I am building a new 355ci Gen. 1 small block Chevy for my Buick Skylark that also has a Procharger supercharger. I’m upping everything inside with a forged crank, rods, pistons, and the rest.

Which should I use for the street and occasional open track time on the road course at Willow Springs – 4032 or 2618 alloy forged piston? I have been looking at Wiseco PTS508a3 Pro True street pistons which are a 4032 with 1/16, 1/16, 3/16 inch rings or Wiseco RED0008x3 2816 alloy pistons with 1.2mm, 1.2mm, 3mm ring pack.

I also talked to Total Seal and they recommended their CS3690 35 Advanced Profiling ring set. This is a steel top ring with a chromium nitride coating. The second ring is cast iron and the oil ring is a 20+ pound conventional.

I plan on using a Howards Boost retrofit hydraulic roller cam with 0.525 and 0.535 inch valve lift and 225/235 degrees duration at 0.050 with a max rpm of 6,400. I will be using AFR as-cast Enforcer 200cc intake runner heads with Inconel exhaust valves with a 64cc chamber and 9.5:1 compression. I plan to run around town with eight pounds of boost and, on the track, change the blower pulley and run 10 to 12 pounds of boost. Does all this sound good on paper?

S.F.

Thanks for the question and the overview on the engine. There’s a lot to address here and frankly I think the whole package sounds well thought-out and should be strong with a couple of considerations.

What’s the Difference Between 2618 & 4032 Alloy Pistons?

First let me answer the question about the main differences between 2618 and 4032 alloy pistons.

Most important is that you are already ahead of the game for only considering forged pistons. Cast or hypereutectic pistons are not a good idea when running a power adder because although a hypereutectic is slightly stronger than a straight casting, it’s still a cast piston. When subjected to detonation, a cast piston will literally explode into hundreds of tiny pieces. I know because I’ve broken more than one engine with cast and hypereutectic pistons and that’s exactly what they do when they fail. So a forging is a smart move with a supercharger.

One difference between 4032 and 2618 is really about how much each alloy grows or expands when subjected to combustion heat. A 4032 forging alloy grows far less than a 2618. This is why many street engine builders choose a 4032 forging because they can run tighter piston-to-cylinder wall clearances compared to a 2618 piston. This makes the 4032 more street friendly because this alloy does not clatter during cold startup because of the tighter clearances.

Unfortunately, the 4032 is not quite as strong or as malleable under high cylinder pressure conditions. What this means is that, if subjected to high rpm, detonation, or extreme cylinder pressures, a 2618 can handle these situations better than a 4032. As an example, a 2618 piston when hammered with detonation may survive—where a 4032 could pinch a top ring land which will require you to replace the piston to prevent damage to the cylinder wall.

Speaking of Piston Rings…

Plus, within your choice between the two Wiseco pistons, the 2618 also is offered with the thinner 1.2mm/1.2mm/3mm ring package, which I think is a better choice. Many enthusiasts don’t trust the thinner rings thinking they will not last as long but the truth is that thinner rings reduce operating friction—especially when combined with the right cylinder wall hone and proper viscosity oil. It has been proven several times in dyno testing that not only do thinner rings last longer than the thicker 1/16, 1/16, 3/16 inch ring package, but are often worth a few horsepower and lb.-ft. of torque as well.

I know this sounds counterintuitive but it’s true. Look at it this way, in the old small block Chevy days, an engine with 100,000 miles was worn out. Conversely, I just pulled the 5.3L LS engine out of my son’s 2007 Tahoe that has clocked over 298,000 miles and the engine was still running decently. That engine is equipped with a 1.5mm/1.5mm/3mm ring package and my guess is there will not be a huge ridge at the top of the cylinder bore that was common with the older family of small block engines.

Part of this longer life is because GM now uses a stronger cast iron material for the cylinder block, but there is far less friction from the thinner rings combined with higher quality engine oil. So the 2618 piston is a far better choice in my opinion for several reasons that include the thinner rings.

The Relationship Between Rings & Oil Choice

With this thinner ring package you will want to consider running a thinner viscosity oil package as well. My pals at Westech recently did a viscosity test on a big block Chevy with thick 5/64-inch piston rings and the hot oil (200 degrees F) test revealed that the thicker viscosity oil sealed the piston rings better, resulting in better cylinder pressure and more power compared to a thinner viscosity oil.

Conversely, based on this test, a thinner ring package like your 1.2mm top ring will respond positively to thinner viscosity oil. You didn’t mention what viscosity oil you will be running but I would avoid a 20w50—which is often recommended for supercharged engines. Instead, I think a 10w30 or perhaps even a 5w30 would be a good choice as this will be a good match for these thinner rings.

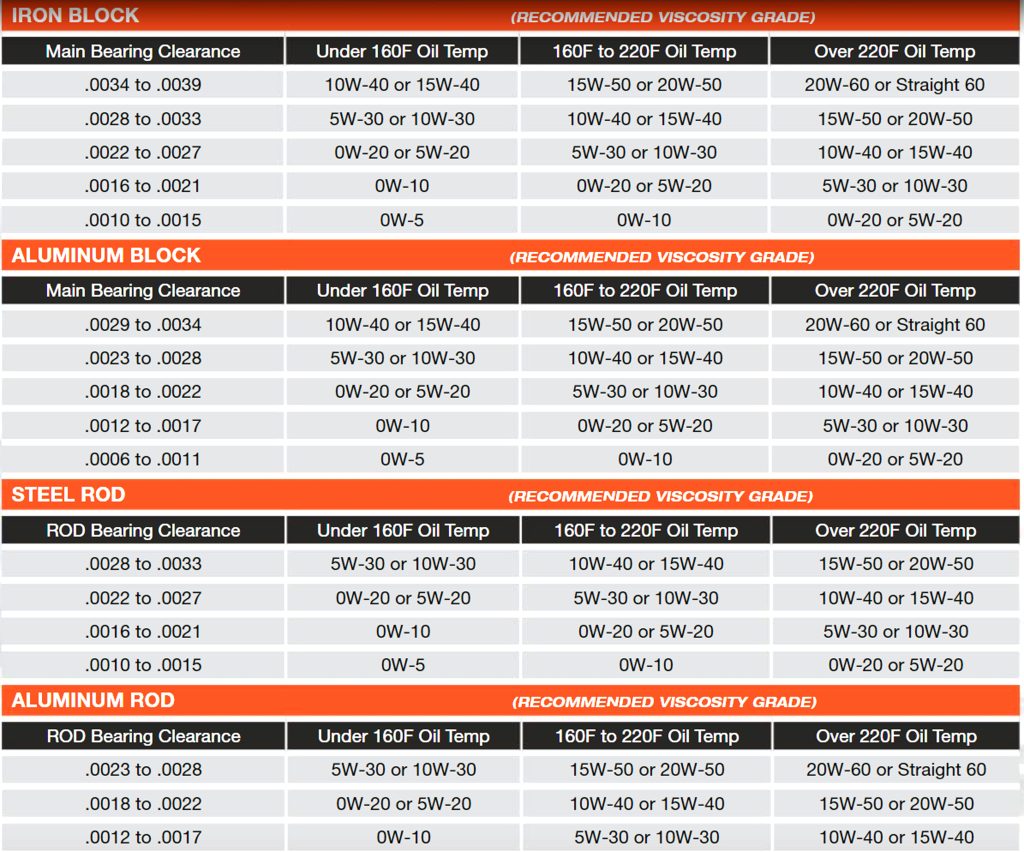

Driven Racing Oil has a chart that connects viscosity with bearing clearances so if you are thinking of thinner oil you might also consider that this may affect the direction of bearing clearances, keeping them on the tighter side of 0.0025 inch instead of on the wider side of that clearance. This means if you measure clearances of 0.0023 or 0.0024 this might be better while clearances of 0.0027 or 0.0028 would be compatible with thicker oil. These are considerations that are all part of the overall package and closer to the definition of what is really blueprinting an engine.

Of course, these are just my opinions and certainly subject to other ideas as well.

Thoughts on Running a Supercharged Engine on a Road Course

You mentioned using your engine on the road course at Willow Springs. The track is located just north of Los Angeles, California and has been around (I think) since 1953. I would be careful running a supercharged engine around any road course for several reasons. You didn’t mention it, but I’m assuming this is a blow-through system and probably not running an after-cooler.

The problem with superchargers is that while they make boost—they also heat the inlet air into the engine.

At 10 psi, a typical centrifugal will heat an ambient air temperature of let’s say 80 degrees up to closer to 150 degrees F at the inlet to the engine. As the inlet air temperature increases (independent of boost) this automatically raises the engine’s octane requirements. A basic rule of thumb is when the inlet air temperature increases a mere 25 degrees it will require one full octane number increase (like from 91 to 92 AKI octane) to prevent detonation!

That means if your small block inlet air temp jumps 70 degrees (150 – 80 = 70 degree increase) this is going to require a fuel octane jump of three full numbers. So if the engine could run in short bursts without detonation with 91 octane pump gas—then to run near-continuously at wide-open-throttle (WOT) on the road course—you will need a minimum of 94 or 95 octane fuel. And this is before we consider the octane requirements of adding boost of let’s say 10 psi.

So really you are looking at running a minimum of 100 octane race gas to stay out of detonation.

Plus, road course excursions are all about on and off the throttle. Before going to the track, I would make sure the belt drive assembly can handle the demands of this kind of abuse. Basically the older serpentine systems tend to exhibit quite a bit of belt slippage. Plus on-and-off throttle work like this can pitch the belts off. Part of this occurs because many aftermarket centrifugal superchargers use a fixed belt tensioner.

I’ve learned through a discussion with Jerry Reeves, manager at belt design at Dayco, that every combustion event sends a pulse through the crankshaft that ends up at the crank pulley. Think of these as waves or pulses through the belt. With a fixed belt tensioner, these waves tend to skip right over the tensioner, allowing the belt to slip slightly. Multiply this times millions of combustion events in a short time and you can see what might happen. Frankly, the fact that the belt only slips slightly is amazing.

This is why the OEs a long time ago went to spring-loaded tensioners, If you look at factory supercharged motors like the Camaro ZL1 or Cadillac LSA engines, they all use a spring-loaded tensioner to reduce the slippage. So based on this, I would not be surprised if you have belt issues at the track so you might want to at least be aware of this and carry more than one spare belt.

Increasing belt tension will not necessarily solve the problem.

***

Overall, I think your package sounds great for a street engine. I would suggest keeping the boost lower on the track compared to on the street and keep the track time to five laps at a session. I would also suggest that you install an oil temperature gauge. I think you will be shocked at how quickly the oil temperature will shoot up beyond 280 degrees F on the race track when running a wet sump engine without an oil cooler.

This also means you had better be running a full synthetic performance oil to be able to handle those temperatures. Conventional oil begins to break down and fail above 250 degrees F and you will hit that number within one to two laps when running near continuous WOT with a supercharged engine. That you can count on.

We could write a whole additional tech column about why this happens but rest assured, you will be looking at 275 to 300 degree F oil temps within three to five laps with a supercharged engine when running the big track at Willow Springs during the summer!

We’ve seen a driver burn up a normally aspirated small block when not monitoring oil temperature on a road course. It can happen far quicker than you imagine, so keeping track of oil temperature is critical.

Comments