Who remembers the late 80’s and early 90’s Callaway twin-turbo Corvettes?

Introduced in 1987, the Callaway B2K RPO was offered as a regular production option right from Chevrolet. Check the box and you received (among other things) a serious motor upgrade, that combined forged internals, lower compression, and (best of all) a pair of turbos pressurizing air through a pair of equally impressive air-to-air intercoolers.

The net results of all this insanity was to increase the power output of the corporate Tune Port Injected (TPI) L98 350 motor from 240 hp and 330 lb.-ft. of torque by a solid 100 horsepower. Running near 10+ psi of boost, the twin turbo Callaway option offered 345 hp and 465 lb.-ft. of torque. This elevated the Callaway Corvette to super car status, thanks to not only serious acceleration (compared to the standard L98-powered Vettes), but also a top speed near 180 mph. These power numbers jumped to 382 hp and an astounding 562 lb.-ft. of torque on later models.

Perhaps the only thing holding back the amazing potential of these cars was (what now must be considered rudimentary) the Miro-fueler used to add additional injectors to provide the fueling necessary for the extra power.

Despite this, the Callaway Vettes were viewed with great admiration by lesser ‘Vette owners—especially a young journalist with an iron-headed, first year 1985 TPI Corvette.

The Test Motor: A Stock(?) 1987 TPI 350

Not making Callaway Corvette money back then (or even now), I was left with the only option available to a guy who specializes in dyno testing. I would build my very own turbo L98 and run it on the dyno as my homage to the time spent drooling over the Callaway in the assorted automotive performance periodicals.

Rather than go whole hog on a build as Callaway did, with forged internals and (boost-friendly) low compression, I decided to try my luck with what we thought was a stock 1987 L98 motor. The mystery motor came from the boys at the (now-defunct) Chevy Race Shop, and while it looked all the world like an aluminum-headed L98, replete with the factory, long-runner, Tune Port Injection, we wondered about the cam specs since the motor made a touch more power than other L98s we had tested in the past.

In addition to what many consider the best-looking factory induction system ever offered by GM (the dual quad cross ram DZ302 notwithstanding), the L98 also introduced factory aluminum heads. Prior to the introduction of the aluminum heads in 1986 (converts only), GM never offered factory aluminum heads. The L98 heads were also big over-the-counter sellers back in the day, as the lightweight aluminum construction and small (58cc) combustion chambers made them a serious upgrade for the previous generation, iron, big (72cc) chamber (low compression) smog-headed small blocks.

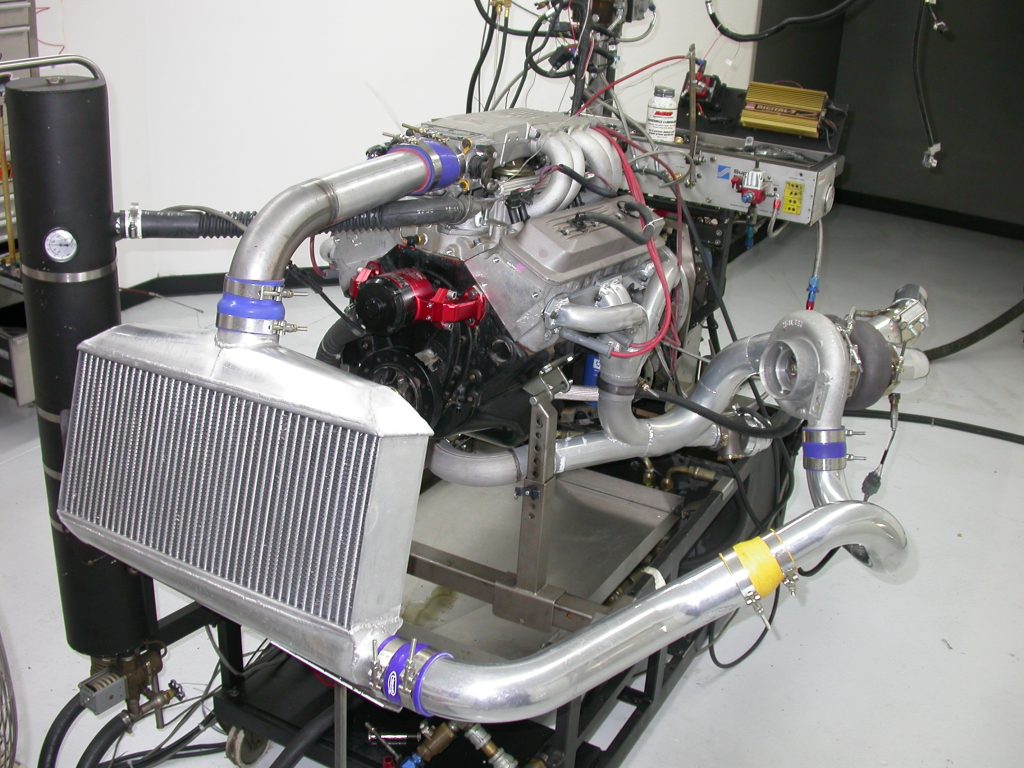

To get thing started, we installed the mystery L98 up on the dyno and equipped with long-tube (1-3/4 inch) headers, collector extensions, and a Meziere electric water pump. Running an open (but stock) throttle body (no air intake system), long-tube headers (no cats or cat-back exhaust), and optimized air/fuel and timing (not the conservative factory tune), meant that our test method always produced higher power numbers than the factory rating.

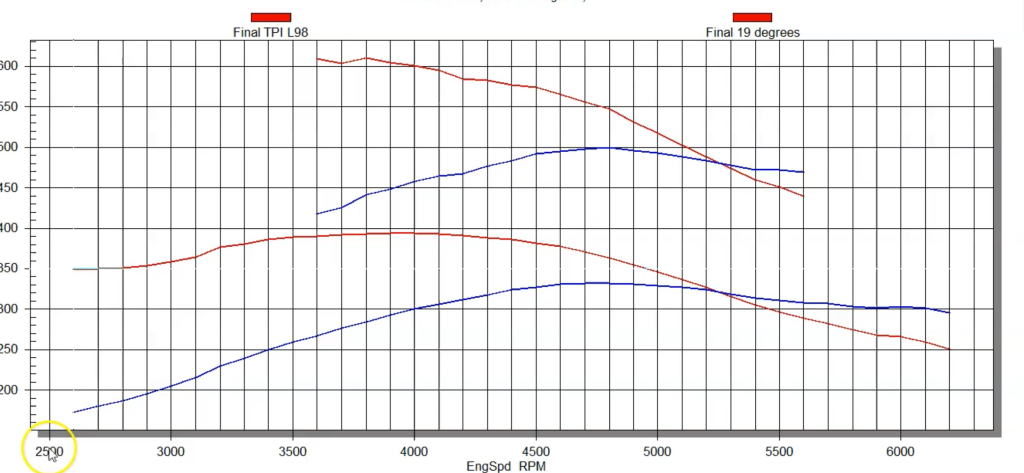

It was not uncommon to see an extra 50 to 60 hp over the factory rating, but we were quite surprised when the dyno spit out peak numbers of 332 hp at 4,800 rpm and 394 lb.-ft. of torque at 4,000 rpm. The torque number didn’t seem too far off from what we expected (and have seen on others), but the elevated horsepower numbers indicated this L98 motor might be sporting something other than stock in the cam department. The idle quality and vacuum were smooth as stock, but the numbers were a solid indication of extra power.

In the end, we elected to not look the Chevy Race Shop gift horse in the mouth, and continued on with the experiment by adding some boost.

Building a Turbo TPI Motor

To make Callaway Corvette performance, we needed the most important part of the B2K option, namely boost. Sure, it would have been cool to run twin turbos (it rolls off the tongue much better), or even simulate the original Callaway configuration, but we figured the Behr intercooler cores might be hard to find or duplicate, and all we were really wanted from the L98 was to duplicate (or say we say exceed) Callaway performance.

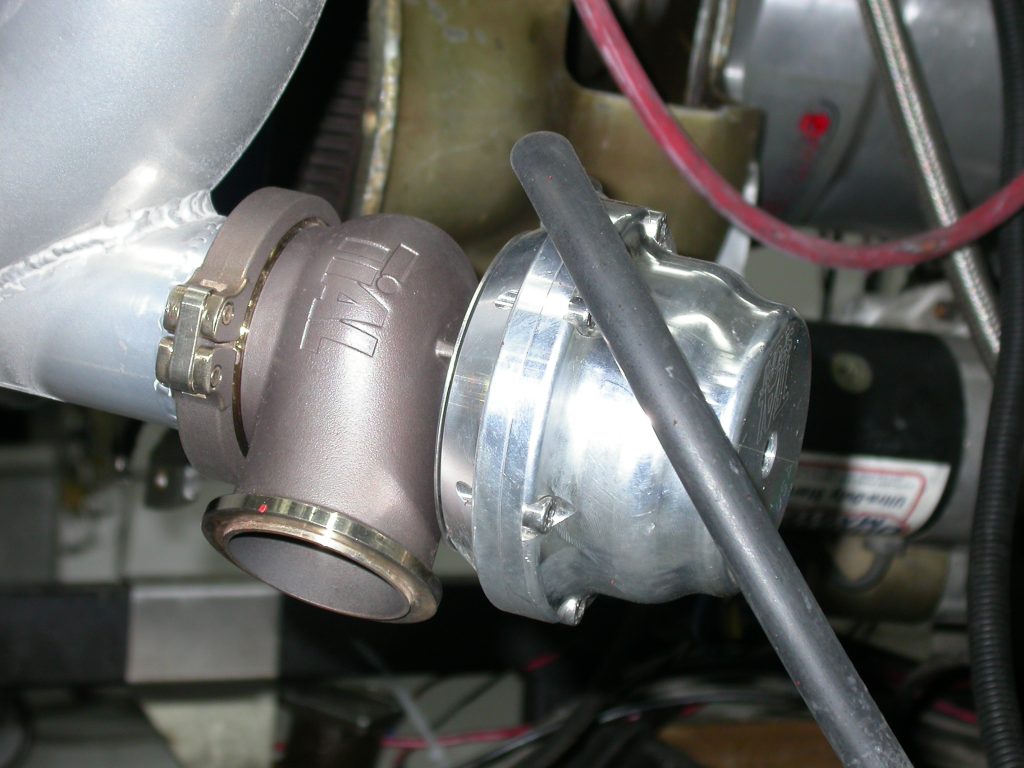

We also had an ace up our sleeve in the form of a dedicated single turbo kit from (now defunct) HP Performance, designed specifically for the TPI Corvette. Using a single Holset turbo, the kit also included dedicated, tubular exhaust manifolds, Y-pipe and front-mounted, air-to-air intercooler. A front mount would be much more efficient than the engine-compartment mounted twin cores on the original Callaway, but it certainly didn’t offer the visual statement of the Callaway engine bay.

Unlike the original Callaway motors, that offered additional fuel under boost through additional injectors controlled by the Micro Fueler, we simply installed larger injectors in the L98 rails and dialed in the A/F and timing curves using the FAST XFI engine management system.

Running just 8.5 psi of boost on pump gas, the turbo L98 produced an even 500 hp at 4,800 rpm and 609 lb.-ft. of torque at 3,900 rpm. Note the shape of the curves (NA and boosted) remained the same, meaning you never had any shortage of tire-turning torque—in fact your only shortage would be the lack of traction!

Remember, not only was there considerably more boost (and horsepower) to be had from this turbo, but we would eventually modified this NA motor with AFR 195 heads, a bigger cam, and Stealth Ram intake that added another 100+ hp NA!

Since we never ran that combo with the turbo, we can only dream of the potential, but for now, I need to find a way to afford a REAL Callaway!

Well appreciated read! Hello from Quincy Griffin, A Chevrolet Loving, Tuned Port experienced car Guy from Jackson MS. My 1st experience with the Tuned Port Injection System was with my 1991 police package Chevrolet Caprice 5.7 that personal installed off A 1987 5.0 Camaro. Impressed by the result of my findings, still to this I am hooked. No longer having that platform but still wanting that combination. I now have A 5.0 Chevrolet Caprice and HUNGRY for more power, I’m interested in returning to this setup! Luckily I still have the intake but hopeful that I can make good power with what I have and A turbo system. Wish me luck as I take this journey up memory lane.