Before serpentine belts and their fancy belt tensioning arms showed up, the humble engine V-belt ruled the roost.

And though V-belts have proven reliable for decades, there is one big catch: They have to remain properly tensioned or they’ll slip and cause all sorts of problems in your accessory drive system. If the V-belt isn’t tensioned correctly, not only will you quickly burn up your belt, there’s a good chance your alternator, A/C compressor, and power steering system won’t work either.

And proper V-belt tension can’t happen, if you don’t have the right pitch length engine V-belt to begin with.

Problem is, if you’ve got an old, unique, or modified engine, you might not be able to go to your favorite automotive parts supplier and pluck an application-specific belt right off the shelf. Nope, in these scenarios, measuring is your best option.

The good news is, you don’t necessarily need the old belt to measure and compare against. All you need to do is ensure your engine accessories (and their pulleys) are in the correct position AND properly aligned. Then you can bust out your tape measure and notepad to check some key specs.

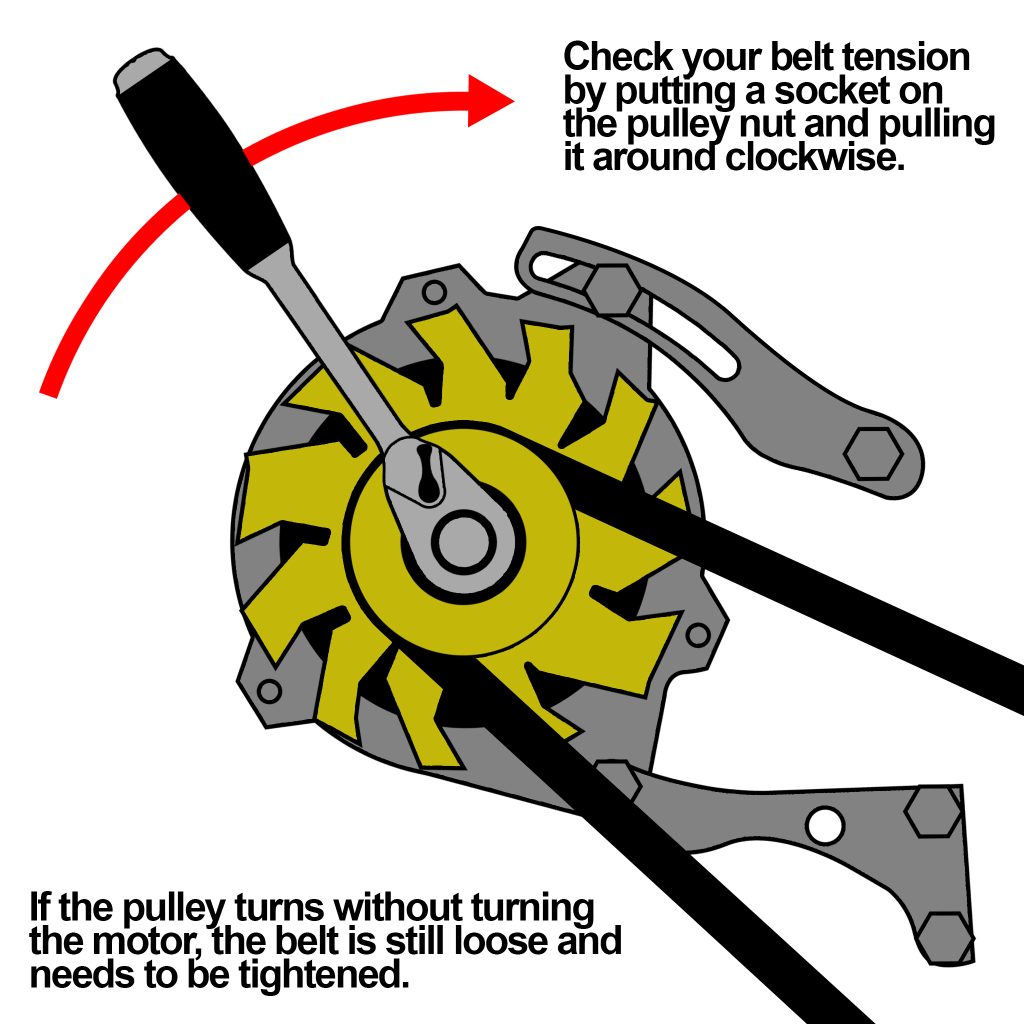

Better yet, our pal Craig Artzner with the Summit Racing tech team made a handy infographic to show you how and where to measure, plus you’ll get a simple formula and some sample calculations to help you determine the correct pitch length V-belt you’ll need.

If you want to make sure you’ve got the best V-belt for your engine, this picture and formula will help you do it. Check it out:

Comments