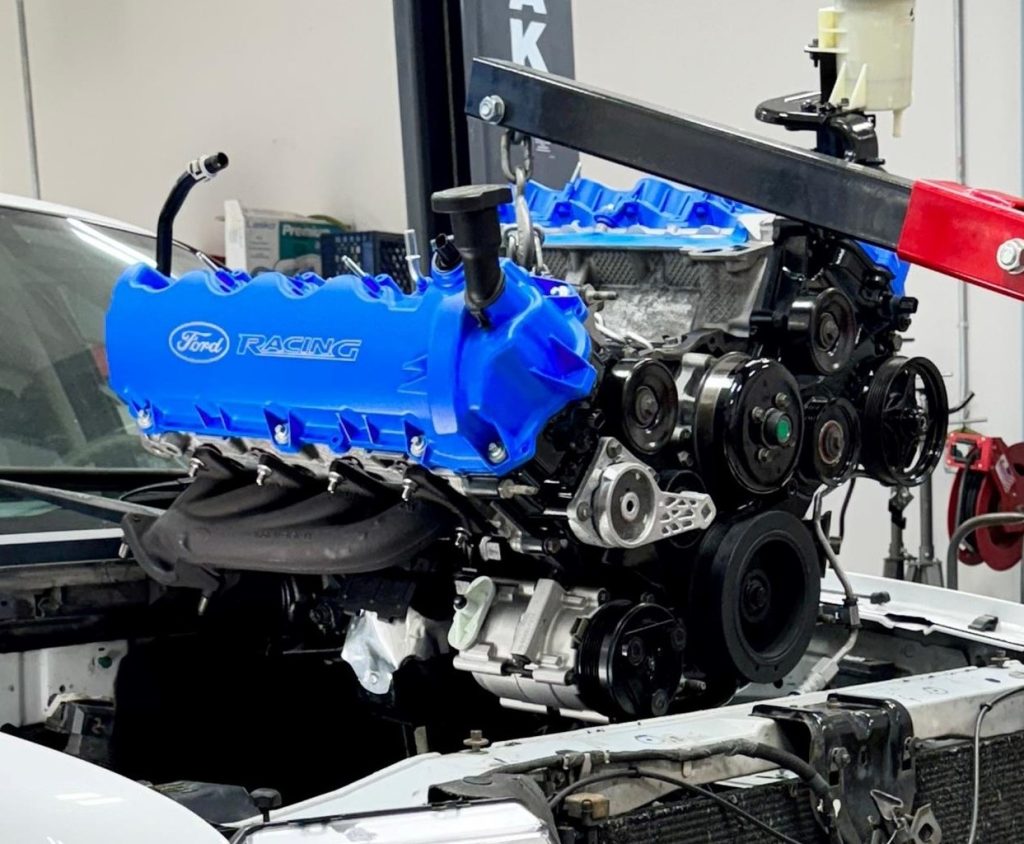

347 CID Small Block Ford

When Ryan Lavacot was in high school, he and a friend decided to rehab the 302 cubic inch small block Ford in the 1981 Bronco owned by the friend’s mother. It was the first engine either one had ever touched, but they got it running again and learned a lot in the process.

Ryan’s friend now owns the Bronco and the 302 was in desperate need of a rebuild. Ryan turned the little Ford into a 347 cubic inch stroker that made 441 peak horsepower at 5,700 RPM and 438 lbs.-ft. peak torque at 4,700 RPM on the dyno. And lucky you, he made a bunch of videos so you can see the entire build.

During teardown Ryan found bent pushrods on cylinders two and three, indicating the engine had hydrolocked at some point. The rod and main bearings were toast, the camshaft and lifters were glued to the block with varnish buildup, and the timing chain was so sloppy Ryan could slide it right off the sprockets.

The block went to the machine shop for a .030-inch overbore and clearancing for the 3.40 inch stroke forged crankshaft in the Eagle Specialties rotating assembly. The assembly also includes forged H-beam connecting rods, forged MAHLE flat top pistons, plasma-moly rings, and rod and main bearings. The rods were weight-matched and the entire rotating assembly was balanced.

Ryan chose a Summit Racing™ Classic Series hydraulic flat tappet cam rated at 218°/228° duration @ .050-inch and .471-inch lift. The cam makes excellent low and midrange torque, making it ideal for the heavy Bronco.

The 302’s cast iron cylinder heads were replaced with AFR 185cc Renegade aluminum heads with CNC-ported 185cc intake runners, CNC-ed 72cc combustion chambers, and 1.290-inch valve springs rated to handle .600 inch of valve lift. Ryan added a set of 1.6 ratio Summit Racing™ Aluminum Roller Rocker Arms.

Ryan pitched the factory two-barrel carburetor for a Summit Racing™ MAX-efi 500 fuel injection system on a Summit Racing aluminum four-barrel intake manifold. The ignition system features a Summit Racing™ Ready-to-Run Billet Distributor, High-Output Coil, and 8.5mm ignition wires.

2CARPROS 347 CID SMALL BLOCK FORD PARTS LIST AT SUMMITRACING.COM

5.4L Ford Triton 3-Valve

When the 5.4L Triton 3V engine in his 2005 Ford F-150 Lariat started making the clattery noise that signals a failing variable cam timing (VCT) system, Ryan had a choice to make—rebuild an engine with 184,000 miles on the clock or get another truck. After recovering from a case of new truck sticker shock, Ryan decided to rebuild the Triton and give the F-150 a new lease on life.

Ryan tore the 5.4L down to the bare block and had it overbored .030-inch. The rotating assembly includes the stock crankshaft; Summit Racing™ Performance Connecting Rods; Speed Pro hypereutectic pistons with Hastings piston rings; and Clevite rod and main bearings.

The Triton’s factory oil pump has trouble maintaining enough oil pressure and volume, which can starve the valvetrain and the VCT system of oil. Ryan installed a Melling high-volume pump to help maintain the proper oil pressure.

Ryan had the cylinder heads rebuilt with new valves and Melling stock replacement valve springs. He installed new camshafts, lash adjusters, and cam followers. Our combo includes Melling OEM replacement parts, including camshafts for 2005-08 5.4L engines in F-150s.

Ryan took no chances and replaced the Triton’s timing chain and VCT solenoids. Our combo includes Melling VCT solenoids and a Ford Performance Parts camshaft drive kit.

Other parts used in the rebuild include:

• ACDelco accessory drive kit

• Motorcraft water pump, power steering pump, and AC compressor

• Motorcraft fuel injectors and platinum spark plugs

• ARP main studs and side bolts, cam tower stud kit, and balancer bolt

• Bosch knock sensors, Standard Motor temperature sensor, Motorcraft cam and crank sensors

2CARPROS FORD TRITION 5.4L 3-VALVE PARTS LIST AT SUMMITRACING.COM

After my machine shop checked my 5.3 LS block/crank, and bored it .020 over, I found 2CarPros/Ryan’s 13 part LM7 series on YouTube. Ryan went through every part from Summit, and bolt w/torque specs, which I followed to a “T”. I was confident enough to install the engine, even before first start. When it started, I was ecstatic and sent a message/video to Ryan to thank him. Ryan (and his shop) knows their stuff!! Thanks again, 2CarPros and Summit!