I have a really strong 421ci Pontiac that had been completely rebuilt for me by a professional shop that is now all wrapped in plastic in my garage. It has been sitting for over 10 years.

I did loosen all the rockers so the springs wouldn’t be half bad, but I’m wondering what would be the best way to go about firing this engine for the first time. There was fresh oil and I sprayed the cylinder walls down with WD-40 when it was stored. Now, I’m wondering about how not to damage it when I try to start it.

D.H.

To begin with, the first thing I would do is not turn the engine over. Instead, remove the valve covers and first look to see if there’s any surface rust on the valve springs. The fact that you wrapped the engine in plastic is worrisome because if it was sealed, humidity changes over the years will trap moisture inside the engine.

Thoroughly Inspect the Cylinder Walls & Valvetrain

If this has happened, you will likely see spots of surface rust on the valve springs since they are near the top of the engine where the moisture can accumulate. If the springs show rust, they must be replaced as this rust will cause tiny pits in the metal that will create stress cracks that will quickly break the springs that could cause a valve to drop and you don’t want that.

If there is surface rust on the iron heads or anywhere else, you can probably assume there is surface rust on the cylinder walls as well. The best way to tell is to remove all the spark plugs and borrow or buy one of those bore scope cameras where you can look inside each cylinder for rust.

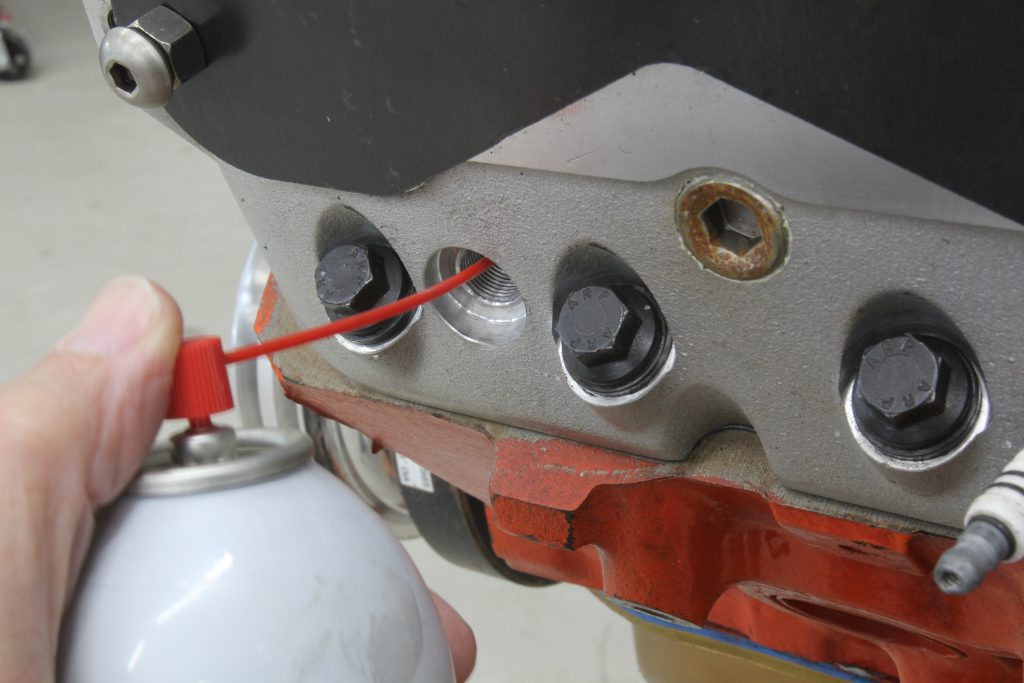

Assuming there is corrosion on the cylinder walls, don’t turn the engine over. Instead choose some kind of upper cylinder wall lubricant that you can spray inside the each cylinder first. Hopefully the rings are not rusted to the cylinder walls. Liberally spray the walls and then consider turning the engine over—by hand—to see if it rolls easily with all the spark plugs removed.

Let’s assume there is only minimal rust on the cylinder walls. There is a product called Foggit that is available through Summit Racing that is specifically designed to prevent corrosion on the cylinder walls. In your case, this might help to lubricate the walls to prevent damage, but it’s really designed to prevent this from happening in the first place. So this would be a good product to use if you were going to store an engine for any period of time, especially over years.

Back to your problem, assuming there is some rust on the walls, getting an oil to help lubricate is essential so that you don’t destroy the cylinder wall finish. If the visual inspection tells you there is serious corrosion—you really will have to pull the engine down and re-hone the cylinder walls. You really don’t have a choice.

Pre-Fire Oil Change & Other Startup Tips

But assuming that there is only minimal corrosion, a liberal coating of oil will help. The next key is to immediately drain the oil and remove the filter from the engine. An engine that has been sitting for over five or six years will allow the additive package in the oil to settle out and fall to the bottom of the oil pan. The additives will not re-mix with the base oil even if you pressure lube or start the engine.

Don’t try to use this oil as it has already failed you. Drain and recycle it and install a fresh load of high quality engine break-in oil. We’ll assume this is not a flat tappet cam engine, but even with a roller, you still need good break-in oil like from Driven, Lucas, Summit Racing, or other to properly break-in the rings.

If you plan to start this engine, fully pressure lube the engine first using a tool that will allow you to spin the oil pump for an extended period of time to push lube all the way up through the pushrods to the rocker arms. This ensures that the engine is fully lubed. In the future, if an engine is to be stored, it should be fully pressure lubed then sprayed with oil on the springs and on the cylinder walls with Foggit or some other lubricant to protect the machined surfaces.

Assuming there is minimal corrosion inside the engine, after a pressure lube you can set the initial timing, pre-fill the carburetor so it has fuel, and then start the engine. Bring the rpm up immediately to at least 1,500 to 1,700 rpm to properly lubricate the lifters with spray from the crankshaft but don’t run the engine for more than a couple of minutes. After that, the engine needs to be loaded on the dyno or in the car in order to properly break-in the rings. Without a load on the engine, cylinder pressure will not push the rings out and the rings will glaze over the cylinder wall and then you will have more problems.

Hope this helps and good luck with your stormin’ Poncho.

Engine Initial Startup Inspection & Prep Parts List

- Milwaukee Bore Scope Inspector – MWT-2319-20

- Summit Racing Bore Scope Inspection Camera – SUM-970050

- Klein Tools Bore Scope for Android Devices – KLE-ET16

- Foggit Anti-Corrosion Fogging Oil – FEP-FG-101

- Lucas Penetrating Oil Spray – LUC-11043-1

Comments