It doesn’t matter how you ask the question about turbos and blowers, what is better or what makes more power or which one should I use?

The answer is always the same: It depends.

Think about this simple fact for a minute. Is there one type of blower or turbo that offers more power than all the rest? Is there one type that offers more torque than all the rest? Is there one type that is less expensive than all the rest? Is there one that is easiest to install, looks better or provides the immediate boost response we all crave? Is there one type chosen by OEMs more often, that lasts longer, doesn’t radiate excessive heat or provides the coldest air temps?

The reality is that there is not one type that provides everything on this list, to say nothing of the many other unlisted variables that help individuals choose their desired form. Simply put, if there was one form of forced induction that offered everything to everyone, every other form of forced induction would cease to exist! The fact that we have so many different forms to choose from is nothing but good, but that didn’t stop us from comparing two distinct forms on the dyno.

The wide variety of variables that affect the purchasing decision aside, the dyno only cares about one thing, power!

Technically speaking, we looked at power vs. boost pressure, but let’s jump right into a comparison between a Whipple twin-screw supercharger and a single Precision turbo.

To compare the gladiators, we needed a suitable test mule, which came in the form of a GM Performance crate motor. Designed specifically for boost, the GM B15 crate motor featured low (9.0:1) compression, a robust Bowtie LSX 6-bolt, iron block, and forged crank and pistons. The motor also featured an LS9 cam (560/55 lift, 211/230 degree duration 122 degree LSA), 68cc 6-bolt, LS3-based heads but came with no induction system. The idea was that you would provide the desired blower (like our Whipple) or the intake should you decide to go the turbo route. This low compression combo when run in naturally aspirated trim with an LS3 intake, 90mm throttle body and 1-7/8 inch long-tube headers usually put out near 470 hp and 445 lb.-ft. of torque.

The GM crate motor can be run as is with boost, but we opted to make a few changes to the LSX prior to our test.

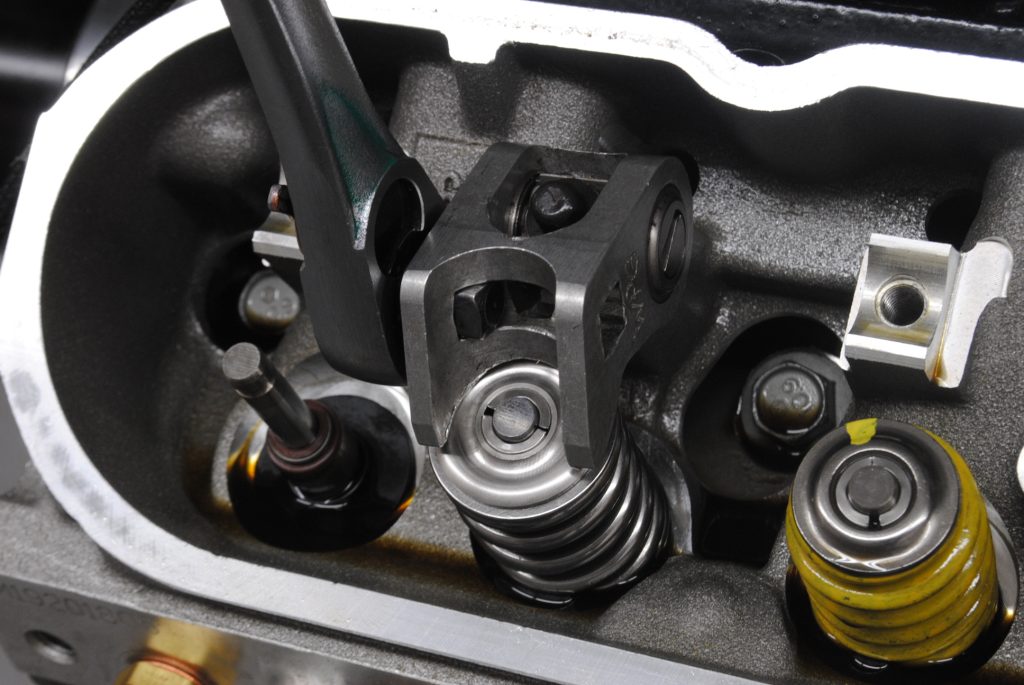

In preparation for 20+ psi of boost from the Whipple supercharger, we replaced the cam, valve springs and factory head bolts. The head bolt were naturally replaced by a set of ARP studs, while the 0.550-lift (LS3) springs were ditched in favor of a set of dual 0.650 lift springs from Brian Tooley Racing. The spring kit allowed us to install much larger cam than the factory LS9 cam provided with the crate motor. The BTR Stage 4 PD blower cam (older version since upgraded) offered a 0.617/0.624 lift split, a 239/258 degree duration split and 119 degree LSA. The cam alone has been shown to offer sizable power gains over the factory LS9 cam, so we felt comfortable using it in our quest for big-boy crate motor power.

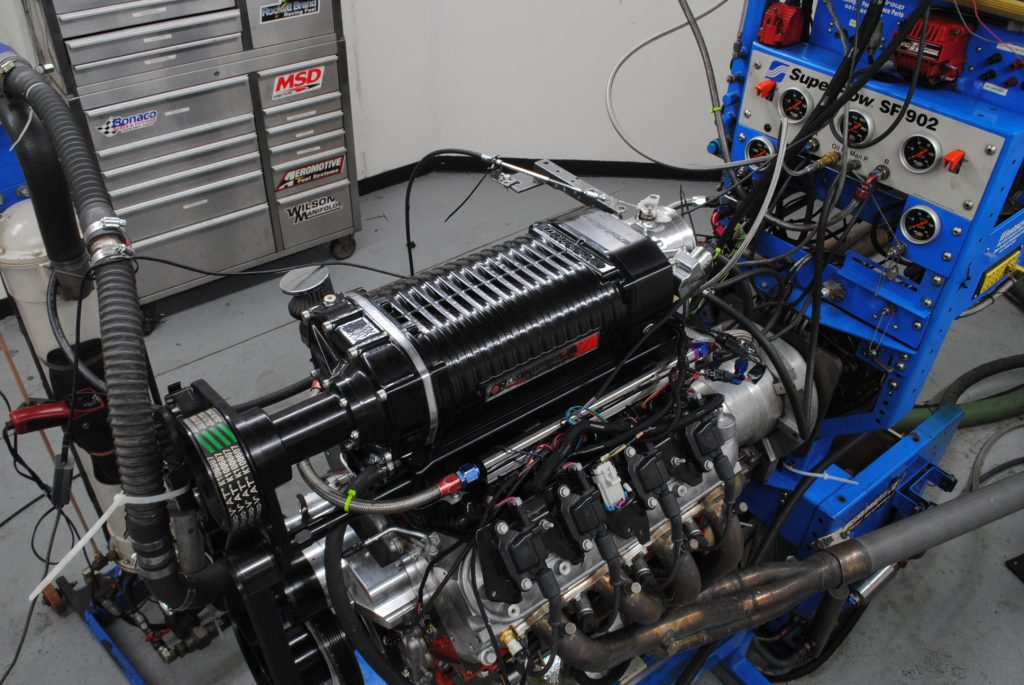

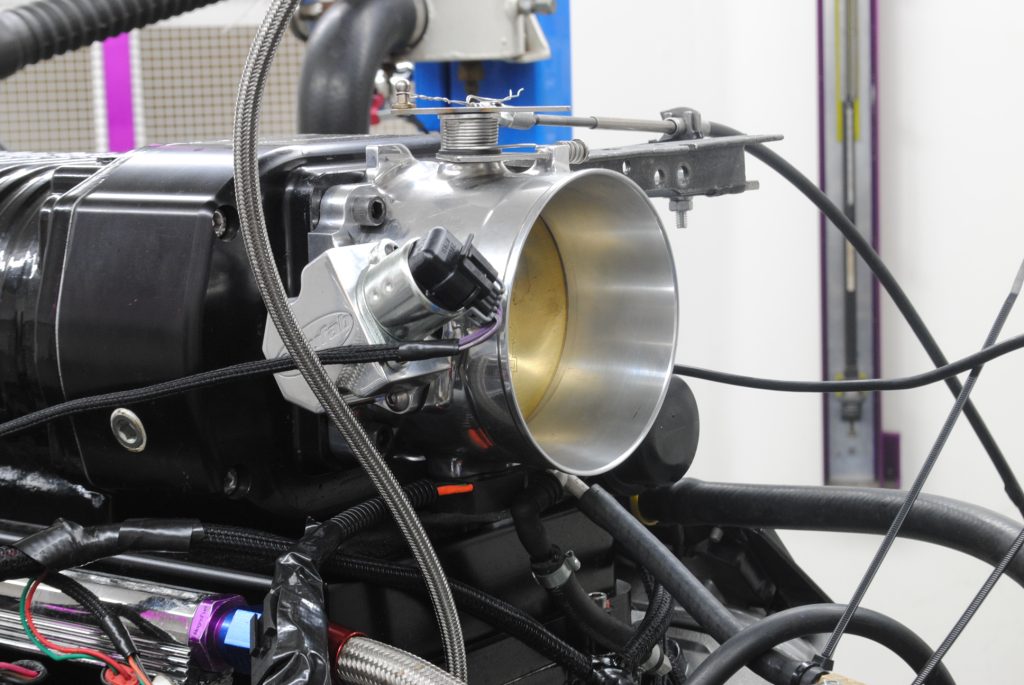

With the crate motor now prepped for boost, we installed the 4.0L Whipple blower kit. The 4.0L blower was capable of supporting 4-digit power levels, but we made sure to enhance the power potential by installing a 102mm FAST throttle body on the blower. In truth, this blower would benefit from an even bigger throttle body. To supply adequate fuel (race and pump gas mix), we installed FIC 1,000cc injectors (from RichardHoldenerPerformance.com). The blower combo was dialed in using a Holley HP engine management system.

We tried several different pulleys, but the best results came with a 4.0-inch blower pulley that pumped out 22.6 psi, where the blown crate motor produced 991 hp at 6,700 rpm and 827 lb.-ft. of torque at 5,000 rpm.

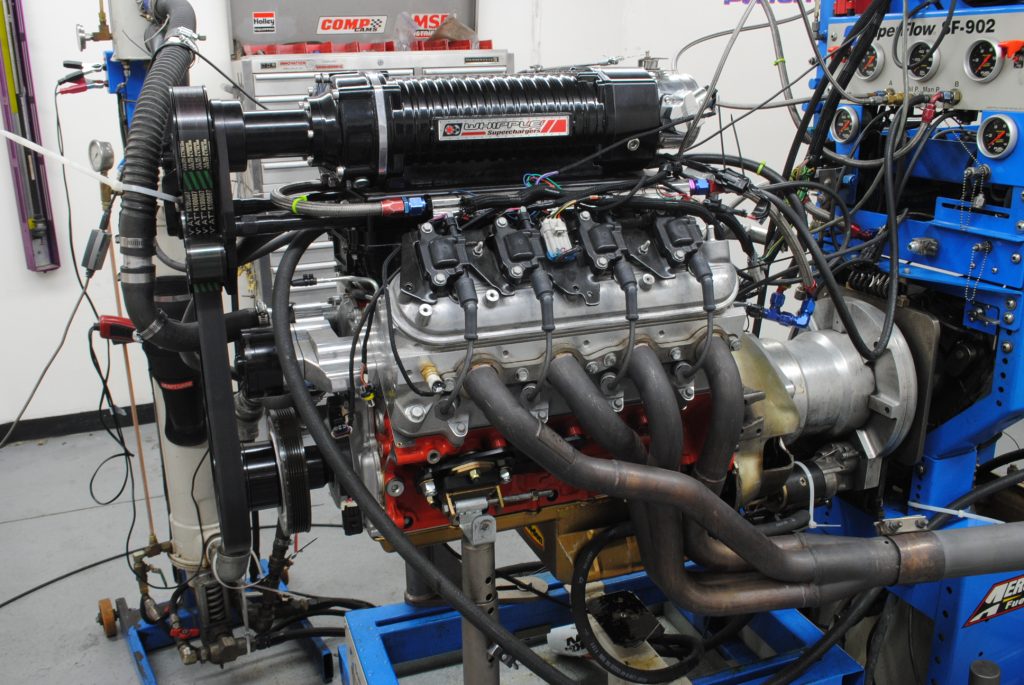

After running the Whipple supercharger on the LXS crate motor, we shifted gears and installed a turbo set up. There were a few changes made to the motor to facilitate the turbo system, including a cam and intake change. The intake change was out of necessity, as the GM crate motor never came with one, and the blower kit included an integrated intake and air-to-water intercooler assembly. After removal of the Whipple, we installed a Holley Hi Ram intake and the same 102mm throttle body.

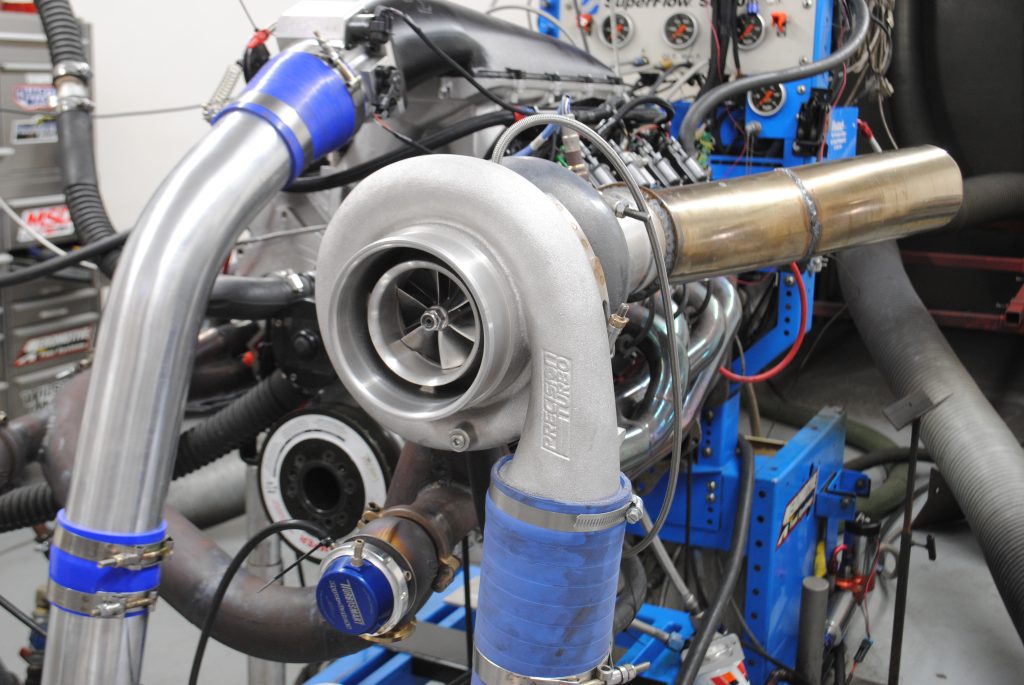

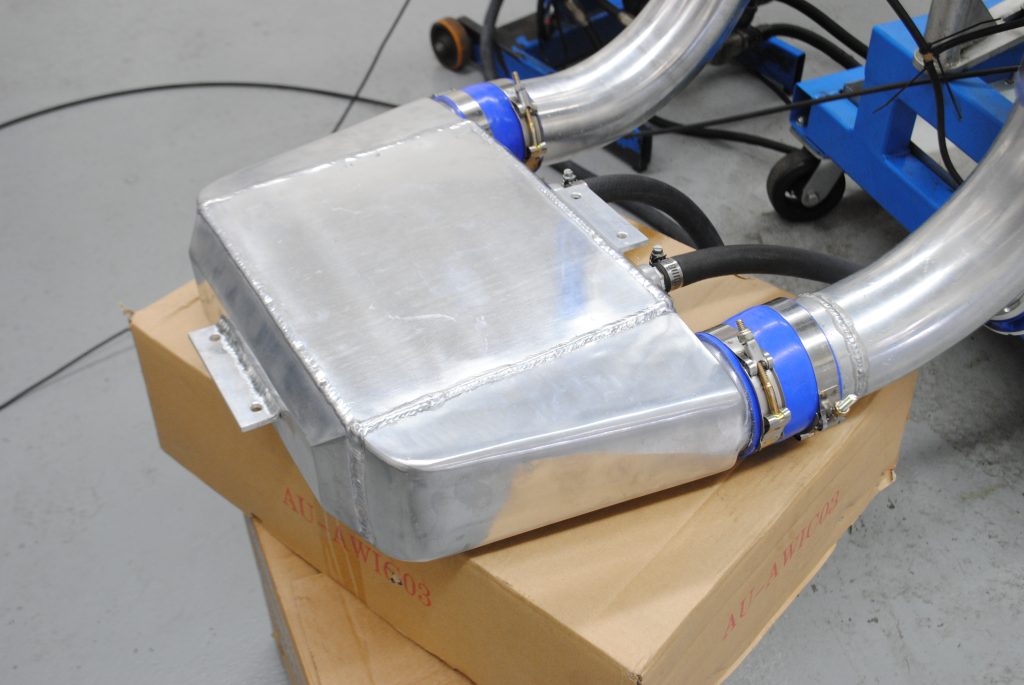

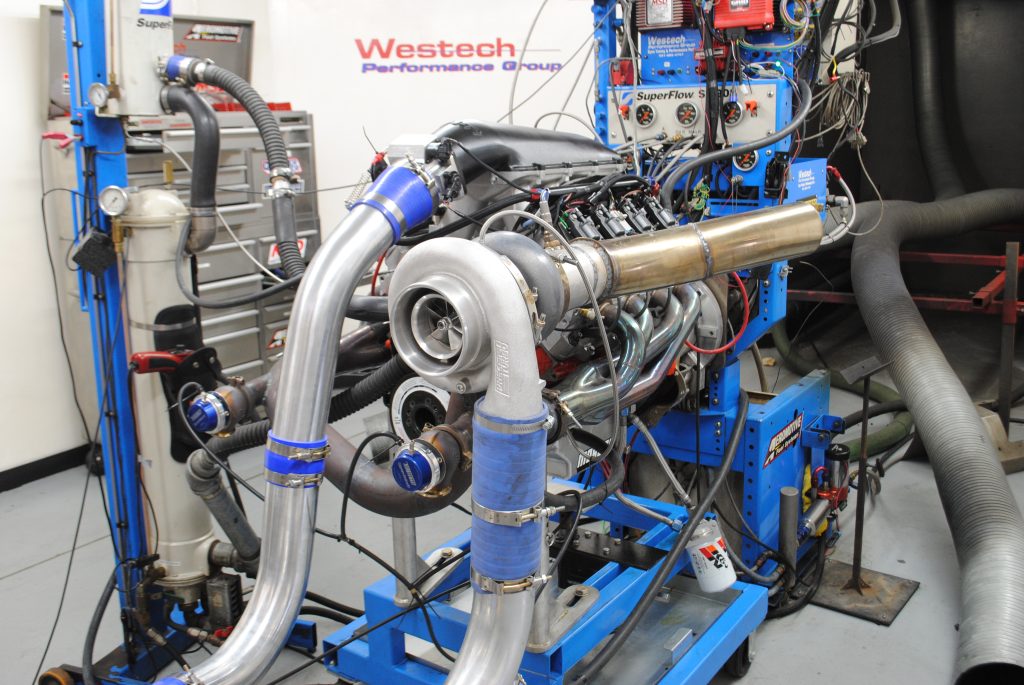

The cam change was not because we couldn’t use the BTR Blower cam with a turbo (we could), it just wasn’t necessary to run such a big cam (designed for higher rpm) with the turbo. We swapped it out in favor of a slightly smaller (by 9 degrees) Stage 3 turbo cam (0.609/0.610 lift, 230/235 degree duration and 114 degree LSA). The turbo set up used on the dyno included inexpensive tubular headers, a custom Y pipe (from Jason at JTFab), and Precision 7675 turbo. The Y pipe included a pair of Turbosmart wastegates and the boost was sent through an air-to-water intercooler (run with dyno water like the Whipple).

Run at a peak of 19.6 psi (at the hp peak), the turbo LSX produced 1,082 hp and 978 lb.-ft. of torque.

Whichever you choose, a boosted crate motor is a joy forever.

Can this be reran with the Whipple being intercooled? This doesn’t appear to be head to head as the turbo gets the advantage of charge cooling. You wouldn’t do a cam comparison with different intakes.

Hello and thanks for reading – the blower assembly has a built-in intercooler in the main housing, under the blower.